Ventilation vest

a technology of ventilation vest and vest body, which is applied in the direction of protective equipment, protective clothing, weapons, etc., can solve the problems of high body temperature risk, substantial danger, and increased cost and complexity of manufacture for soldiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] For a more complete understanding of the present invention and advantages thereof, reference is now made to the following description of various illustrative and non-limiting embodiments thereof, taken in conjunction with the accompanying drawings submitted herewith.

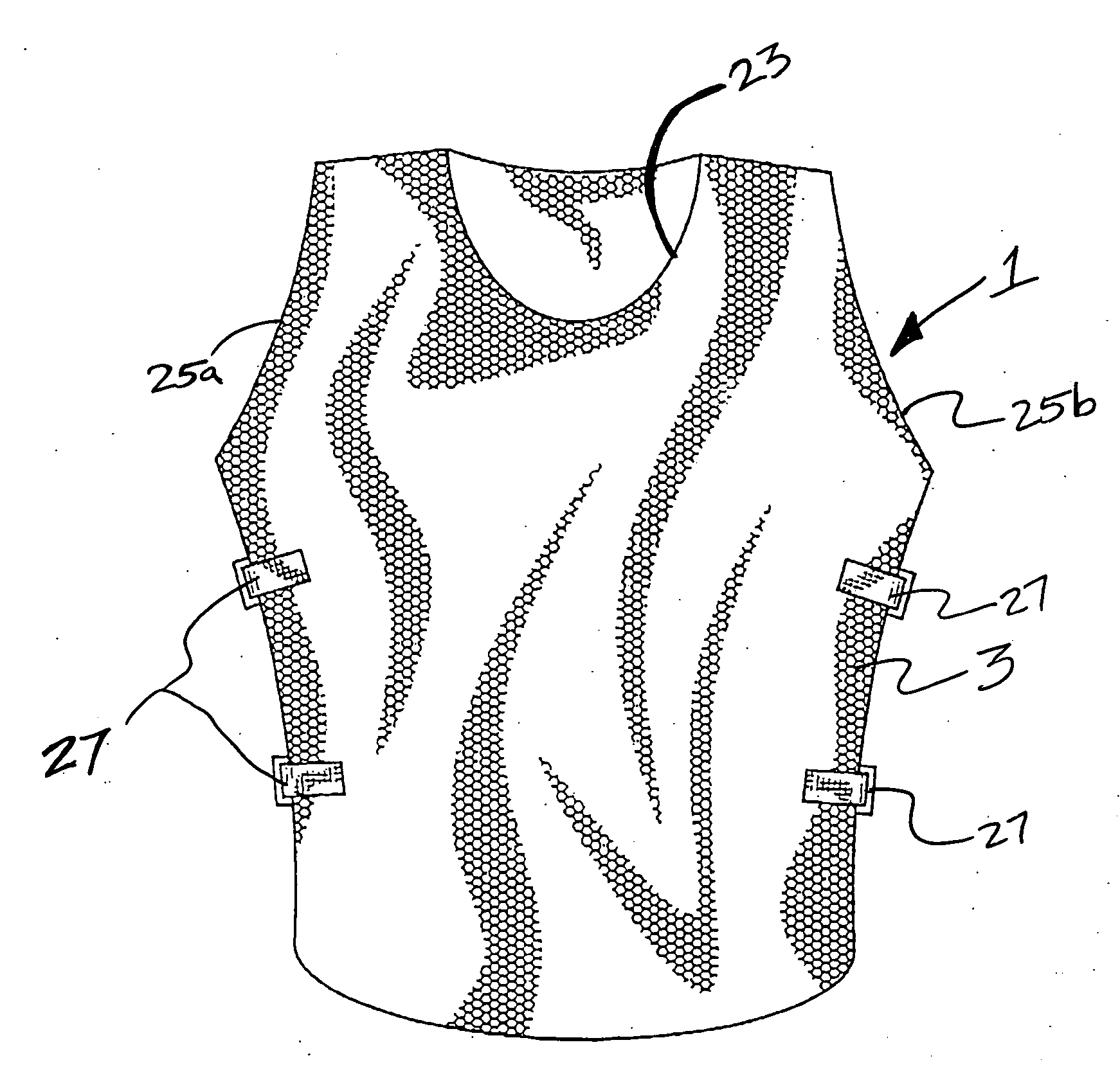

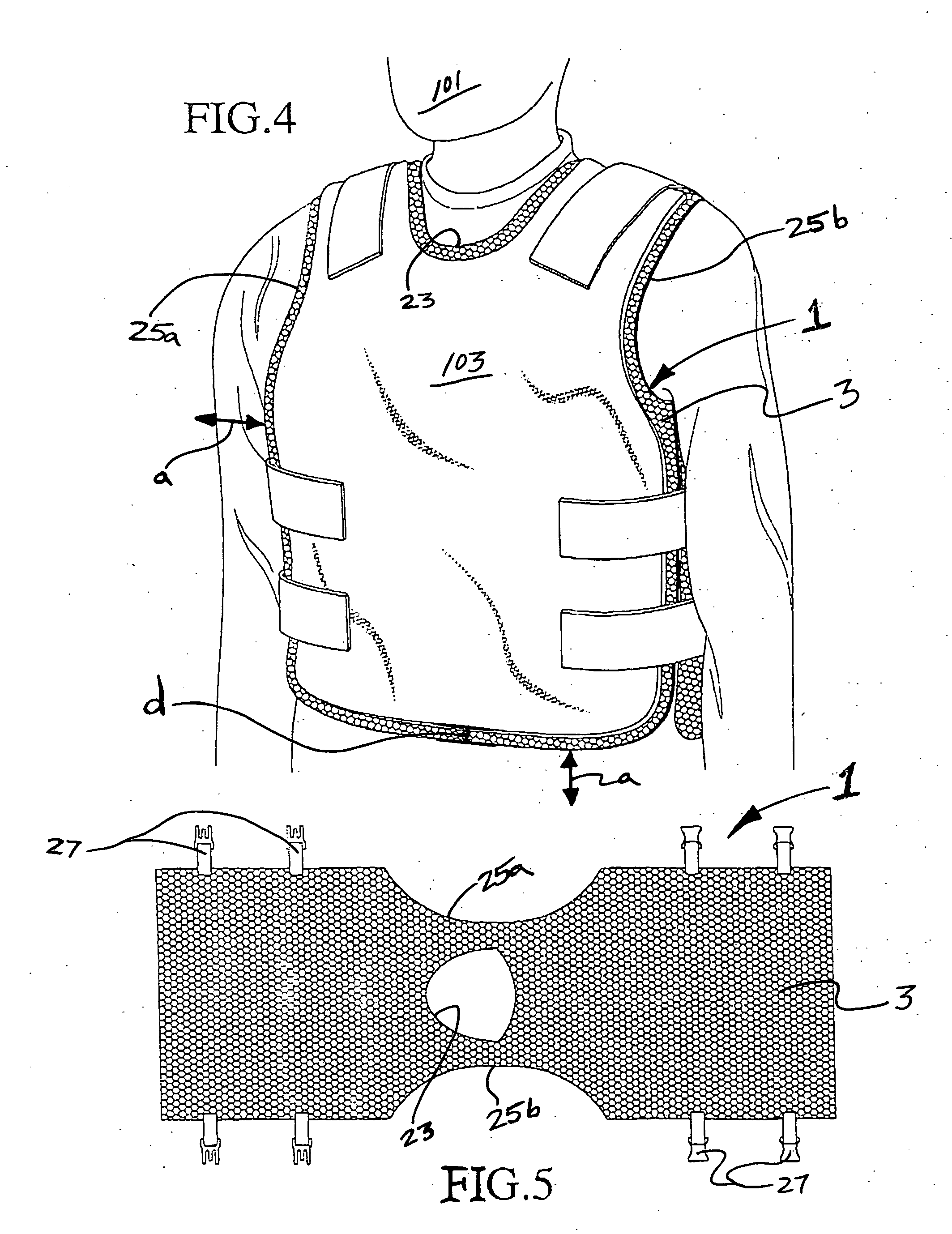

[0027] Referring initially now to FIG. 1, therein is illustrated ventilation garment 1 as one exemplar embodiment of the subject invention. As can be seen in FIG. 1, garment 1 generally comprises a quantity of three-dimensional fabric 3 configured in the shape of a wearable vest. In this regard, garment 1 includes a neck aperture 23 as well as two opposing arm apertures 25a and 25b. Additionally, garment 1 includes a set of fasteners 27 for securing garment 1 to a user as well as for adjusting the fit of the garment according to various body sizes.

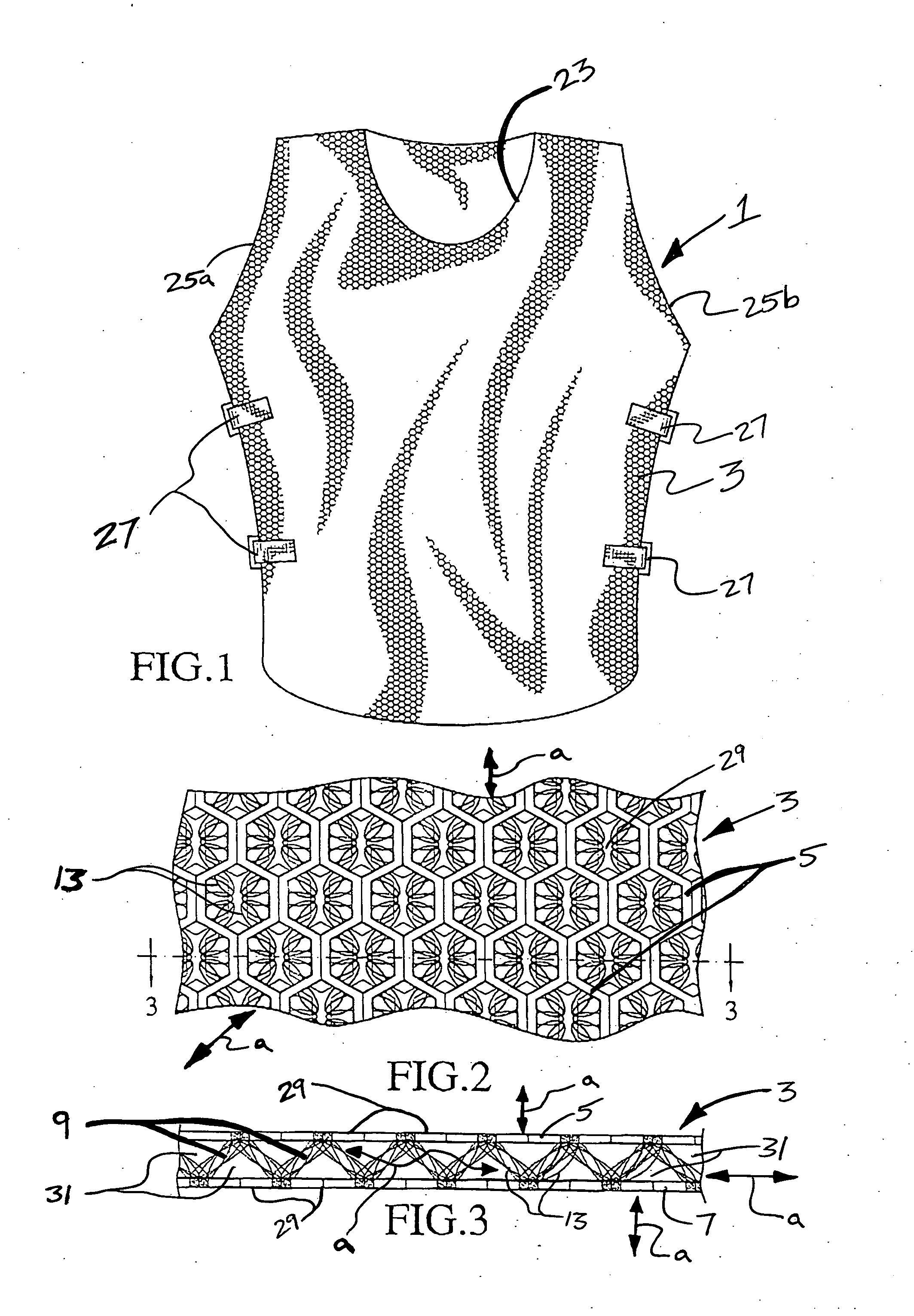

[0028] Turning now to FIGS. 2 and 3, an example of a specific three-dimensional configuration of fabric 3 can be seen therein. Specifically, as seen most clearly in FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com