Alternative geometry ridge vent louvers

a technology of ridge vents and louvers, which is applied in the direction of ventilation systems, heating types, lighting and heating apparatus, etc., can solve the problems of unreasonable cooling energy requirements and uncomfortable living quarters of buildings, and achieve the effects of increasing surface area, reducing noise, and increasing nfa values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

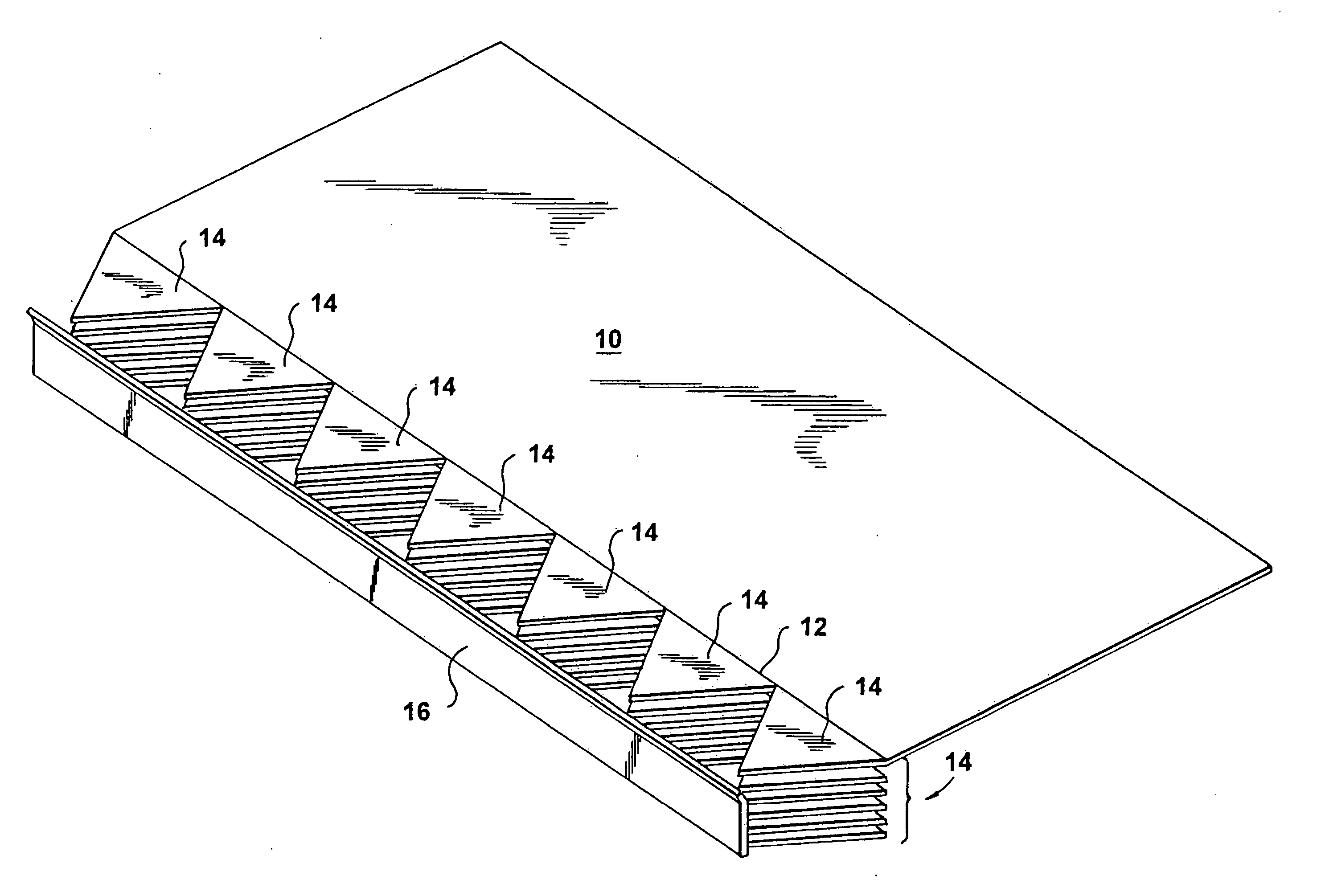

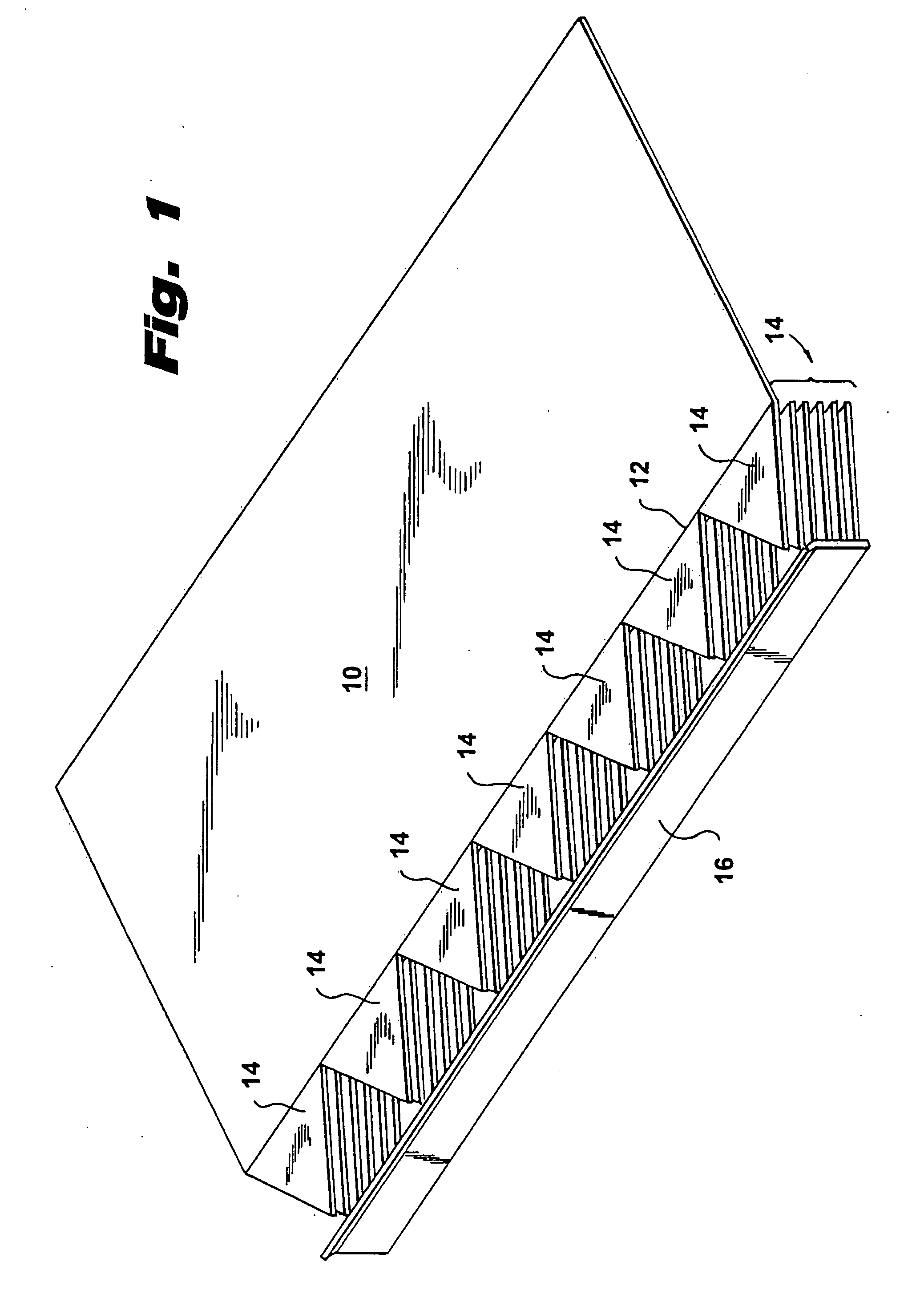

[0010]FIG. 1 illustrates one embodiment of the present invention. A ridge vent panel 10 is shown from a top view perspective. At side wall edge 12 of panel 10 are a plurality of louver ribs 14 having a chevron configuration. As illustrated, chevron-shaped louver ribs are horizontally layered, however the invention is not limited in this respect and the invention contemplates other configurations such as vertically arranged chevron-shaped louvers ribs. It should be understood that panel 10 in commercial form will have louver ribs 14 provided on both sidewalls 12. Louver ribs 14 may be arranged in parallel rows extending from sidewall 12 as illustrated in FIGS. 1 and 2, or they may vertically from sidewall 12.

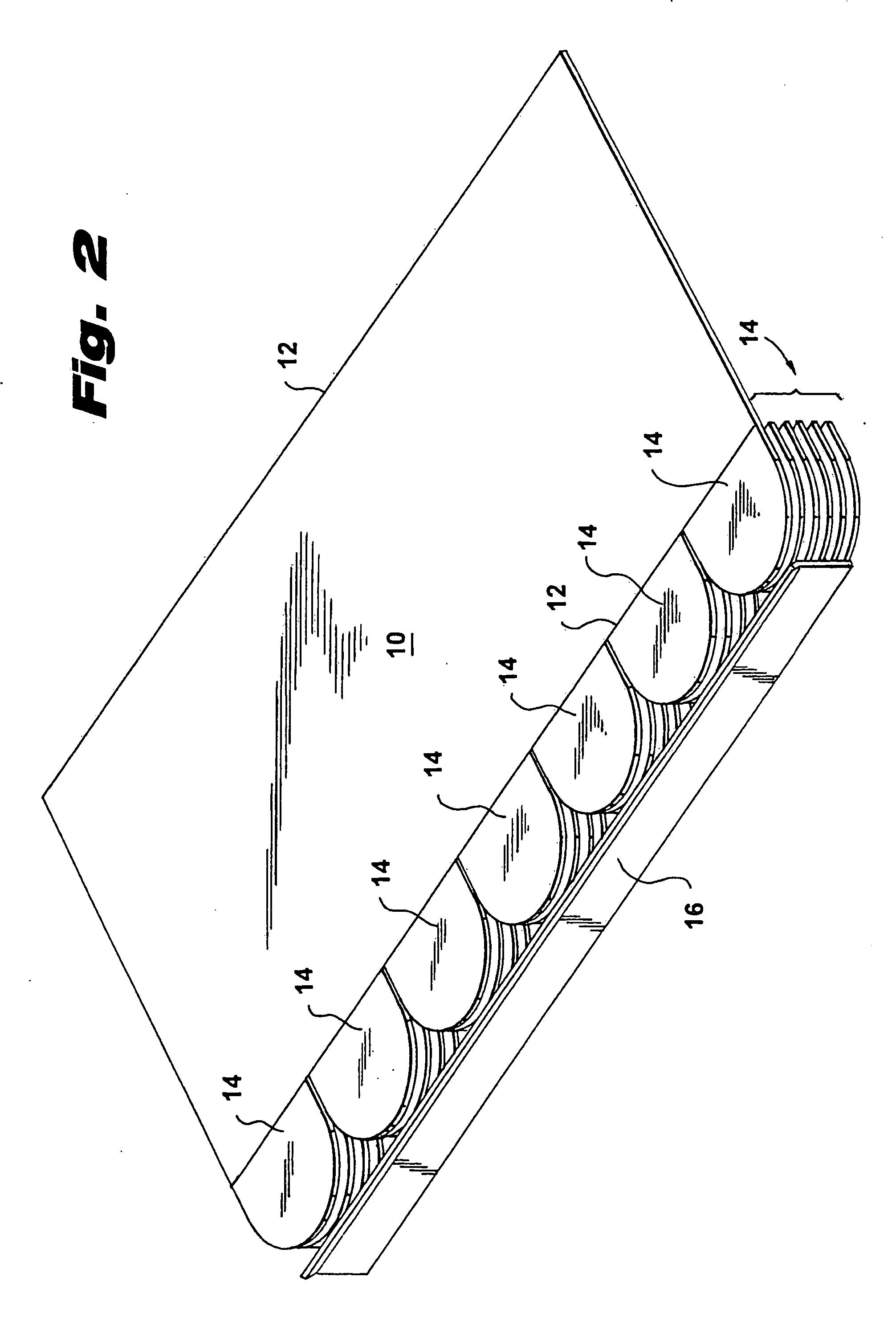

[0011] An alternative embodiment is illustrated in FIG. 2 in which louver ribs 14 are curved, undulating or elliptical in shape. Other embodiments contemplated by the present invention include any and all irregular (non-straight) shaped louver ribs.

[0012] As shown in FIGS. 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com