Needle for stereographic embroidery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

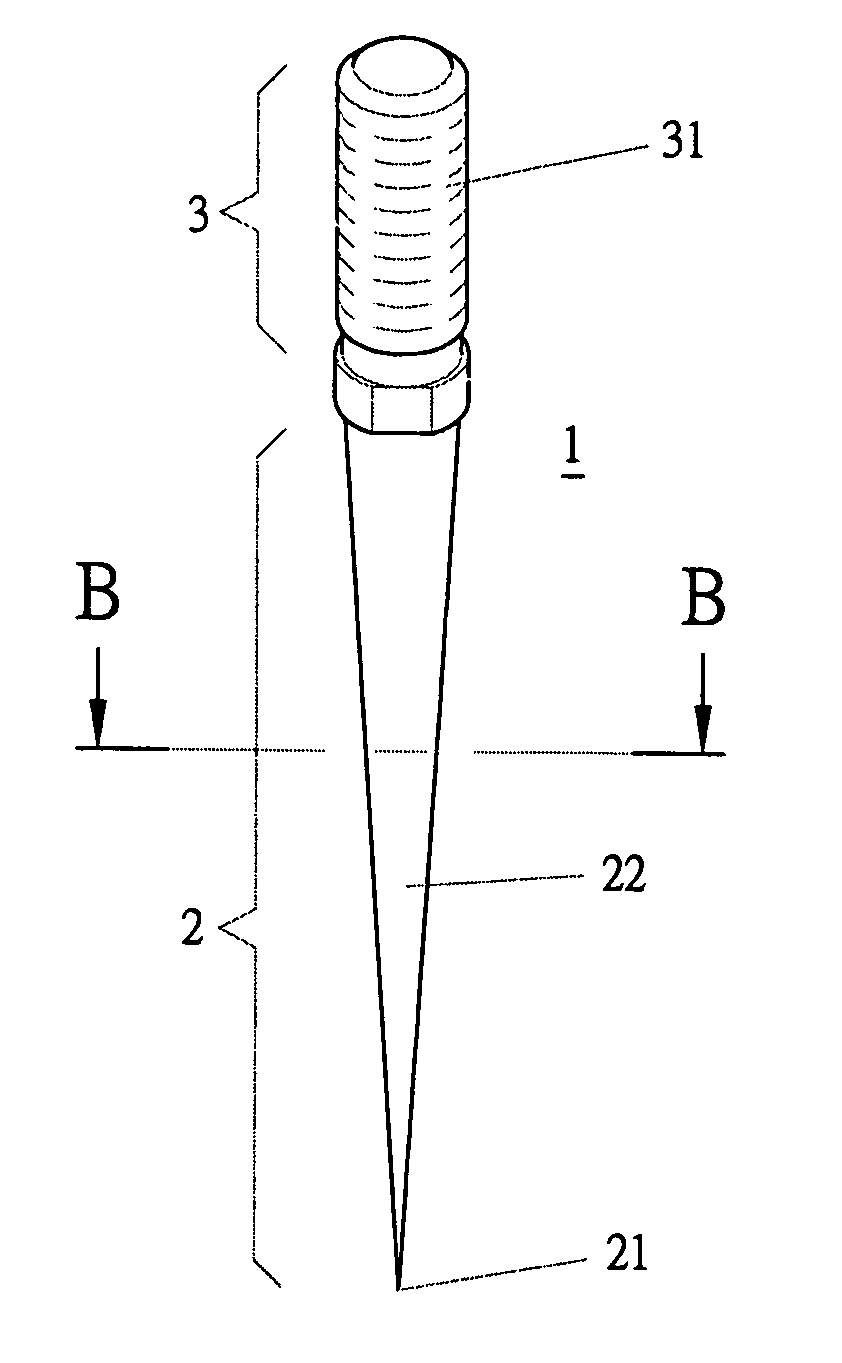

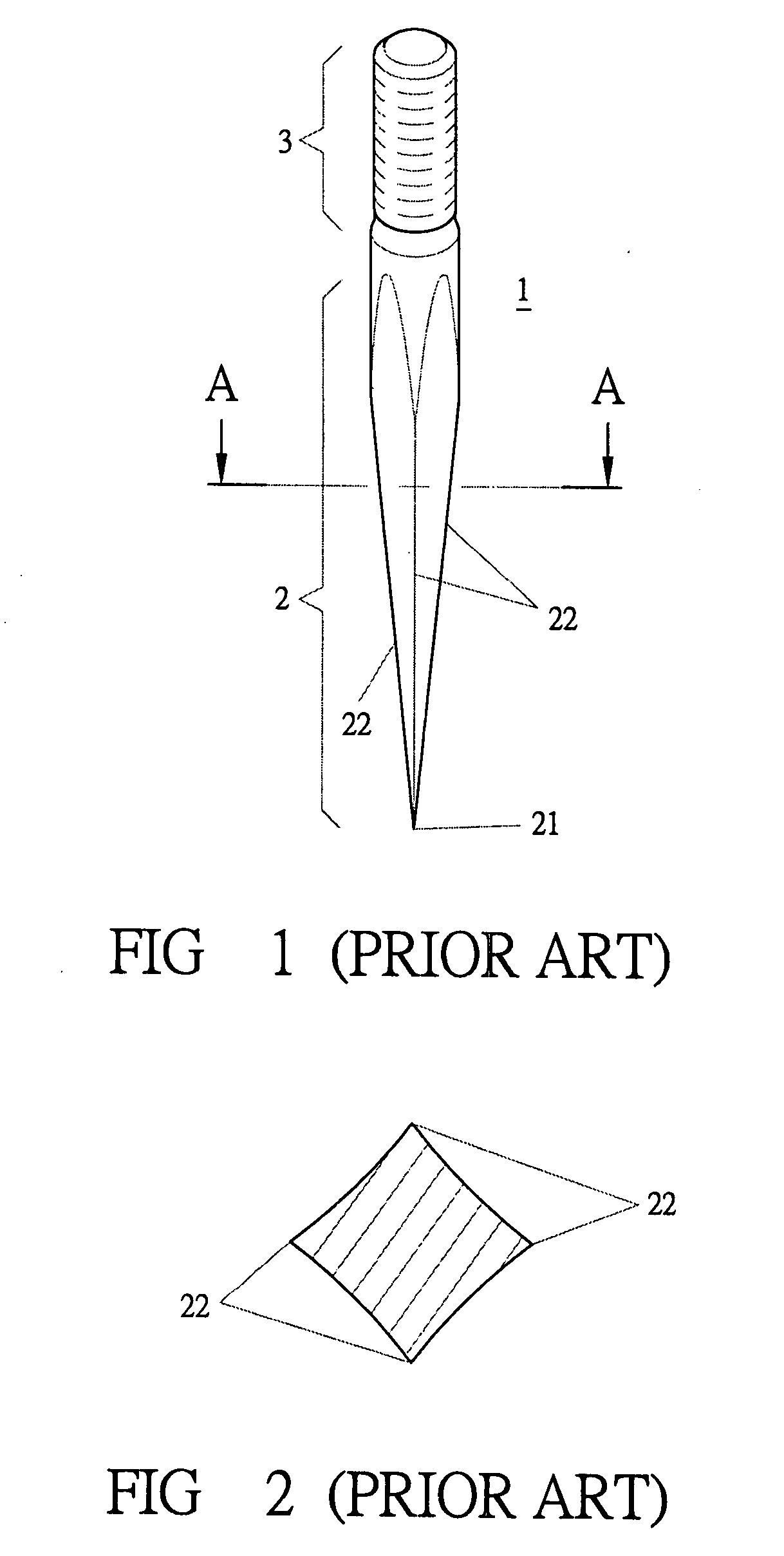

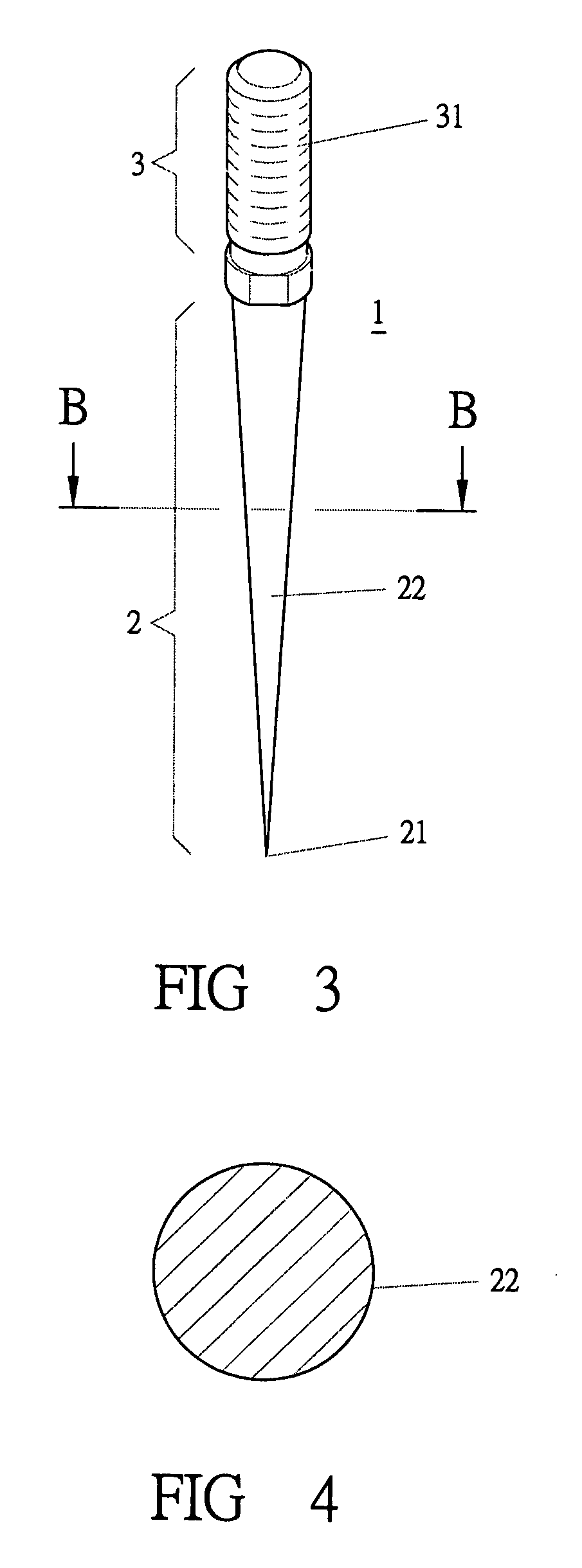

[0022] As shown in FIGS. 3 and 4, a preferred embodiment of a needle for stereographic embroidery in the present invention is mainly composed of a main body 1 which is provided with a tapered drilling part 2 and a fixing pivot 3. The fixing pivot 3 is provided with a thread 31 to screw with an embroidering machine. The tapered drilling part 2 is shaped as a smooth cone having a drilling tip 21 and a drilling circumference 22.

[0023] In using, when the needle in the invention is to drill through a cloth 4, the drilling tip 21 will first pass through a hole 41 in the cloth 4 and, then, the 22 is to squeeze yarns 42 as shown in FIG. 5, making the yarns 42 become denser. Next, while the needle in the invention moves away from the cloth 4, the hole 41 is kept as shown in FIG. 6. By the same time, a wanted picture can be embroidered on the denser yarns 42, which will make the embroidered picture be more vivid and stereographic.

[0024] Furthermore, the tapered drilling part 2 is not merely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com