Stopper for bottles and similar containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

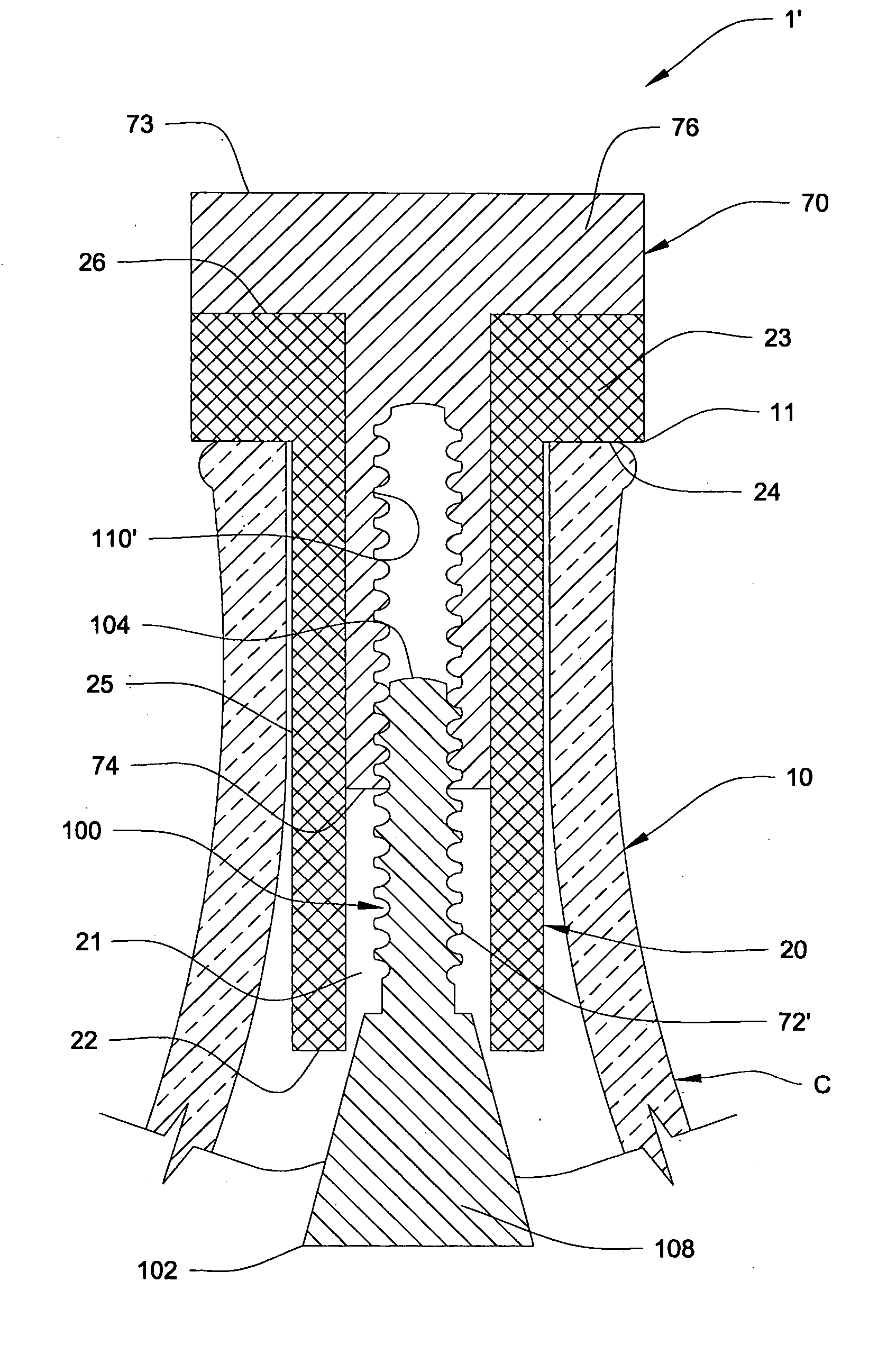

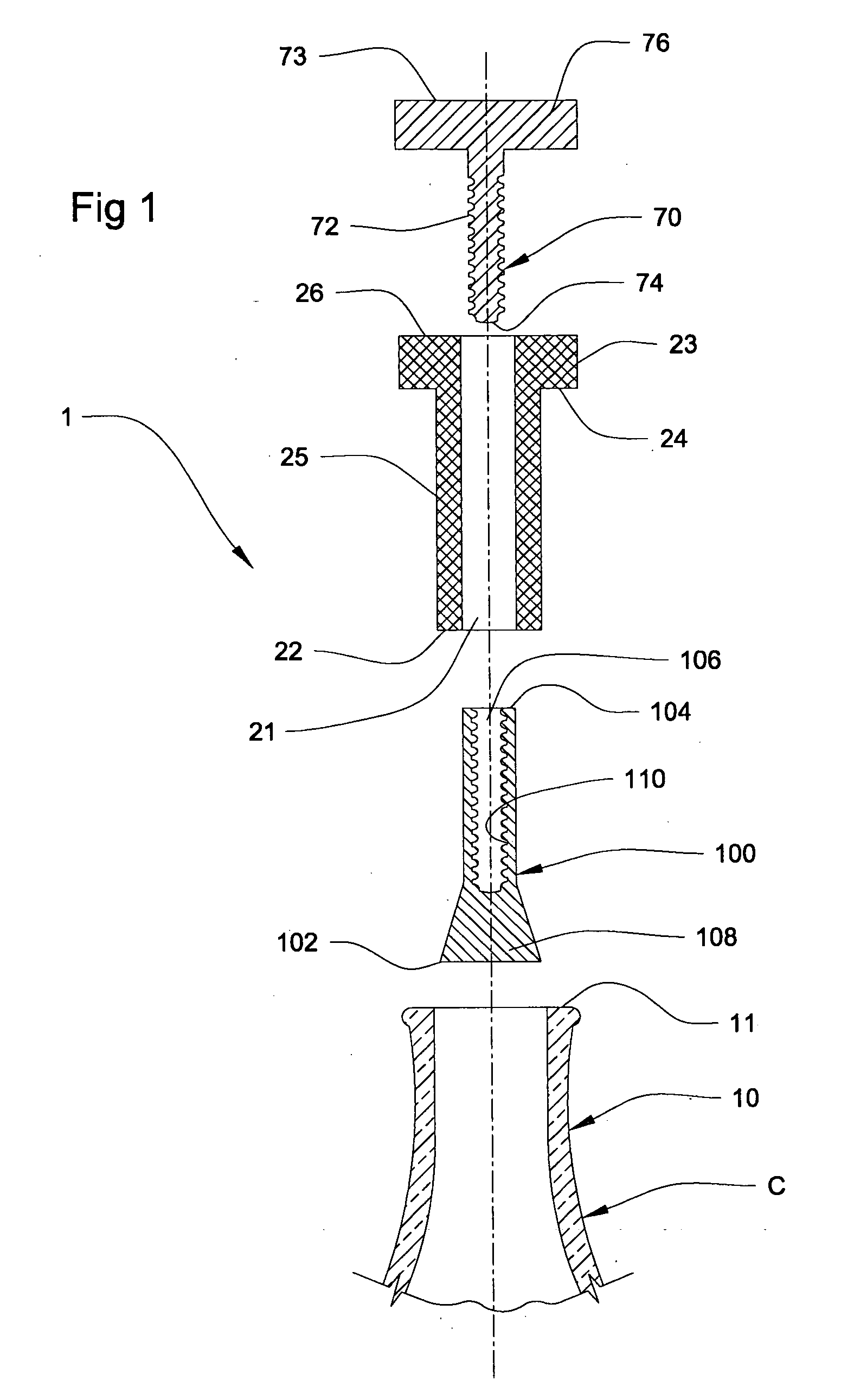

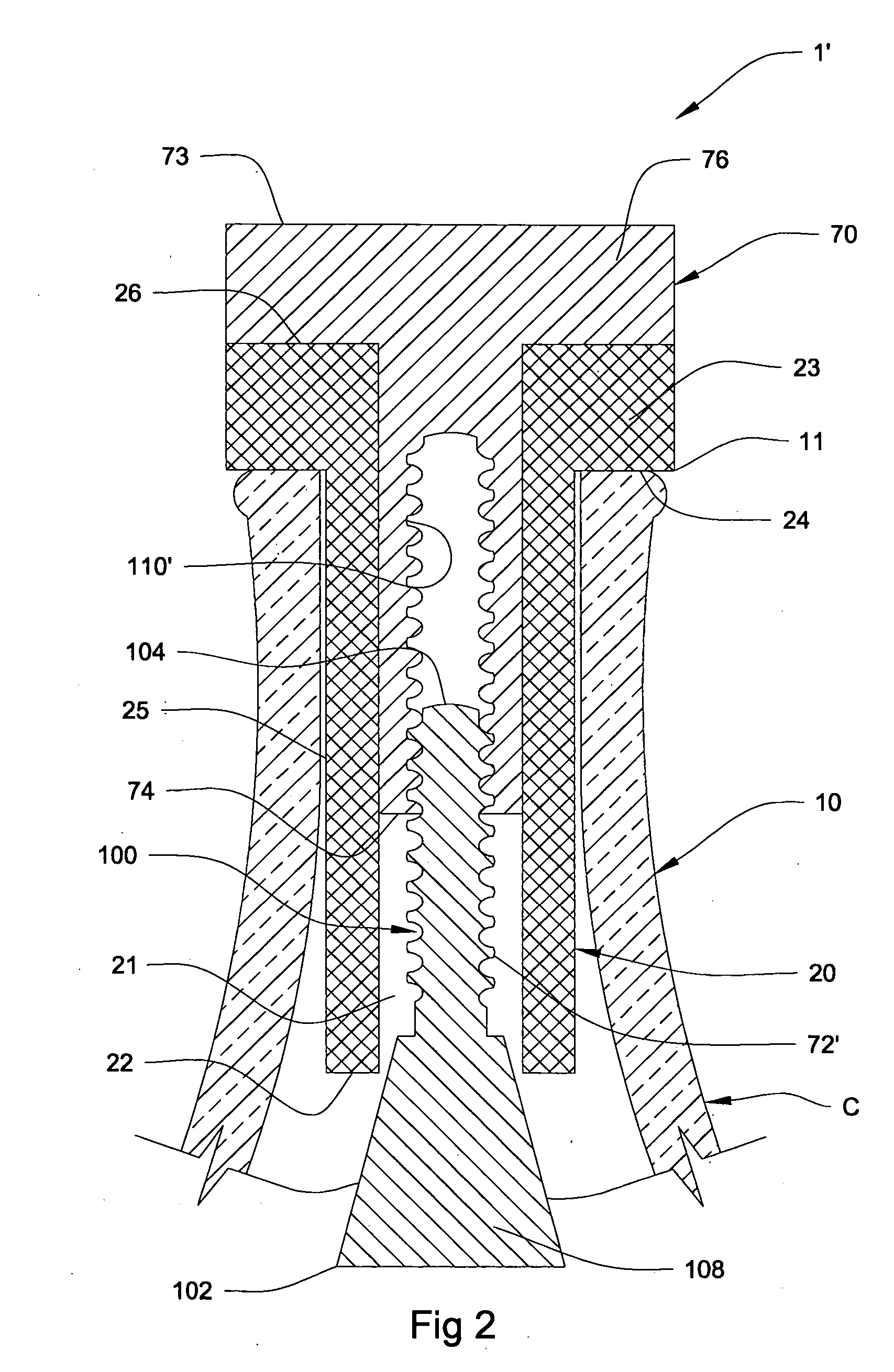

[0020] Referring now to the drawings, where the present invention is generally referred to with numeral 1, it can be observed that it is used with containers C having neck 10. Stopper 1 subject of the present application includes tubular cylindrical assembly 20, pin assembly 70 and plug assembly 100. Basically, cylindrical assembly 20 is partially and snuggly received within neck 10. Assembly 20 includes a central through opening 21 that partially receives assemblies 70 and 100 in mating cooperative engagement. A user rotates assembly 70 causing assembly 100 to advance (assembly 20 is functionally held in place within neck 10) towards peripheral flange 76 with frustroconical end 108 pushing the internal wall of lower end 22 against the interior surface of neck 10 sealing the interior of the container C.

[0021] One of the preferred embodiments is shown in FIG. 1. Tubular cylindrical assembly 20 is made out of a deformable and resilient material, such as rubber or equivalent. Cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com