Desk with novel installation structure

An installation structure and table technology, applied in the field of furniture, can solve the problems of poor stability of installation and molding, increased transportation costs, high packaging carton height, etc., and achieve the effect of fast and convenient installation, simple installation and connection, and low processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

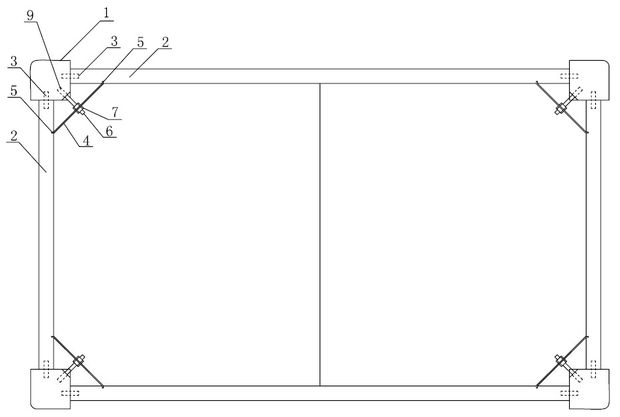

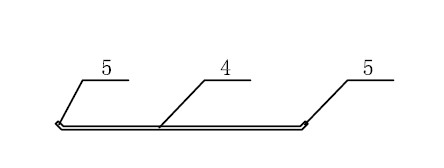

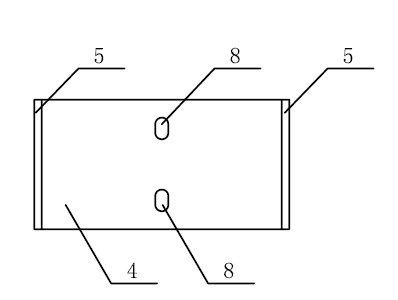

[0034] A table with a new installation structure, including table legs 1, a table frame and a table top, the table frame includes four surrounding panels 2, the four surrounding panels 2 are connected with the four table legs 1 alternately, and at least two ends of the surrounding panels 2 are provided There is a wooden pin 3, and a pin hole corresponding to the wooden pin 3 is arranged on the table leg 1, and the wooden pin 3 is snapped into the pin hole so that the coaming board 2 is connected with the table leg 1 to form a table frame; every two pieces of the table frame There is also a metal connecting piece between the adjacent enclosure plates 2, the metal connecting piece at least includes a connecting surface 4 in the middle and clamping surfaces 5 at both ends, there is a certain degree of bending between the two clamping surfaces 5 and the connecting surface 4, The two clamping surfaces 5 are respectively clamped in the clamping grooves on the two adjacent coamings 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com