Ejector-type cycle

a technology of ejector and cycle, applied in the direction of machine operation, transportation and packaging, light and heating apparatus, etc., can solve the problem of inefficiency of conventional techniques, and achieve the effect of improving refrigeration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

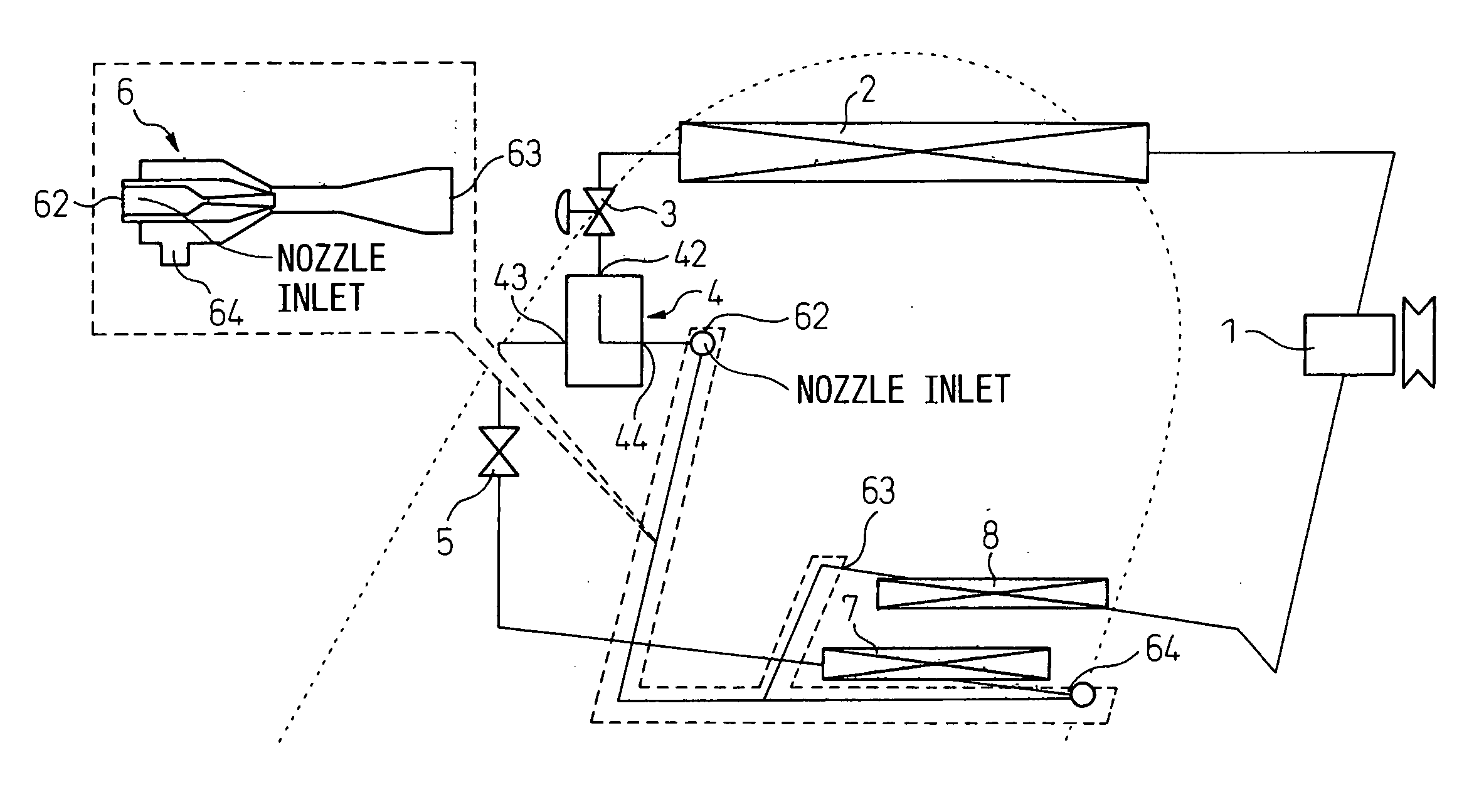

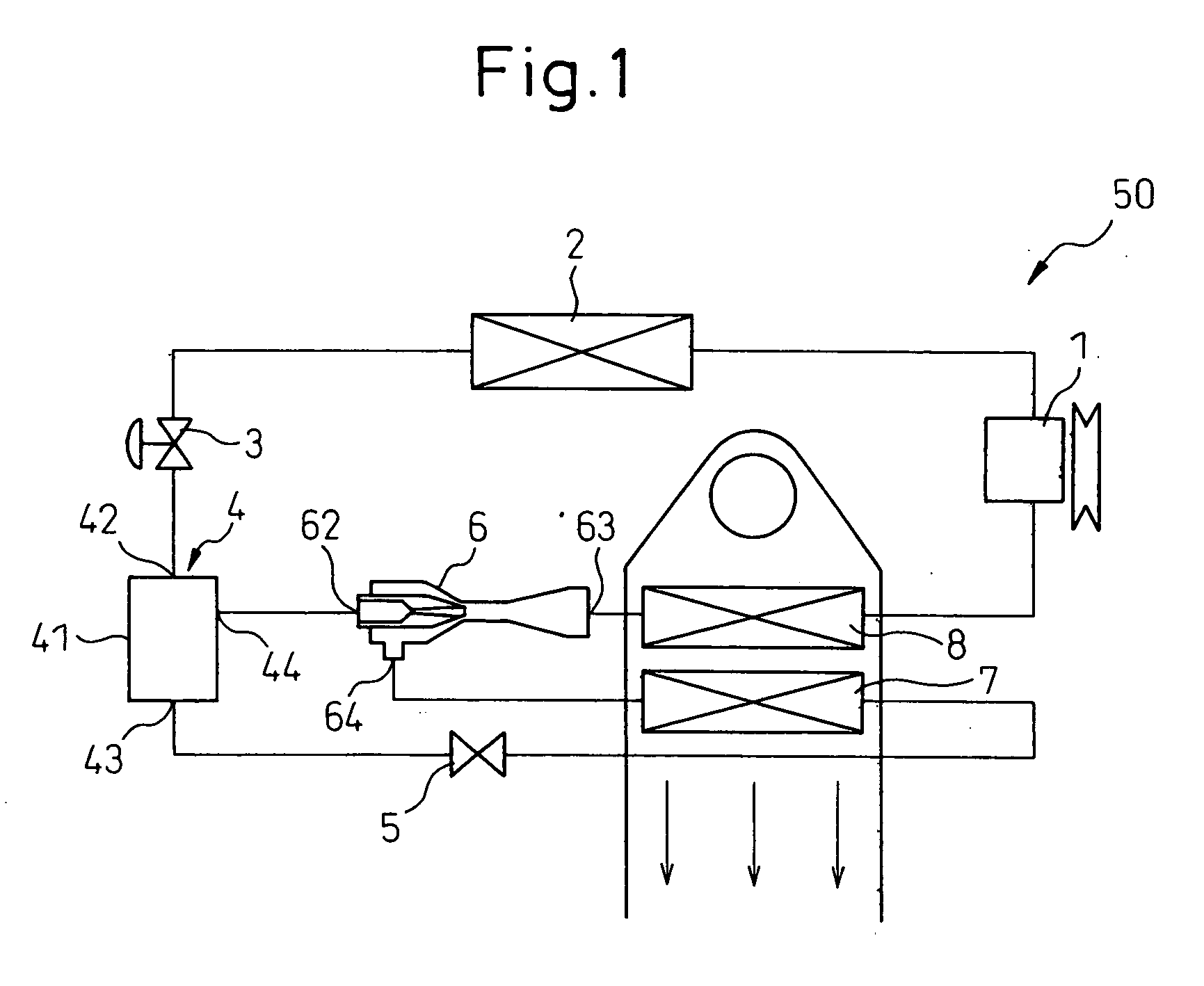

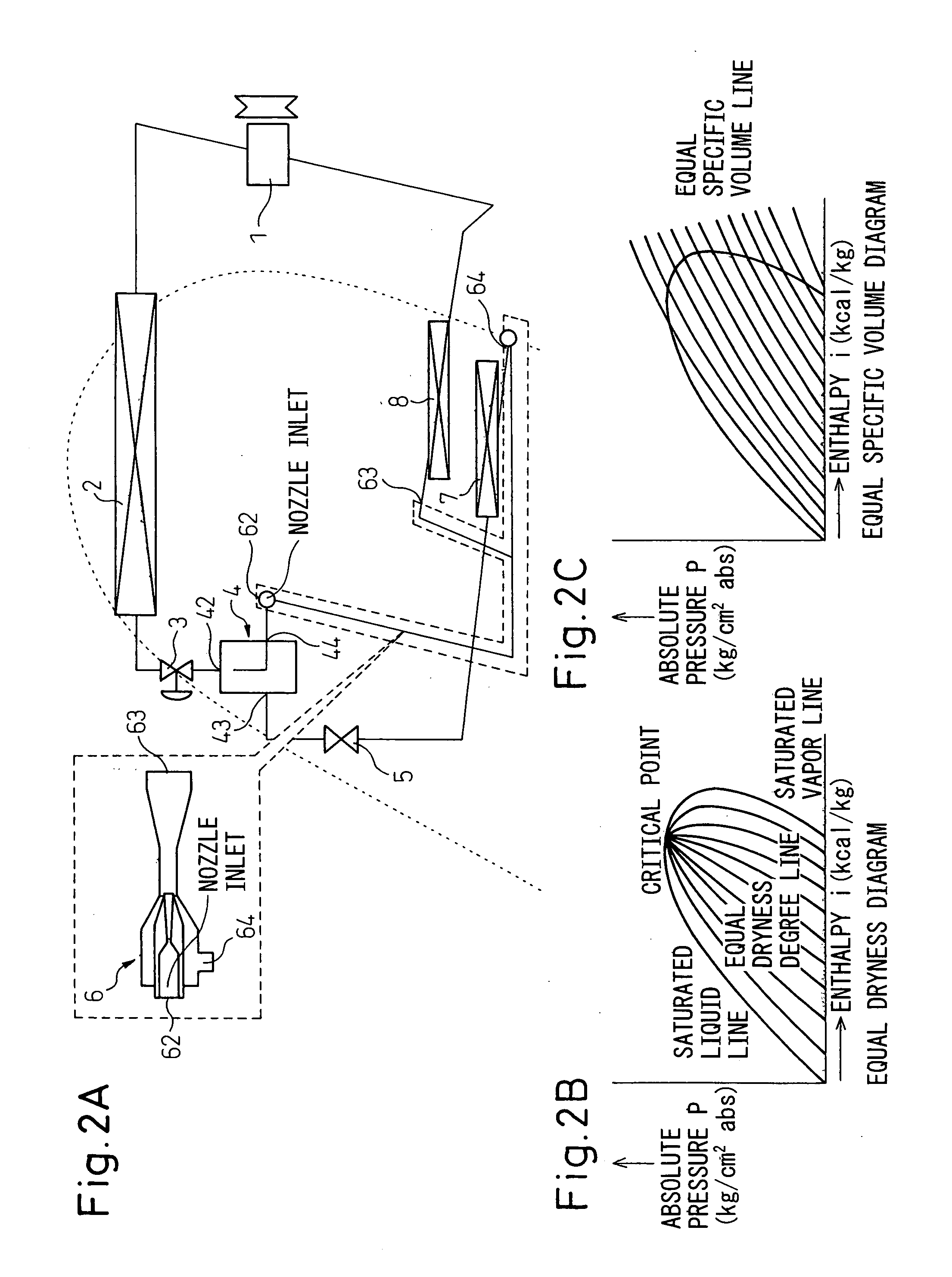

[0029] An embodiment of the ejector-type cycle according to the present invention is explained in detail below with reference to the drawings. FIG. 1 is a diagrammatic view for explaining a first embodiment of the ejector-type cycle according to the invention. In this embodiment of the invention, the ejector-type cycle is used with the climate control system of a vehicle. In FIG. 1, the component elements identical or similar to those of the conventional ejector-type cycle shown in FIG. 6 are designated by the same reference numerals, respectively.

[0030] The ejector-type cycle 50 according to the first embodiment of the invention shown in FIG. 1 comprises a compressor 1 for compressing the refrigerant, a condenser 2 for condensing a high-temperature, high-pressure gas refrigerant, a first orifice mechanism 3 for decompressing the high-temperature, high-pressure refrigerant at the outlet of the condenser 2, a dryness degree adjusting mechanism 4 for separating the refrigerant decomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com