Cement-based tile-setting spacers and related process

a technology of cement-based tiles and spacers, which is applied in the field of spacers, can solve the problems of reducing affecting the quality of tiles, and affecting the appearance of grout, so as to save time and money, reduce the risk of damage to tiles, and eliminate the effect of damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

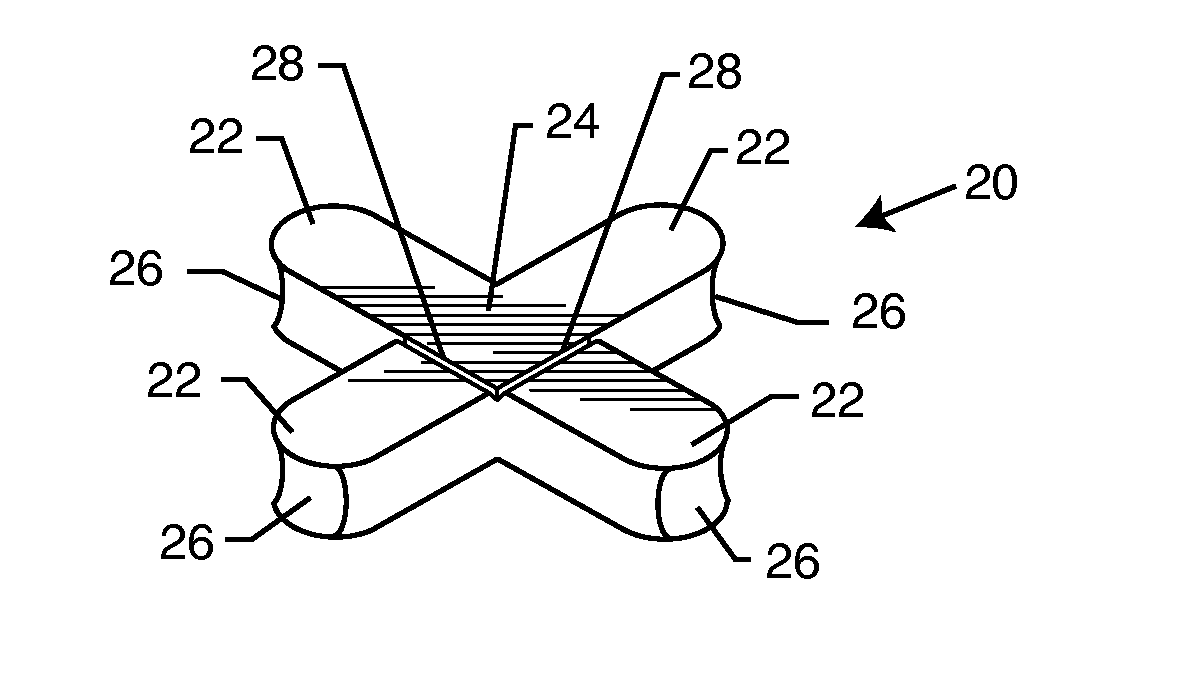

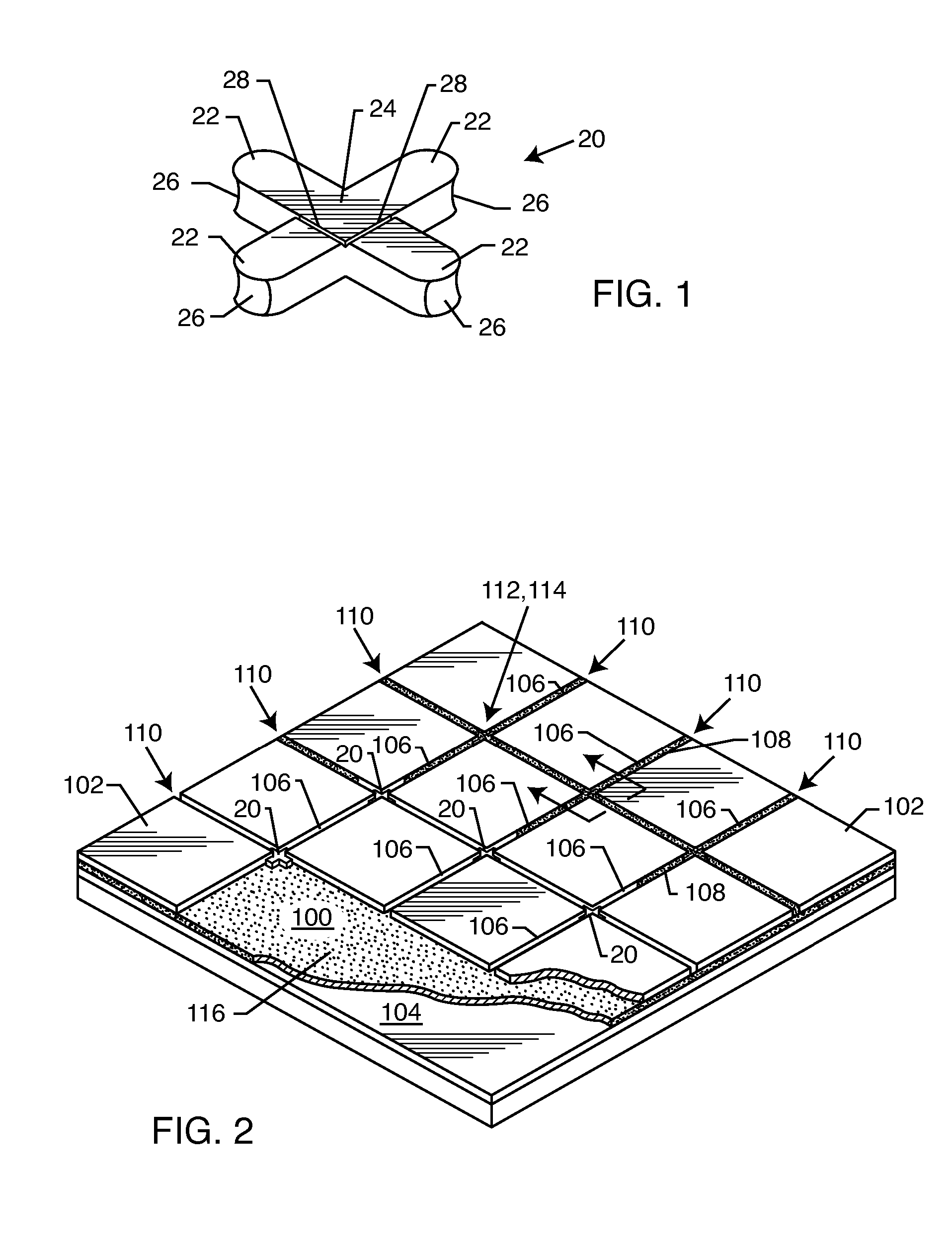

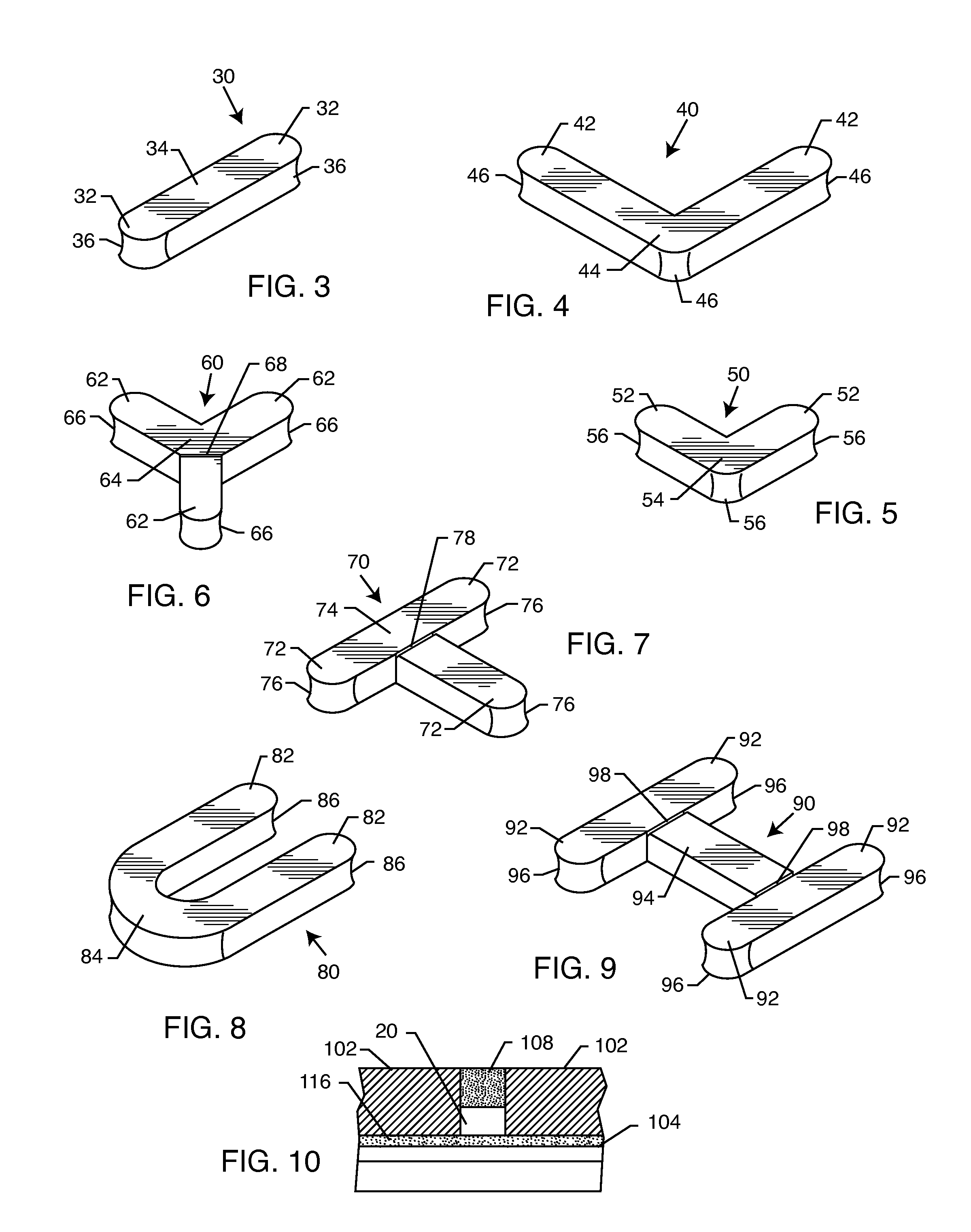

[0029] As seen in FIGS. 1-10, the present invention resides in a tile-setting spacer 20, 30, 40, 50, 60, 70, 80, 90. An X-shape spacer 20 includes four limbs or legs 22 extending radially outward from a common junction 24 to form the X-shape or cross-shape (approximate size being one inch by one inch in length and width, with a thickness of three sixteenths inch to one half inch). There is a slight, concave recess or cutout 26 at an end of each leg 12 distal from the common junction 24. However, in addition to the X-shaped spacer 20, a tile spacer can also come in a variety of other shapes including, without limitation, a linear shape 30 (FIG. 3), an L-shape 40 (FIG. 4), a V-shape 50 (FIG. 5), a Y-shape 60 (FIG. 6), a T-shape 70 (FIG. 7), a U-shape 80 (FIG. 8), an I-shape 90 (FIG. 9) or the like. Each spacer 30, 40, 50, 60, 70, 80, 90 includes a number of radial limbs or legs 32, 42, 52, 62, 72, 82, 92 extending radially outwardly from a common junction 34, 44, 54, 64, 74, 84, 94 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com