Rotary hydraulic cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the following description, similar features in the drawings have been given similar reference numerals.

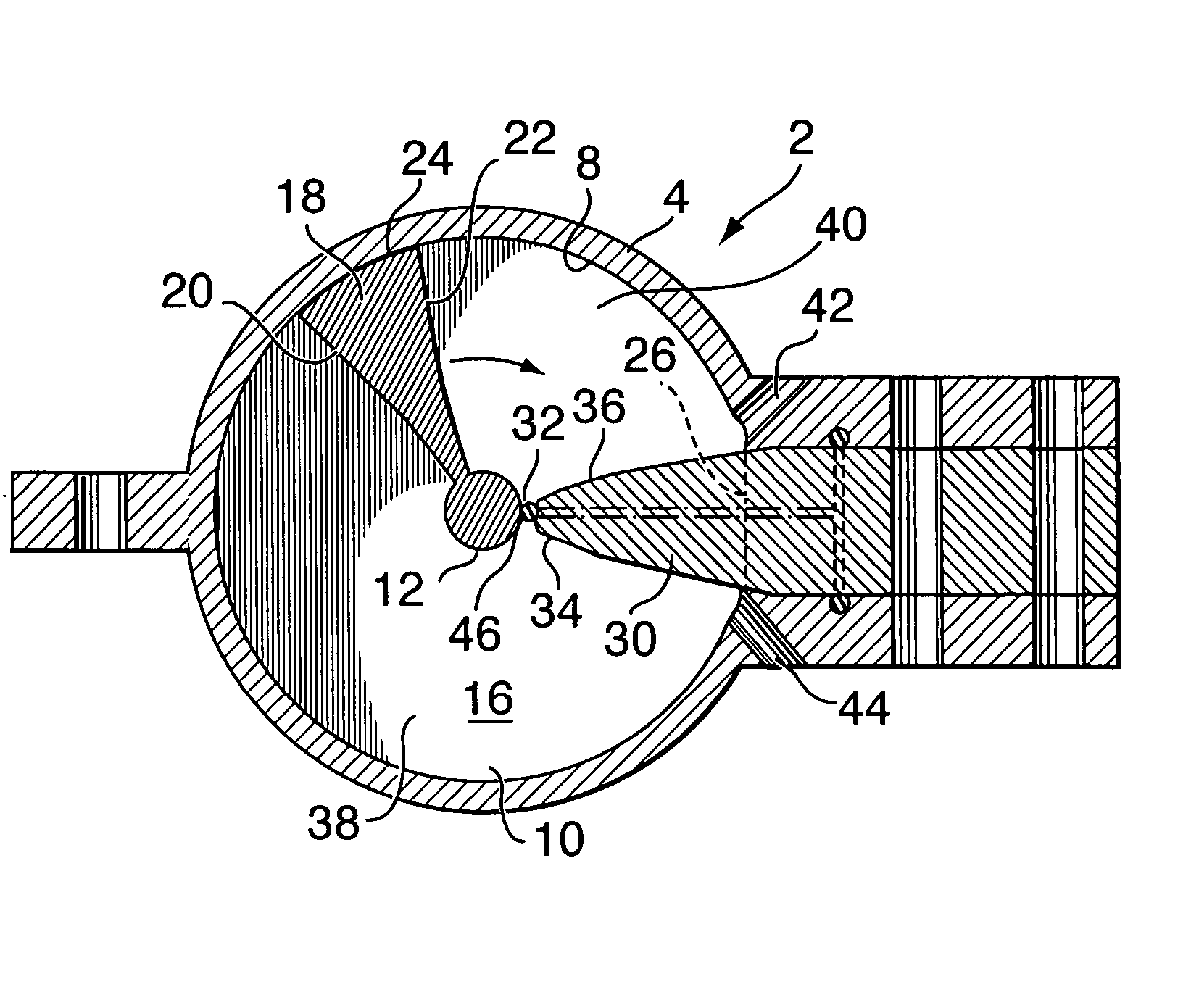

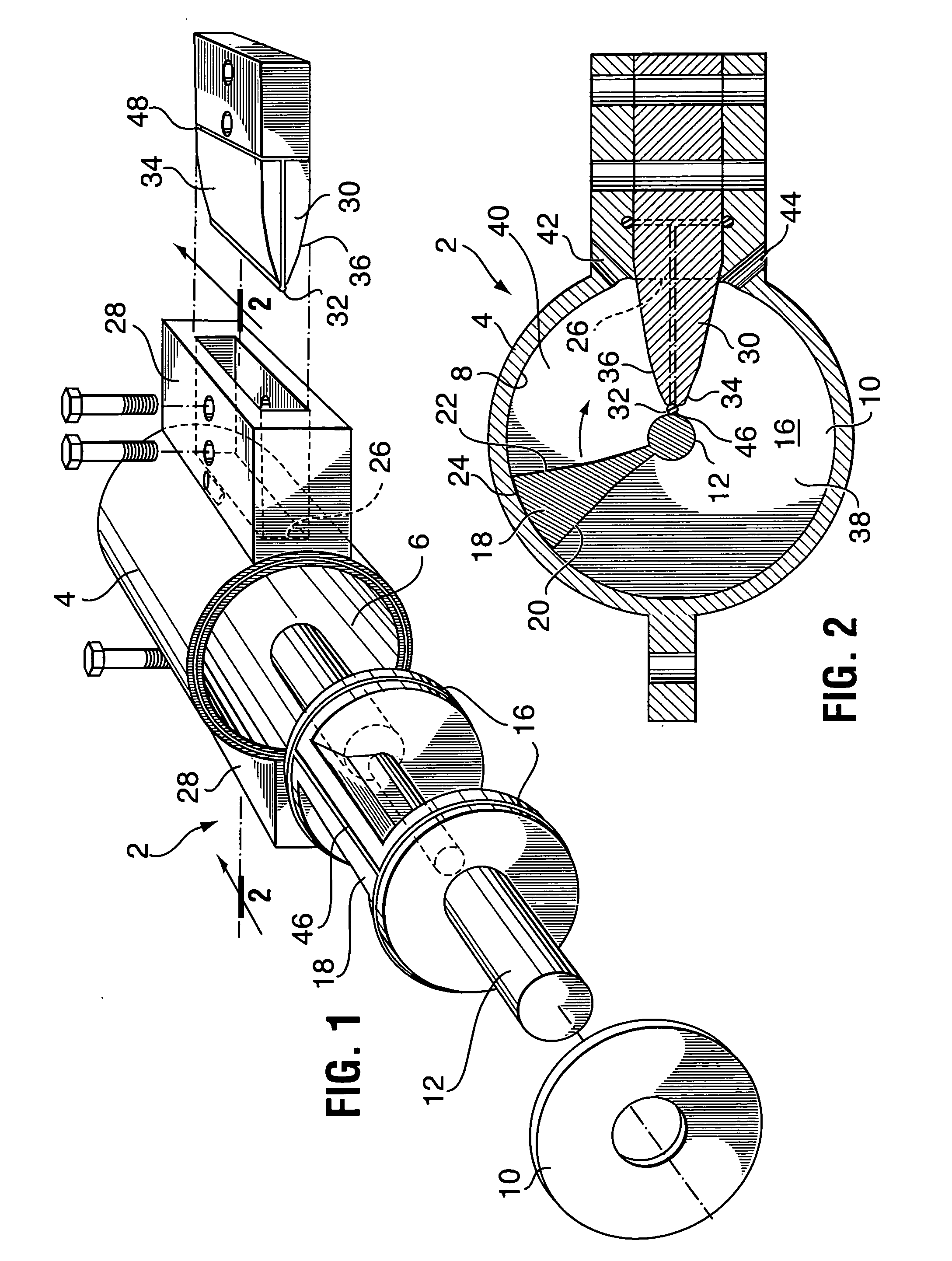

[0015] Turning to FIG. 1, there is illustrated, in exploded fashion, a rotary fluid pressure actuator 2 in accordance with the present invention. Actuator 2 comprises a housing 4 having an inner chamber 6 which has a cylindrical side wall 8 and end walls 10. End walls 10 are normal to the central axis of the cylindrical side wall.

[0016] A shaft 12 is centrally positioned within chamber 6 with respect to side wall 8, for rotation on that central axis. One end of shaft 14 extends beyond the corresponding end wall 10 for connection to, and driving, an appropriate work tool or machine component (not illustrated) beyond housing 4. Shaft 12 is supported within housing 4 by conventional bearings (not illustrated) which hold shaft 12 in alignment. End wall 10 acts as a shield to keep dirt and debris out of chamber 6. Formed as an integral unit with shaft 12 are a pair of spaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com