Fastener, roofing system and method

a technology of fasteners and roofing systems, applied in the direction of threaded fasteners, screwdrivers, mechanical equipment, etc., can solve the problems of membrane to wrinkle or pinch around the plate, membrane to wrinkle or pinch around the fastener, and the fastener is inclined to strip out of the roof deck, so as to improve the resistance to wind uplift forces and reduce labor. , the effect of improving the durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should, of course, be understood that the description and drawings herein are merely illustrative and that various modifications and changes can be made in the structures disclosed without departing from the spirit of the invention. Like numerals refer to like parts throughout the several views.

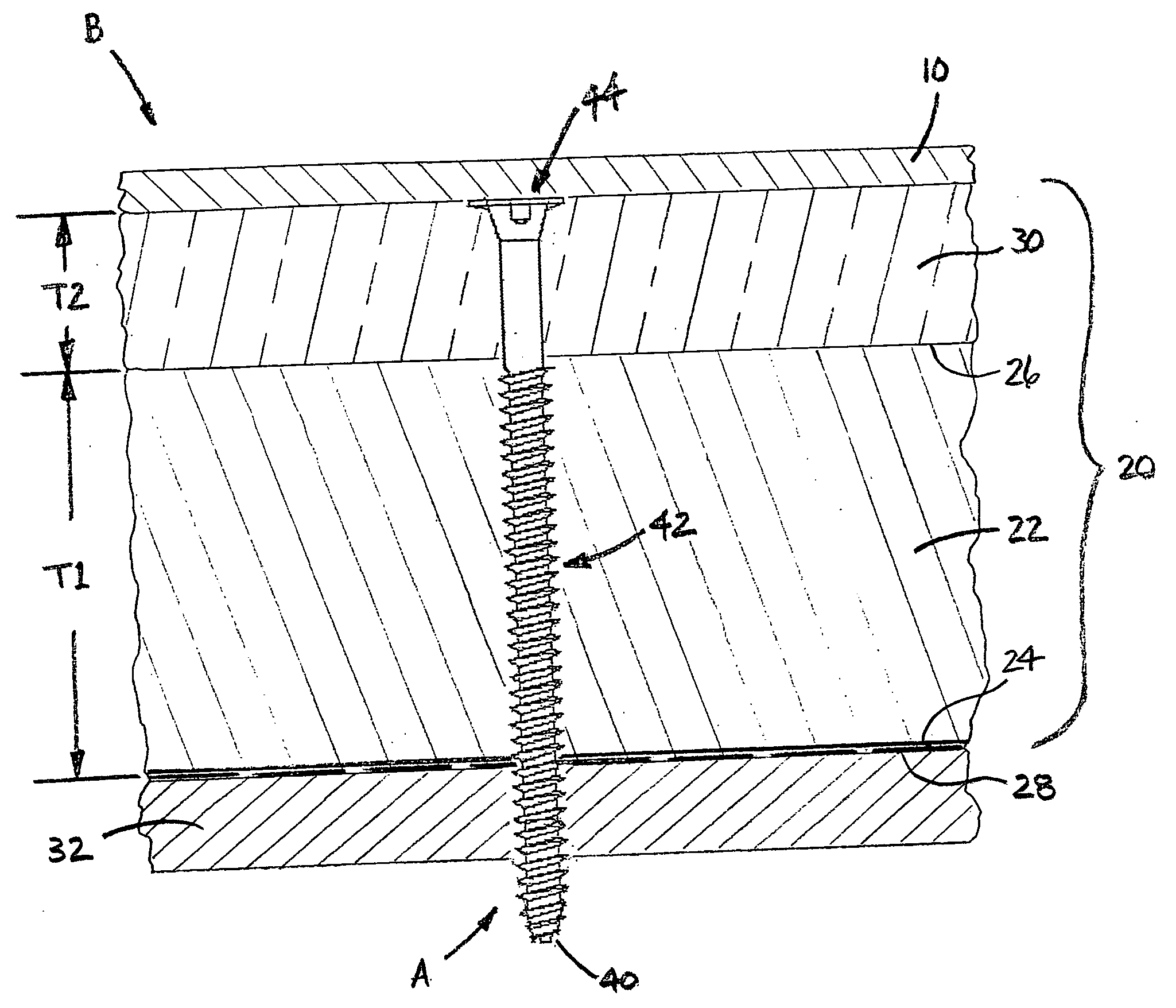

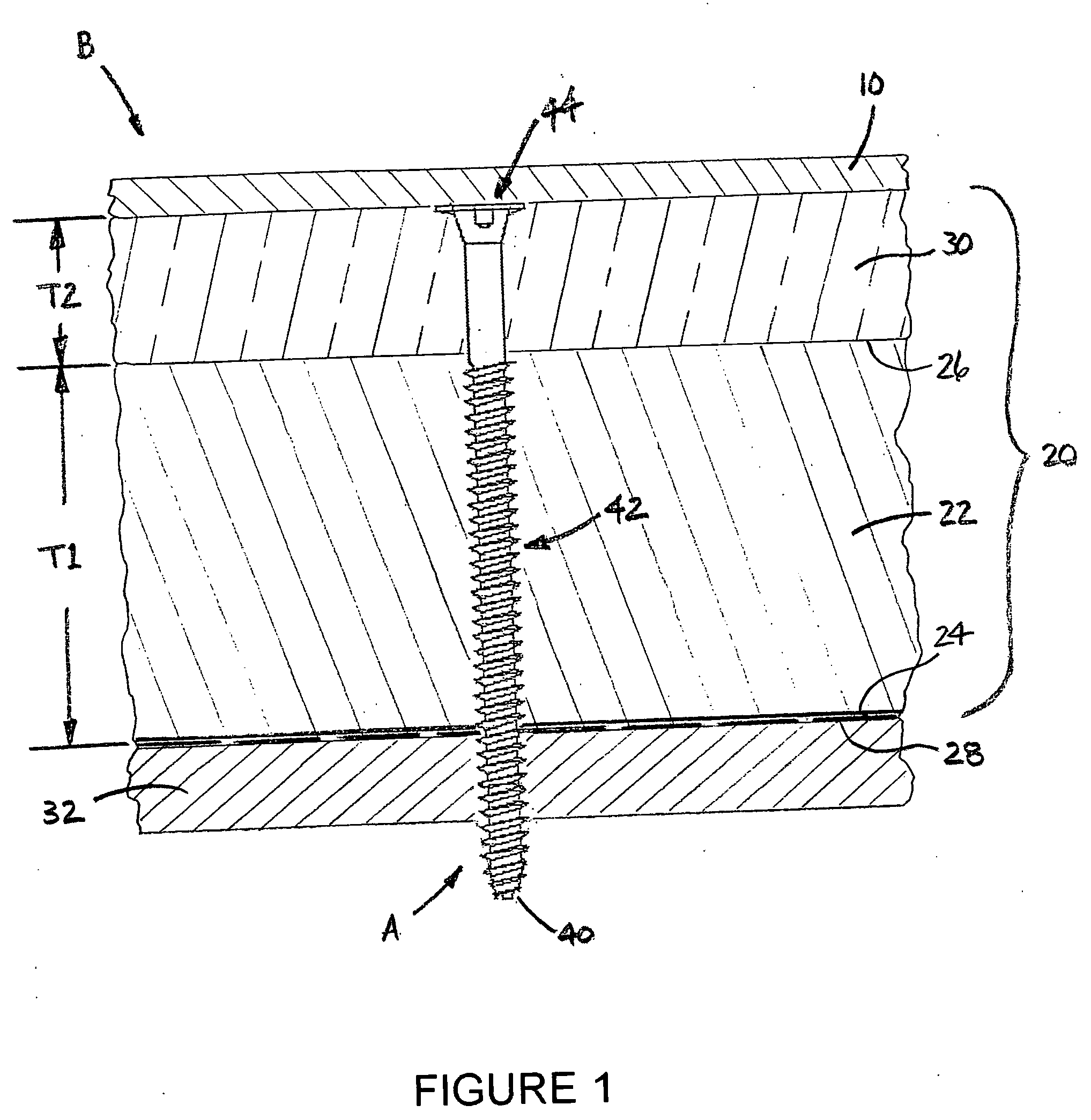

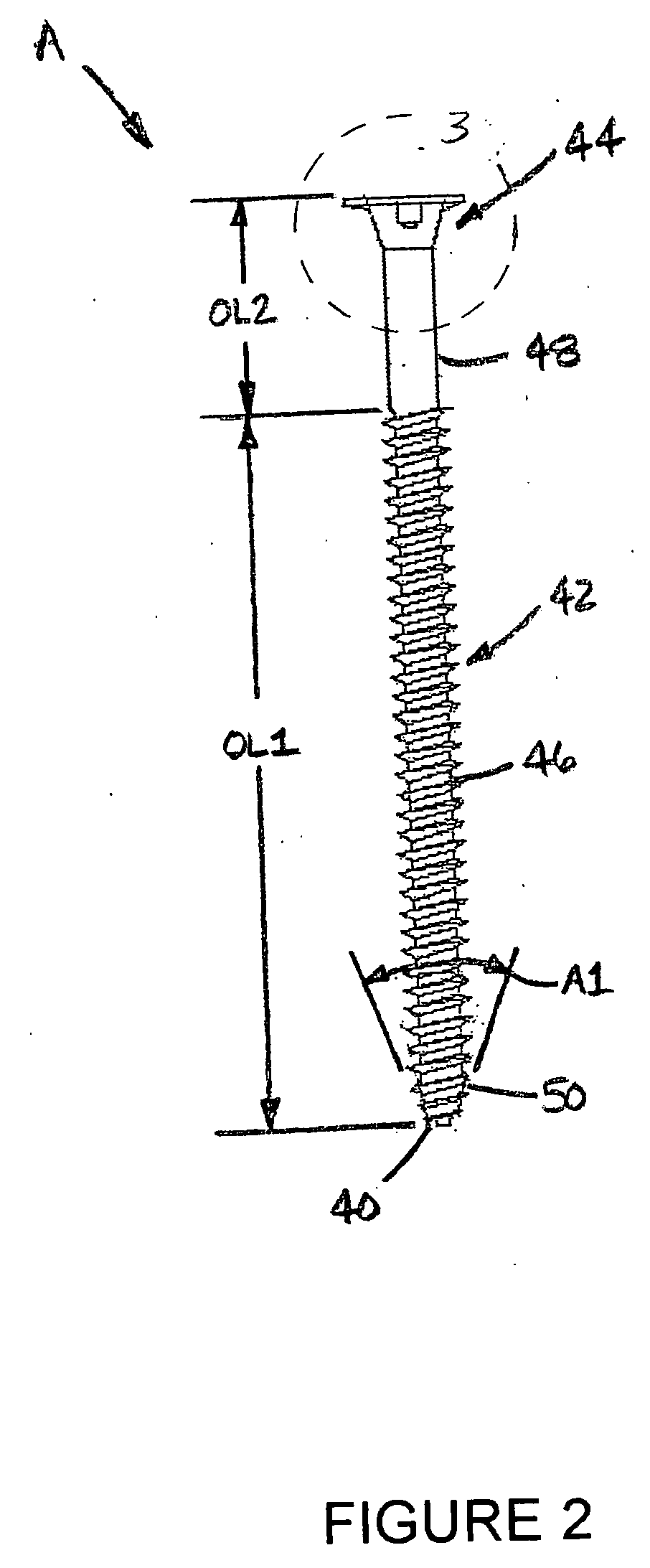

[0023] Referring now to the drawings, wherein the showings illustrate an embodiment of the invention only and are not intended to limit same, FIGS. 1-3 show a penetrating fastener A for a roofing system B. Roofing system B typically includes a flexible waterproof roof membrane 10, generally a single sheet of synthetic, flexible polymer material designed for long term waterproofing performance. Preferably, the roof membrane is an ethylene propylene diene rubber (EPDM) or thermoplastic polyolefin (TPO), however, other synthetic polymers can be used for the roof membrane without departing from the scope and intent of the present invention.

[0024] The roof membrane sealingly engages a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com