Bacteria-based and enzyme-based mechanisms and products for viscosity reduction breaking of viscoelastic fluids

a technology of viscoelastic fluid and gelled fluid, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical apparatus and processes, etc., can solve the problems of fluid deformation, complex development of suitable fracturing fluid, and inability to close or heal completely cracks or fractures, etc., to reduce the viscosity of ves-gelled fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-3

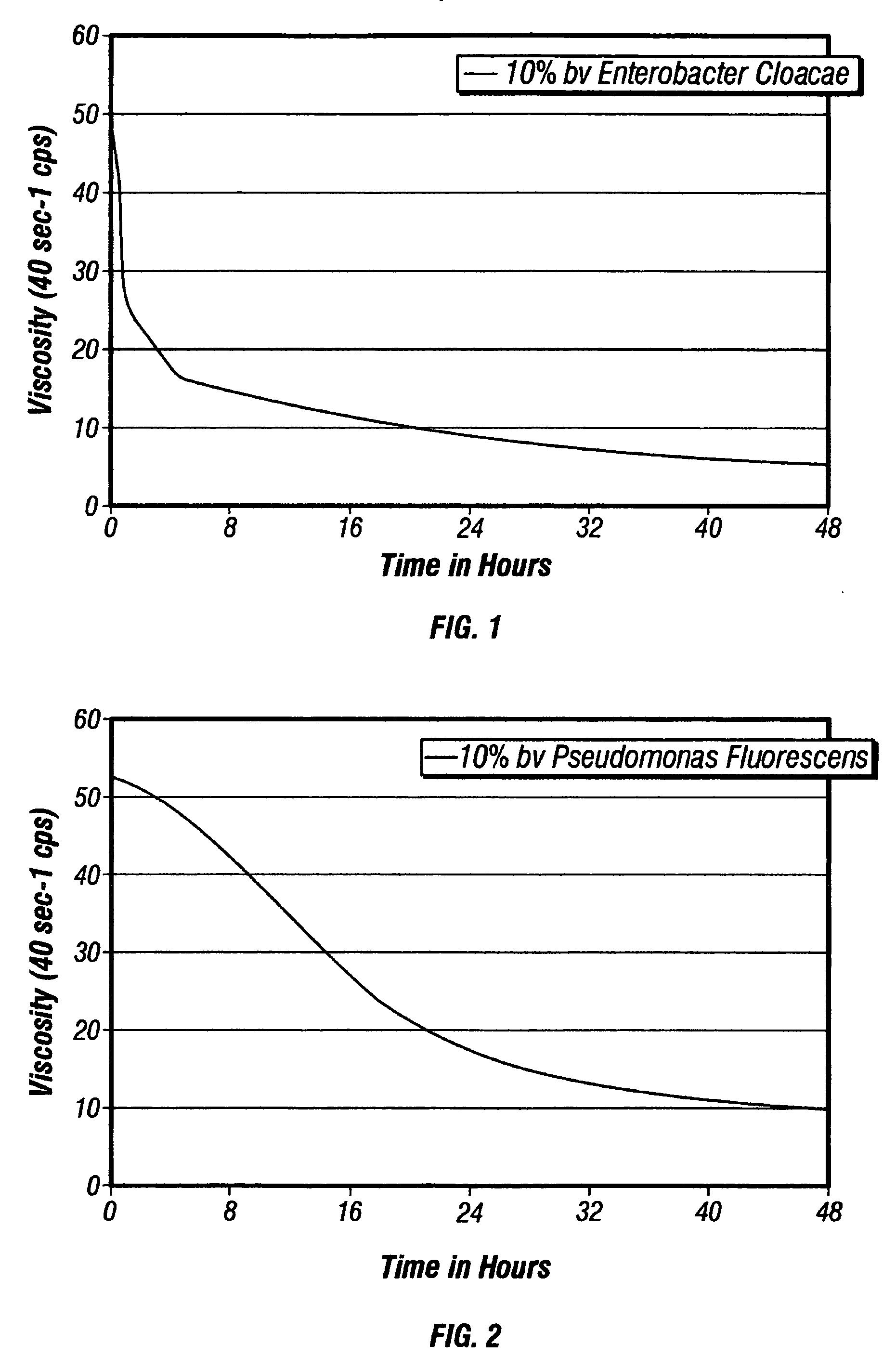

[0065]FIGS. 1-3 show the results of Examples 1-3, respectively, charting the effects of using the indicated bacteria at 10% by volume concentrations. It may be seen that the SurFRAQ viscosity broke most quickly with Enterobacter colacae, losing most of its viscosity in the first 2-3 hours (Ex. 1, FIG. 1). Viscosity reduction was also more complete in this Example 1. Pseudomonas fluorescens (Ex. 2, FIG. 2) and Pseudomonas aeruginosa (Ex. 3, FIG. 3) gave viscosity reduction as well, but more gradually than Enterobacter colacae. All Examples were run using 2% TAPAO in 3% KCl. Example 1 (FIG. 1) was conducted at 125° F. (52° C.); Examples 2 and 3 (FIGS. 2 and 3, respectively) were conducted at 75° F. (24° C.).

Examples 4 AND 9

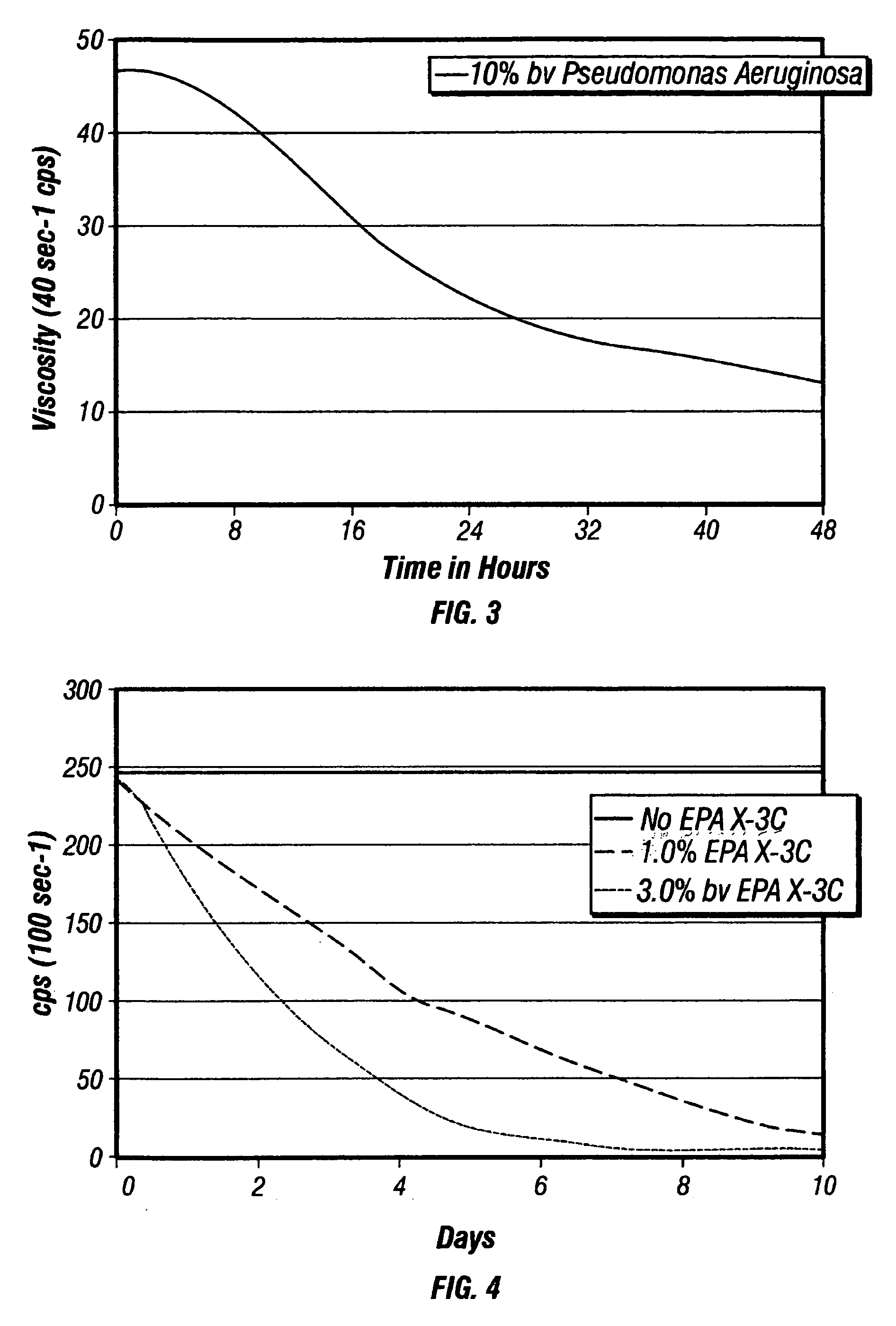

[0066]FIGS. 4 and 9 show the results of Examples 4 and 9, respectively. Both Examples use 6.0% bv TAPAO surfactant at 180° F. (82° C.) and 950 psi (6.5 kPa) on a Fann 50 rheometer. Both compositions contained 3% KCl. The order of mixing was: DI water, KCl, NH4NO3, ...

examples 5-8

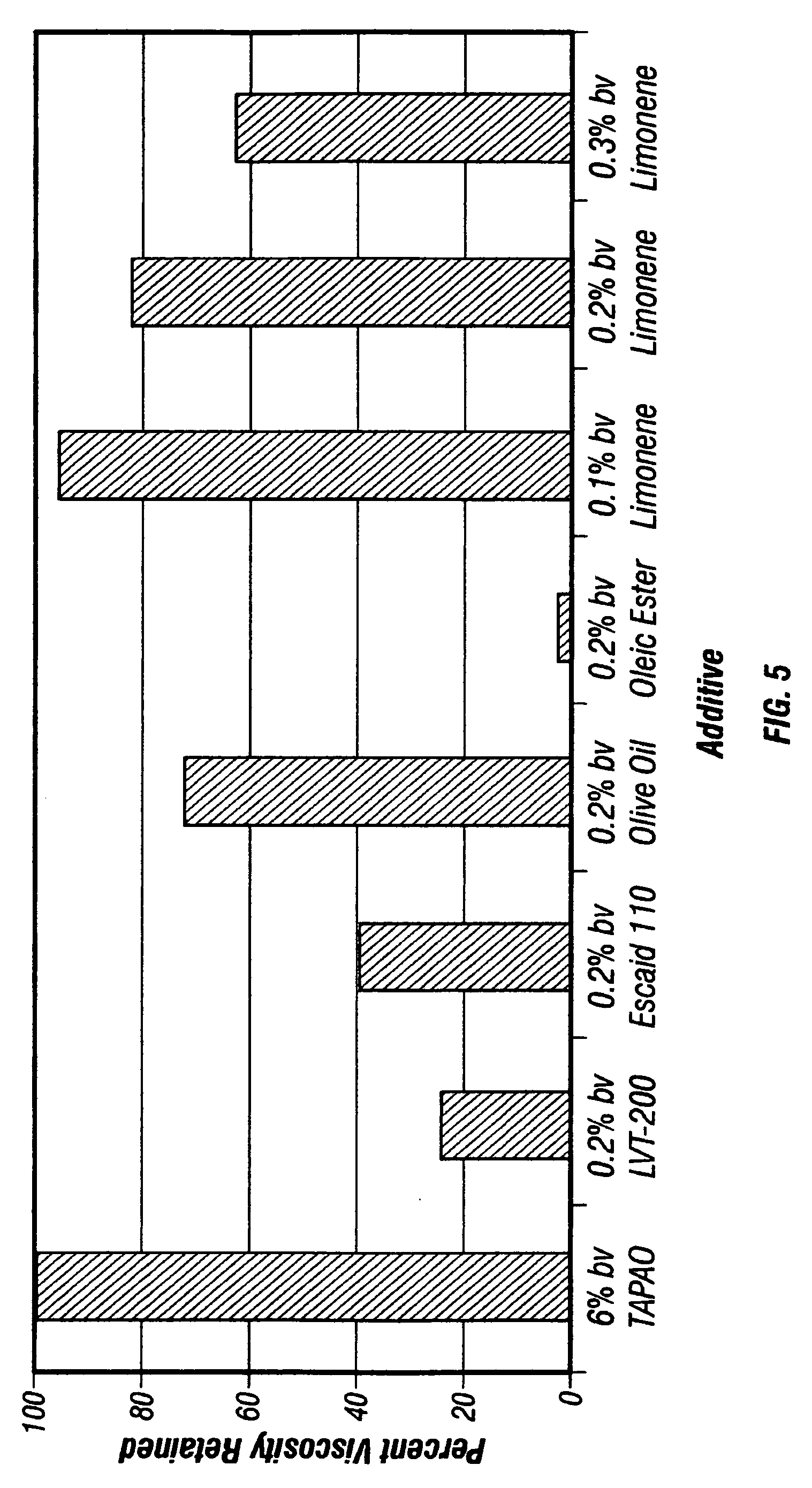

[0068]FIGS. 5-8 show the results of Examples 5-8, respectively, charting the effects of various bacteria or microbe nutrients on 6% bv TAPAO surfactant at 180° F. (82° C.) and 950 psi (6.5 kPa). It may be seen that proper selection of microbe nutrient is possible that has minimal effects on the TAPAO viscosity.

[0069] All of Examples 5-8 used a Fann 50 rheometer at 180° F. (82° C.) at 400 psi (2.8 kPa). Examples 5-7 used 6% TAPAO, 3% KCl, 30 pptg (3.4 kg / m3) NH4PO3 and NH4NO3 combined, and 20.0 pptg (2.4 kg / m3) TSB. Example 8 used 6% TAPAO and 3% KCl with the indicated additives. EGMBE in Example 6 refers to ethylene glycol monobutyl ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentrations | aaaaa | aaaaa |

| concentrations | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com