Molding machine and a pattern carrier used therefor

a molding machine and pattern technology, applied in the direction of moulding machines, manufacturing tools,foundry moulding apparatus, etc., can solve the problems of high cost, large and high cost of related facilities, so as to reduce the amount of sand spillage or scraps, the effect of low cost and easy replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

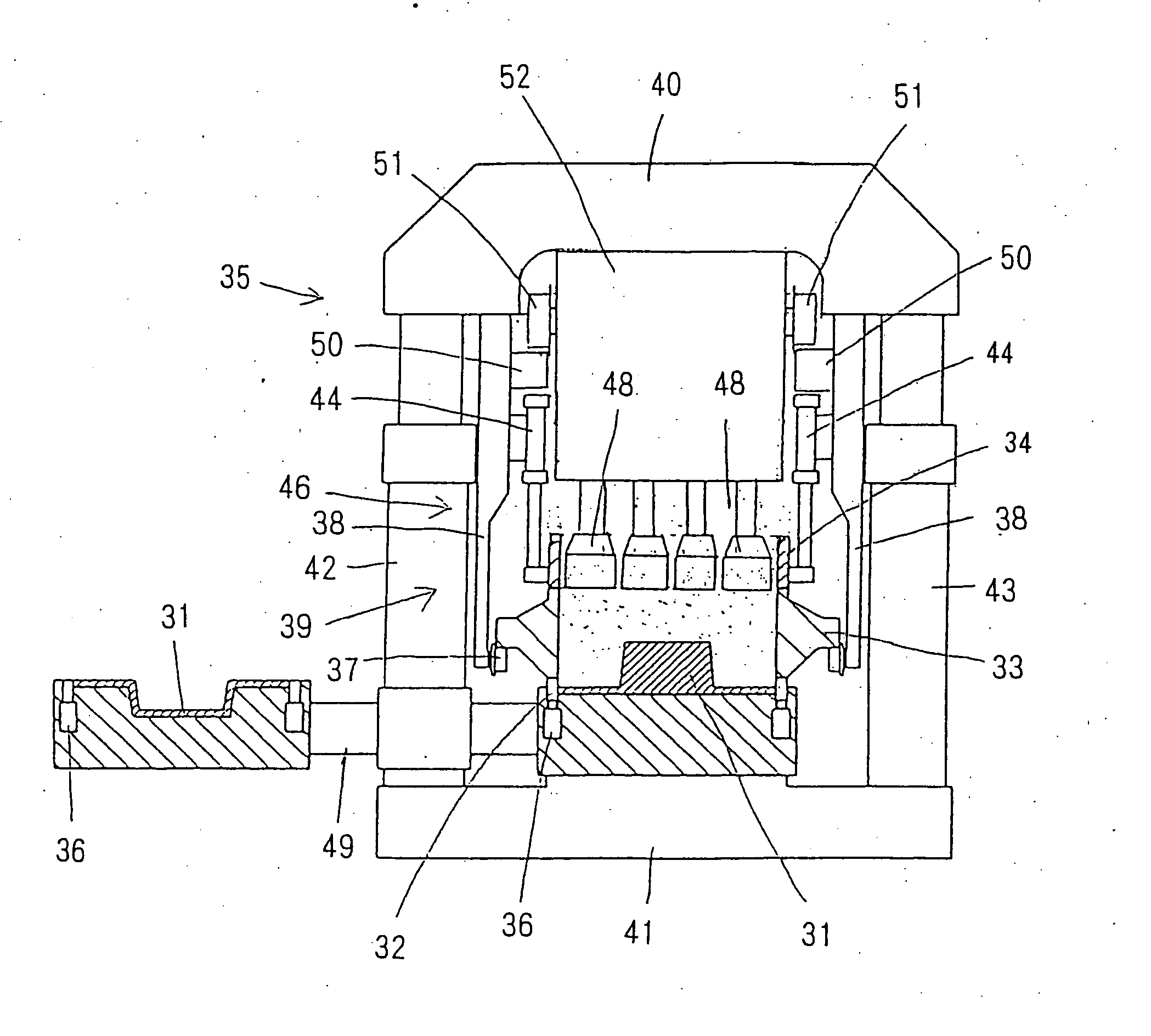

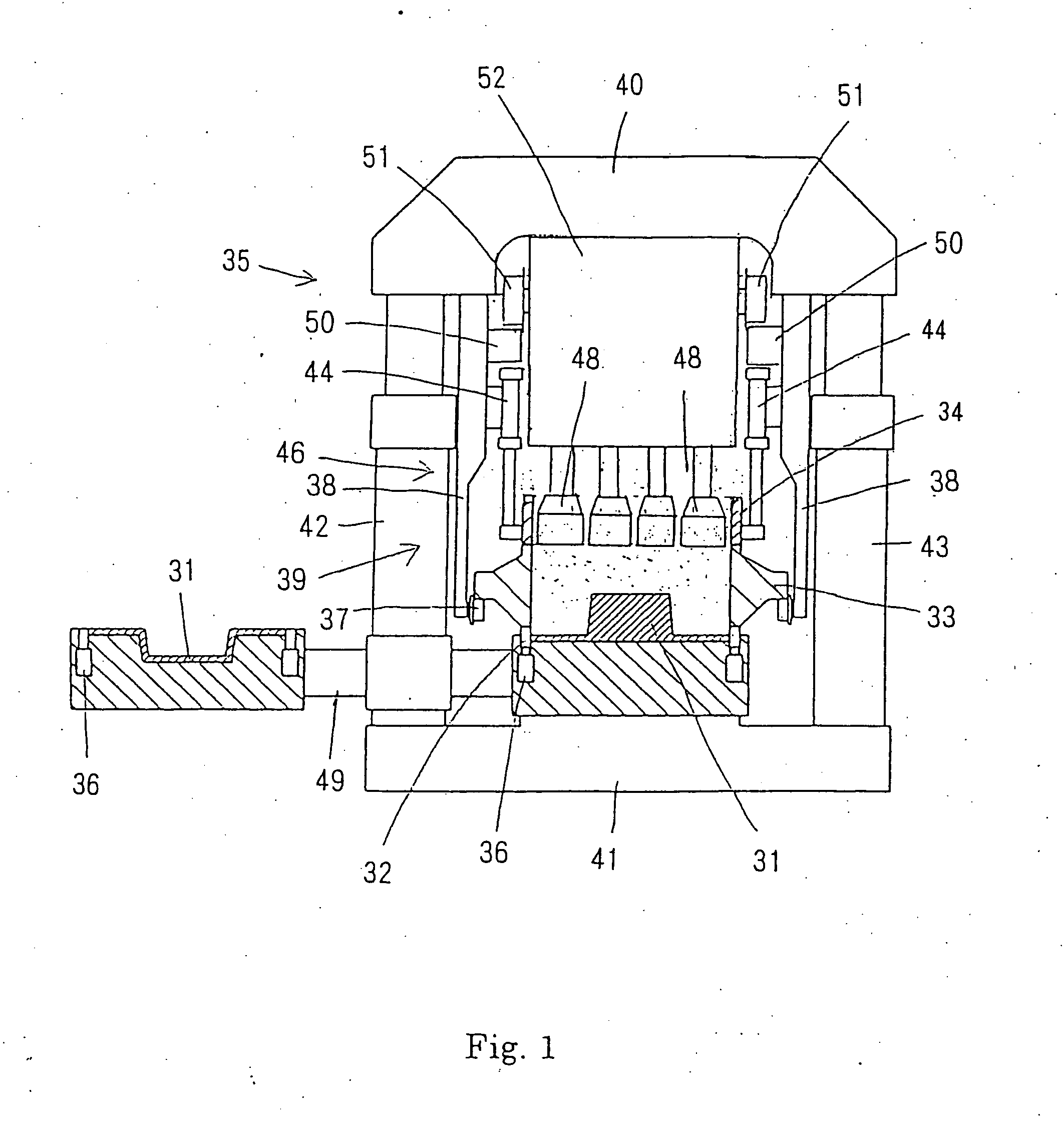

[0025] Referring to FIG. 1, now we explain the molding machine of this invention. The molding machine comprises a pattern plate 31 fixed horizontally, a lower subsidiary flask 32 that surrounds the periphery of the pattern plate 31 and that is disposed such that it can be both slid and moved up and down, a molding flask 33 that is disposed above the lower subsidiary flask 32 so as to be moved up and down, an upper subsidiary flask 34 disposed above the molding flask 33 so as to be moved up and down, and the squeeze feet 48 of the compressing means 35, which are disposed so as to be movable up and down above the molding flask 33 such that their ends can reach within an area surrounded by the upper subsidiary flask 34.

[0026] The pattern plate 31 is mounted on the upper surface of a turntable 49, described below. In the upper surface of the pattern plate 31, vent-plugs (not shown) are embedded according to the shape of the pattern plate. The lower subsidiary flask 32, mounted on the tu...

second embodiment

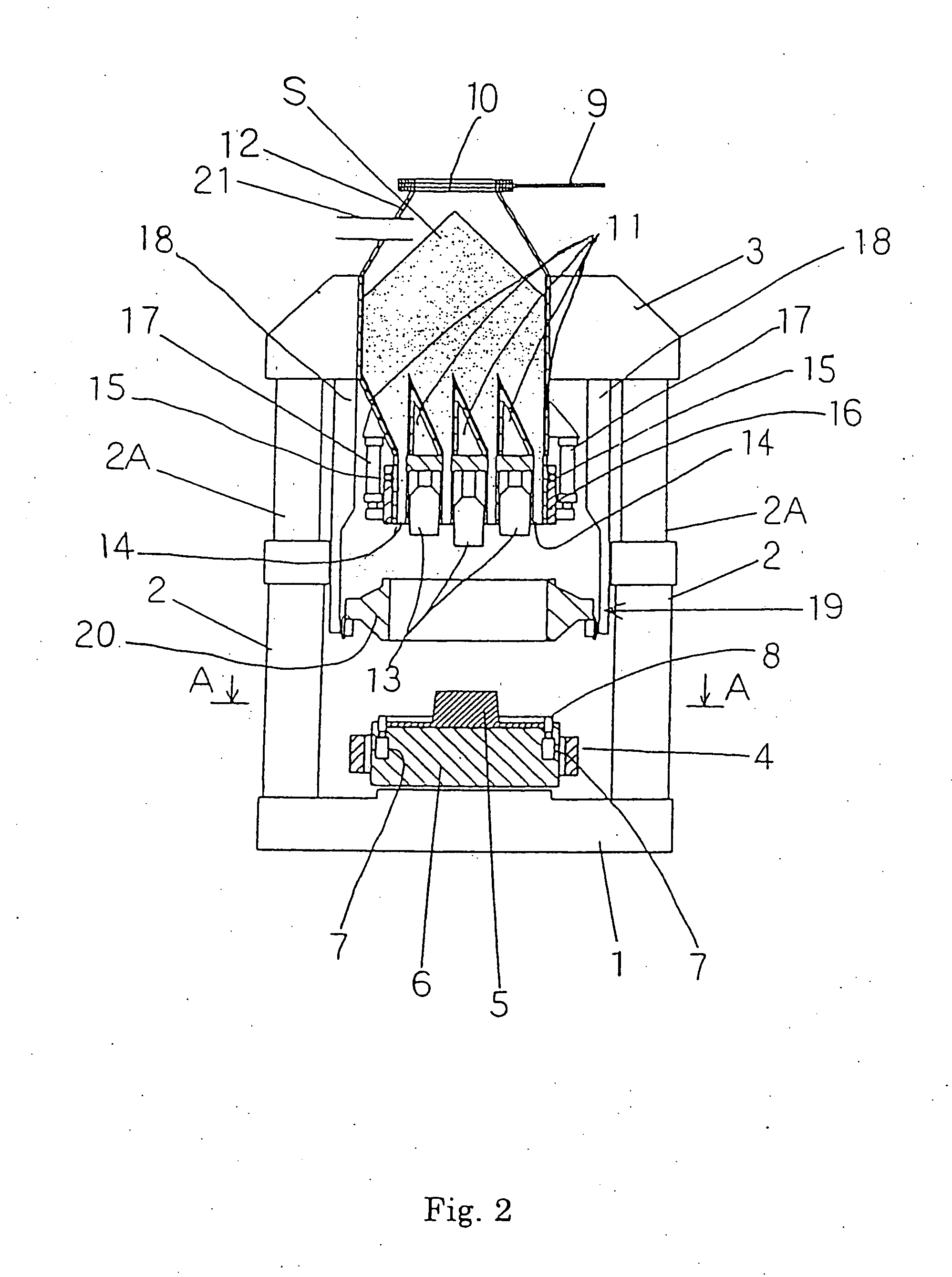

[0033] Now we explain this invention by referring to FIGS. 2-10.

[0034] In FIG. 2, upward flask-setting cylinders 2,2 are mounted on a molding base 1, and a frame 3 for supporting the lifting movement of molding members bridges the rods 2A,2A of the cylinders 2,2. A pattern-replacing device 4 for alternatively transporting a pattern carrier 6,6A (see FIG. 9), on which a pattern plate 5,5A is to be mounted, is disposed above the molding base 1 in a direction perpendicular to the left and right directions of the flask-setting cylinders 2,2. The pattern-replacing device 4 is disposed so as to be movable perpendicular to the face of the drawing by an actuator (not shown).

[0035] A pattern carrier 6,6A, on which a pattern plate 5,5A (an upper and lower pattern plates) is to be mounted, is mounted on both sides of the pattern-replacing device 4 such that the pattern carrier 6,6A is in a raised state by about 5 mm through a spring (not shown), and such that the pattern plate 5,5A is alterna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com