Stackable container and container blank (L corner)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

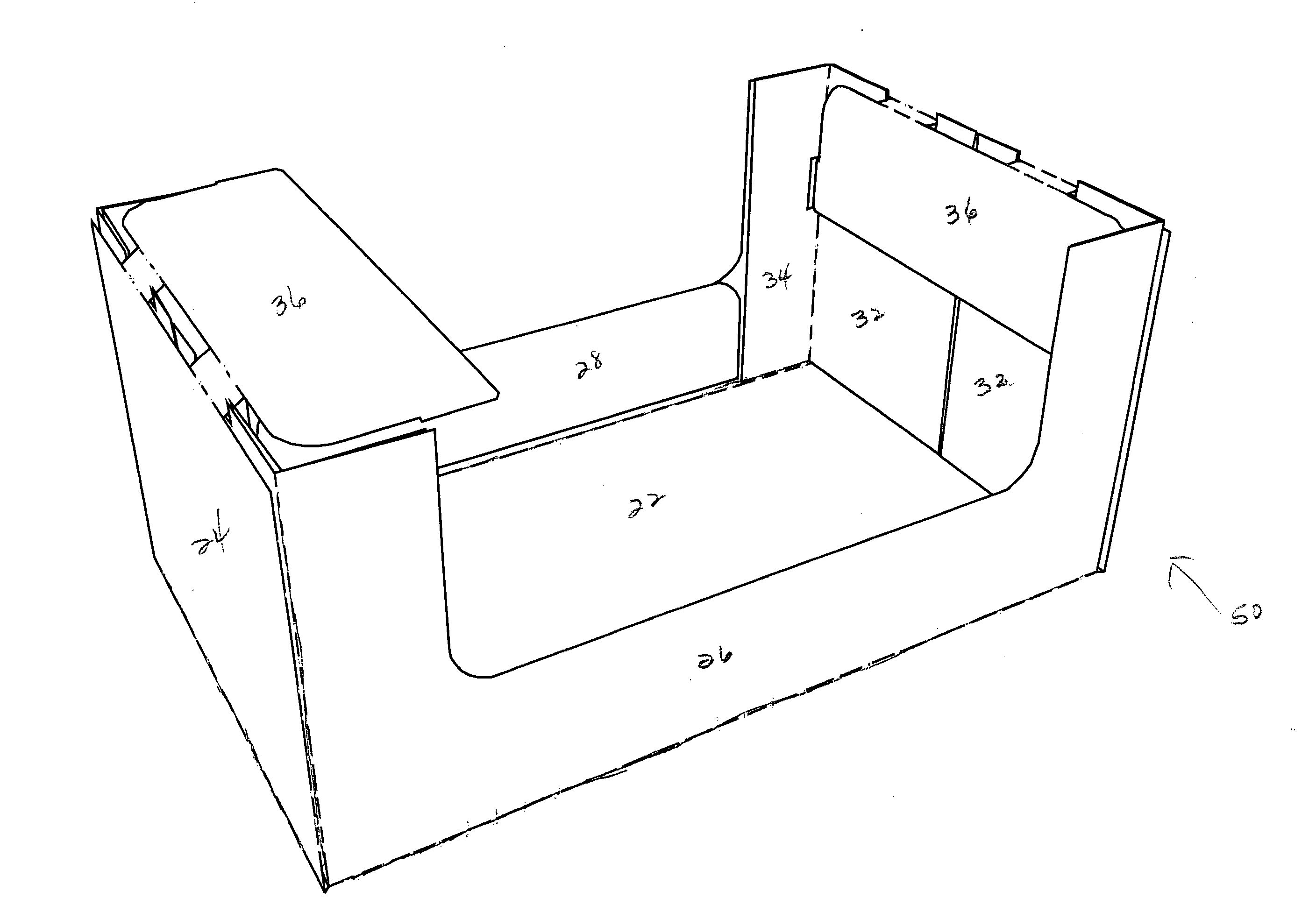

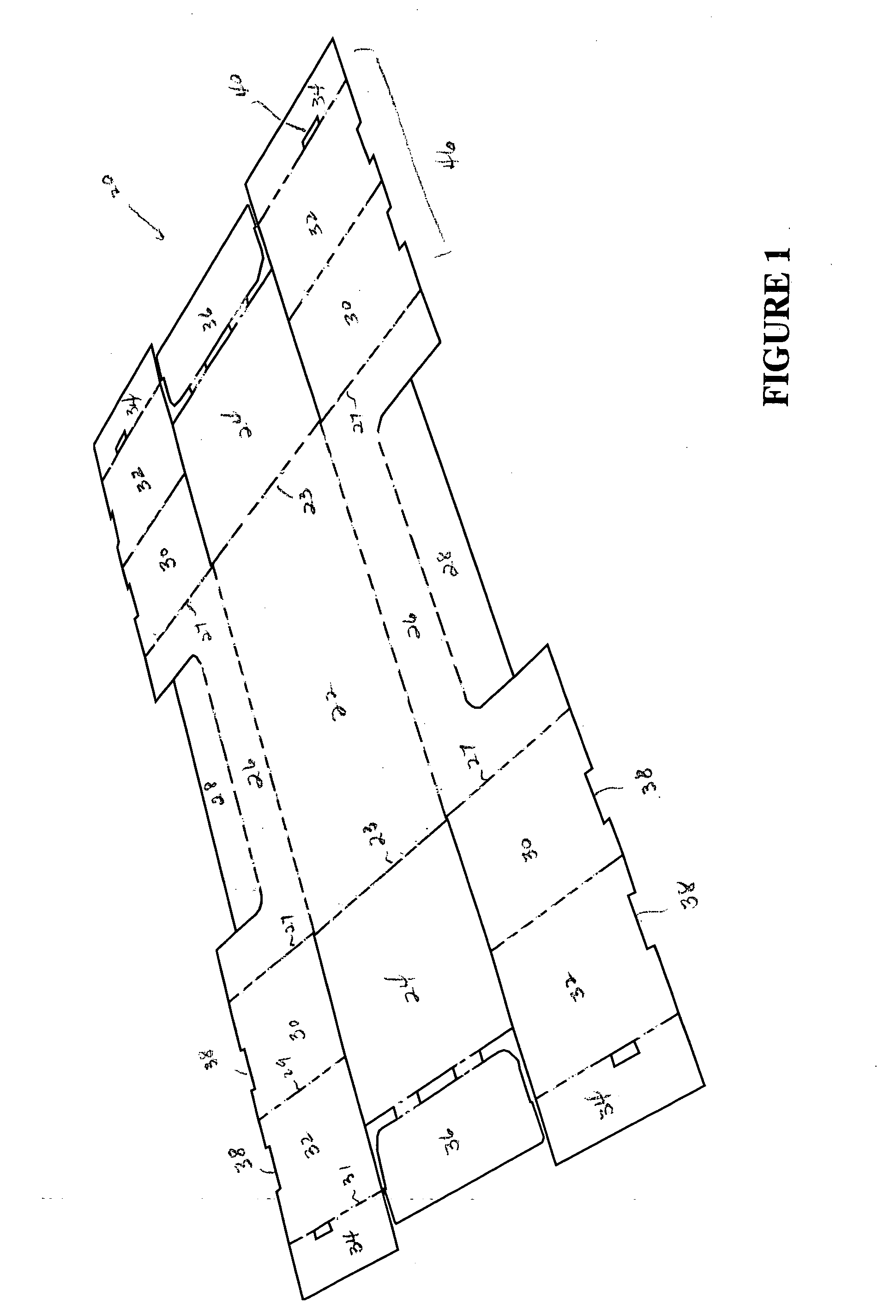

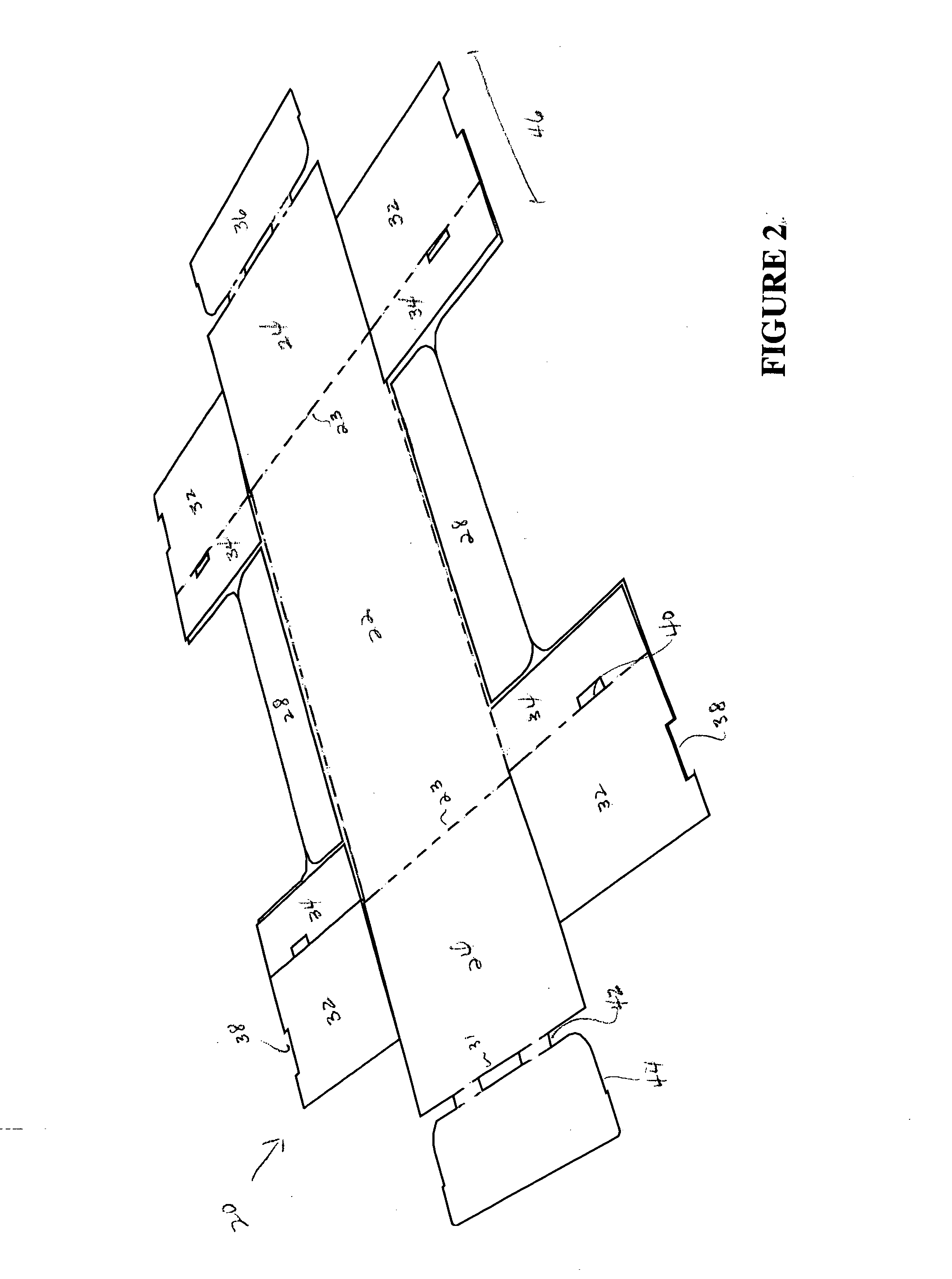

[0014] The present invention includes a single sheet of foldable material cut and scored to form a blank formable into a container. By way of overview and with reference to FIGS. 1-5, an embodiment of the present invention includes a single piece blank 10 arranged to form a stackable container 50. Specific details of the blank 20 and container 50 are described with more particularity below.

[0015] The present invention will now be described with reference to the accompanying FIGS. 1-5 where like numerals correspond to like elements. In all FIGURES, cut lines are shown as solid lines, score lines or lines of weakness are shown as broken lines. The present invention is directed to a tray-type container that utilizes a corner assembly to create a modular stackable container. The container includes an arrangement of panels, which are adapted to provide suitable container stability.

[0016] One suitable embodiment of the blank 20, constructed in accordance with the present invention is il...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com