Protection profile for a substantially plate-shaped body

a protection profile and substantially plate-shaped technology, applied in the direction of packaging goods, plastic containers, transportation and packaging, etc., can solve the problems of insufficient protection of the peripheral regions of the plate-shaped body, insufficient for many applications, and insufficiently large, etc., to achieve excellent shock absorption and widen the effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

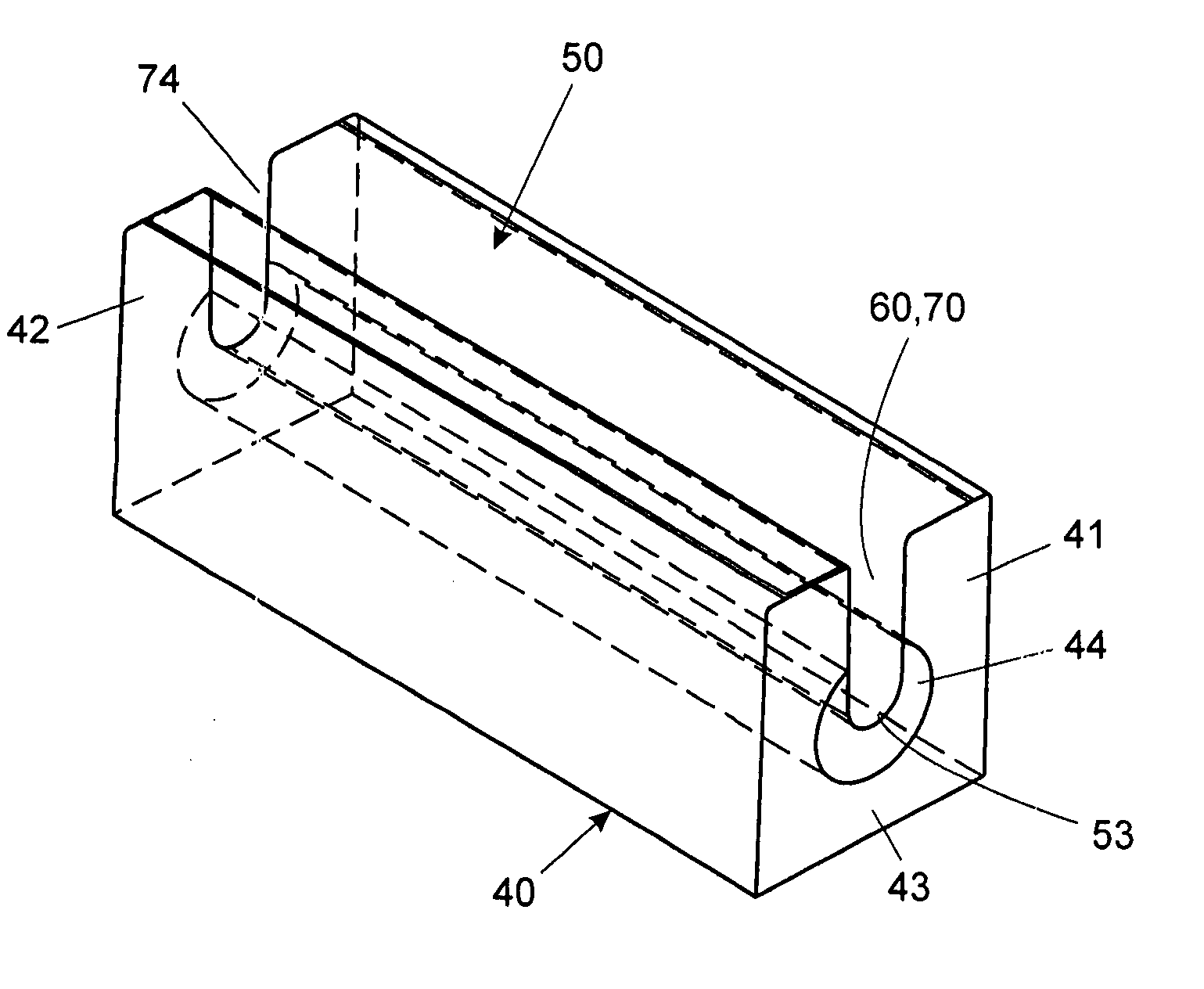

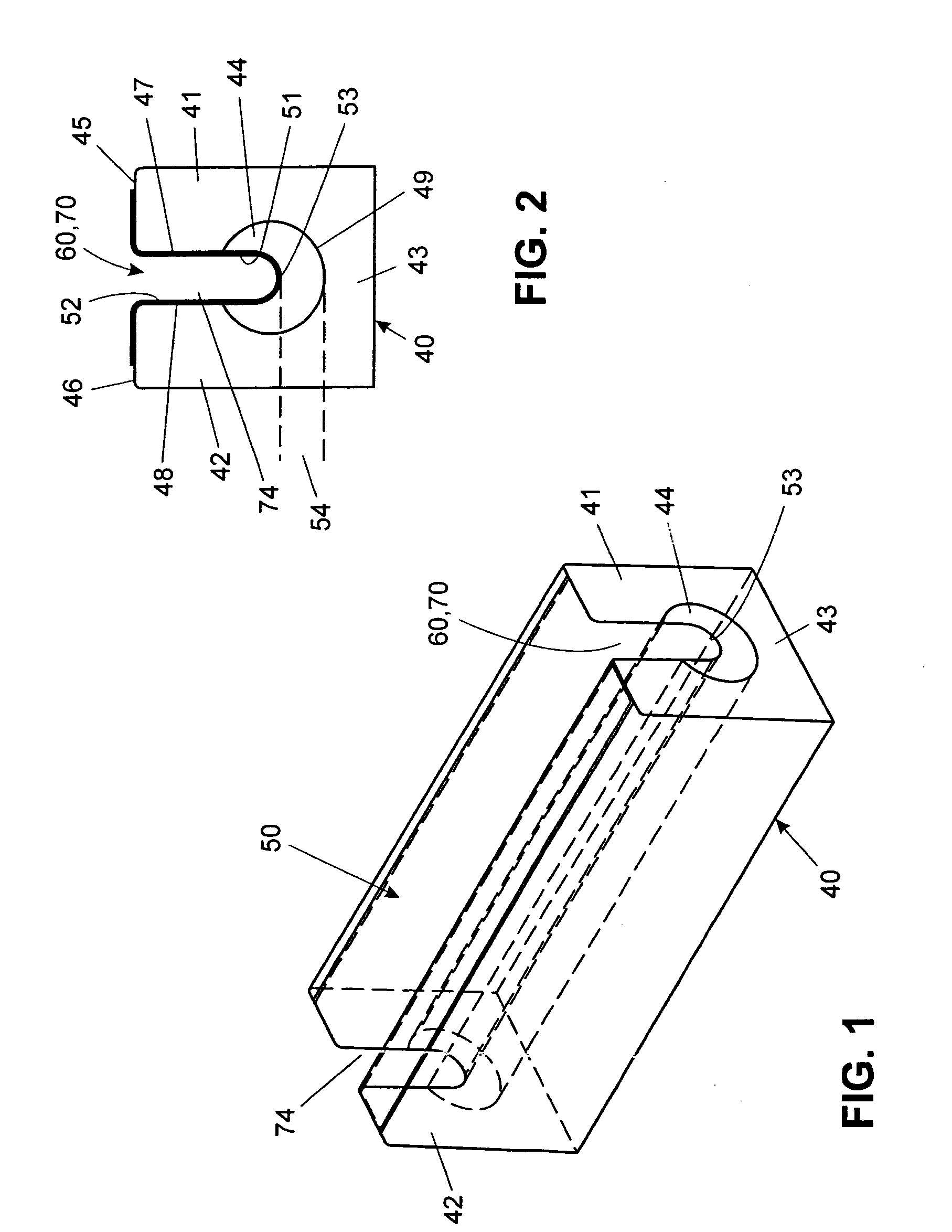

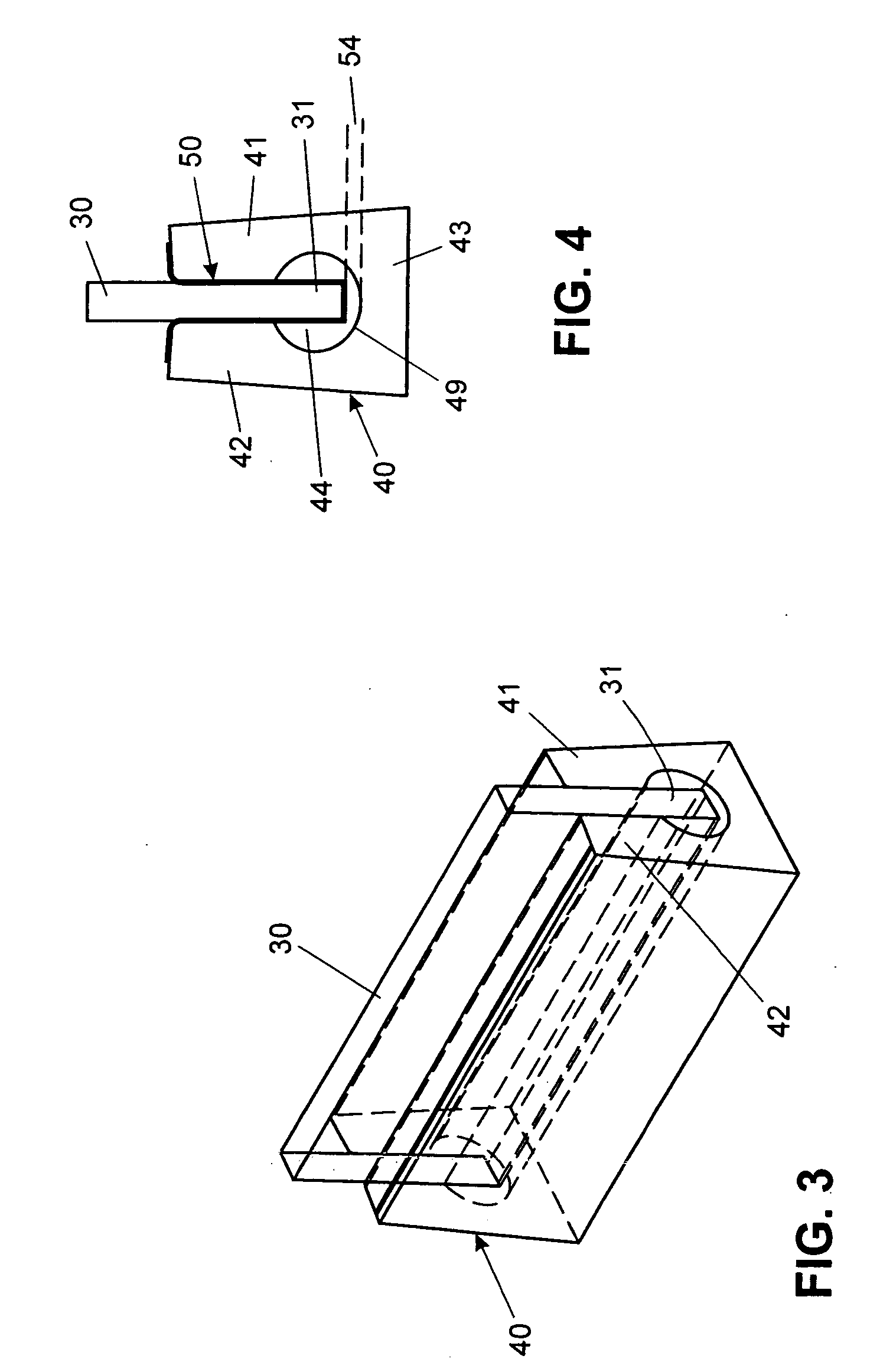

[0042] The protection profile shown in FIGS. 1 to 4 has a U-profile strip 40 made of a thermoplastic foam. The U-profile strip 40 has two flanks 41 and 42 as well as a slat 43, which form one piece. On the side facing the slat 43 each flank 41 and 42 in each case has an exposed front face 45 and 46. The flank 41 has a flank inner face 47, the flank 42 a flank inner face 48. The slat 43 has a slat inner face 49. The flank inner faces 47 and 48 changing into the slat inner face 49 delimit a receiving space 44, which has a strip opening 60 extending in the longitudinal direction of the U-profile strip 40 between the exposed front faces45 and 46 of the flanks 41 and 42.

[0043] A U-shaped foil inlay 50, whose strength, in particular tensile strength, but also cutting resistance, slip resistance and the like is greater than that of the foam or which possesses other properties, is arranged in the receiving space 44 for contact with the plate-shaped body 30. The foil inlay 50 has sidewalls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com