Semi-transmission type liquid crystal display which reflects incident light coming from outside to provide a display light source and transmits light from a light source at the back

a liquid crystal display and incident light technology, applied in static indicating devices, instruments, non-linear optics, etc., can solve the problems of reducing the efficiency of rubbing process, and reducing the intensity of rubbing process, so as to reduce the effect of color chang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

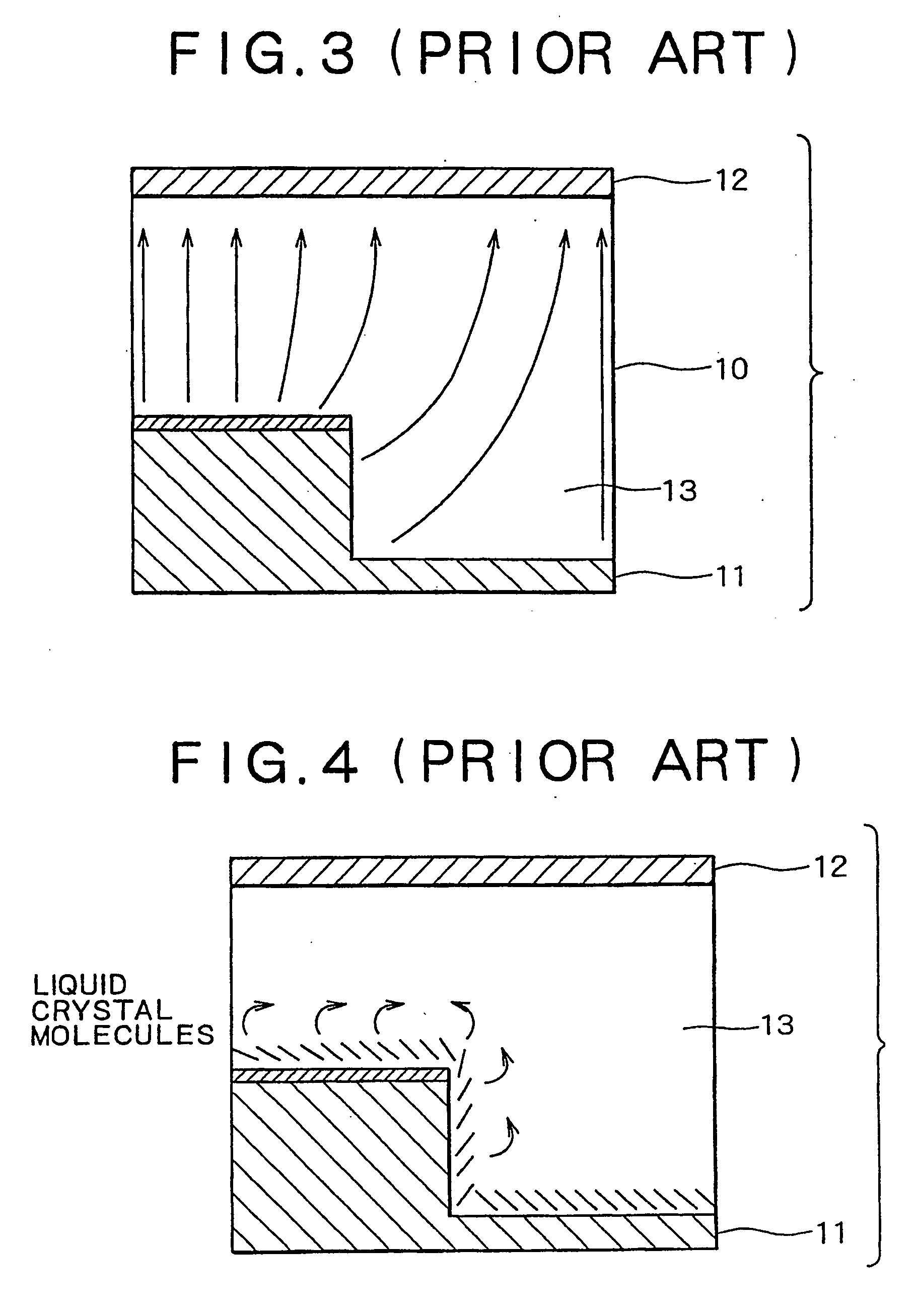

[0062]FIG. 6 is a partial cross-sectional view of a semi-transmission type liquid crystal display according to the invention. As shown in FIG. 6, the semi-transmission type liquid crystal display has, inside, a lower substrate 11, an opposite substrate 12 so arranged as to face the lower substrate 11 and a liquid crystal layer 13 sandwiched between the lower substrate 11 and the opposite substrate 12. The semi-transmission type liquid crystal display employs an active matrix system which has, for example, thin film transistors (TFTs) provided as switching elements pixel by pixel.

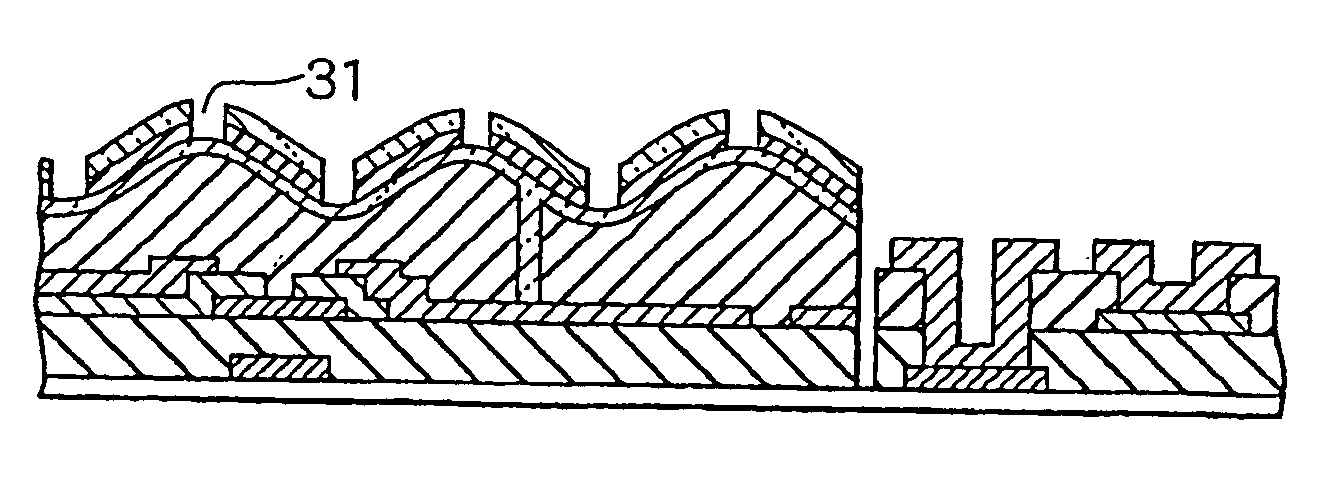

[0063] The lower substrate 11 has an insulative substrate 14, an insulating protection film 15, TFTs 16, an insulating layer 17, a reflection electrode 18 and a transparent electrode 19. The insulating protection film 15 is deposited on the insulative substrate 14 and the TFTs 16 are formed on the insulating protection film 15. Each TFT 16 has a gate electrode 16a on the insulative substrate 14, a drain elec...

second embodiment

[0076]FIG. 10 is a cross-sectional view showing a part of the lower substrate of the second embodiment in a simplified form. A contact hole 20 reaching the source electrode 16d of the TFT 16 is bored in the insulating layer 17. The reflection electrode 18 and transparent electrode 19 are deposited, covering the contact hole 20 and the insulating layer 17. The transparent electrode 19 is connected to the source electrode 16d of the TFT 16 and has a function to serve as a pixel electrode. The reflection electrode 18 is electrically connected to the transparent electrode 19 via an insulating film 21 and has a function to serve as a reflector and a pixel electrode. The transparent insulating film 21 of SiO2 or the like is deposited on the reflection electrode 18. At this time, the insulating film 21 is deposited on the entire surface of the reflection electrode 18 in such a way as to completely cover the reflection electrode 18. Although not illustrated, an alignment film 22 of polyimid...

fourth embodiment

[0093]FIG. 14 is a cross-sectional view showing a part of the lower substrate of the fourth embodiment in a simplified form. A contact hole 20 reaching the source electrode 16d of the TFT 16 is bored in the insulating layer 17. The transparent electrode 19, the insulating film 21 and the reflection electrode 18 are deposited, covering the contact hole 20 and the insulating layer 17. The transparent electrode 19 is connected to the source electrode 16d of the TFT 16 and has a function to serve as a pixel electrode. The transparent insulating film 21 of SiO2 or the like is deposited between the transparent electrode 19 and the reflection electrode 18. The reflection electrode 18 is electrically connected to the transparent electrode 19 via an insulating film 21 and has a function to serve as a reflector and a pixel electrode.

[0094] The insulating layer 17 has an undulating surface and the transparent electrode 19 and the reflection electrode 18 deposited on the insulating layer 17 als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflection area | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com