Swallow tailed boat hull

a technology for watercraft and hulls, which is applied in the direction of waterborne vessels, floating buildings, vessel construction, etc., can solve the problems of adverse stability of watercraft, achieve the effect of facilitating water flow, facilitating break with water flow, and substantially maintaining waterline width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

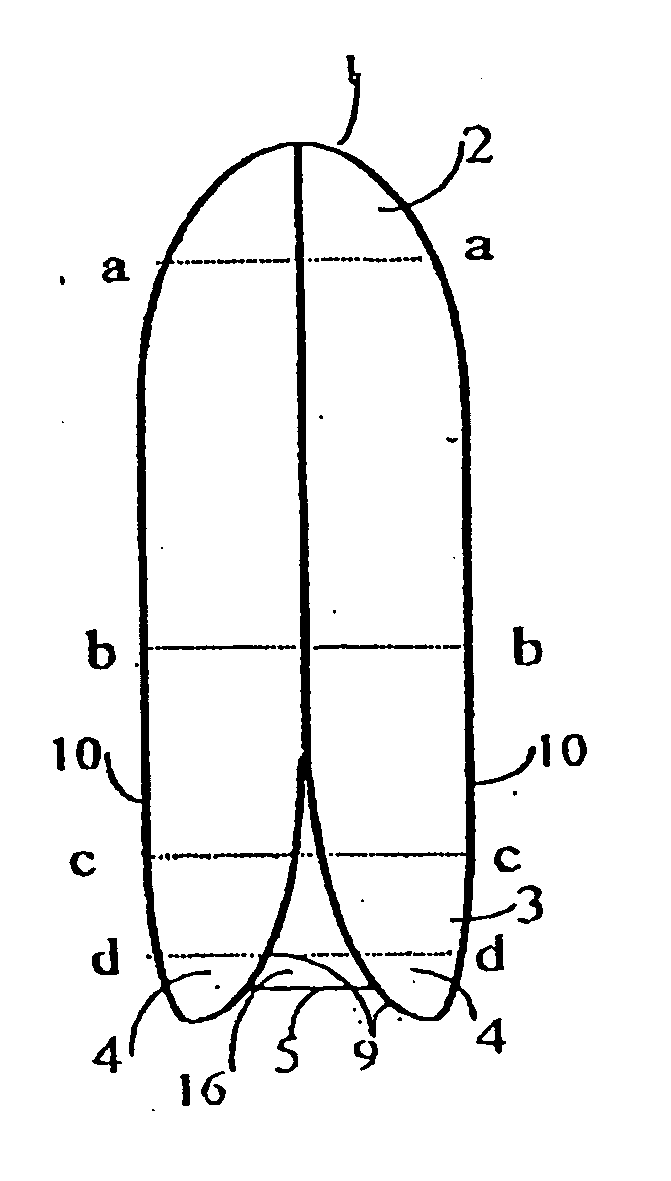

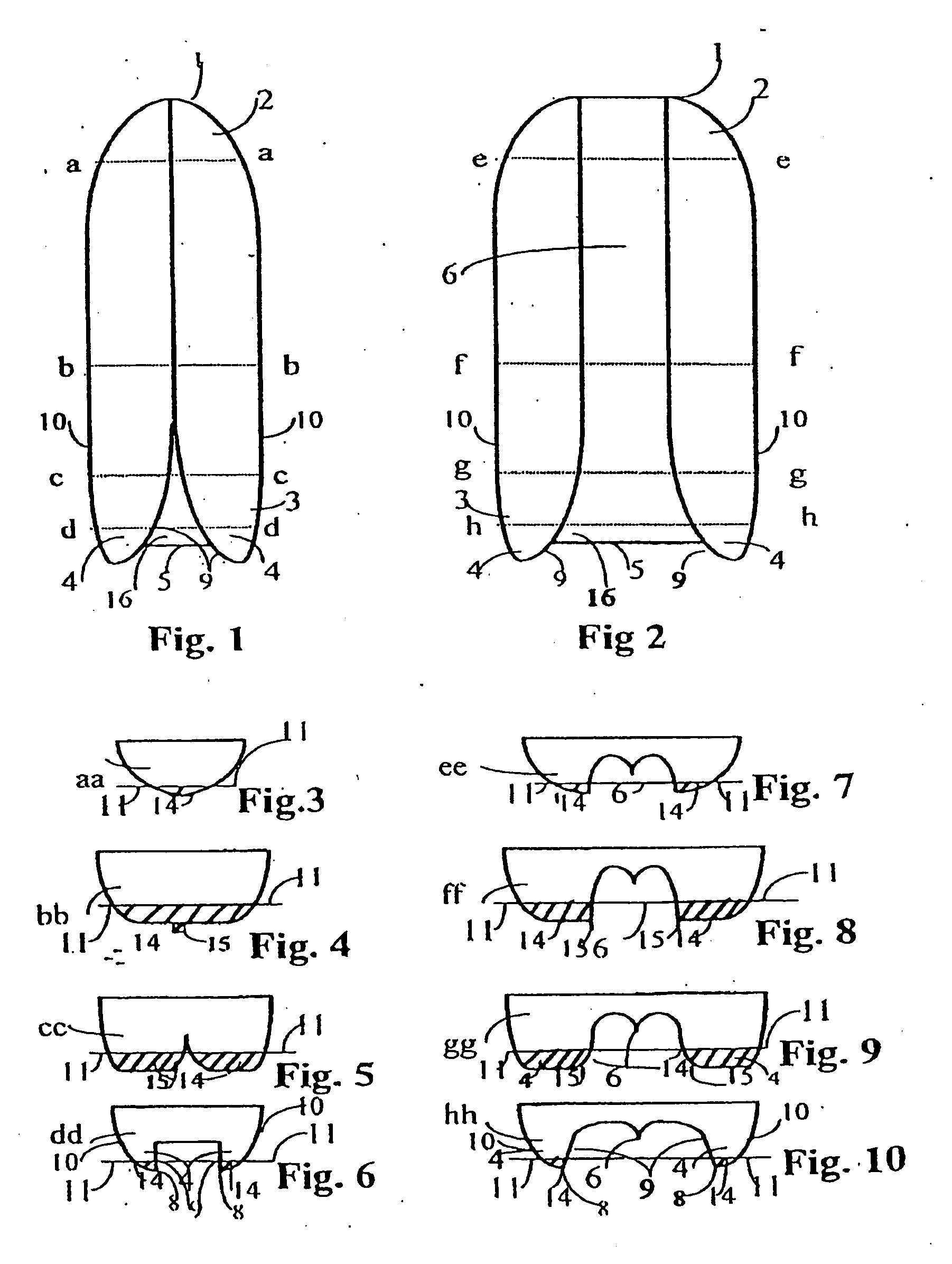

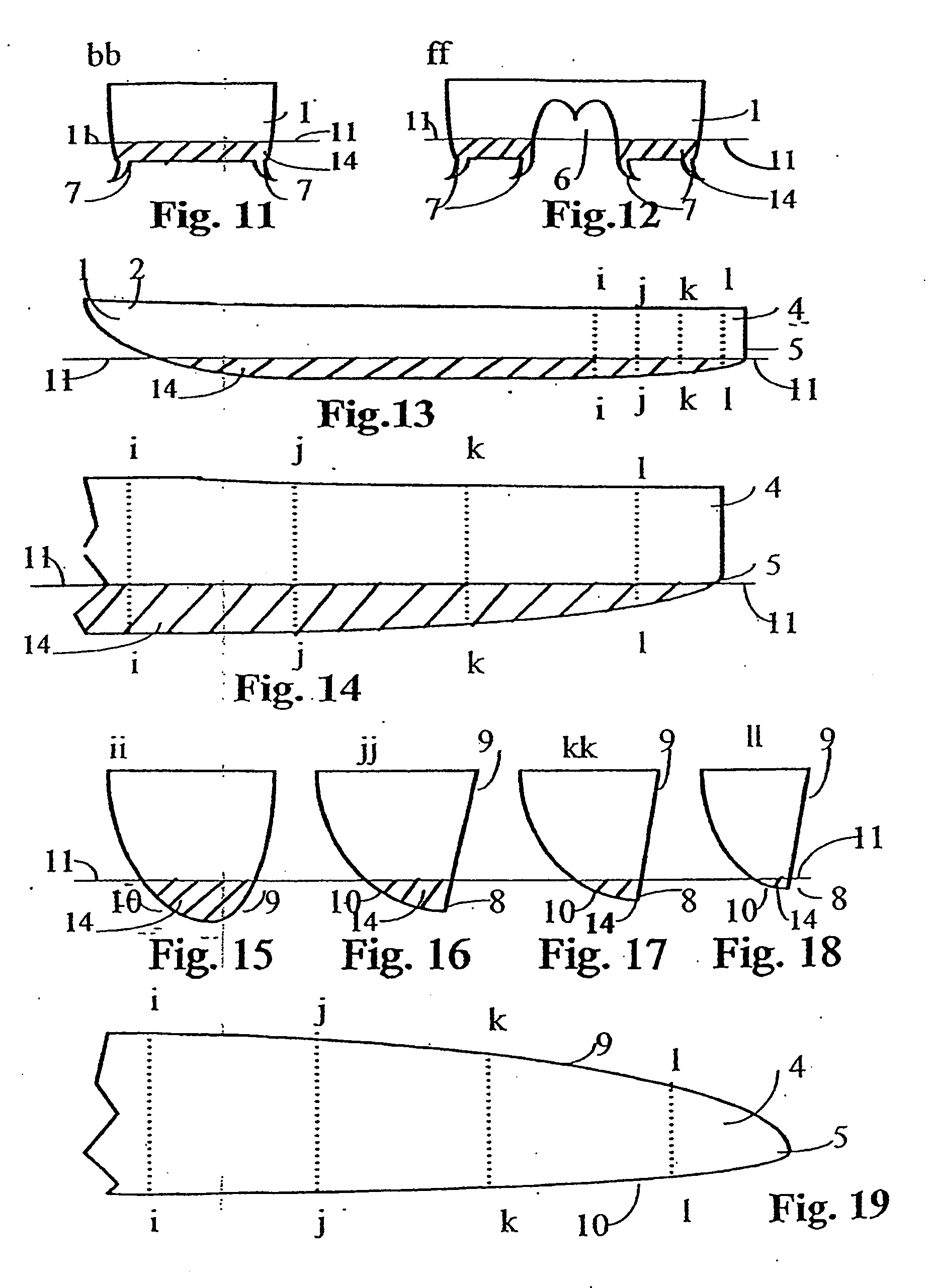

[0047] Referring to the drawings: [0048]1=a boat hull; 2=the Bow; 3=the Stern; 4=a swallow tail hull section; 5=a transom; 6=a tunnel; 7=a hook keel; 8=a sharp edge; 9=an inside side of a swallow tail hull section; 10 an outside side of a swallow tail section; 11=a waterline; 12=an outside side concave section; 13=concave sections; 14=hatched areas denoting areas below the waterline—or wetted areas; 15=keels; 16=hull section connection

[0049] Referring firstly to FIG. 1, a water craft hull (1) viewed from below has a bow (2) with the body of the hull (1) extending to the stern (3) where it splits into two sections forming swallow tails (4) connected by a transom (5). The transom (5) may be located anywhere along the swallow tails (4) or forward of them. The swallow tails (4) may start to split from the keel (15) or keels (15) and splay out anywhere aft of mid-ships. The split may begin below the waterline and extend aft below the waterline extending from the keel line (15) aft and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com