Weight plates stacking system for fitness training equipment

a stacking system and weight plate technology, applied in the direction of weights, gyms, sport apparatus, etc., can solve the problem of requiring costlier production to achieve such precision, and achieve the effect of avoiding the problem of accumulated thickness errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

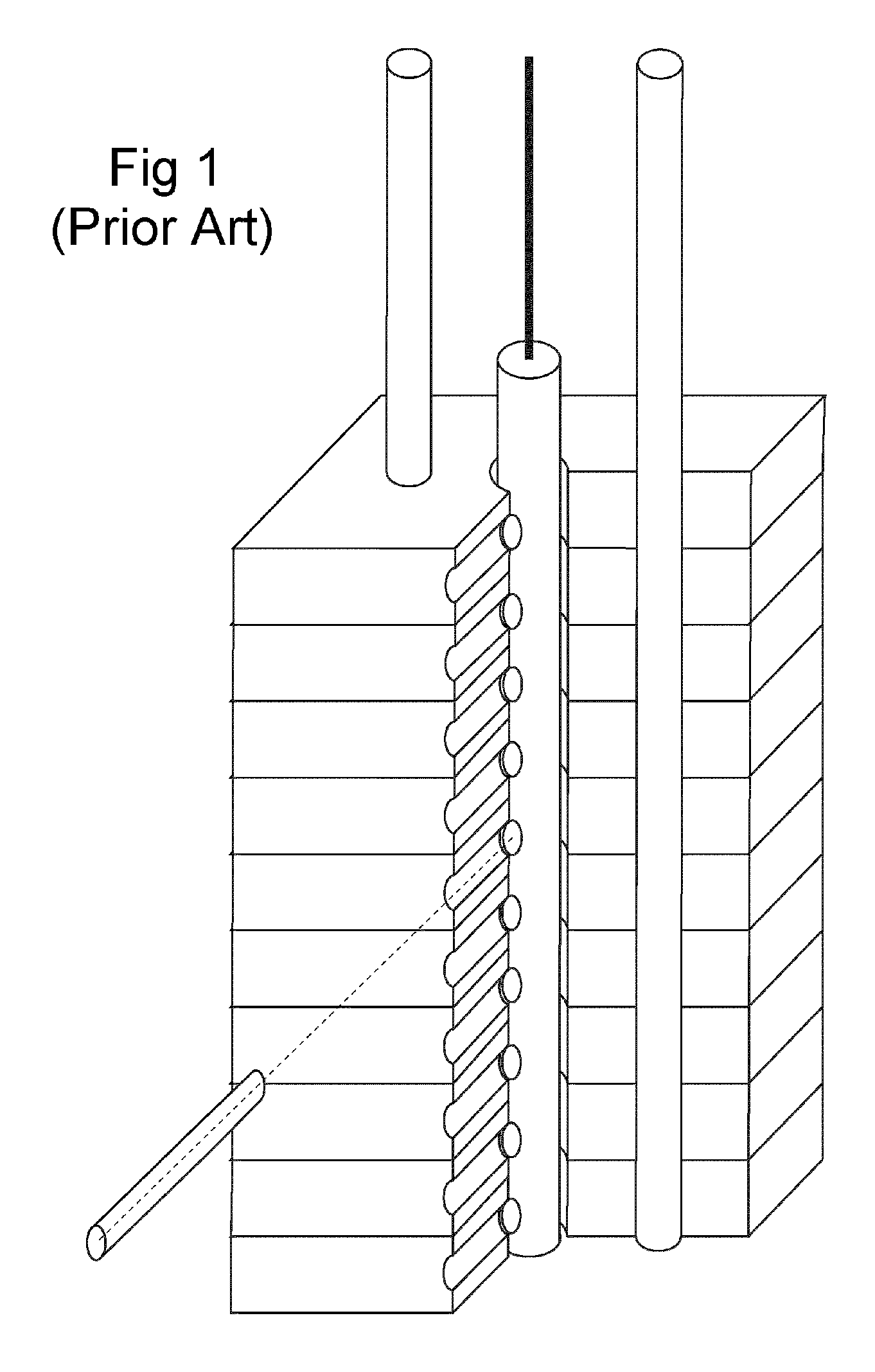

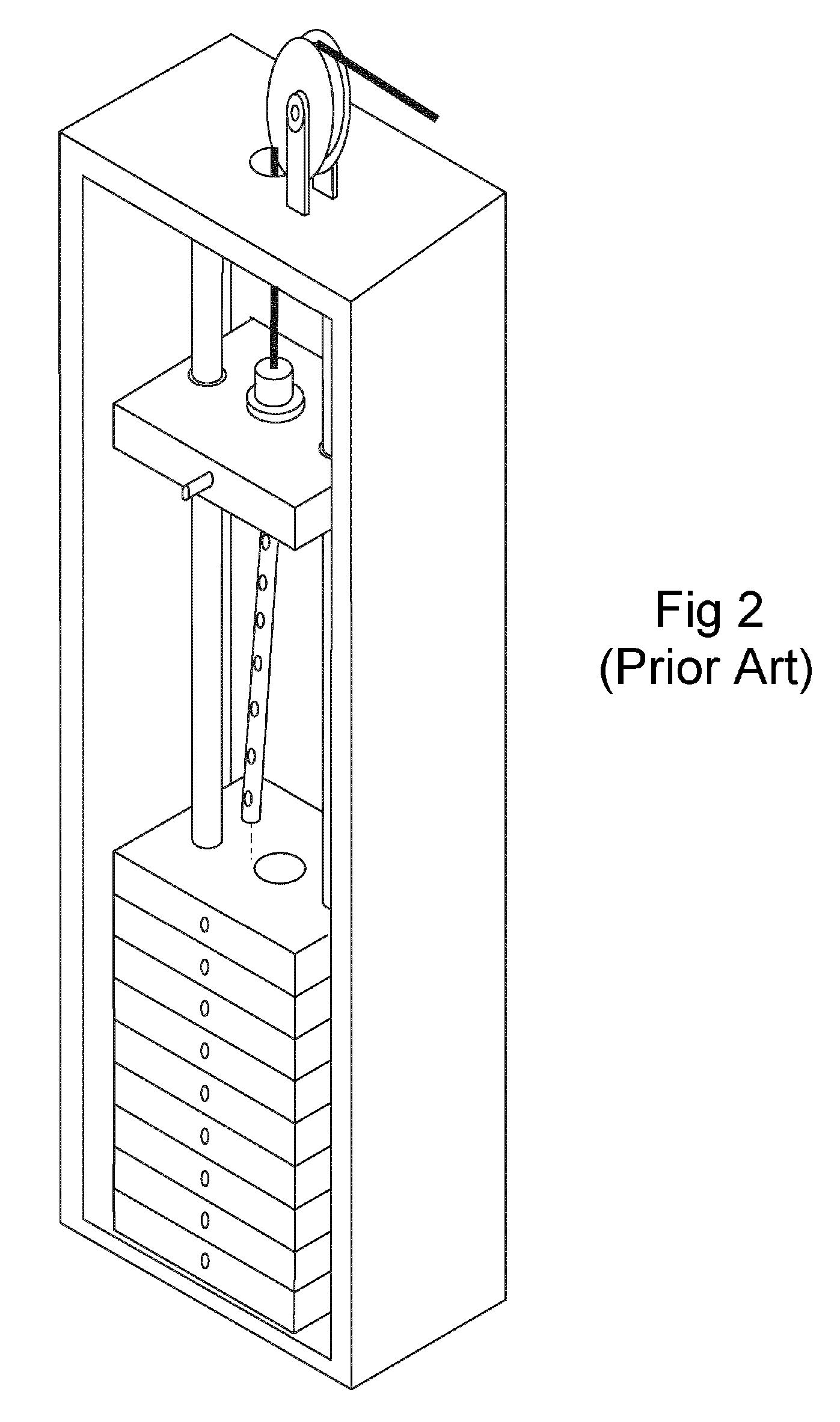

[0027] In FIGS. 1 and 2, the problem with current industry fitness equipment is seen clearly. Insertion pin at the top of the weight stack may be difficult due to the accumulated thickness errors of the weight stacks.

[0028] The central stem is oftentimes made offset, as to cause trouble when the cable tension is released, the bottom tip of the central stem cannot successfully come down through the center holes of all the remaining weight plates.

[0029] Present invention uses link-connectors, each fitting to one weight plate having center portion machined out to contain one link-connector.

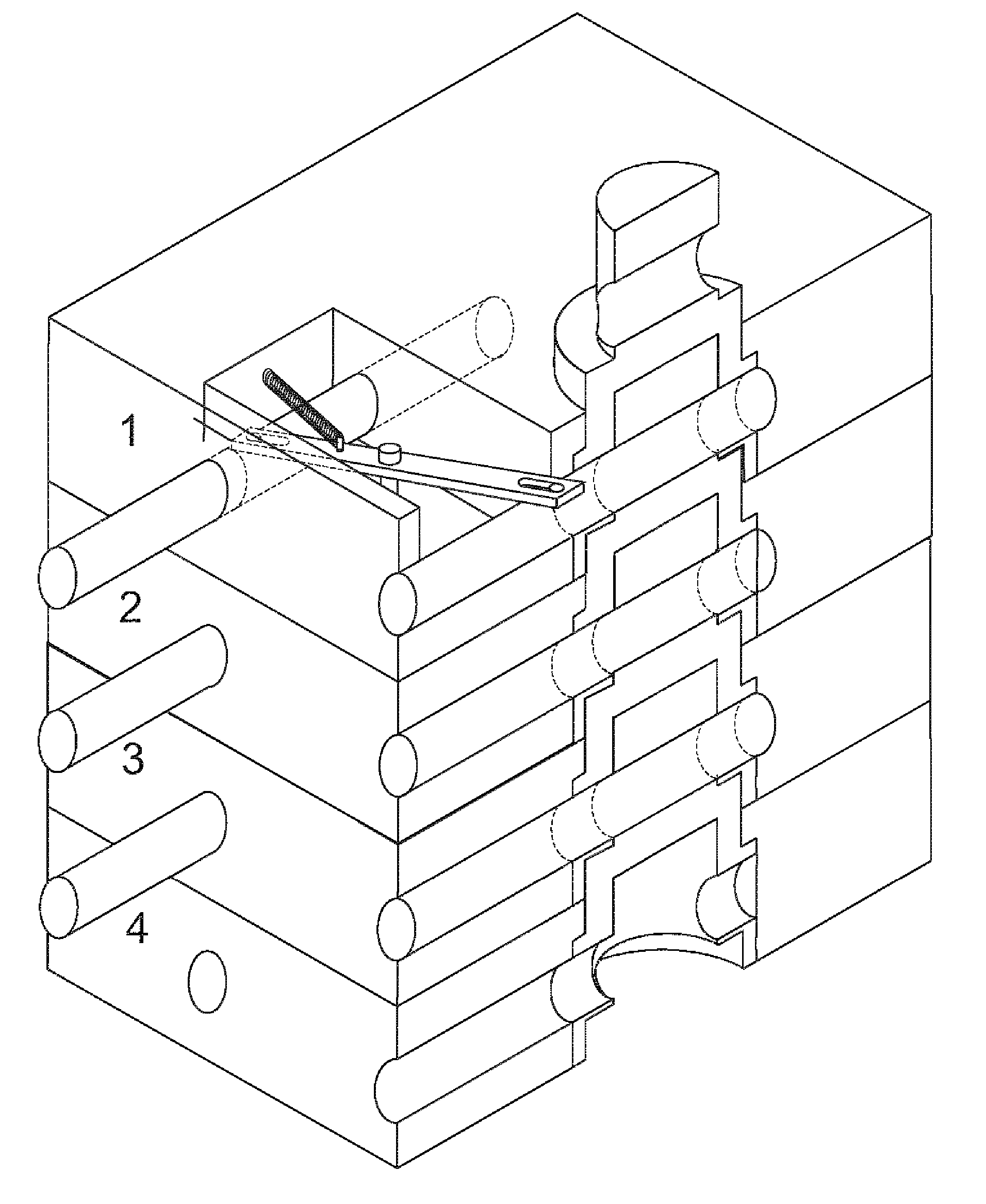

[0030]FIGS. 3-7 show the construction of link-connectors and how they are used on weight plate machined to fit said link-connectors.

[0031] As shown in FIG. 10, there is only a small length of tip from a link-connector, when the cable is lifted. The selected portion of weight plates can come easily back to stack on top of unselected weight plates.

[0032]FIGS. 8 and 9 show the link-connector can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com