Trash bucket

a technology of trash buckets and buckets, which is applied in the direction of way cleaning, construction, and gathering refuse, etc., can solve the problems of affecting the operation efficiency, and affecting the operation of the bucket,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

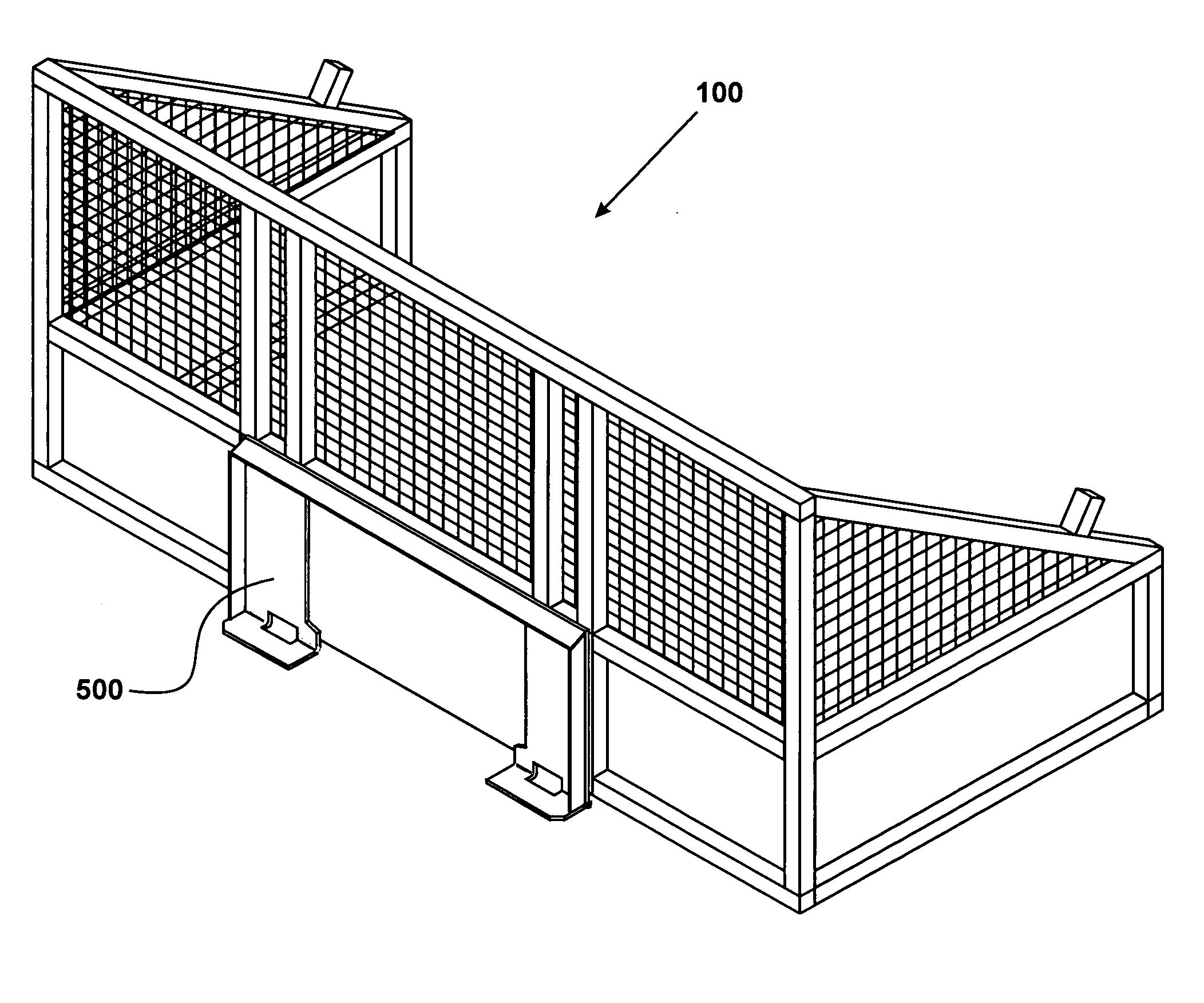

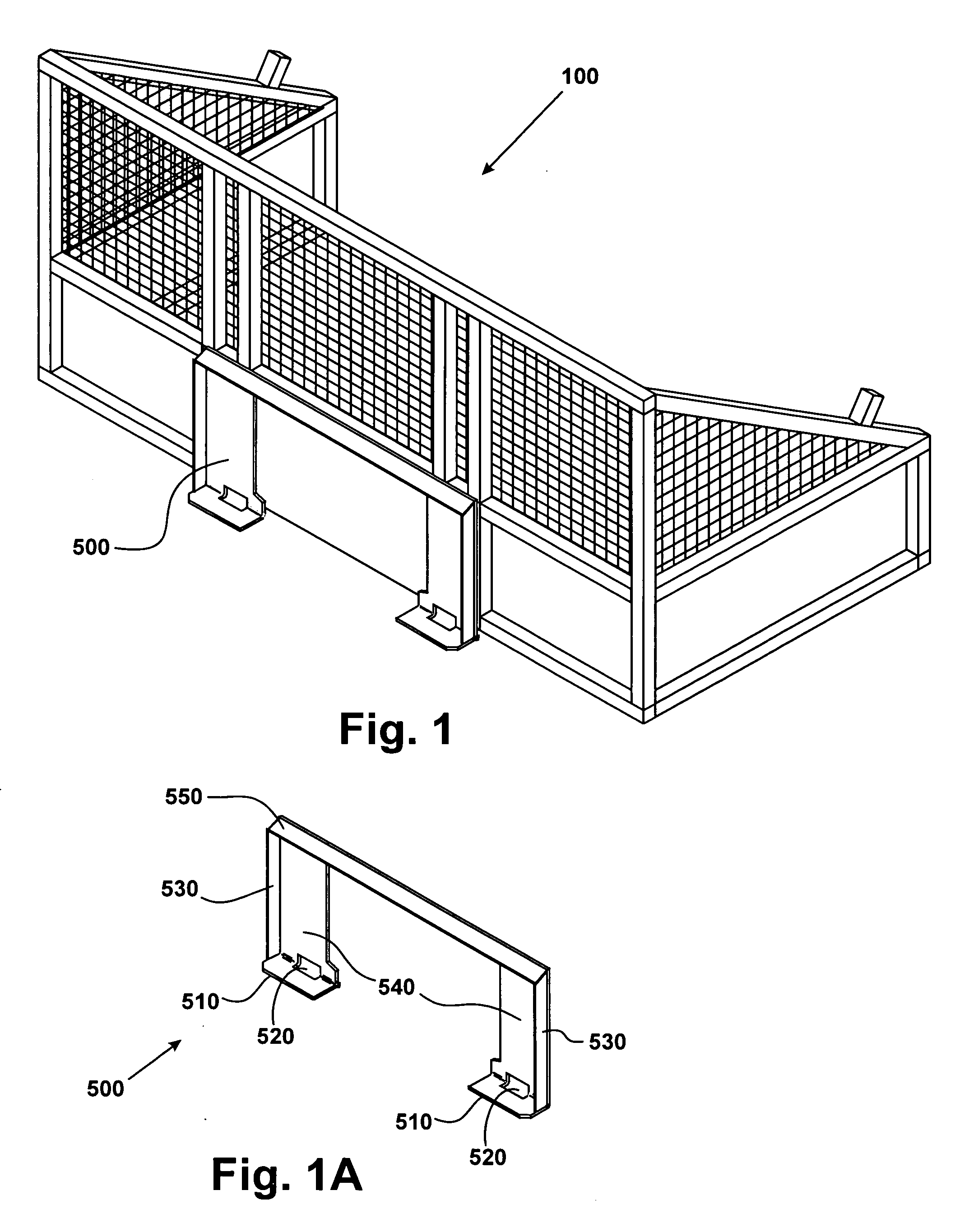

[0015]FIG. 1 shows the present invention, generally at 100, including mounting frame 500. Mounting frame 500 is designed to adapt various pieces of power equipment to be used in conjunction with the present invention. Mounting frame 500 is attached to the present invention by means of welding and / or mechanical fasteners. Other mounting frame assemblies may be adapted to the present invention to allow it to be used with other types of power vehicles.

[0016] Mounting frame, FIG. 1A, comprises body 540, feet, 510, sides 530, and top flange 550. Slots 520 are used to receive part of a power vehicle.

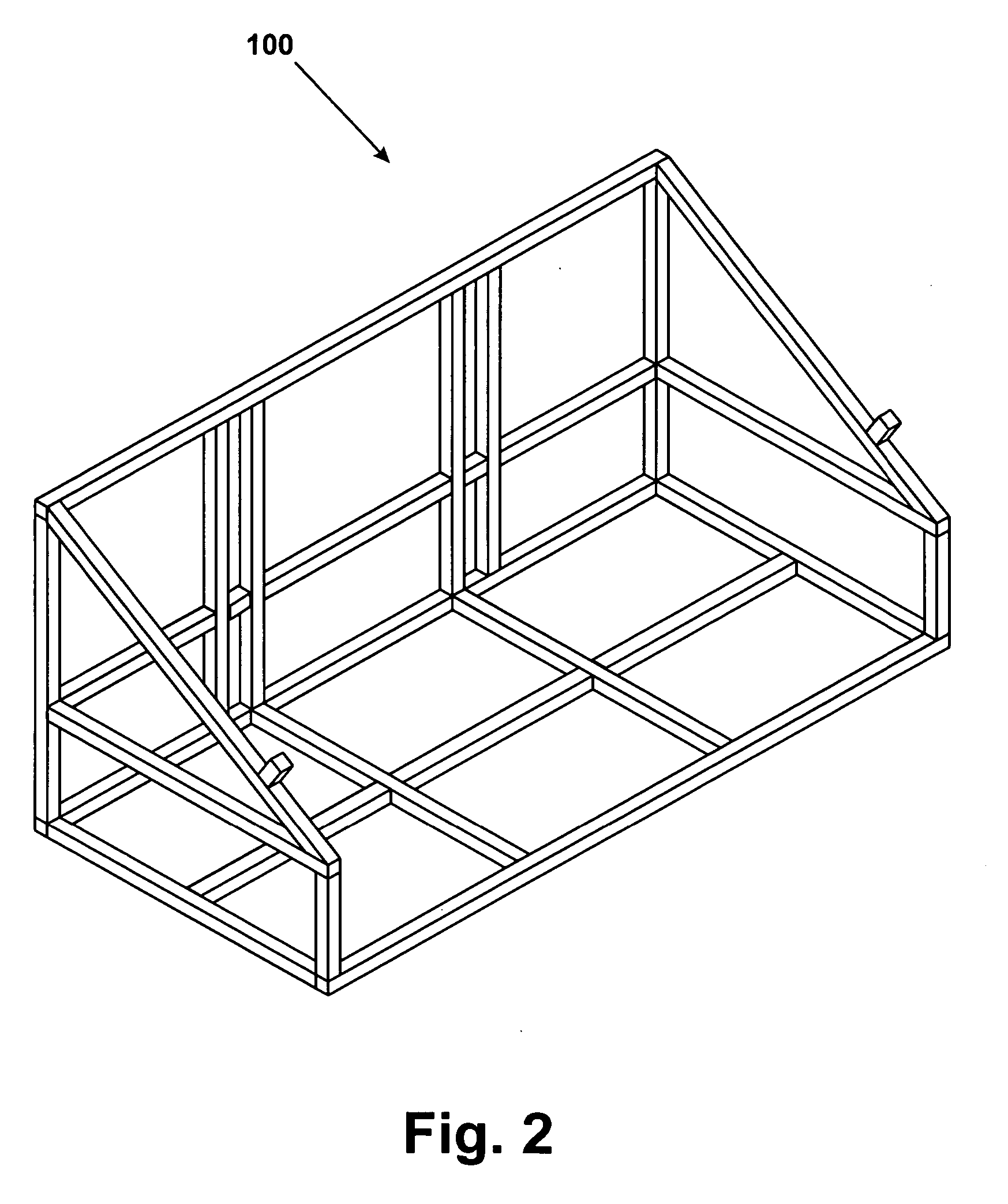

[0017] As shown in FIG. 3, the present invention further comprises one or more of the following subassemblies: rear wall 200, two side walls 300, and bottom 400. The subassemblies are attached to each other by means of welding and / or mechanical fasteners.

[0018] Rear wall 200 comprises rear wall frame top 205, rear wall frame bottom 210, two rear wall frame sides 215, four rear wall frame ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com