Ratchet wheel for a lashing apparatus

a technology of lashing apparatus and ratchet wheel, which is applied in the direction of manufacturing tools, wire tools, transportation items, etc., can solve the problems of difficult implementation, low practicability, and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

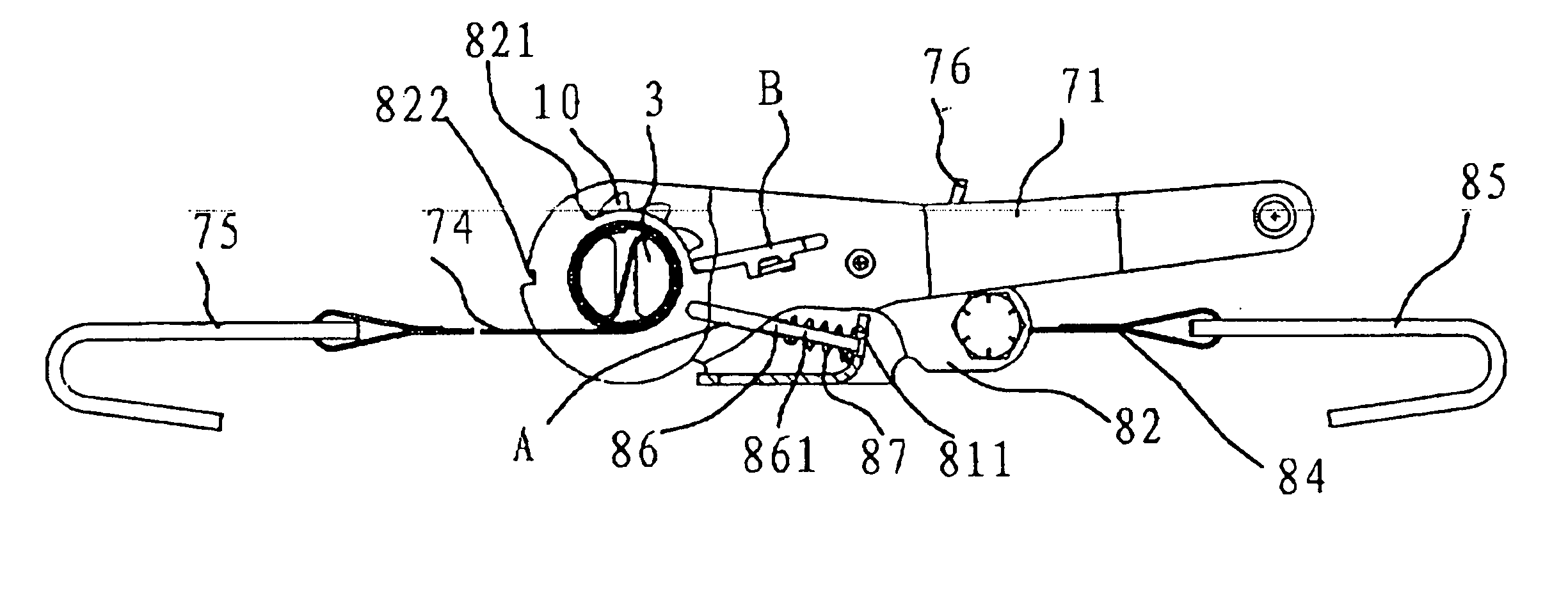

[0024] As shown in FIGS. 12 and 13, a lashing apparatus generally comprises a body 8, a ratchet wheel 10, a baffle 86, a spring 87, a handhold 76, a reel 3, a side piece 71, a mobile strap 74, a positioning strap 84, a positioning hook 85 and a mobile hook 75. The mobile strap 74 is wound around the reel 3, with the mobile hook 75 at the end. The positioning hook 85 and mobile hook 75 at the ends of the lashing apparatus are locked to the goods or the vehicle. The ratchet wheel 10 makes unidirectional rotation by repeatedly turning the side piece 71, so that the mobile strap 74 is wound around the reel 3 continuously to tighten the mobile strap 74. Thus the goods are finally lashed and secured.

[0025] As shown in FIGS. 12 and 13, the body 8 is comprised of a connector 81 and two side plates 82 symmetrically fixed to the sides of the connector 81. The connector 81 is perpendicular to the side plates 82 as an integral. A hinge hole 83 is correspondingly arranged at one end of said two...

embodiment 2

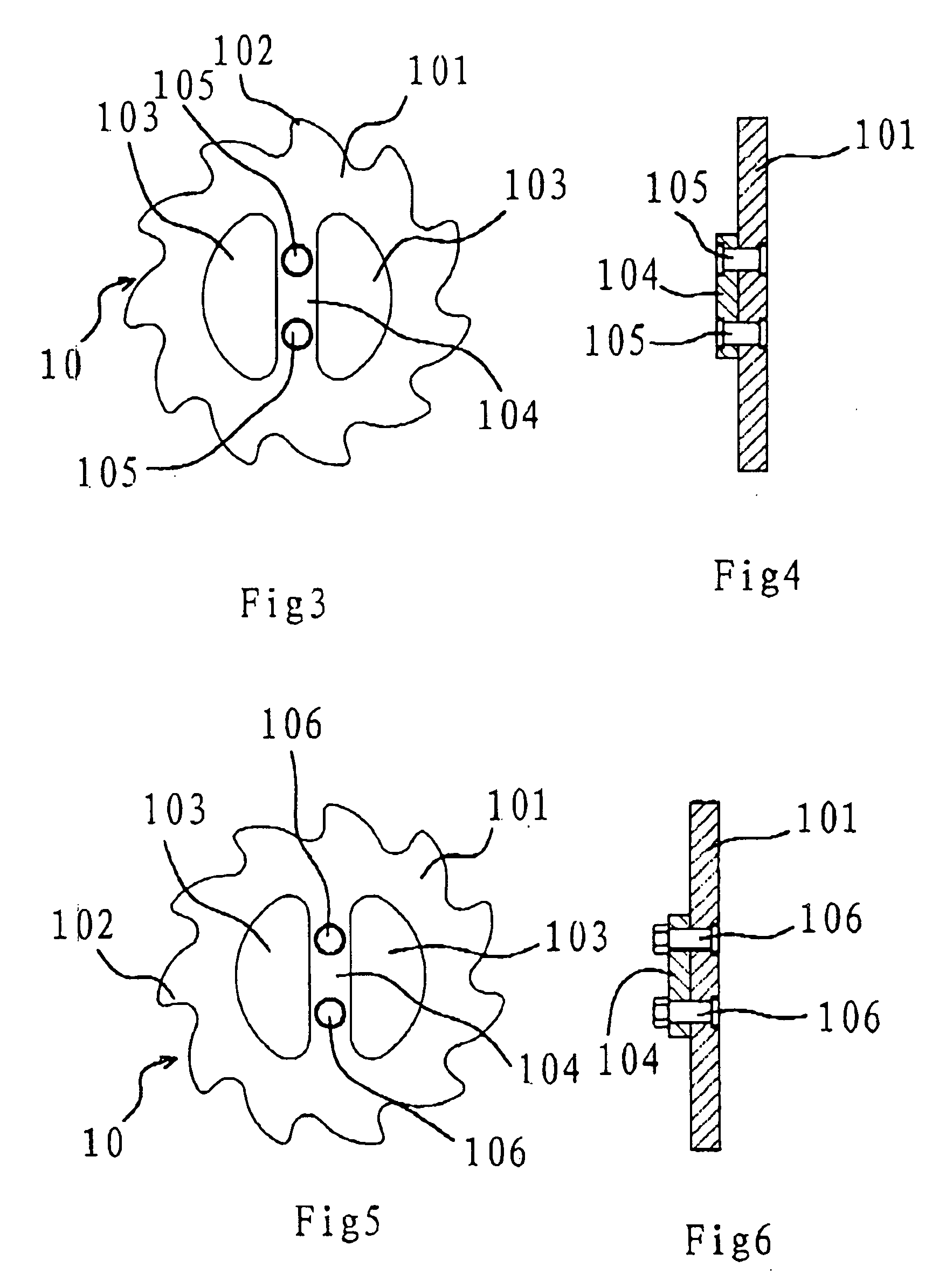

[0043] As shown in the FIGS. 3 and 4, the supporting strip 104 is fixed to the wheel body 101 through rivets 105 according to the Embodiment 2. In such a structure, the connection is secure and the supporting strip 104 has a relatively large protrusion distance from the wheel body 101.

embodiment 3

[0044] As shown in FIGS. 5 and 6, the supporting strip 104 is fixed to the wheel body 101 via a bolt 106 according to the Embodiment 3. Compared with the aforementioned embodiments, the least number of equipments are used for manufacturing the ratchet wheel 10 according to the present embodiment. Having been manufactured, the supporting strip 104 is connected to the wheel body 101 directly by a bolt 106.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com