Bucket Glides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

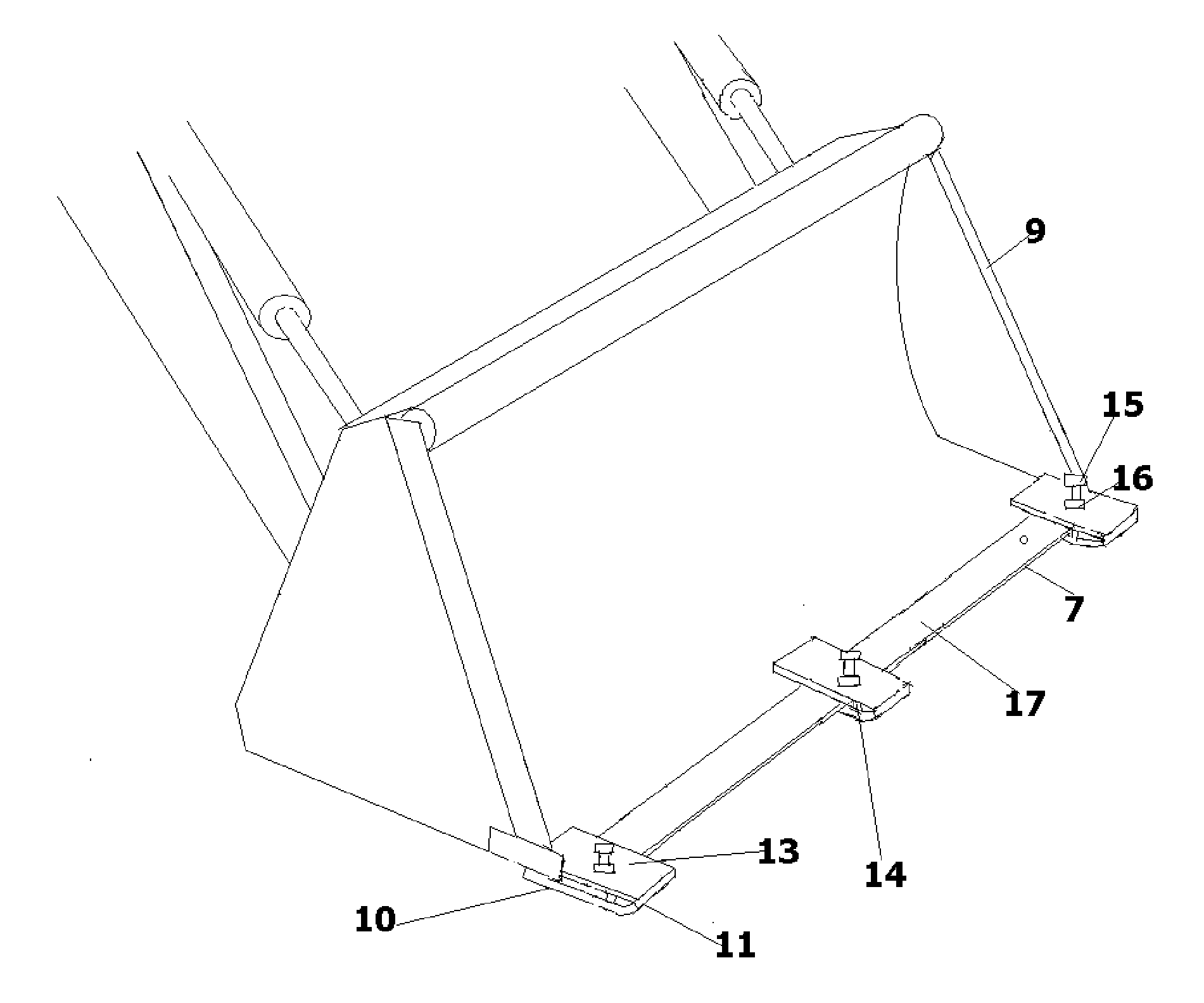

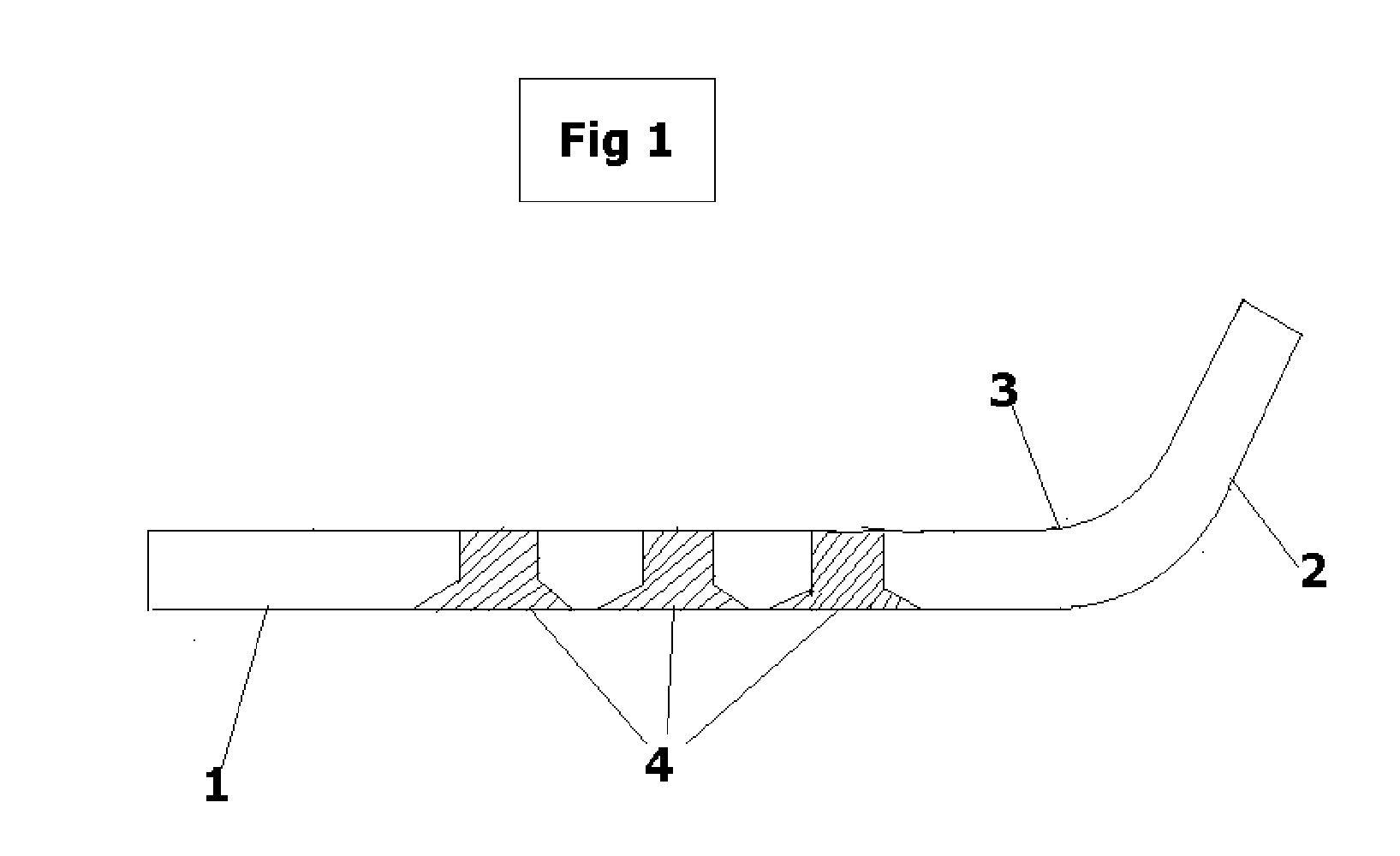

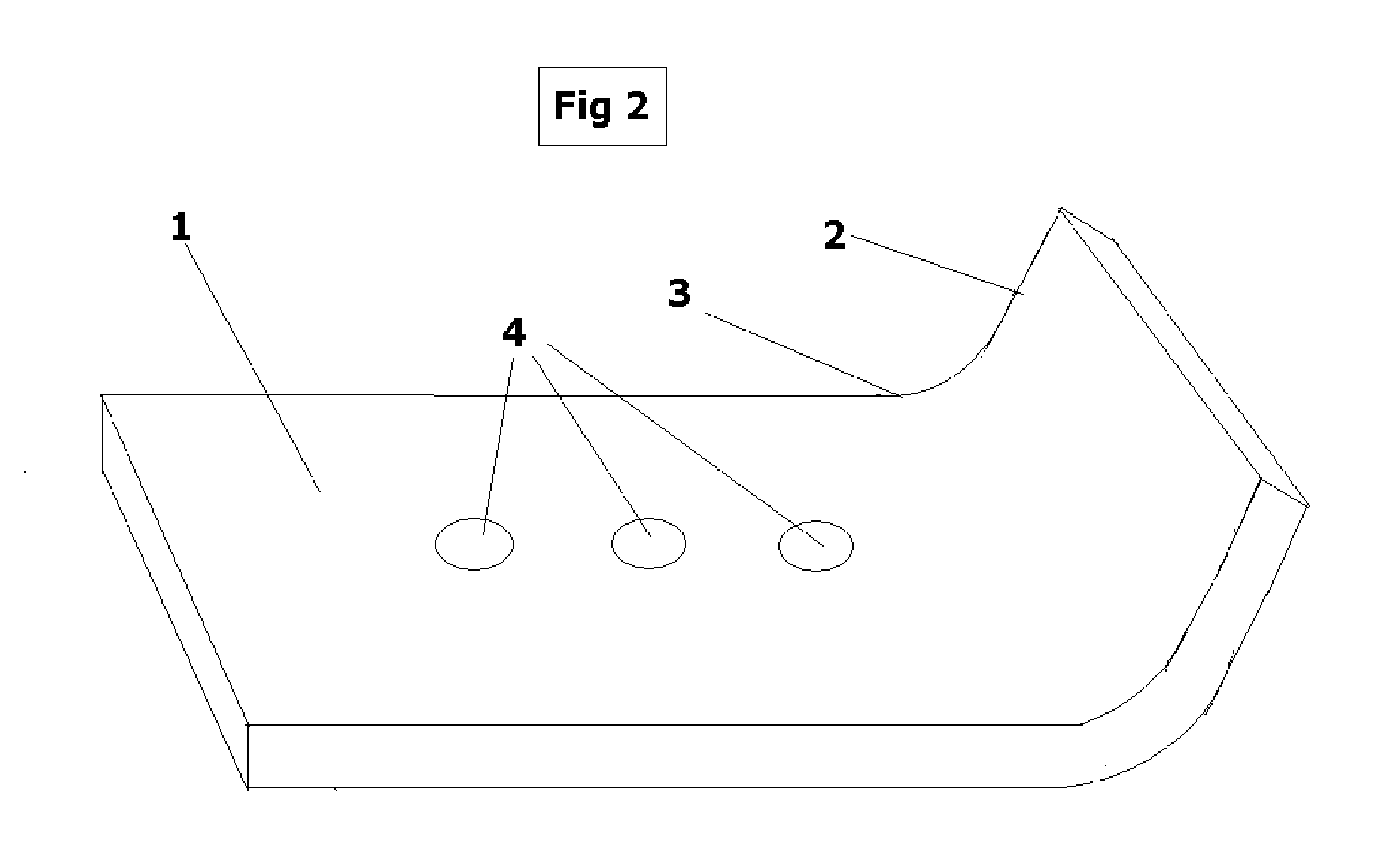

[0018] Bucket-glides are designed to greatly reduce and in some cases eliminate the problems encountered when plowing snow with a bucket 9 attached to a front-end loader with the lift hydraulics in float position. In the past the operator has had to constantly adjust the tilt angle of the bucket 9 to prevent the problem of the cutting edge 7 from digging in and removing unwanted material especially when the ground conditions under the snow were soft and / or uneven. If the bucket 9 had even the slightest downward tilt angle this problem was unavoidable because the exact location of the cutting edge 7 was difficult for the operator to see. When the operator would attempt to correct the “digging in” problem by reducing the tilt angle, the bucket 9 would then tend to “toboggan” upwards and over the snow, leaving behind and packing down what was to be removed. Bucket-glides make plowing with a bucket easy and efficient. They allow the operator to retain the utility of his bucket 9, and fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com