Refillable grout dispenser with guide

a dispenser and grout technology, applied in the field of dispensers, can solve the problems of compound back up into the tip and blockage of the opening, gap in the sealing compound, waste of repeated disposal of empty tubes,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

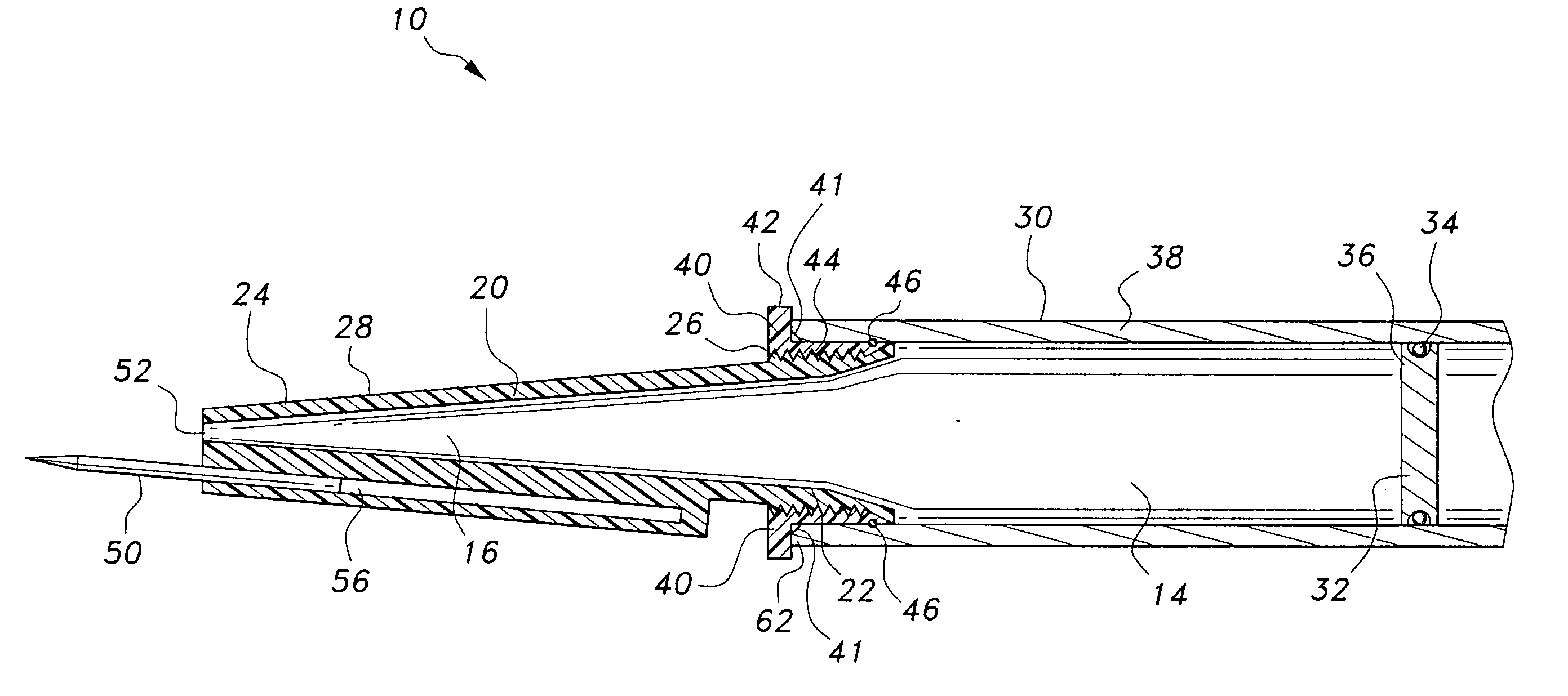

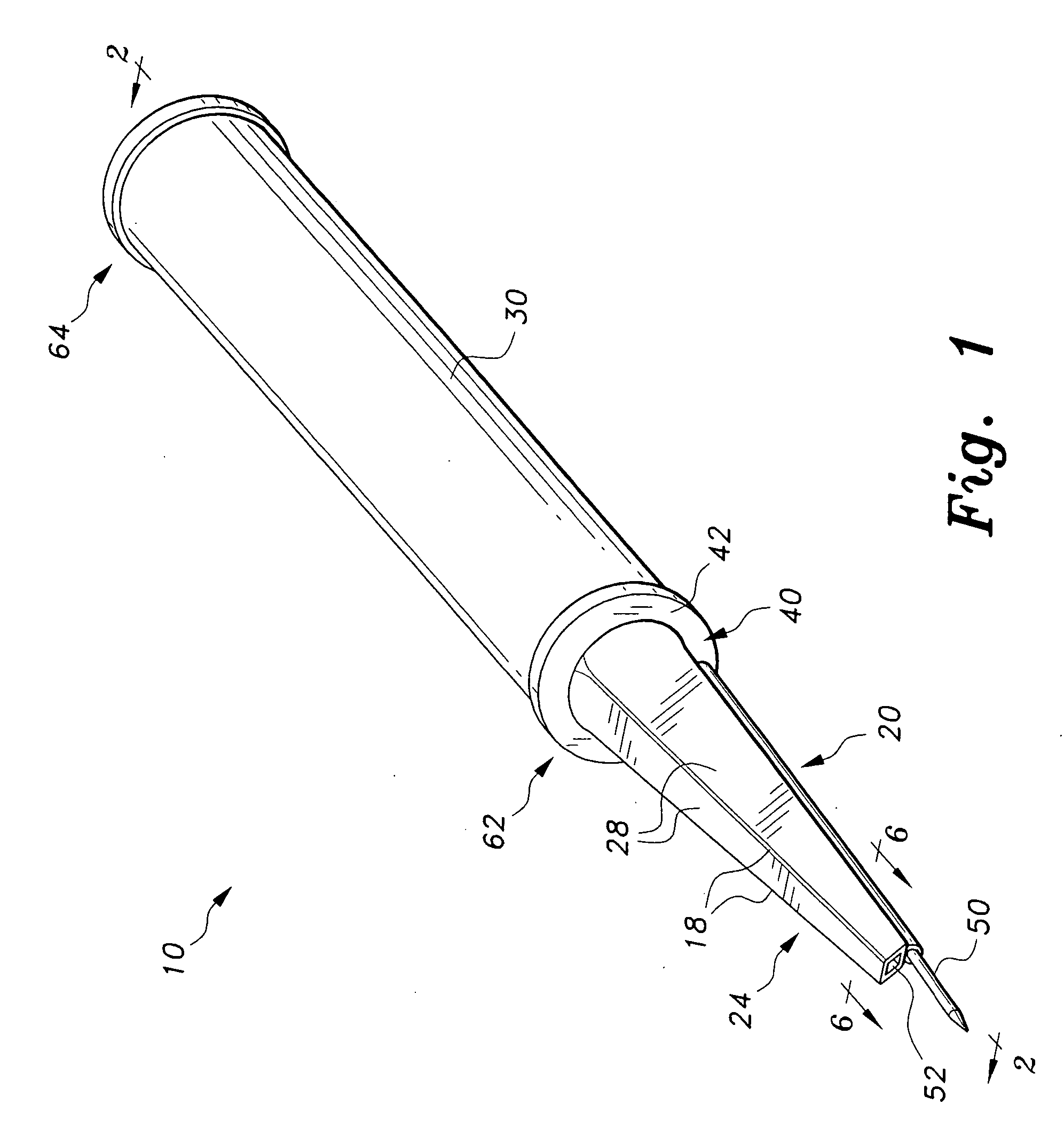

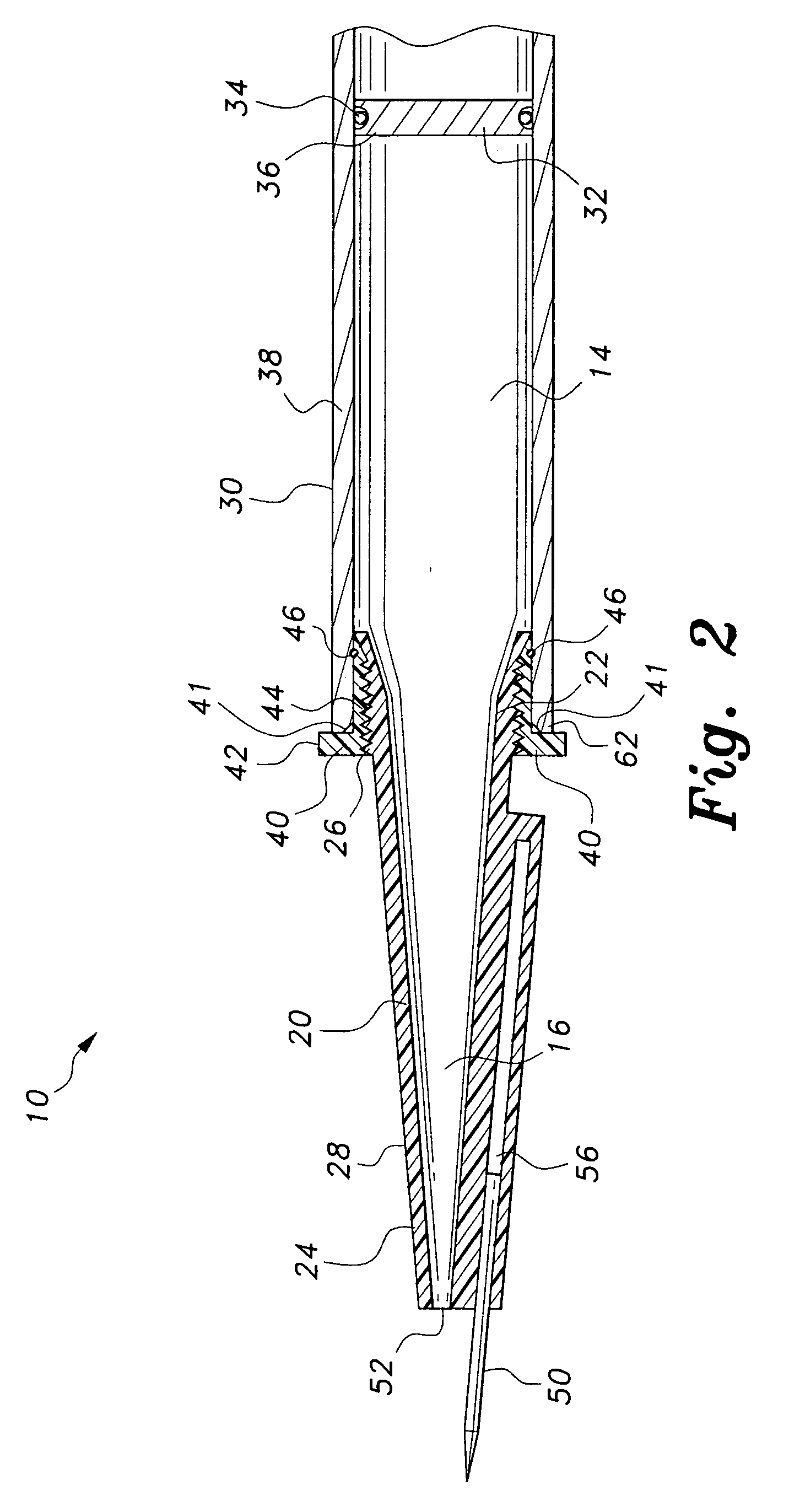

[0025] Referring to FIGS. 1 and 2, in a first embodiment, jam ring 40 slides into the end 62 of the tube 30 and holds the dispensing tip 20 to the tube 30 using a compression fit. To aid in the insertion of jam ring 40 into the end 62 of tube 30, the inside edge 41 of the tube end 62 may be beveled. The jam ring 40 has a flange 42 extending radially from one end of the ring 40. The flange 42 acts as a stop to prevent the jam ring 40 from being pushed completely into the tube 30, holding the jam ring 40 at the end 62 of the tube 30. The jam ring 40 has screw-threading 44 along its inner diameter in order to allow the dispensing tip 20 to be attached to the jam ring 40. The jam ring 40 is expandable, so that when the dispensing tip 20 is screwed into the jam ring 40, the jam ring 40 is pressed outward, forming the compression fit against the inside wall 38 of the tube 30, thereby holding the dispensing tip 20 in the tube 30.

[0026] An O-ring 46 or gasket may be secured around the outer...

second embodiment

[0027] Referring to FIGS. 3 and 4, in a second embodiment, receiving end 43 of dispensing tip 20 includes a locking pin 45 that extends radially outward from the outer side of the receiving end 43. The dispensing tip 20 has a flange 49 extending radially therefrom adjacent to the receiving end 43. The end 62 of tube 30 has an L-shaped slot 47 defined therein, the slot 47 having an axial leg 51 that extends inward from the edge of tube end 62 and a transverse leg 53 substantially perpendicular to the end of axial leg 51. To assemble the refillable grout dispenser of this embodiment, receiving end 43 of dispensing tip 20 is inserted into, and forms a compression fit with, the end 62 of tube 30, with locking pin 45 engaging and sliding down the axial leg 51 of L-shaped slot 47. To aid in the insertion of the receiving end 43 into the end 62 of tube 30, the inside edge 41 of the tube end 62 may be beveled.

[0028] Once the receiving end 43 of dispensing tip 20 is fully inserted into tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com