Structure of carbon cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

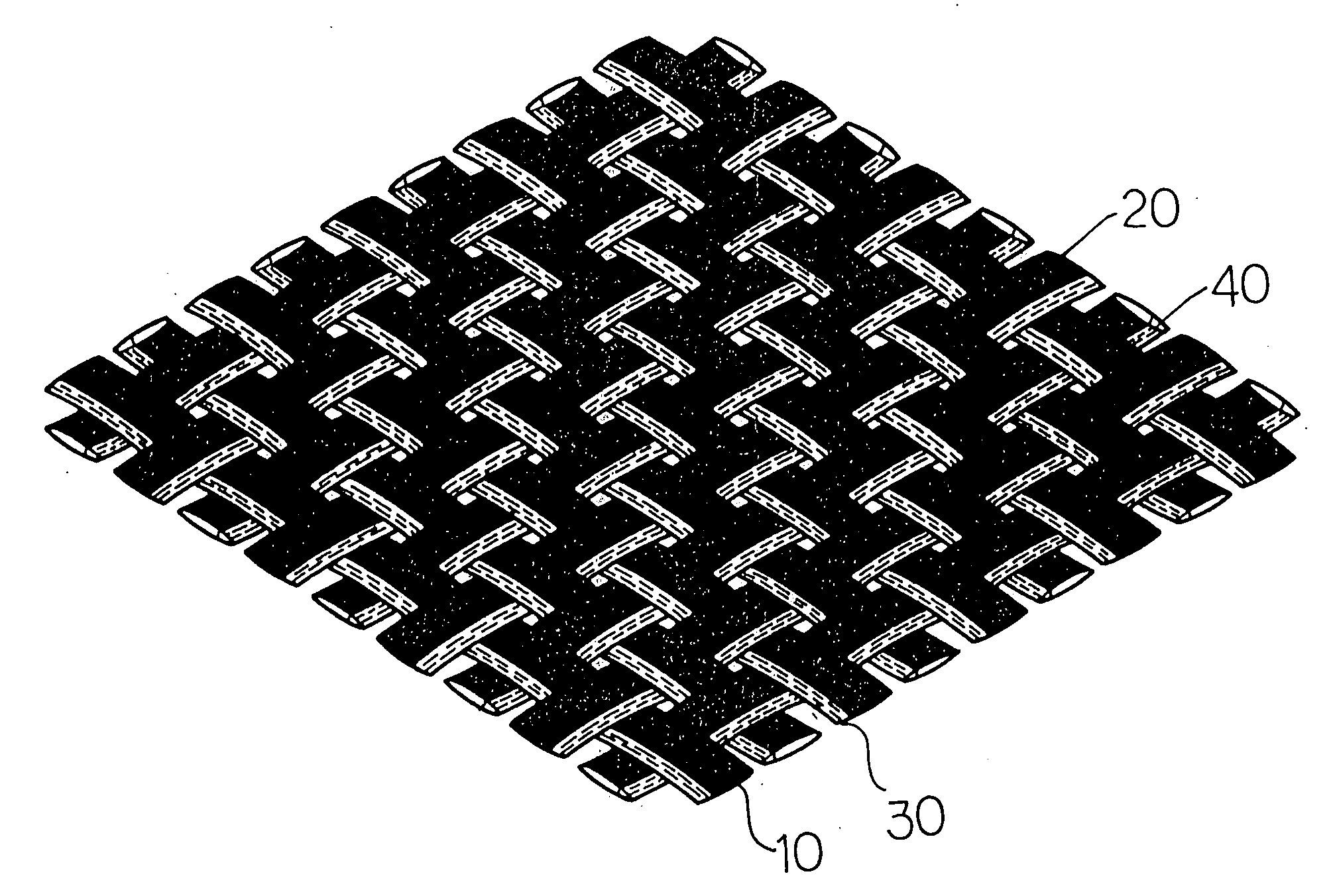

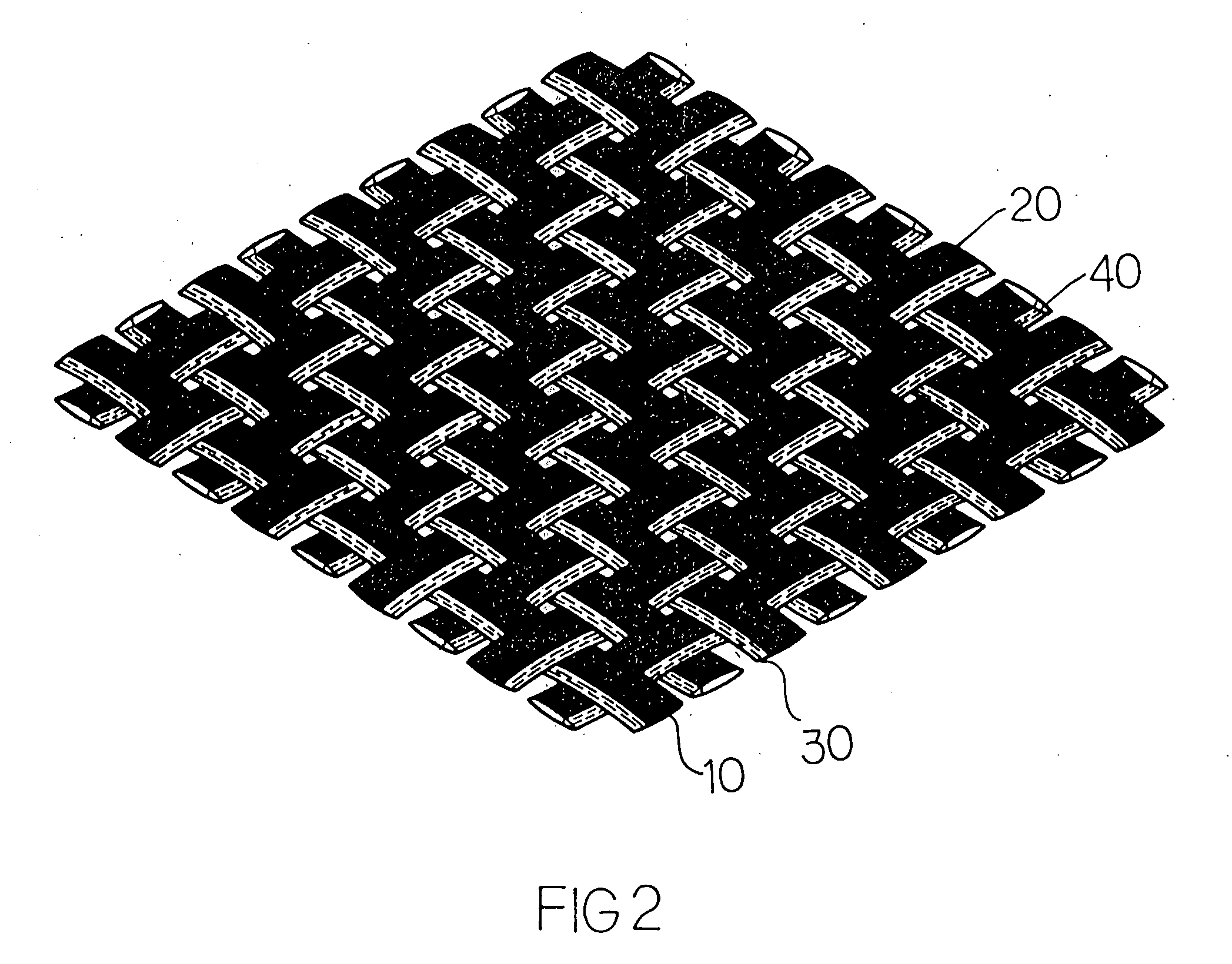

[0009] Firstly, please refer to FIG. 2. As shown in the figure, the present invention provides an improved structure of carbon cloth. That is, when weaving carbon cloth, color plastic thread 30 or metallic yarn 40, or glitter yarn of high retractility is skillfully added in the carbon fiber warp contexture 10 and carbon fiber weft contexture 20, thus making the cloth have a structure of rigidity and elasticity, and have bright colors as well as functions of reflecting, etc. Where, the foresaid plastic thread 30, or metallic yarn 40 or glitter yarn may be arranged nearby the outer side of the rigid carbon fiber warp or weft. Thus the surface of the carbon cloth is mainly made of jet black carbon fiber thread assisted with color plastic thread 30, metallic yarn 40 or glitter yarn of high retractility, better showing the bright colors of the plastic thread 30, metallic yarn 40 or glitter yarn. Since the section diameter of plastic thread is smaller than that of carbon fiber thread, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric dipole moment | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com