Prefab material for adjusting level of floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

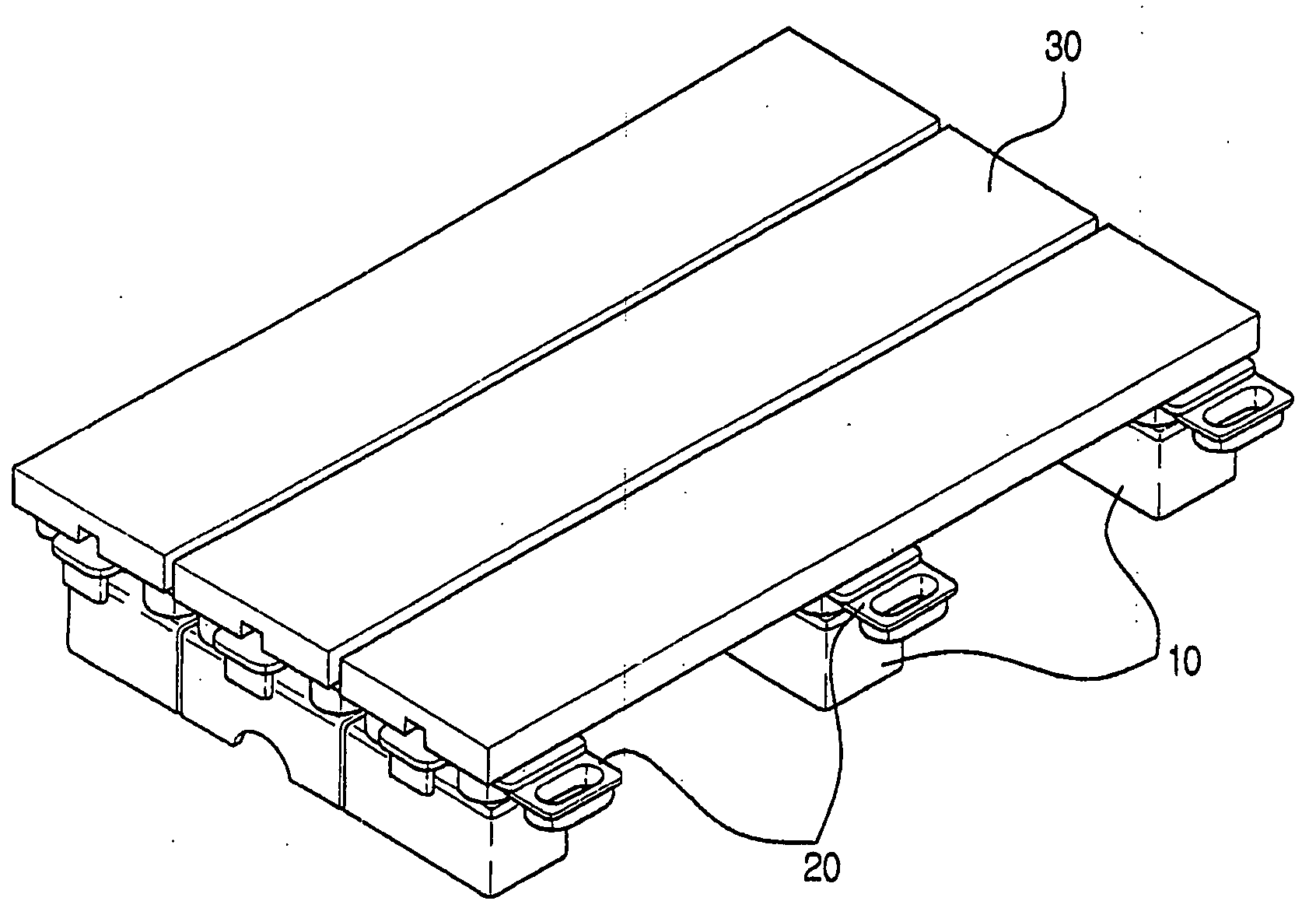

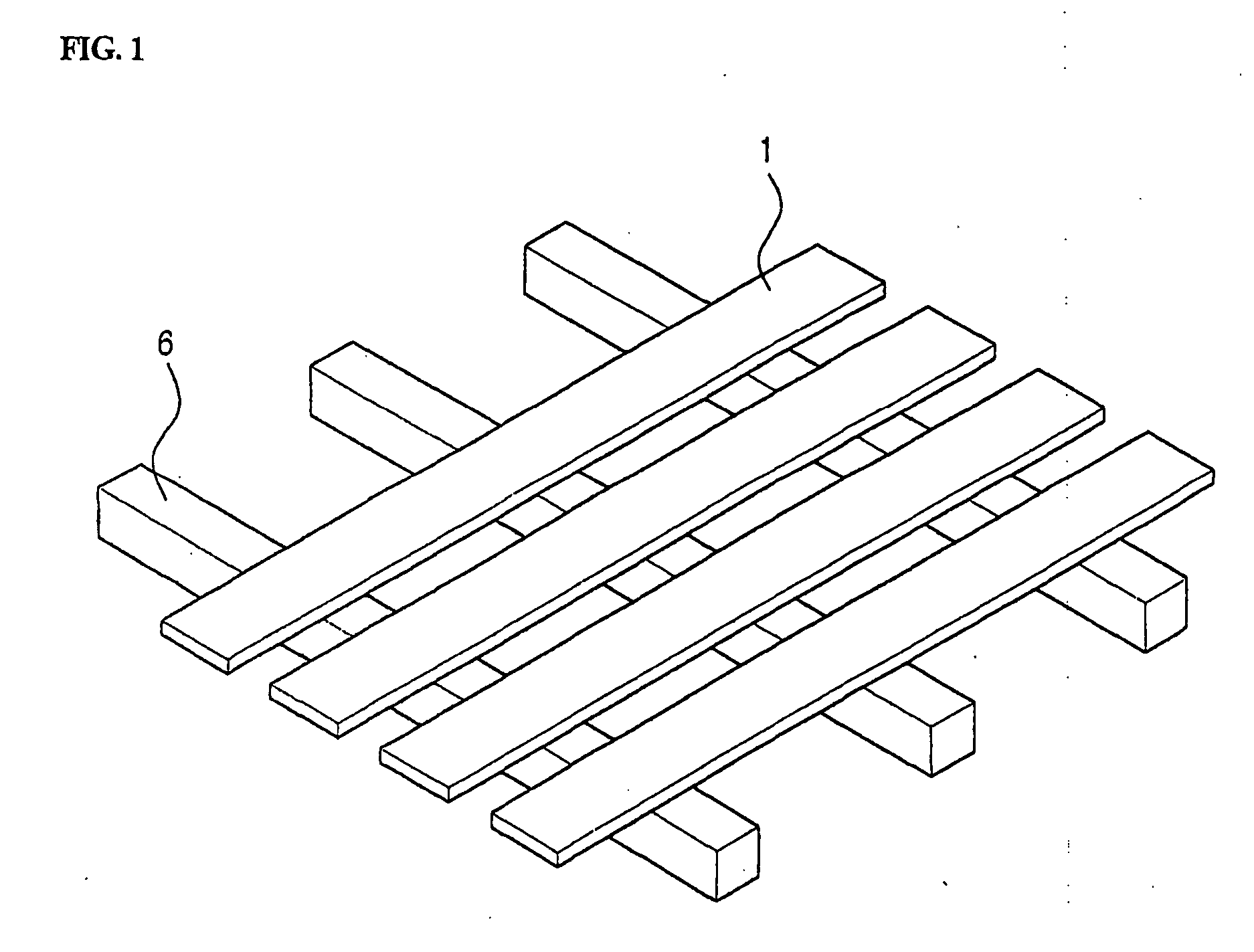

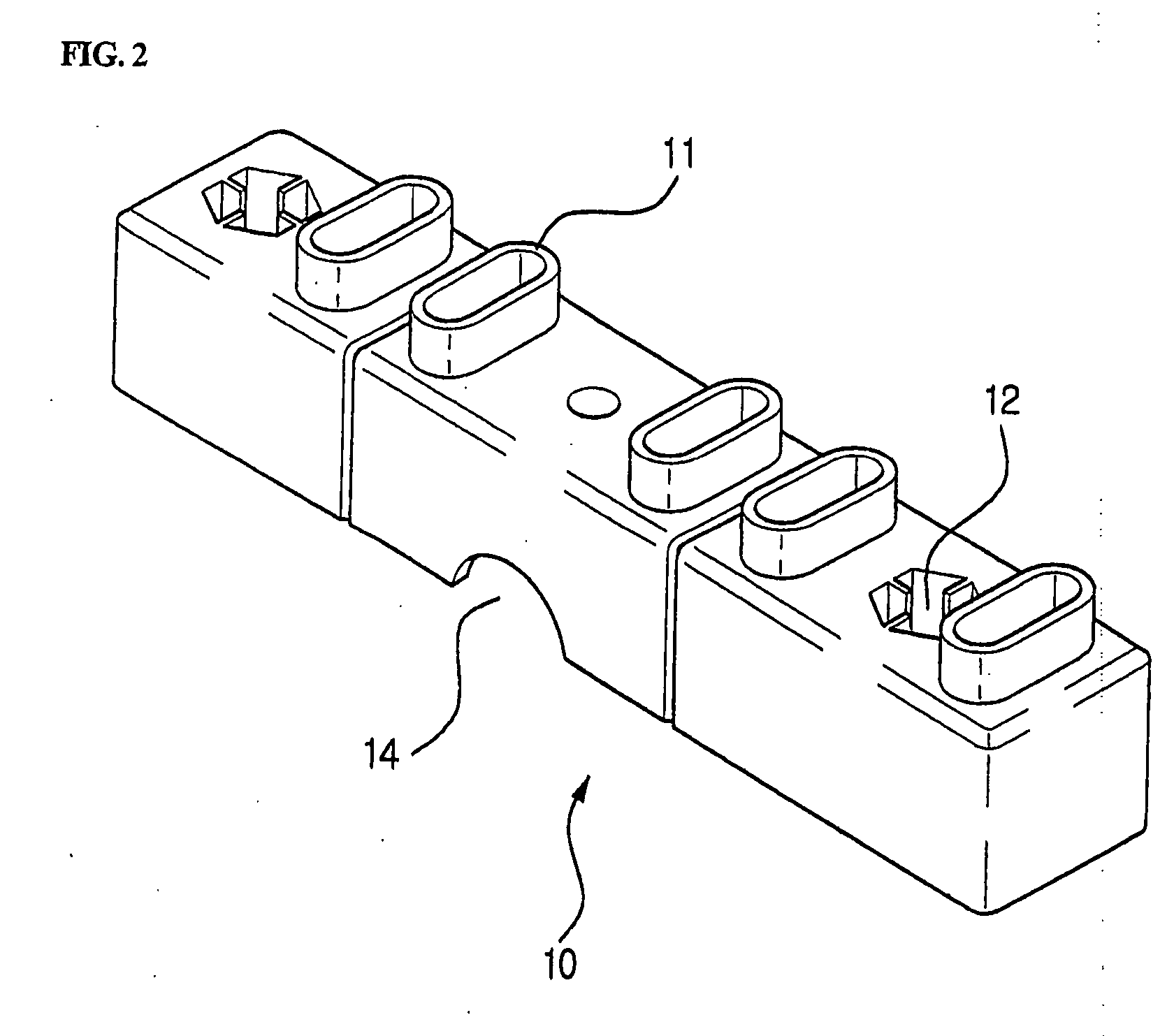

[0036] The present invention will now be described in detail in connection with preferred embodiments with reference to the accompanying drawings.

[0037] As shown in FIGS. 2 and 3, a height adjusting block 10 includes connecting tongues 11 formed on the upper surface of a height adjusting block 10, vertical holes 12 perforating the upper surface and the lower surface of the height adjusting block 10, and built-in nuts 13 respectively embedded and fixed in the vertical holes 12.

[0038] The shape of the connecting tongues 11 is not restricted to the shape shown in FIG. 2, and one of various shapes, such as a circle, an oval and others, can be selected. Also, the shape of the section of the vertical hole 12 is not restricted to the shape shown in FIG. 2 or 3, and one of various shapes, such as a circle, a hexagon and others, can be selected if the built-in nut is embedded and fixed therein and spaces for moving screw bars of horizon adjusting devices 40 vertically through the vertical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com