Pusher apparatus for merchandise

a technology for pushing apparatuses and merchandise, which is applied in the field of pushing apparatuses, can solve the problems of spilt merchandise, the speed of the pushing machine is also a problem, and the known pusher apparatus suffers various problems, so as to avoid the problem of potential injury and spilt merchandis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

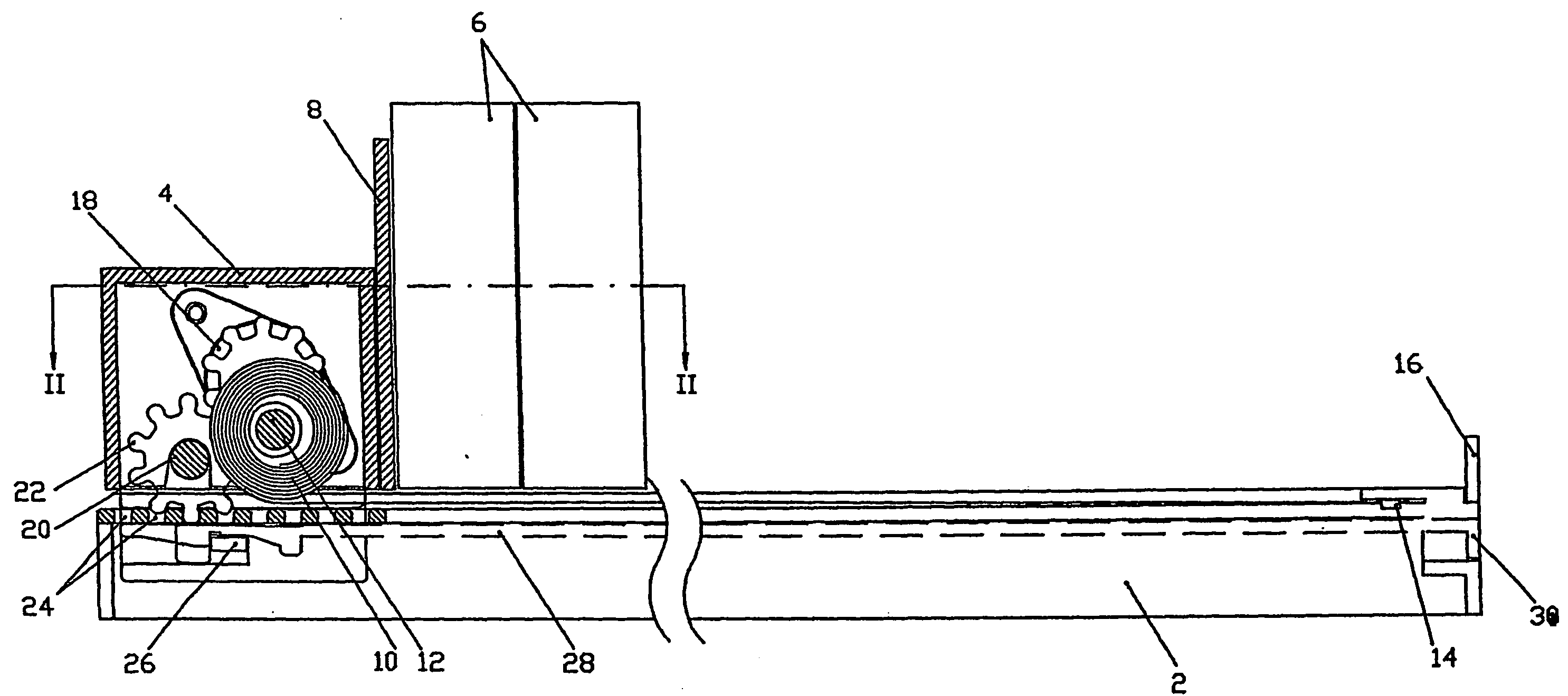

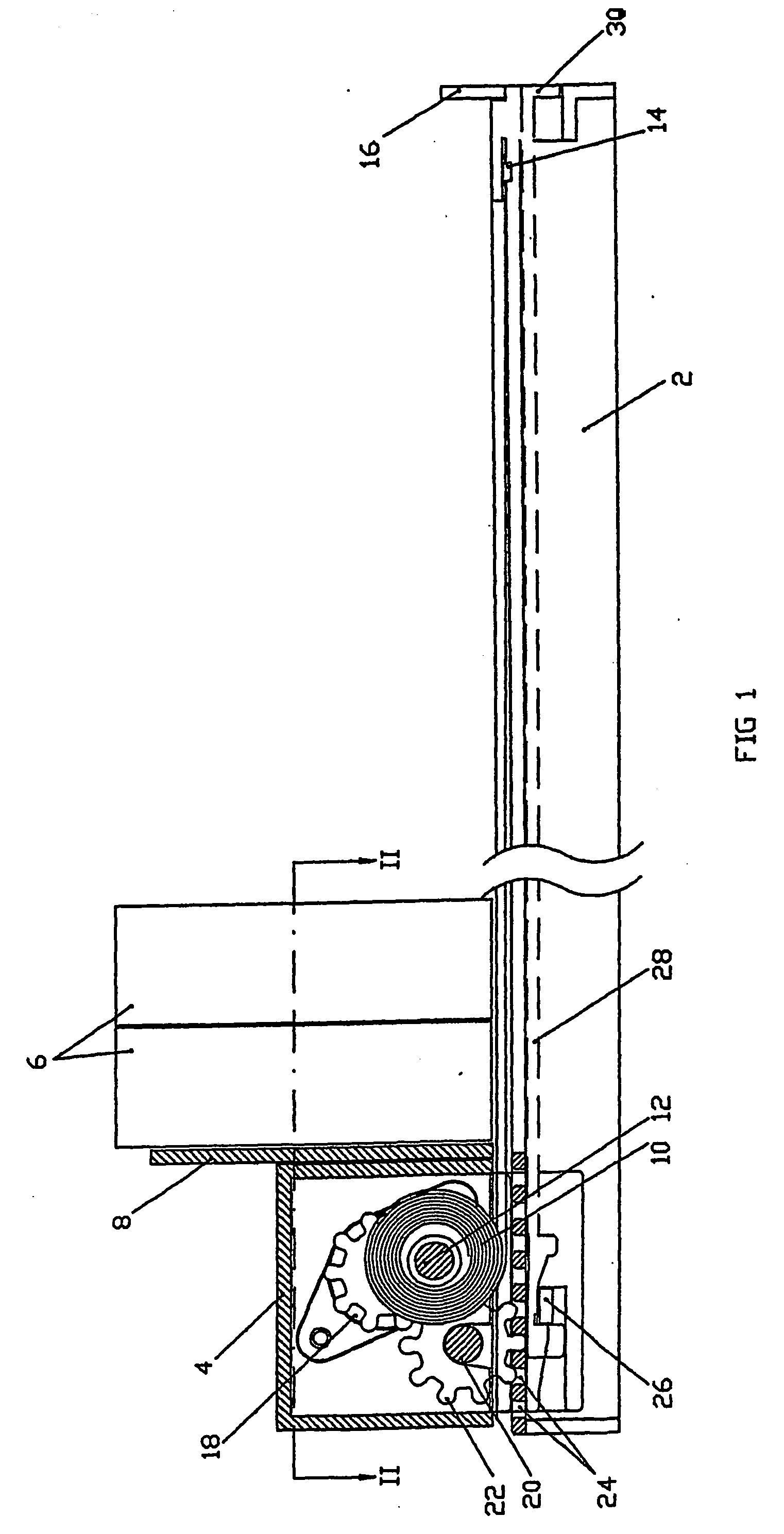

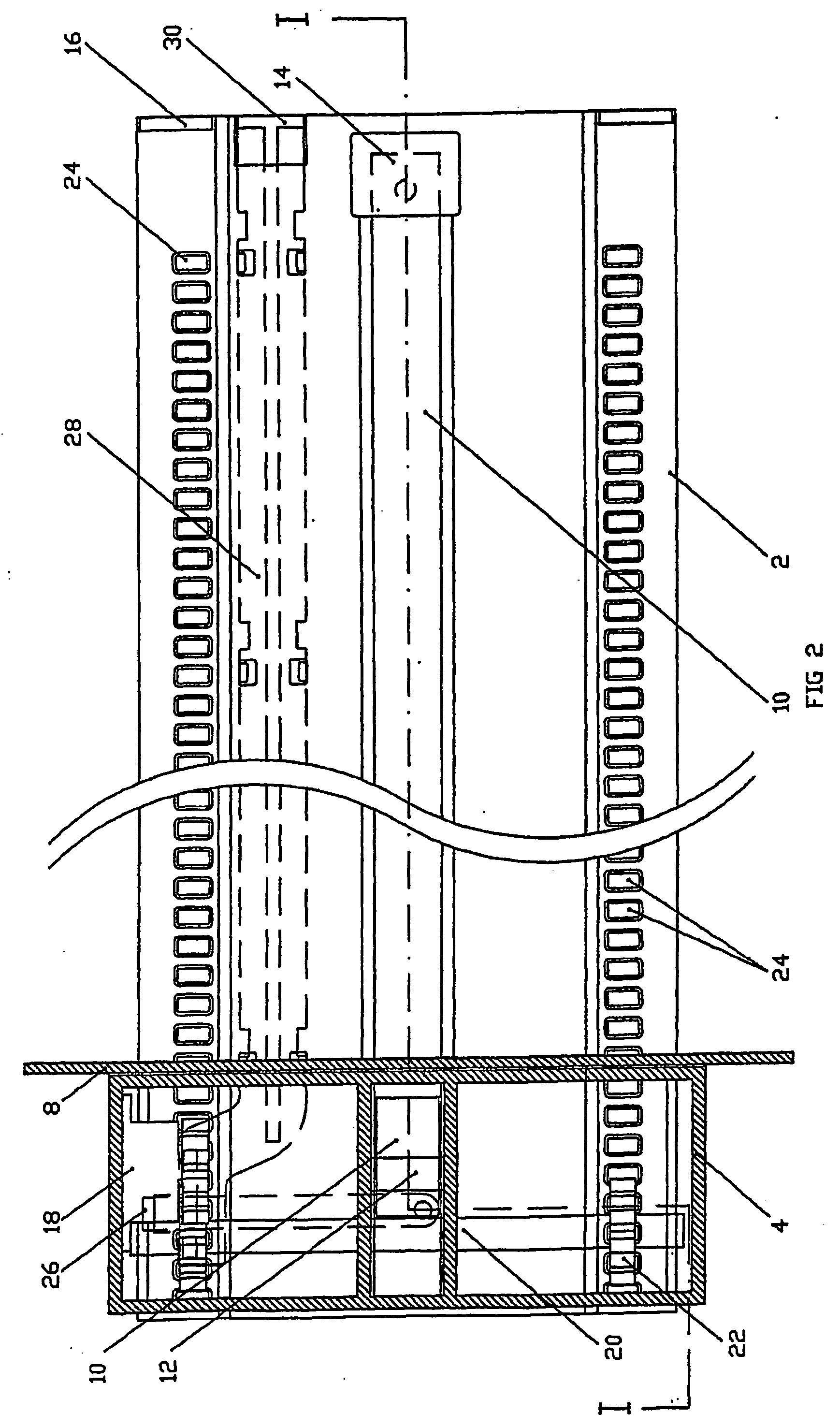

[0022] The pusher apparatus shown in FIGS. 1 to 4 comprises an elongate track 2, which in use rests on or is integral with a shelf (not shown) for displaying merchandise. A pusher unit 4 is mounted on the track 2 so as to be capable of sliding along the track 2. Merchandise 6 for display is stacked along the track 2 and is engaged by a pusher plate 8 of the pusher unit 4.

[0023] A coil spring 10 is coiled about a spring axle 12 that is rotatably mounted in the pusher unit 4, one end of the spring being attached to a ring (not shown) freely rotatable on the spring axle 12. The other end of the spring is attached at 14 to the track 2, near to the front end of the track 2. As the pusher unit 4 is drawn back along the track to the position shown in FIG. 1, the spring 10 uncoils and lies flat along the track 2. The natural tendency of the spring 10 to coil up again draws the pusher unit 4 forwards along the track 2, pushing the items of merchandise 6 on the track ahead of it, until the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com