Microdispensing pump

a micro-dispensing pump and pump body technology, applied in the direction of instruments, single-unit apparatuses, movable measuring chambers, etc., can solve the problems of high undesired label removal inadvertently or improperly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

:

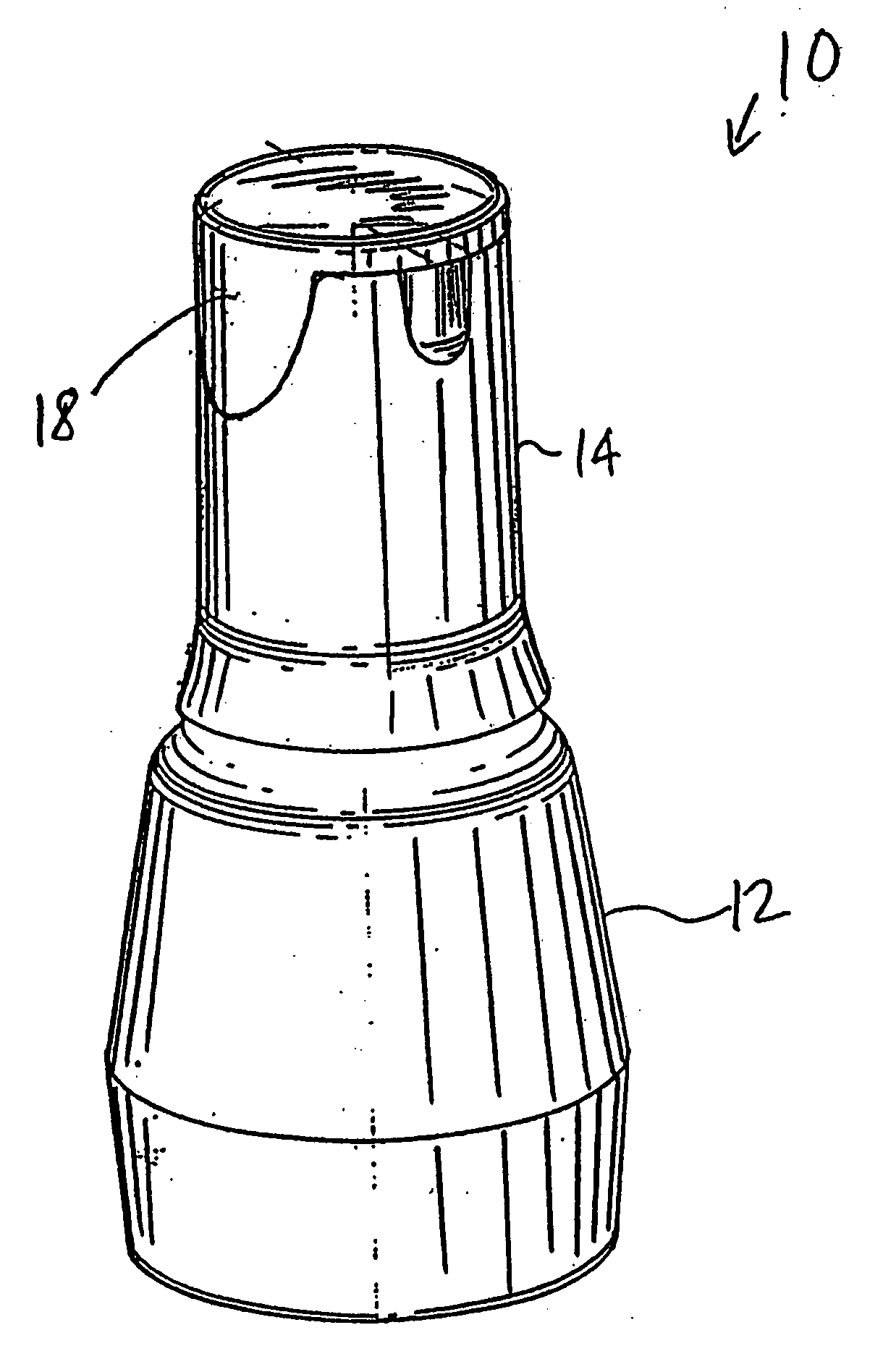

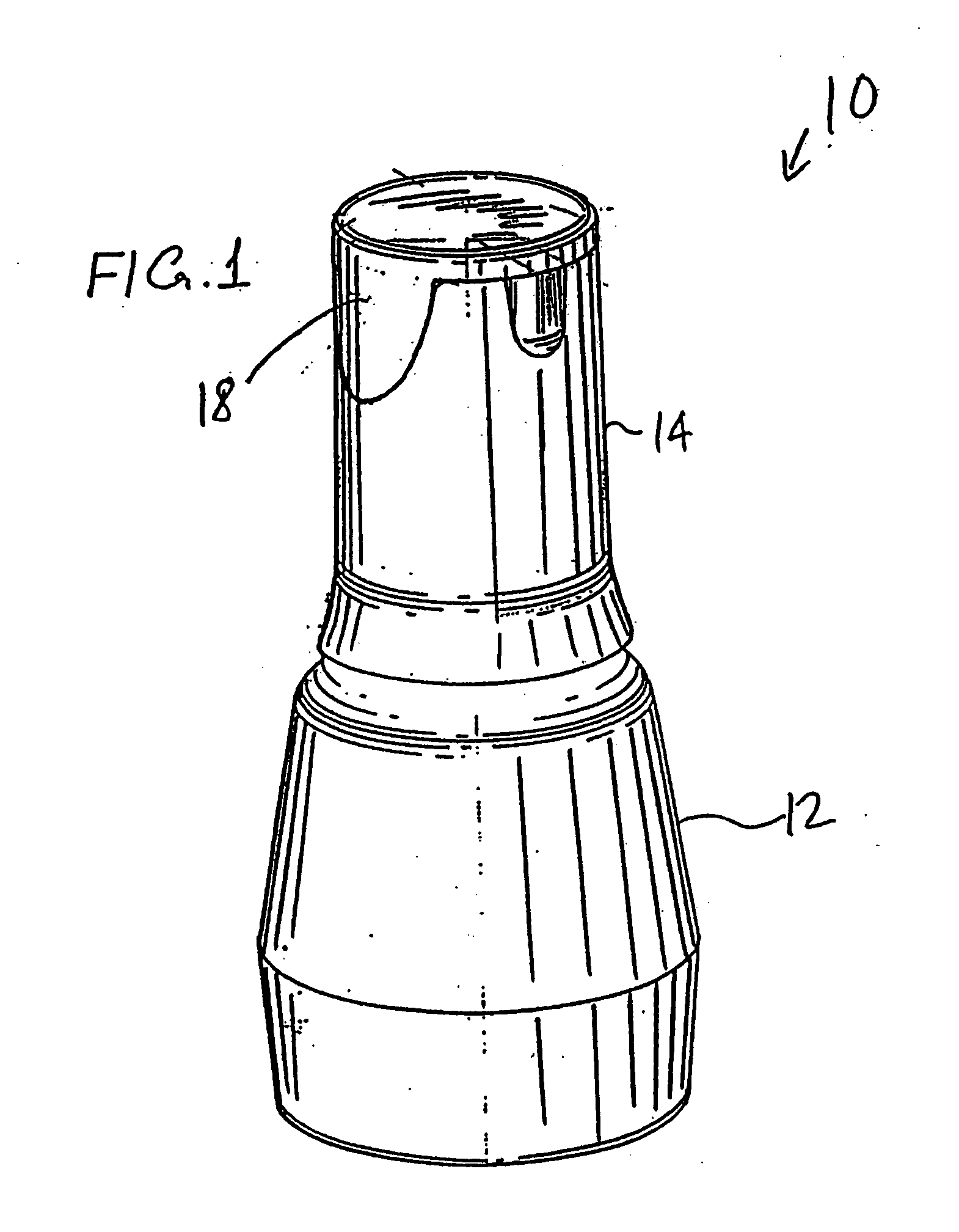

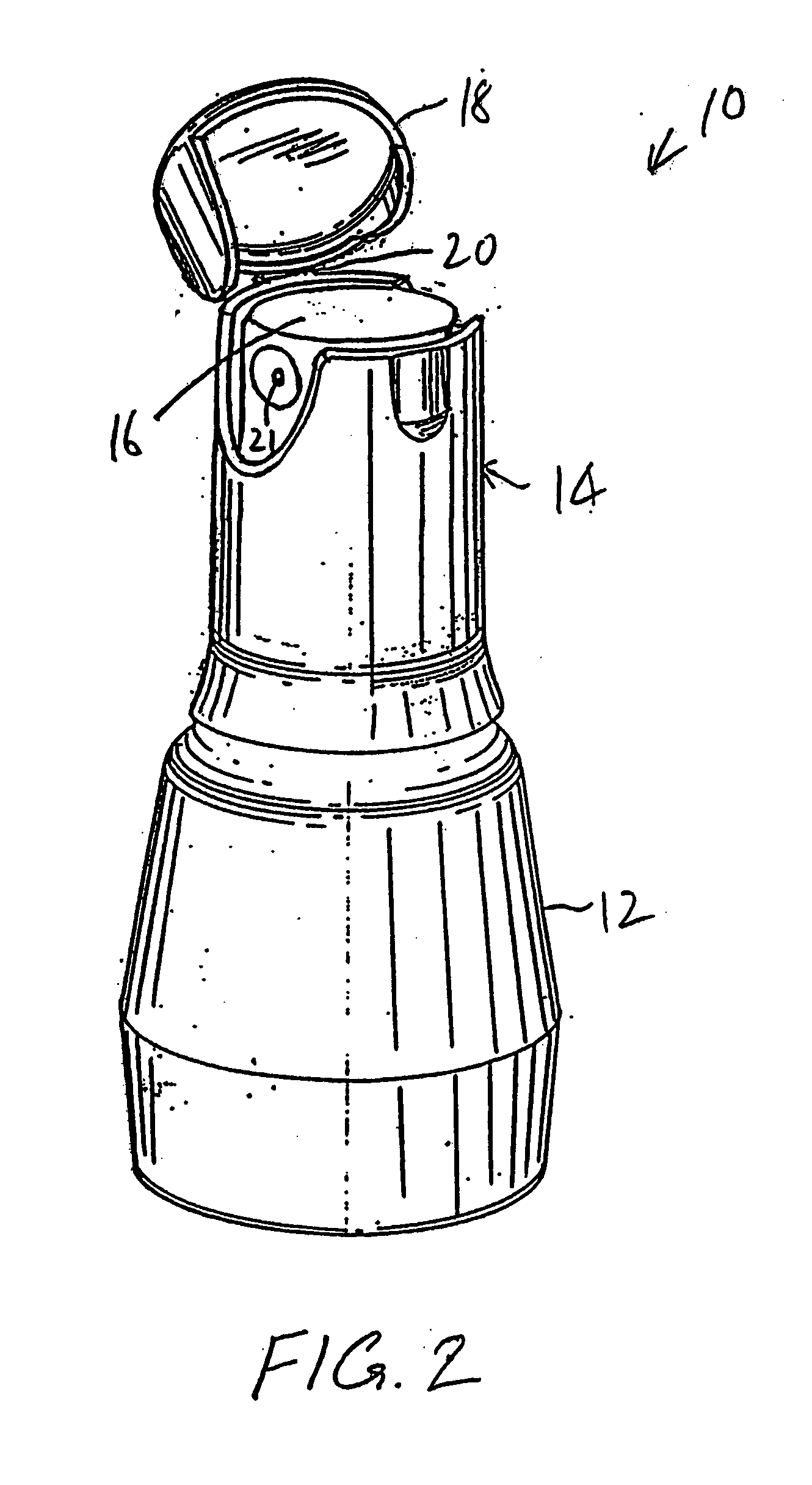

[0018] With reference to FIGS. 1 and 2, a representative pump 10 is depicted, which may include one or more of the aspects of the subject invention. The pump 10 is formed for dispensing fluid, preferably ophthalmic medication. As will be recognized by those skilled in the art, the pump 10 may be formed with any configuration; for illustrative purposes, the pump 10 includes a pump body which may include a handle 12 (which may house a fluid reservoir), a neck portion 14, a dispensing cap 16 disposed within the neck portion 14, and a flip cap 18 hingedly mounted to the neck portion 14 via a hinge 20. A nozzle 21 is formed in the dispensing cap 16 to dispense the fluid upon actuation of the pump; the actuation preferably being achieved by depressing the dispensing cap 16 and causing downward travel thereof. The pump 10 is preferably of a lift-pump type formed in accordance with the teachings set forth in U.S. Pat. No. 5,881,956 and U.S. patent application Ser. No. 10 / 123,390, but may a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com