Clamp device for securement of scaffolding to large-girth structures

a technology for scaffolding and large girths, applied in the field of scaffolding, can solve the problems of high cost, high risk, and high time-consuming and expensive, and achieve the effects of high safety, easy installation and removal, and large girth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

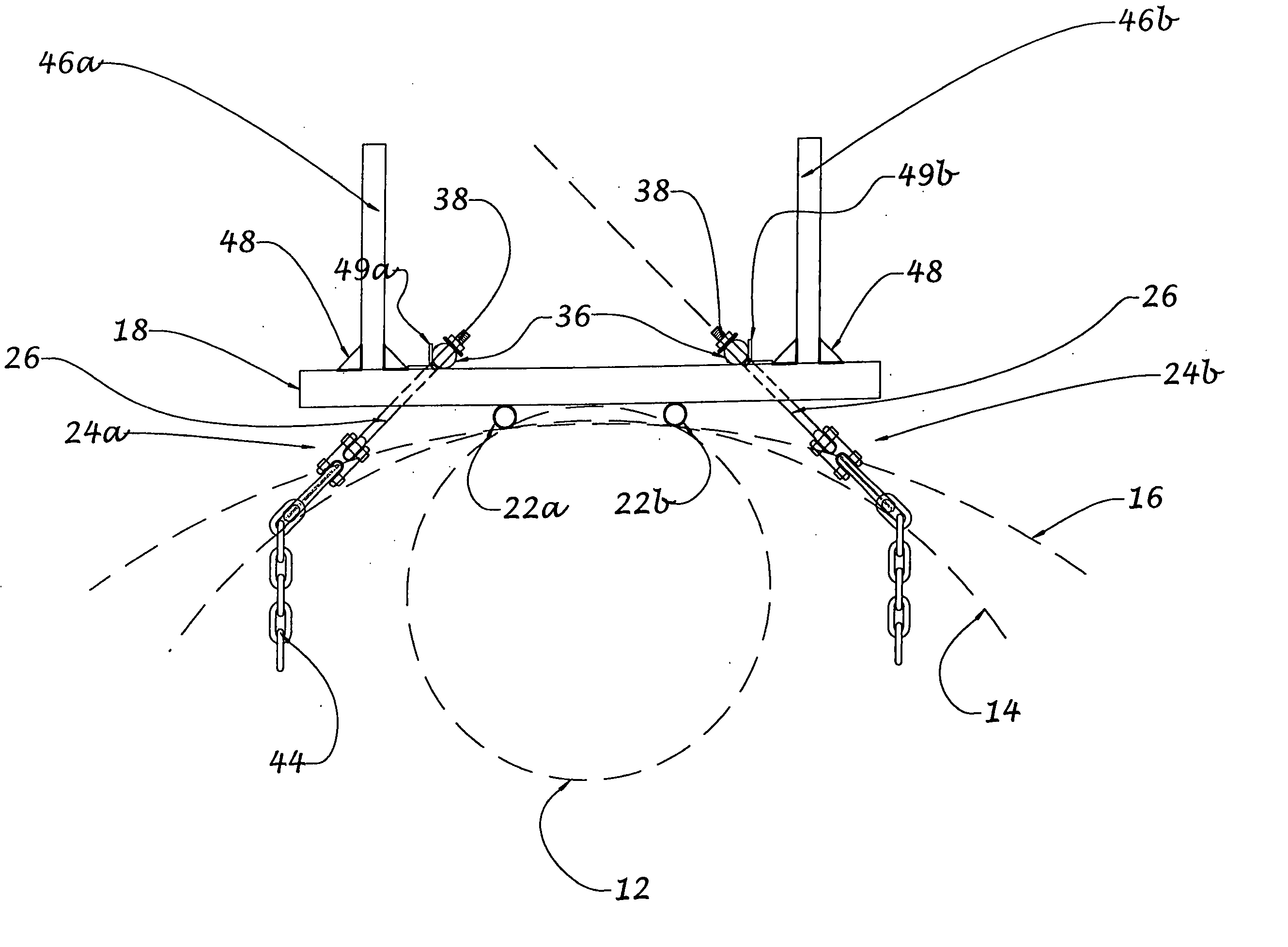

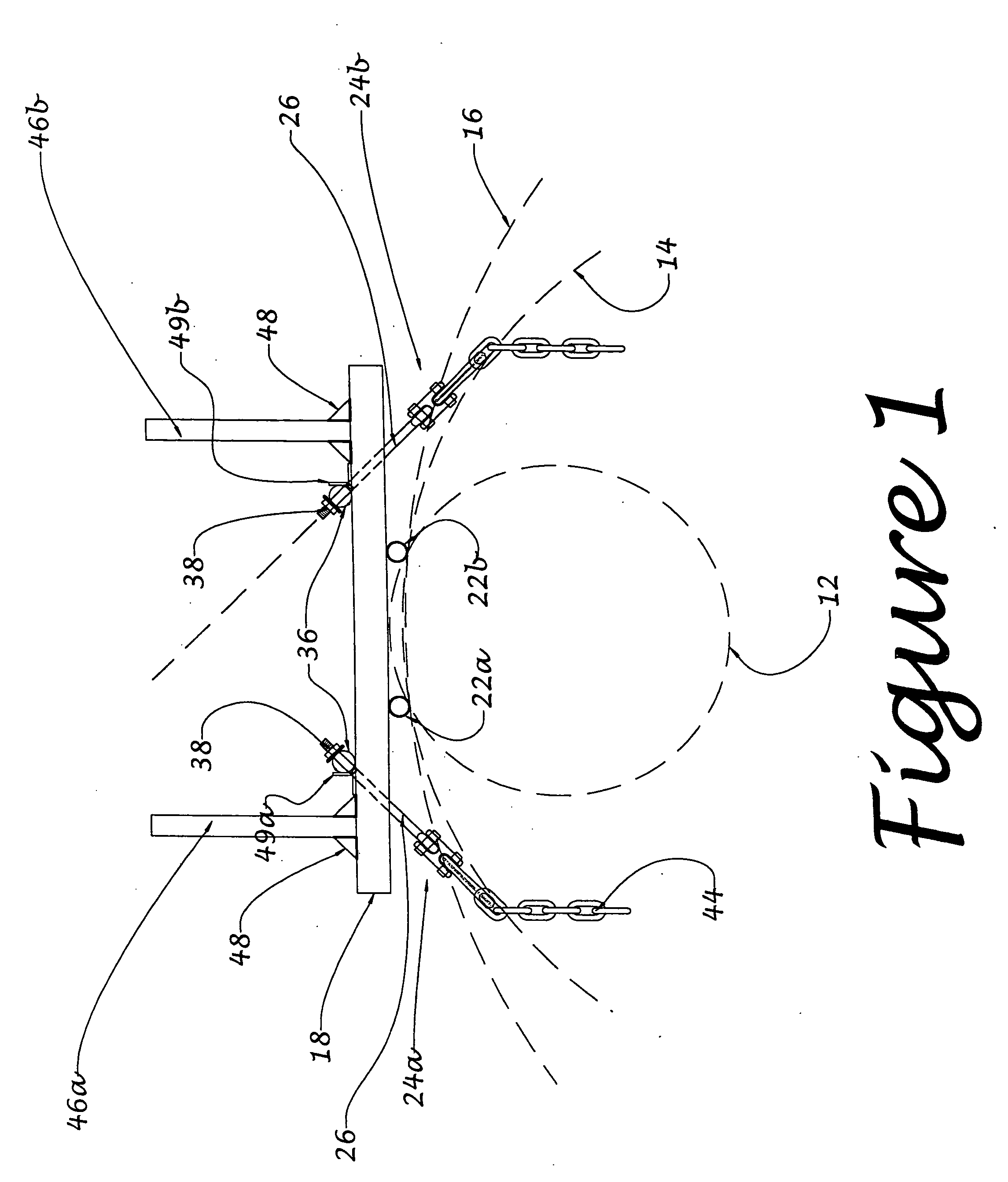

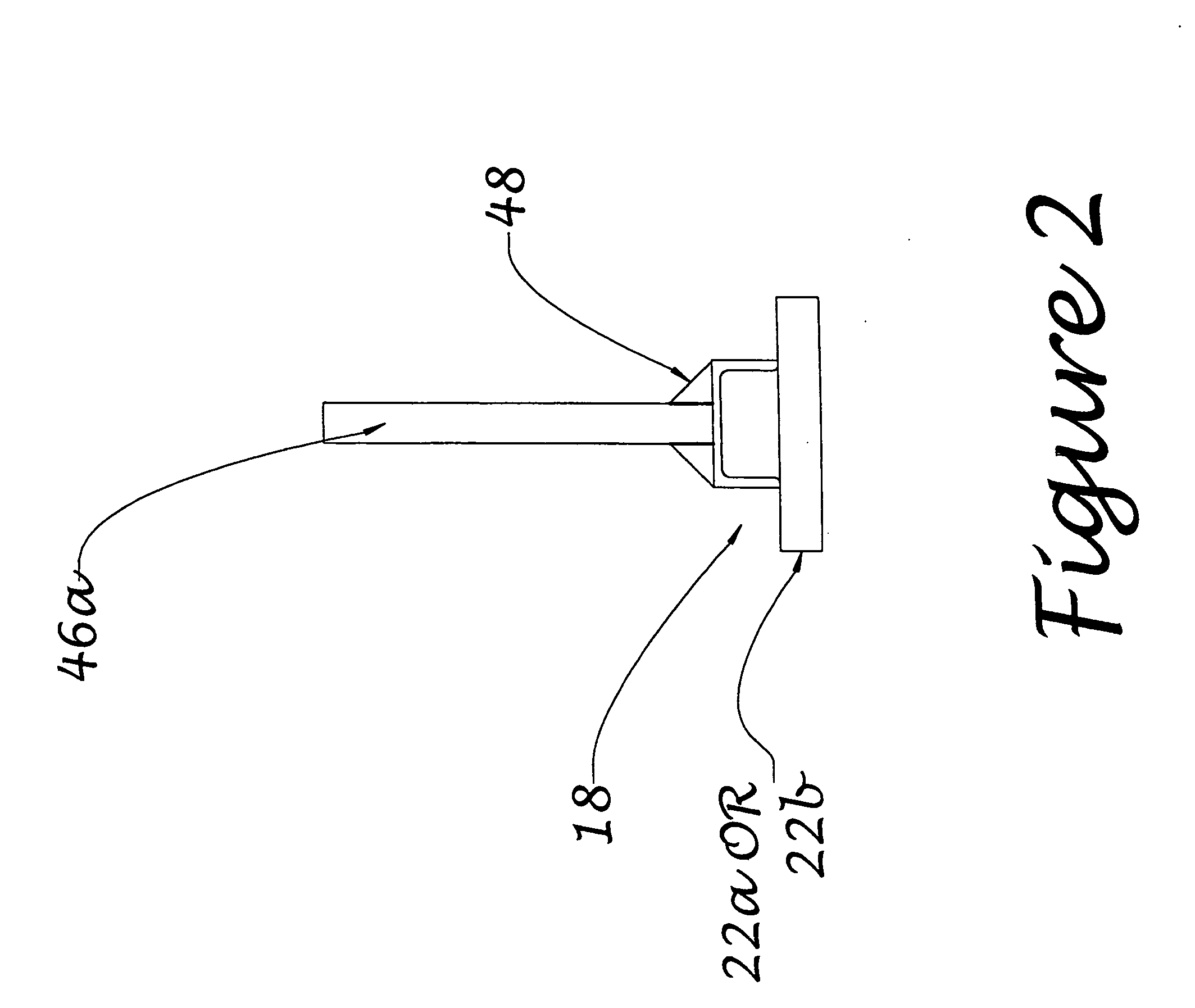

[0025] Referring now to the drawings, particularly the FIG. 1, the new clamp device is designated generally 10. It is here shown as it may be attached to one of several large-girth structures (LDPs). For example, a 30-in. pipe (where the dimension refers to the diameter) is designated at 12, a 7 ft. diameter pipe is 14 and a 12 ft. diameter pipe is at 16. Clamp 10 can be used with any of such large-girth structures for temporary clamping attachment of scaffolding apparatus or other access apparatus (such as catwalks, access ladders, and various possible devices and structures) to any one of possible such LDPs, where the girth could vary over substantially great range such as from a few feet to more than 40 feet, if not greater, and where the orientation of such a structure could also vary, as for example, being vertical, horizontal or oblique, or where the diameter may vary from one end to the other as in a tapered LDP. Therefore, it will be understood that the variety of large-girt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com