Electric vehicle frame with front-middle-rear three-section type structure

An electric vehicle, three-stage technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the complex body structure, inconvenient production and assembly, can not adapt to the small size of miniature low-speed electric vehicles, reasonable structure, easy production and assembly and other problems, to achieve the effect of large activity space, favorable model modification, and shortened assembly line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

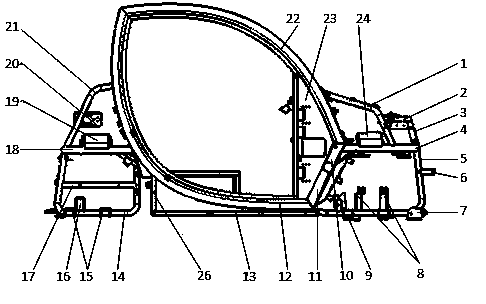

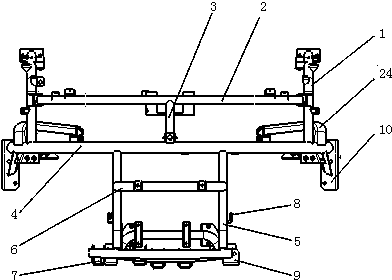

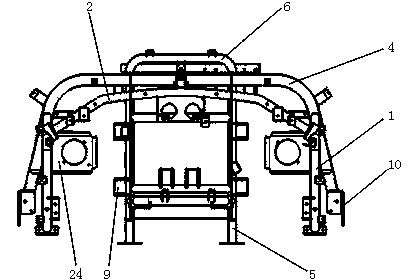

[0024] Such as Figure 1-11As shown, the present invention is a front, middle and rear three-stage structure electric vehicle frame, which includes a front frame, a middle frame and a rear frame, and is characterized in that: the front frame, the middle frame and the rear frame The upper frame is assembled from three parts and adopts a platform structure. The front frame is formed by welding a plurality of round tube beams and sheet metal parts. The first front frame main beam 4 is welded to the second front frame main beam 5. One end of the second front frame main beam 5 Welded with the first front frame main beam 4, the other end of the second front frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com