Bottle with retained ring finish feature

a bottle finish and retainer technology, applied in the direction of closures using stoppers, liquid handling, caps, etc., can solve the problems of unfavorable user disposal of ratchet rings and unsightly crusts, and achieve the effect of preventing the ratchet rings from falling off with friction resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

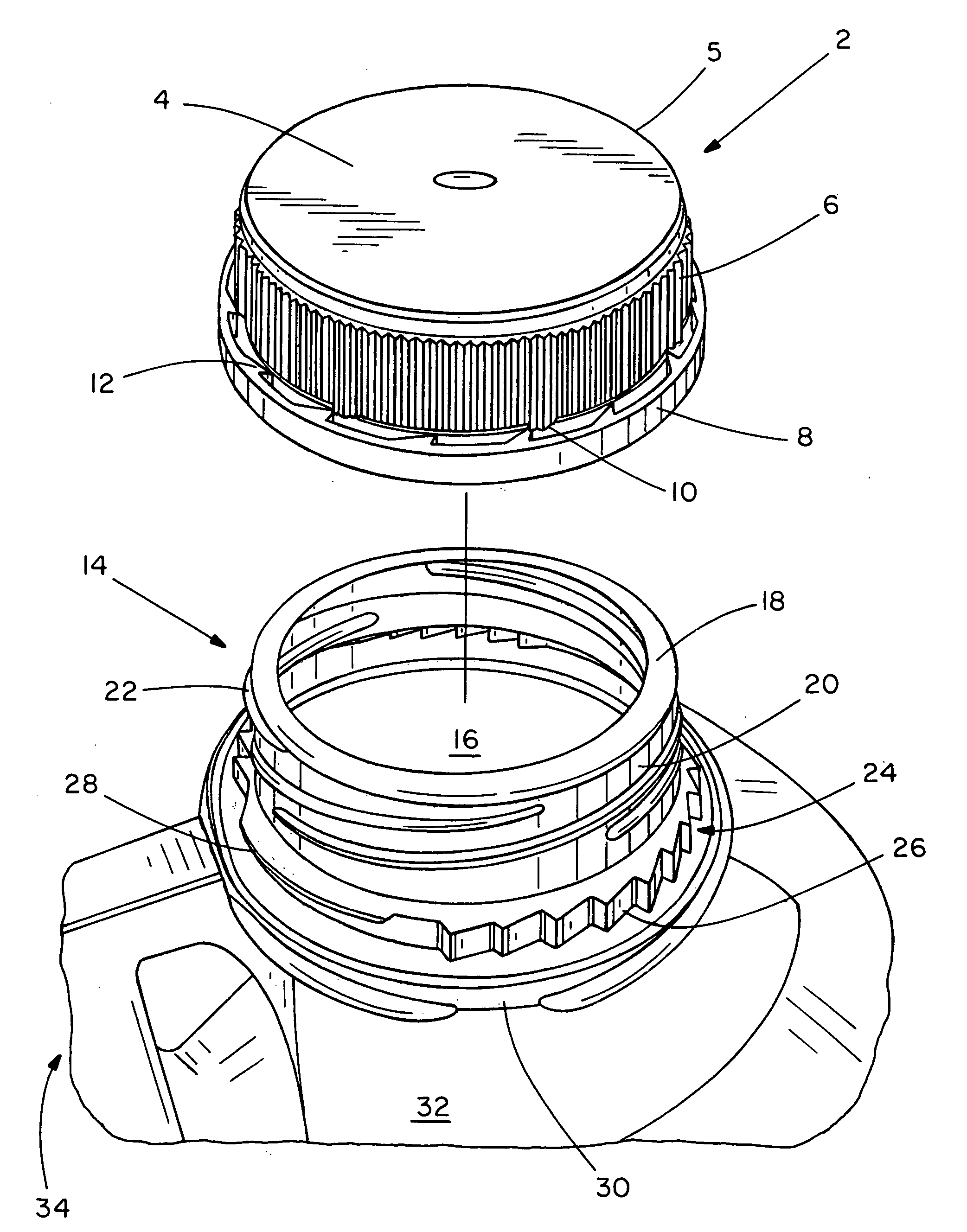

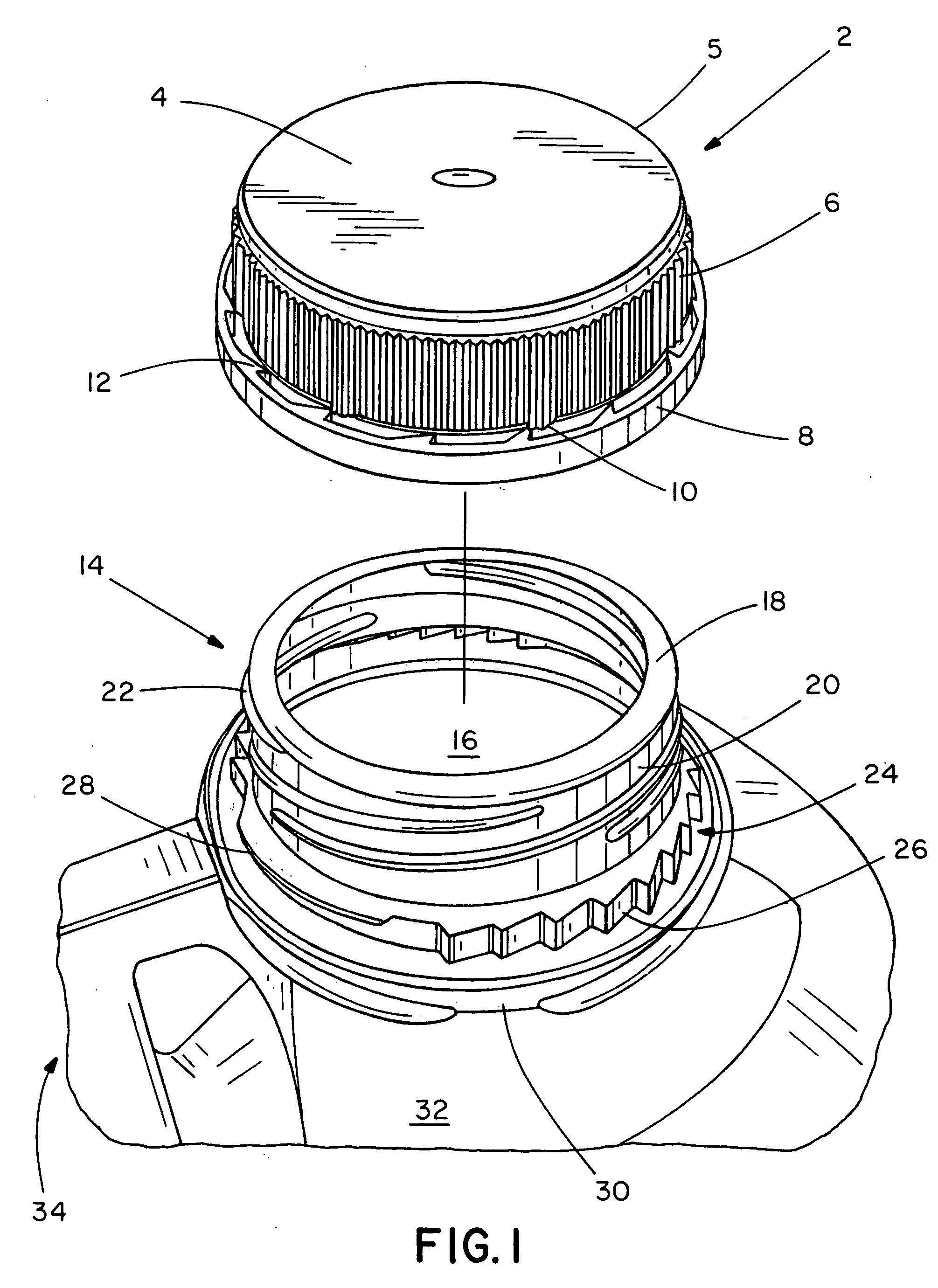

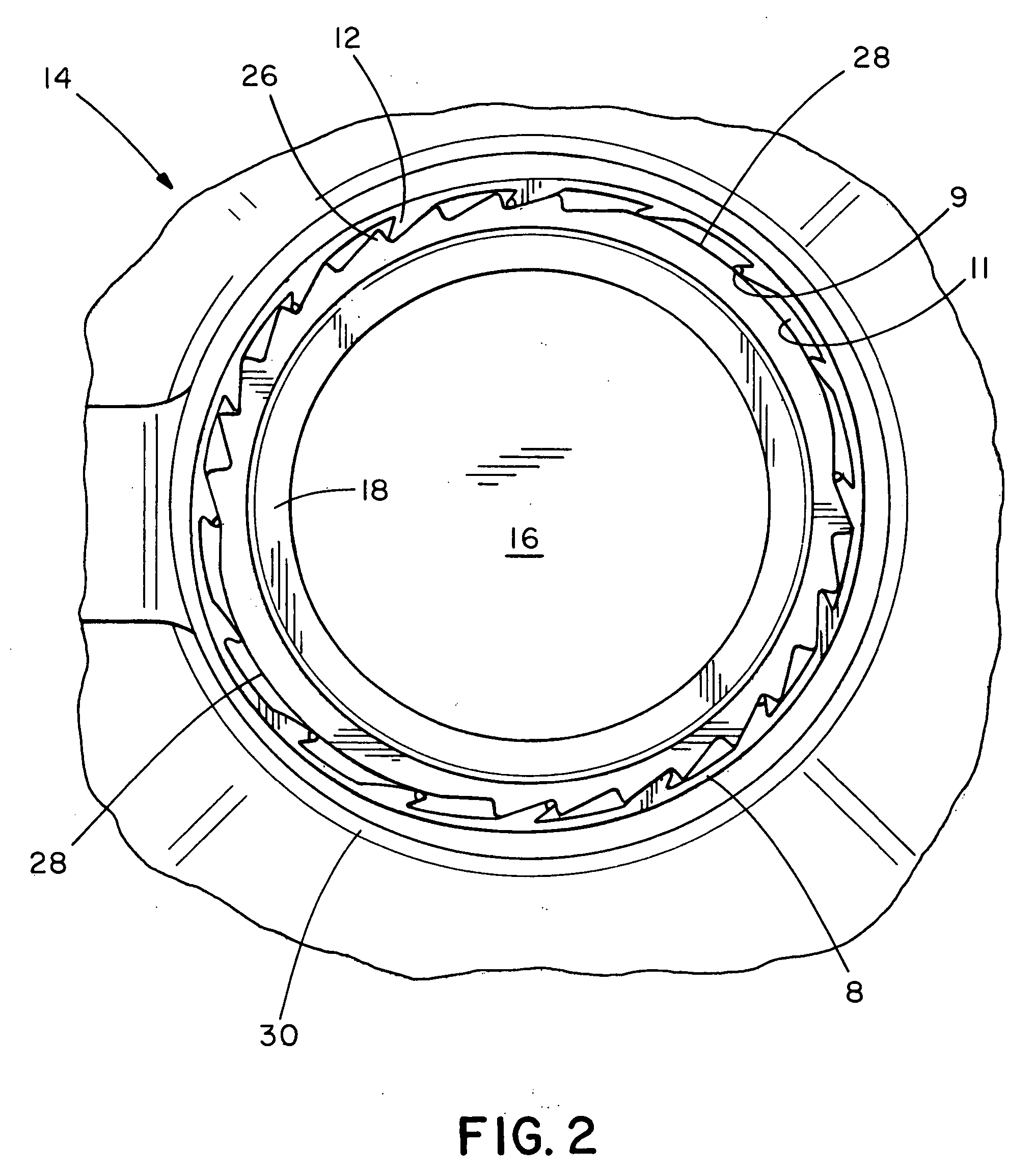

[0029] It may be necessary to modify the standard cap 2 described herein to allow for an interference engagement between the bottle neck 14 and ratchet ring 8. The ratchet ring 8 of the standard cap 2 is generally placed nearly flush against the bottom edge 44 of the cap 2, as shown in FIG. 4. Such flush placement of the ratchet ring 8 would prevent the projection from extending between the cap 2 and the ring 8. Accordingly, in a first embodiment to the modified cap 2, as shown in FIG. 5, elongated frangible connections 46 are utilized to increase the gap between the ratchet ring 8 and the bottle cap 2. Whereas the prior art connections extend between the outwardly extending tabs and the internal ratchet teeth 12, the frangible connections 46 of the present invention preferably extend between the outwardly extending tabs 10 and the upper surface 42 of the ratchet ring at approximately the interface 48 between the internal teeth 12 and the ratchet ring band 50. The frangible connecti...

second embodiment

[0030] the modified bottle cap 2 is depicted in FIG. 6. FIG. 6 is a side view of the bottle cap 2 with a partial cut away showing the inside surfaces of the bottle cap 2 and ratchet ring 8. The ratchet ring 8 is maintained nearly flush to the bottom surface 44 of the bottle cap 2, but is characterized in that at least one portion of the band 50 is stepped down. As before, every other ratchet tooth 12a is frangibly attached to the tabs 10 by frangible connections 46. However, the band 50 has at least one stepped-down portion 56, each of which are preferably characterized by two ramped segments 52 and a top surface 54. There is at least one stepped down tooth 12b placed on the inside surface of the stepped-down portion 56, each having a height “b.” The remaining teeth 12a have a height “a” which is greater than height “b.” Therefore, a gap is formed between the bottom surface 44 of the cap 2 and the top surface 54 of the stepped-down portion 56 to facilitate engagement between the tee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com