Assembling type sectional shelf structure

a shelf structure and sectional technology, applied in the direction of folding cabinets, dismountable cabinets, cabinets, etc., can solve the problems of many difficulties, easy wear, and shelves cannot be used, and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

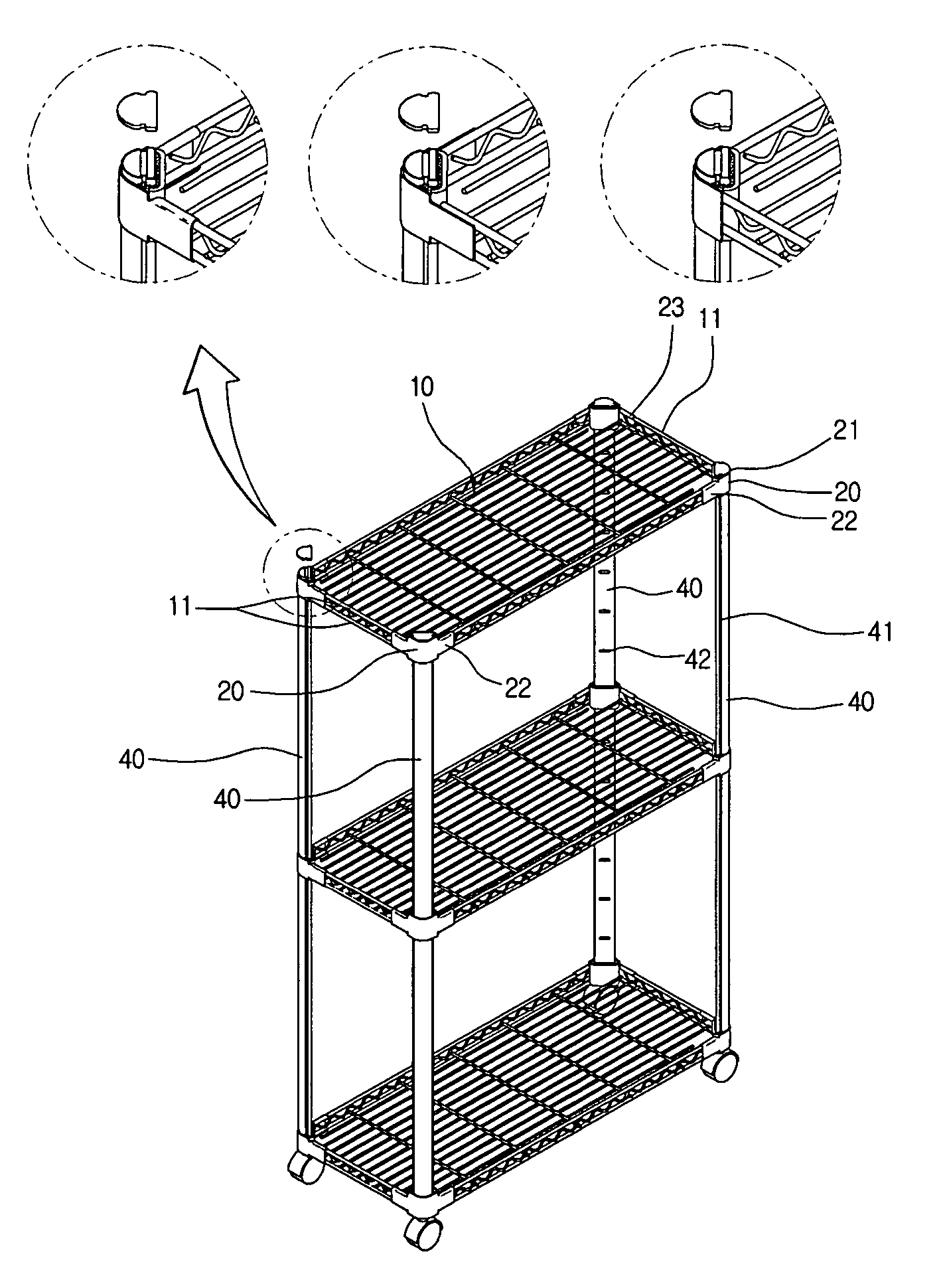

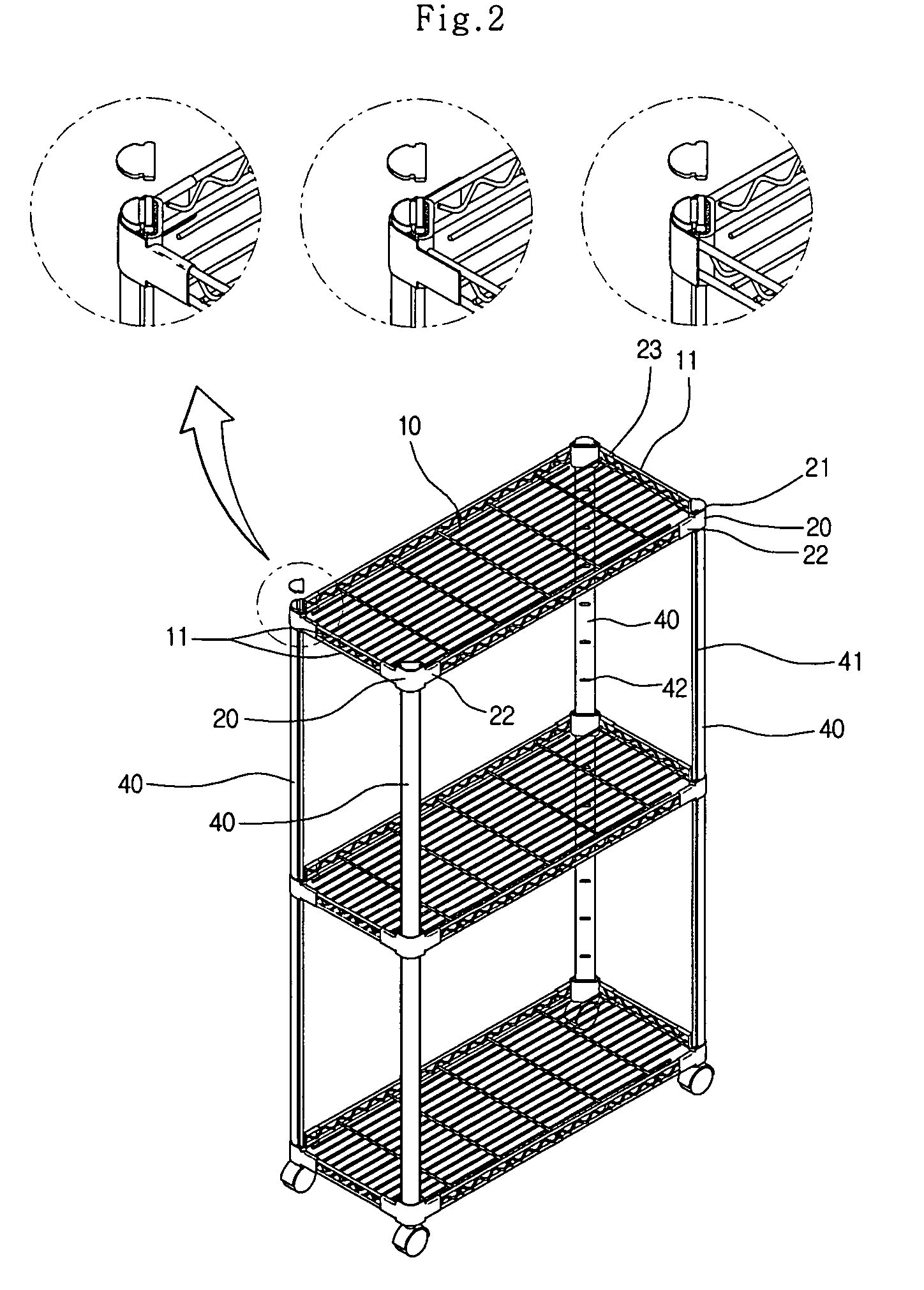

[0018]FIG. 2 is a perspective view illustrating an assembled shelf structure according to the present invention, FIG. 3 is a disassembled perspective view illustrating major elements of an assembling type shelf structure according to the present invention, FIG. 4 is a perspective view illustrating the engaged portions of an assembling type shelf structure according to the present invention, and FIG. 5 is a plane view illustrating the engaged portions of an assembling type shelf structure according to the present invention.

[0019] The preferred embodiments of the present invention will be described with reference to FIGS. 2 through 5. The assembling type self structure according to the present invention includes a plurality of selves 10, with each self being formed in a rectangular prism shape having an opened upper side.

[0020] The assembling members 20 assembled at the corner portions of the opposite sides of the shelves 10 include triangle shaped through holes 21 each having narro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| structure | aaaaa | aaaaa |

| shapes | aaaaa | aaaaa |

| heights | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com