Cone sleeve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

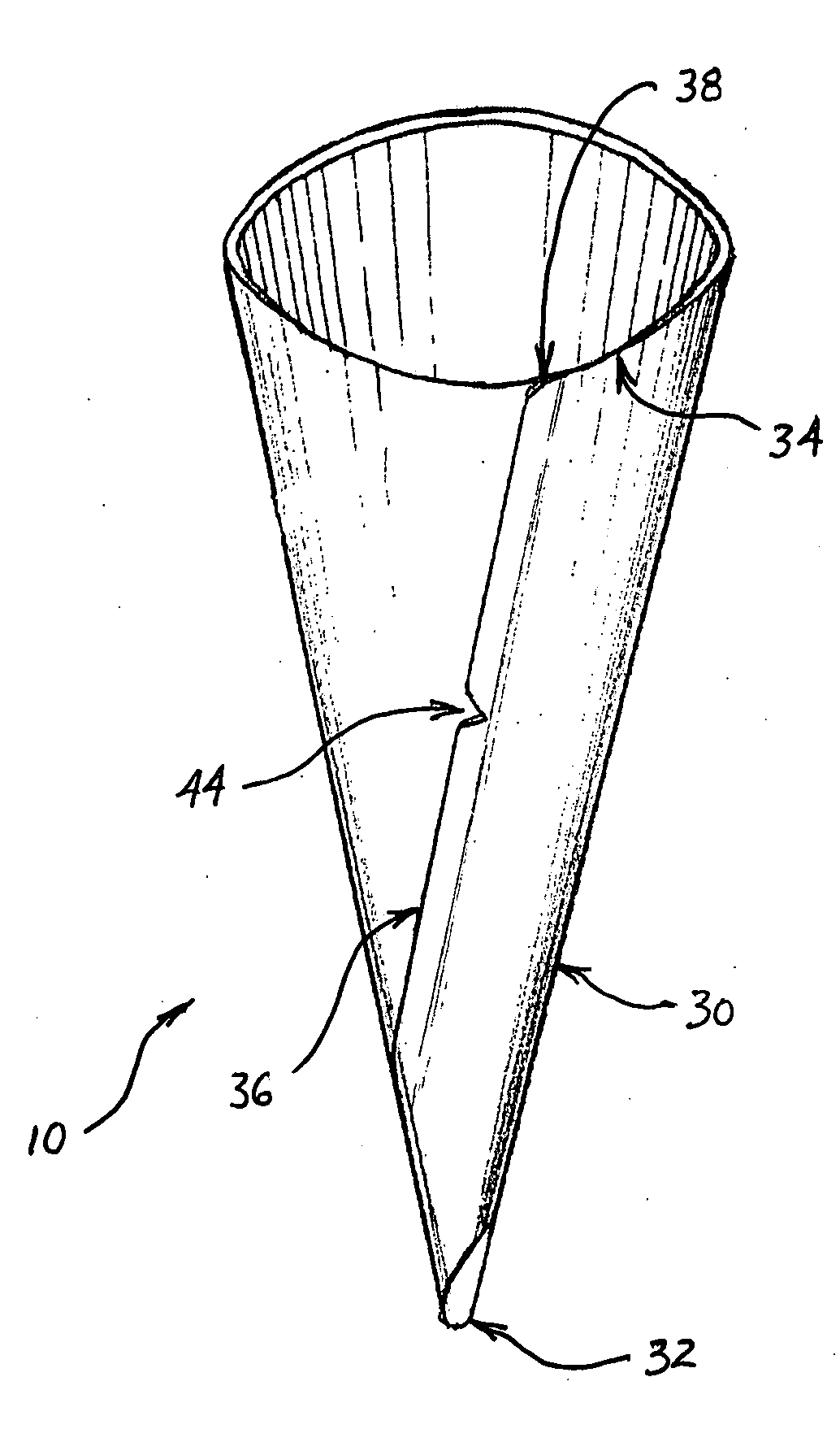

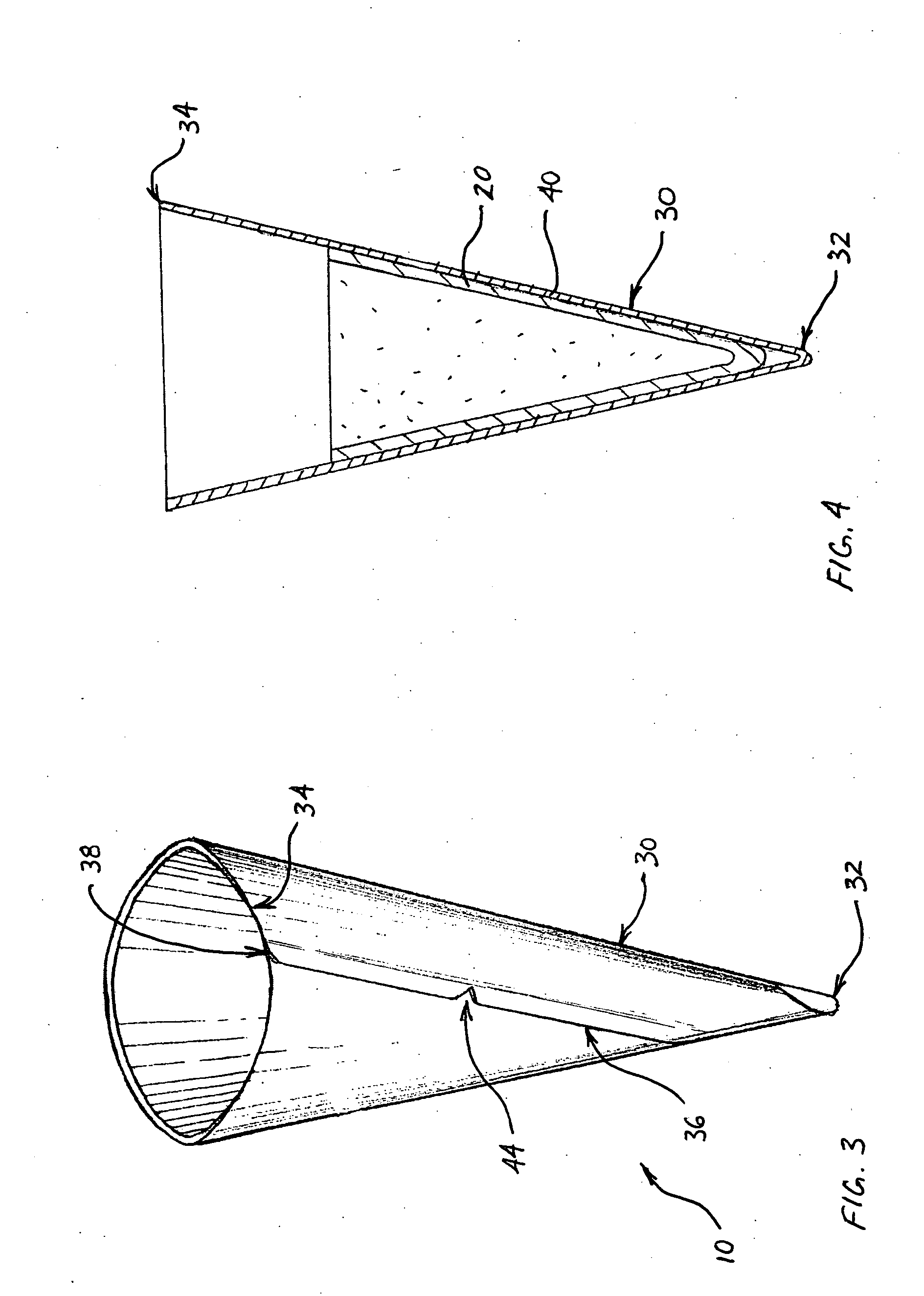

[0021] Referring generally to FIGS. 1-9, it will be appreciated that a package for hand-held frozen ice cream cones 20 (ice cream not shown) having a rolled, cone-shaped polymer film cone sleeve 30 generally may be embodied within numerous configurations.

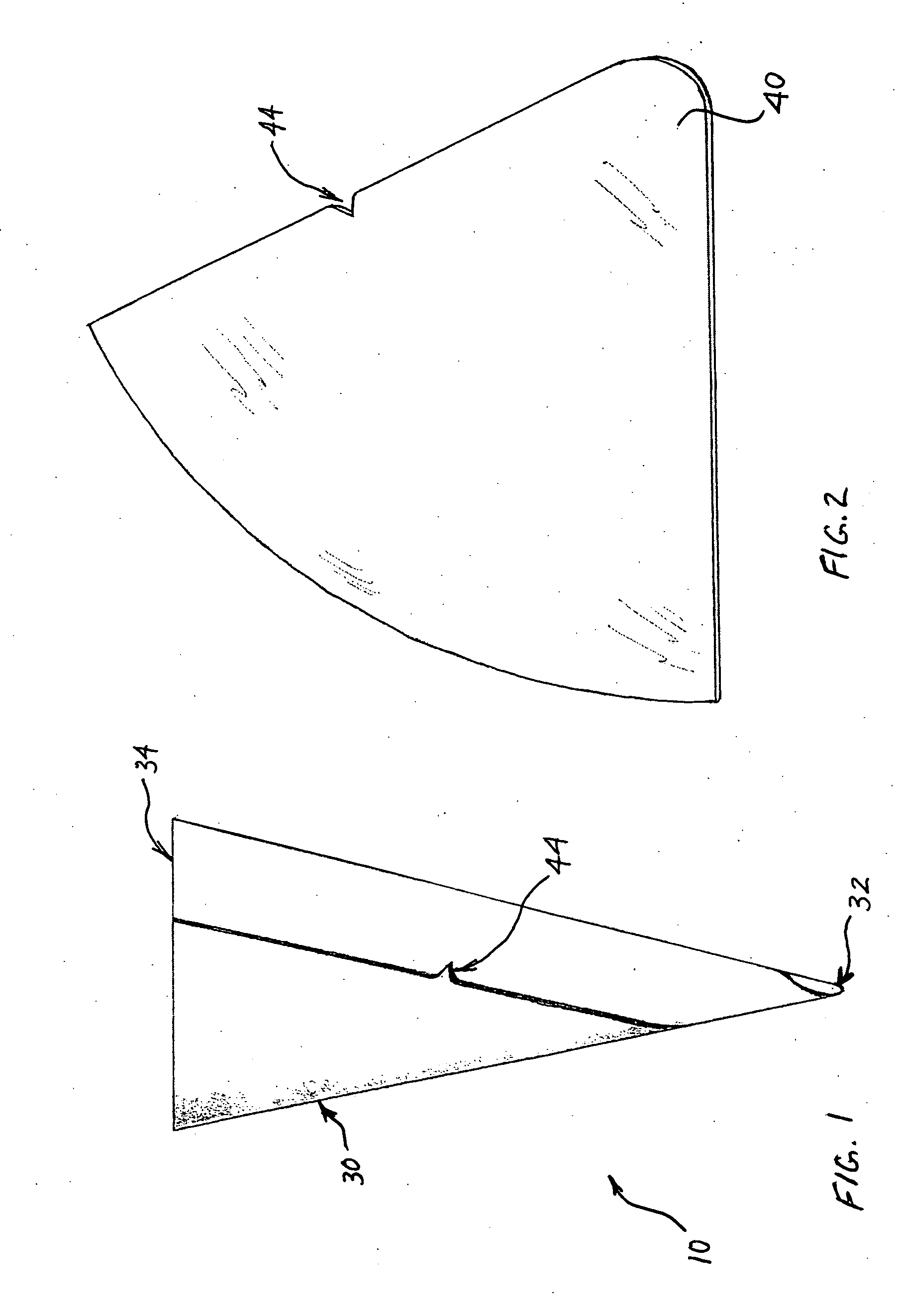

[0022] A package 10 having a polymer film ice cream cone sleeve 30 of the present invention, as shown in FIGS. 1 and 3, may be produced by using current generally accepted methods of spiral winding a substrate portion. In FIG. 2, film layer 40 is shown in a flat pre-rolled format. Once wound around a conical mandrel, film layer 40 becomes a rolled, cone-shaped sleeve 30. The sleeve 30 has a first end with a closed tip 32 and an open second end 34 opposite the first end 32. The stock polymer film product may be fed into a winding machine either in a continuous roll stock form or by means of dispensing pre-die-cut material through a loading magazine. In either format, a film layer 40, such as shown in FIG. 2, is wound around a conica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com