Helmeted lock ring for a sender module closure system for a fuel tank

a technology of helmeted lock and seal, which is applied in the direction of caps, applications, liquid handling, etc., can solve the problems of increasing the criticality of reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

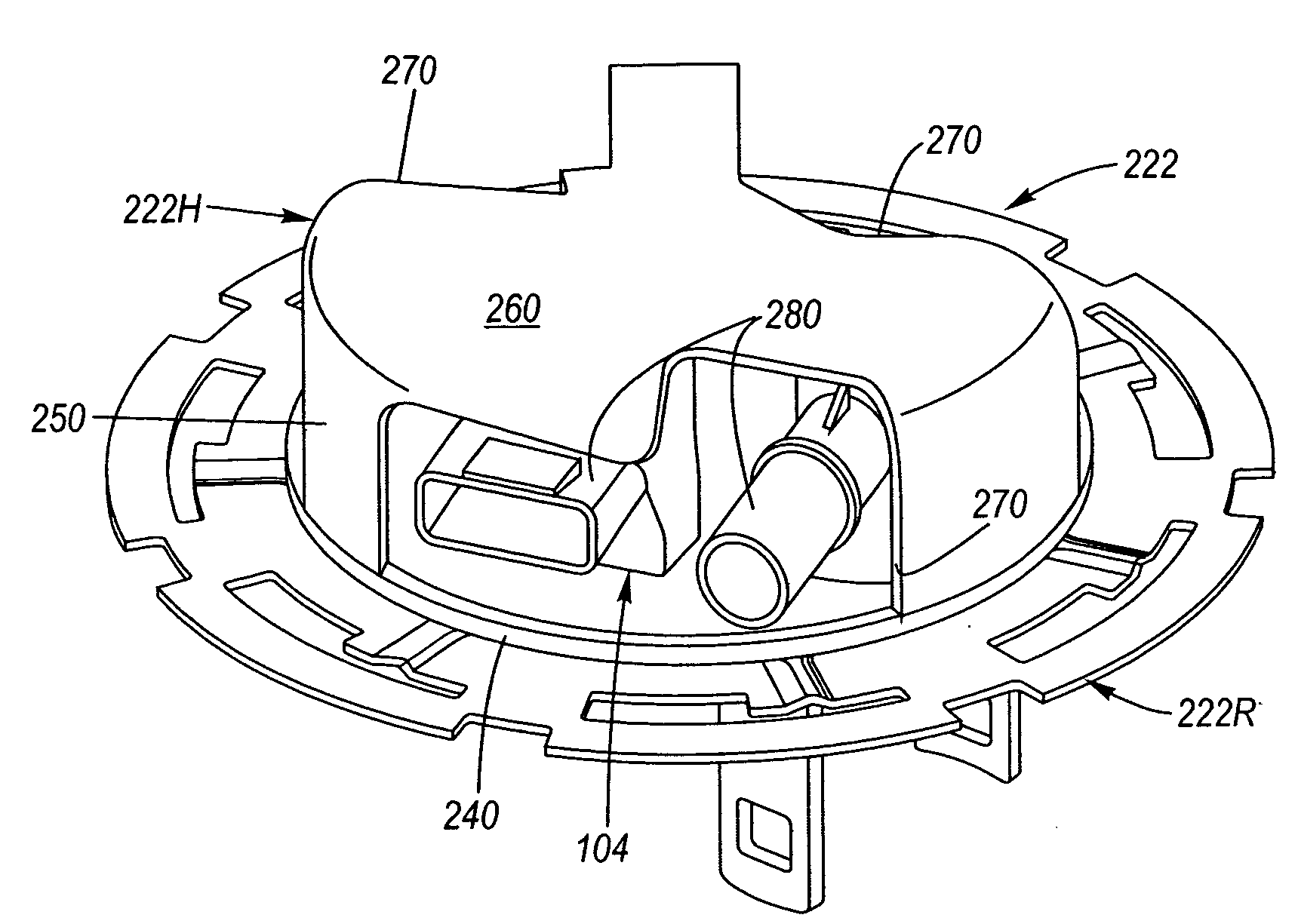

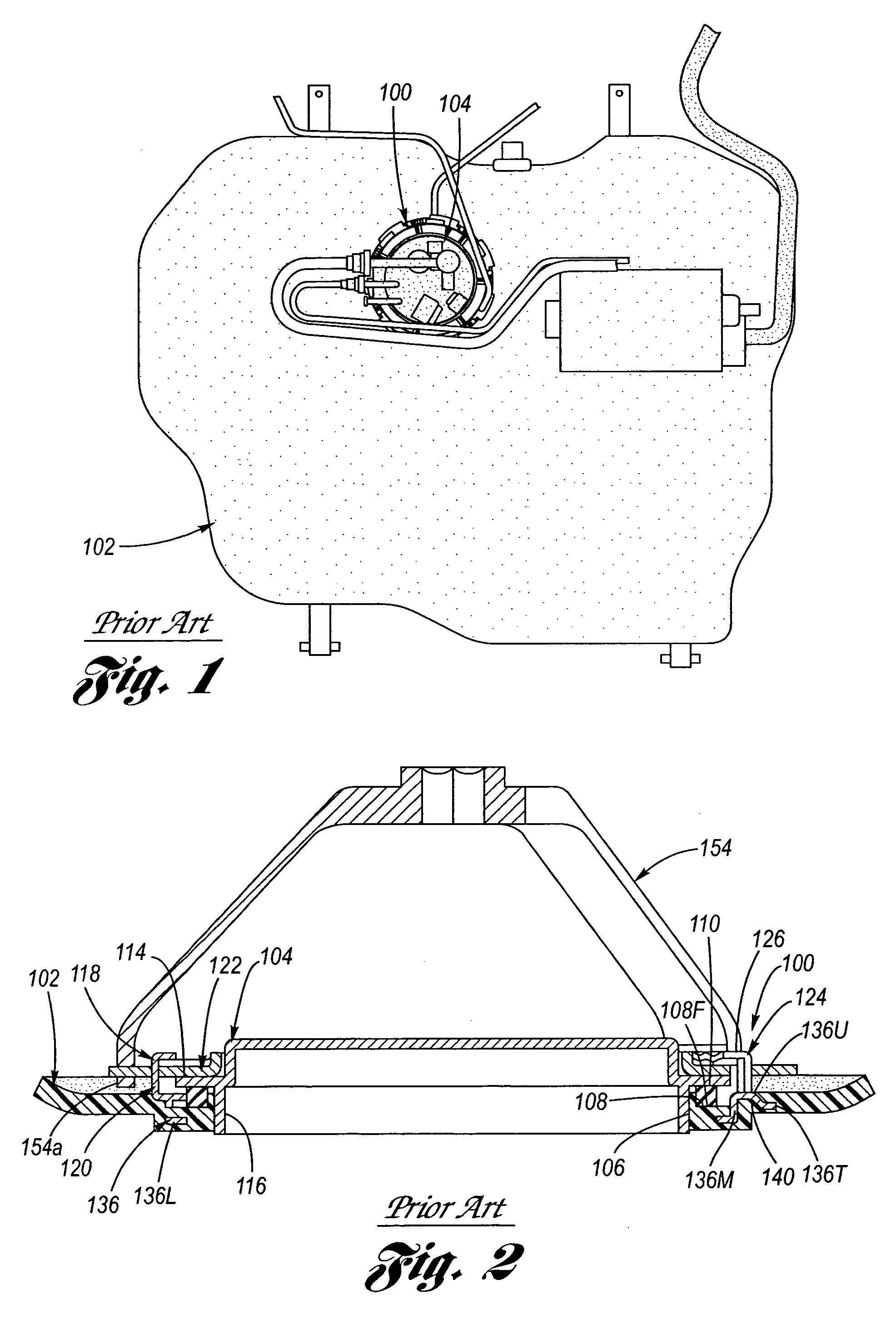

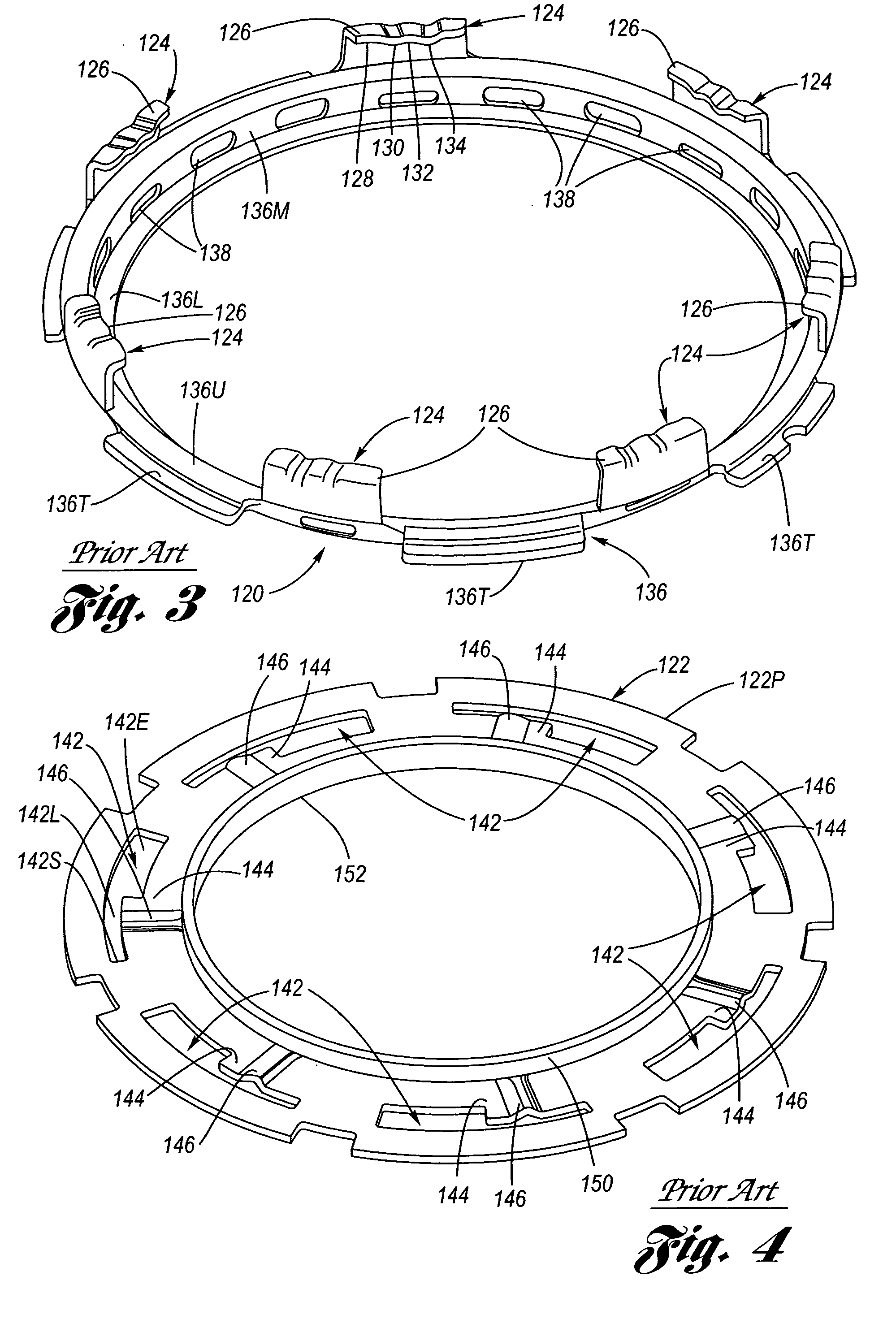

[0062] The present invention is a helmeted lock ring 222, as shown at FIGS. 16 through 21B, which is structured to replace the hereinabove described prior art lock ring 122 to thereby improve the hereinabove described sender module closure system 100. In this regard, the helmeted lock ring 222 has a lock ring component 222R which is structurally and functionally the same as the aforementioned prior art lock ring 122, wherein one may be substituted for the other in the aforesaid sender module closure system. Therefore, the description hereinabove with respect to FIGS. 1 through 15 is applicable to the lock ring component 222R exactly as it is applicable to the prior art lock ring 122, so that the description and reference to FIGS. 1 through 15 in the hereinabove Background of the Invention is fully applicable to the structure and function of the lock ring component 222R with respect to the sender module closure system 100. Accordingly, like components and features as discussed herein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com