Simplified linear recliner having a fixed pawl

a linear recliner and fixed pawl technology, applied in the direction of chairs, vehicle components, vehicle arrangements, etc., can solve the problems of overcoming the assembly capability, the seatback of an unoccupied seat may tend to oscillate, and the seatback of an unoccupied seat can move a small amount, so as to reduce the stacking of tolerances and reduce the stacking. , the effect of compact construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

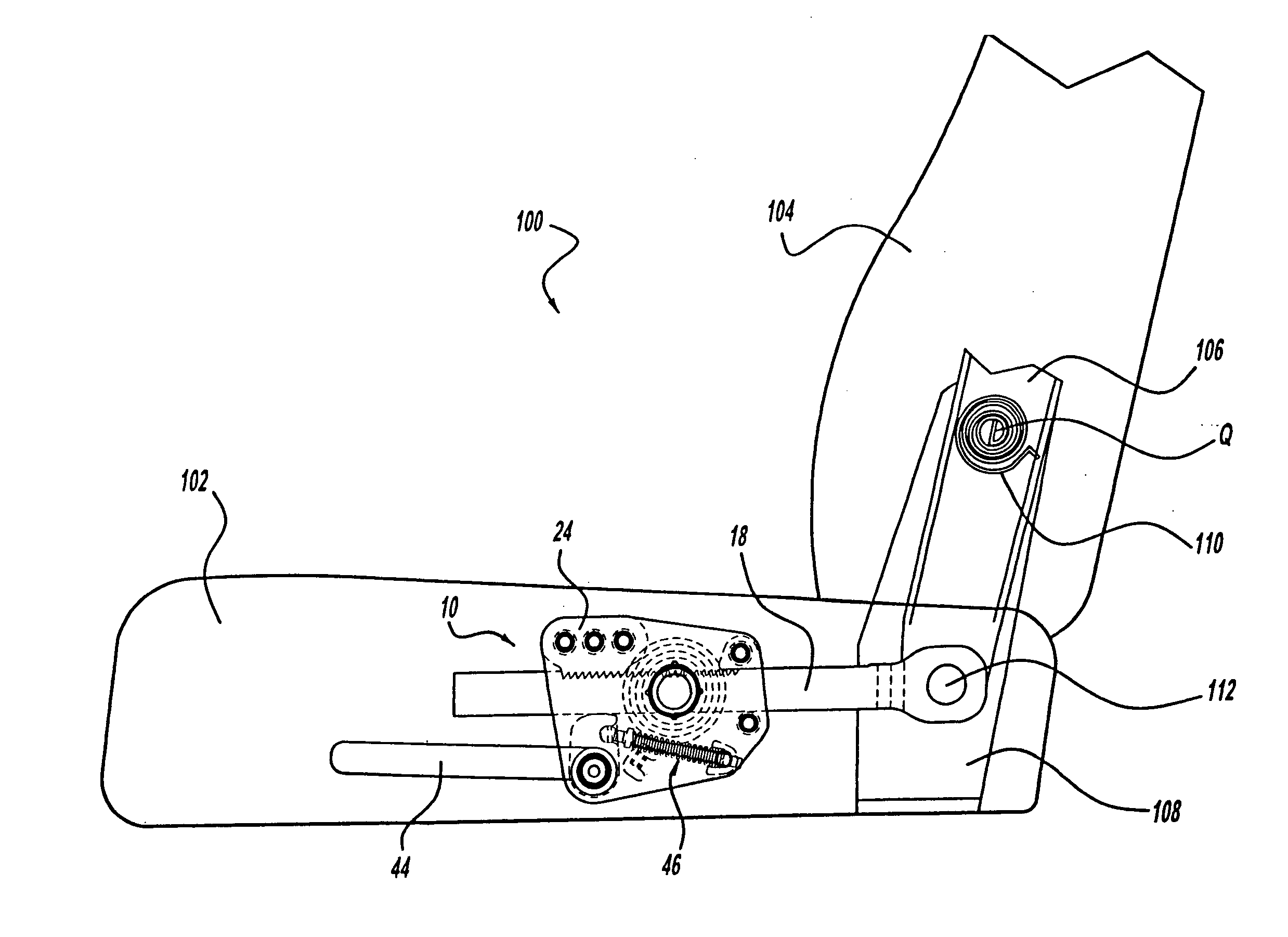

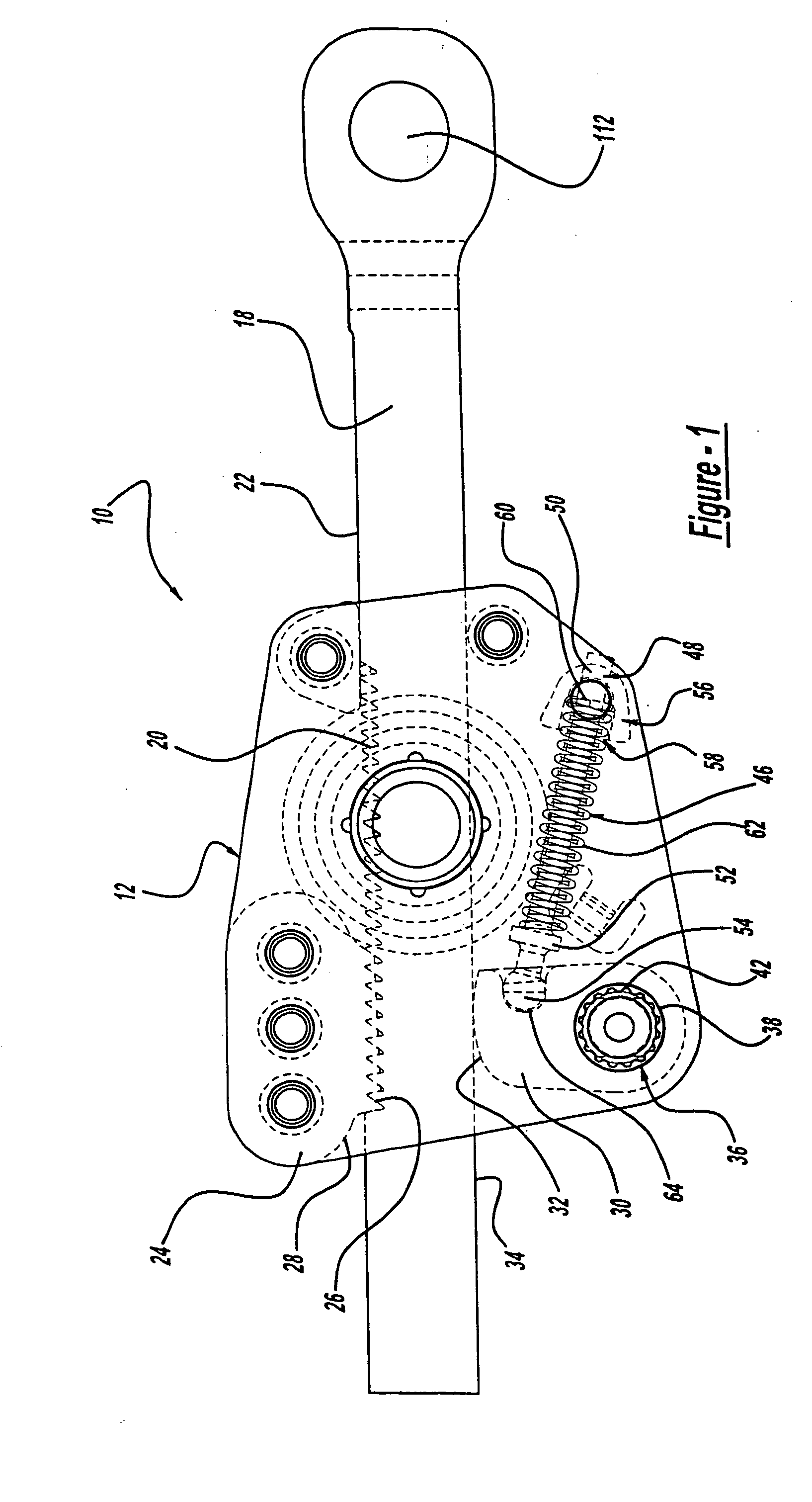

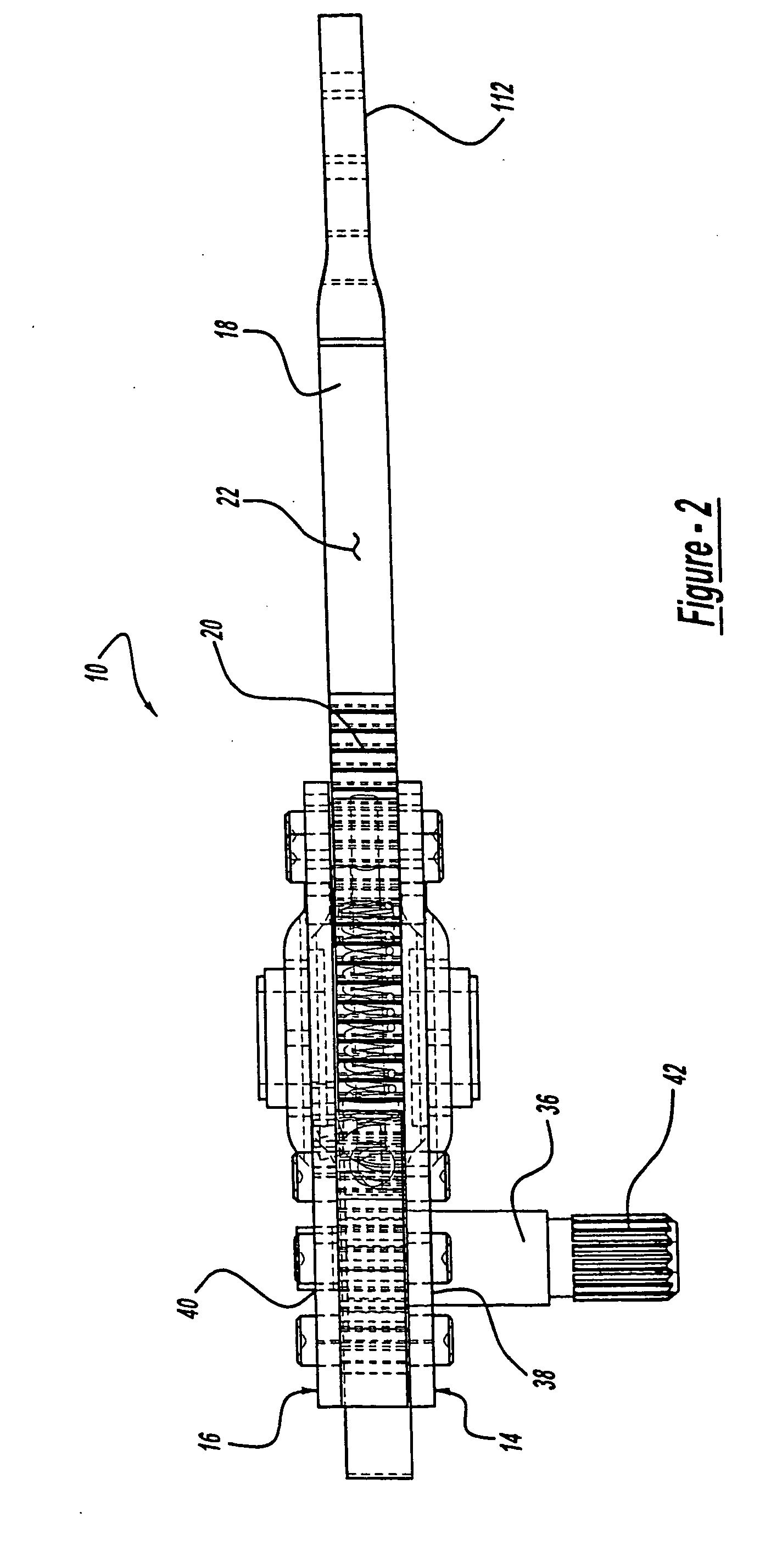

[0019] With reference to FIGS. 1 through 3, a preferred embodiment of a linear recliner assembly 10 will be described in detail. The linear recliner assembly 10 includes a housing 12 that includes a first support plate 14 and a second support plate 16. A recliner rod 18 is slidably supported within the housing 12 and includes a toothed rack 20 formed in a top face 22. A pawl 24 is supported within the housing 12 and has a tooth portion 26 on a surface 28 facing the toothed rack 20 of the reclining rod 18. The pawl 24 is fixed between the first and second support plates 14,16 to prohibit pivoting or other movement relative to the housing 12. A cam 30 is rotatably supported between the first and second support plates 14,16 and has a cammed surface 32 that contacts a bottom face 34 of the recliner rod 18. The cam 30 is fixed for rotation with a spindle 36, which is rotatably supported by the first and second support plates 14,16 through respective openings 38,40. The spindle 36 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com