Holder for inverted bottles

a bottle and inverting technology, applied in the direction of washstands, stands/trestles, kitchen equipment, etc., can solve the problems of inconvenient use, inconvenient use, and high manufacturing cost, and achieve the effect of extra stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below is described a preferred embodiment of the invention which is not intended to be a limiting example.

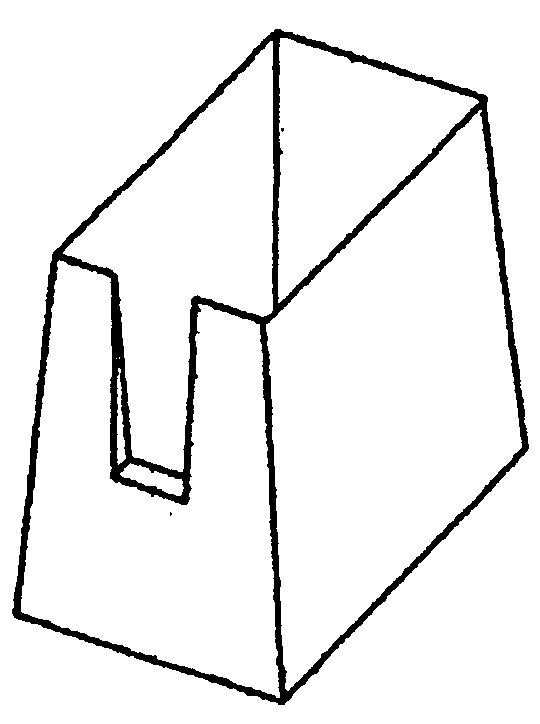

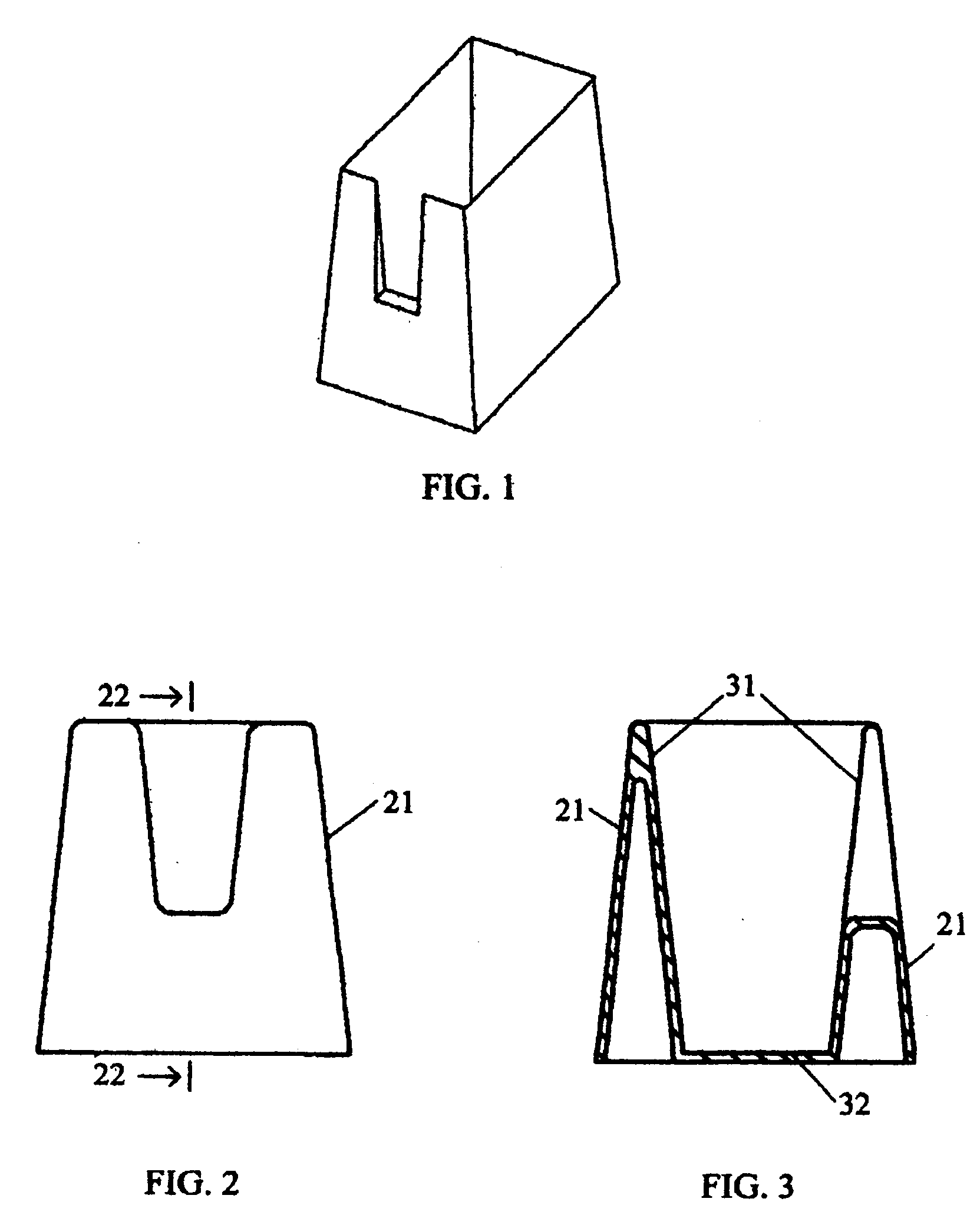

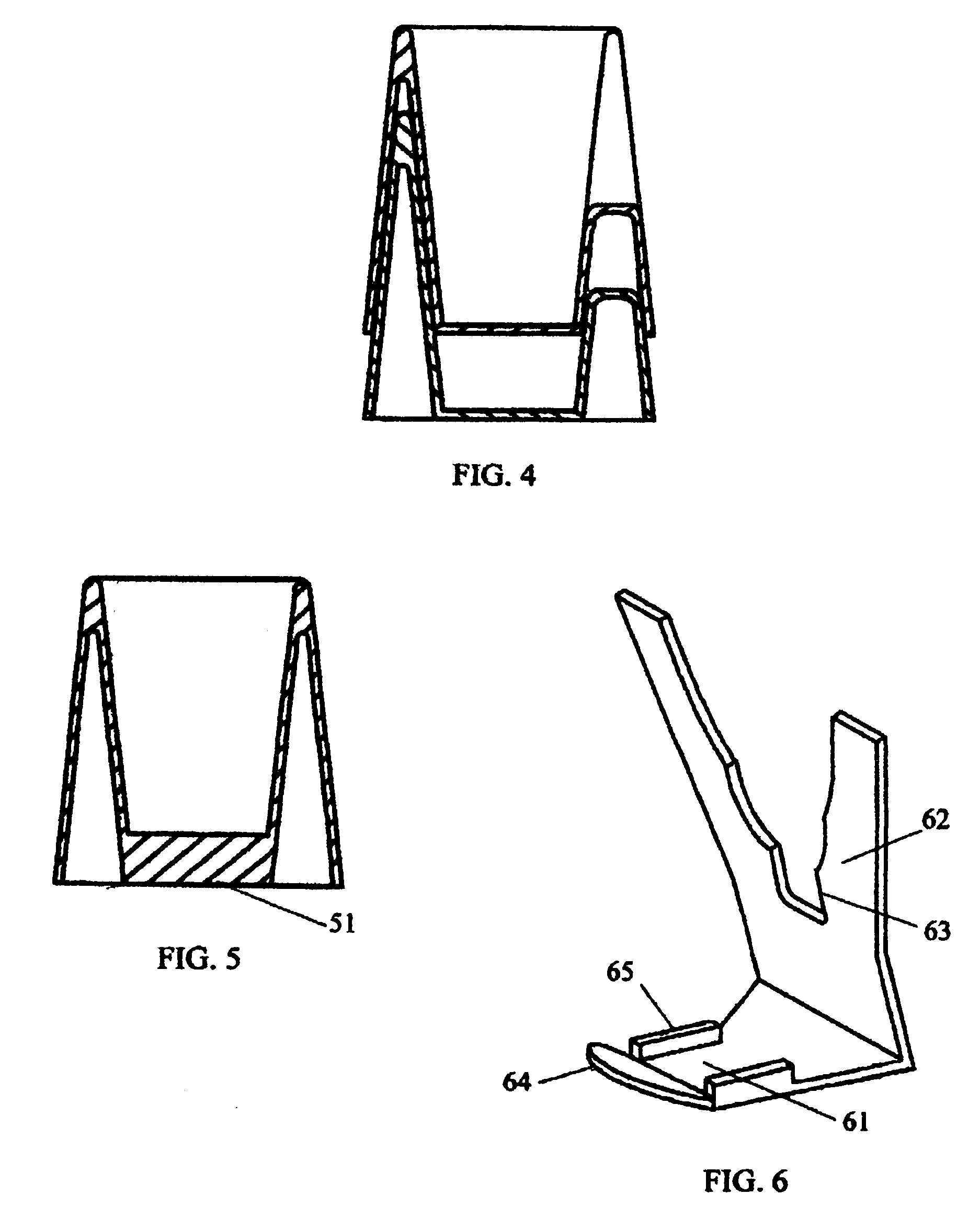

[0041] A key feature of the invention is to allow many different bottles to be easily dropped, lid first into the holder and corralled into a vertical or nearly vertical position. This will cause any viscous product to gravitate into the neck of the bottle for easy extraction. To do this, the holder must generally have an interior which is somewhat cup shaped, narrowing downwards almost vertically, conforming very roughly to the shape of an inverted bottle. The inside shape, for example, may be an inverted truncated cone or its sides may be trapezoidal. FIG. 1 shows a simplified three-dimensional rendering of the holder.

[0042]FIG. 2 shows a front view, and features which are described below. To provide stability, the exterior part of the walls 21 of the holder are flared, which provides that the three dimensional envelope of the holder has a greater cross-sectional area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com