Stackable plastic container

a plastic container and stackable technology, applied in the field of stackable plastic containers, can solve the problems of difficult stackability of bulky or large plastic containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

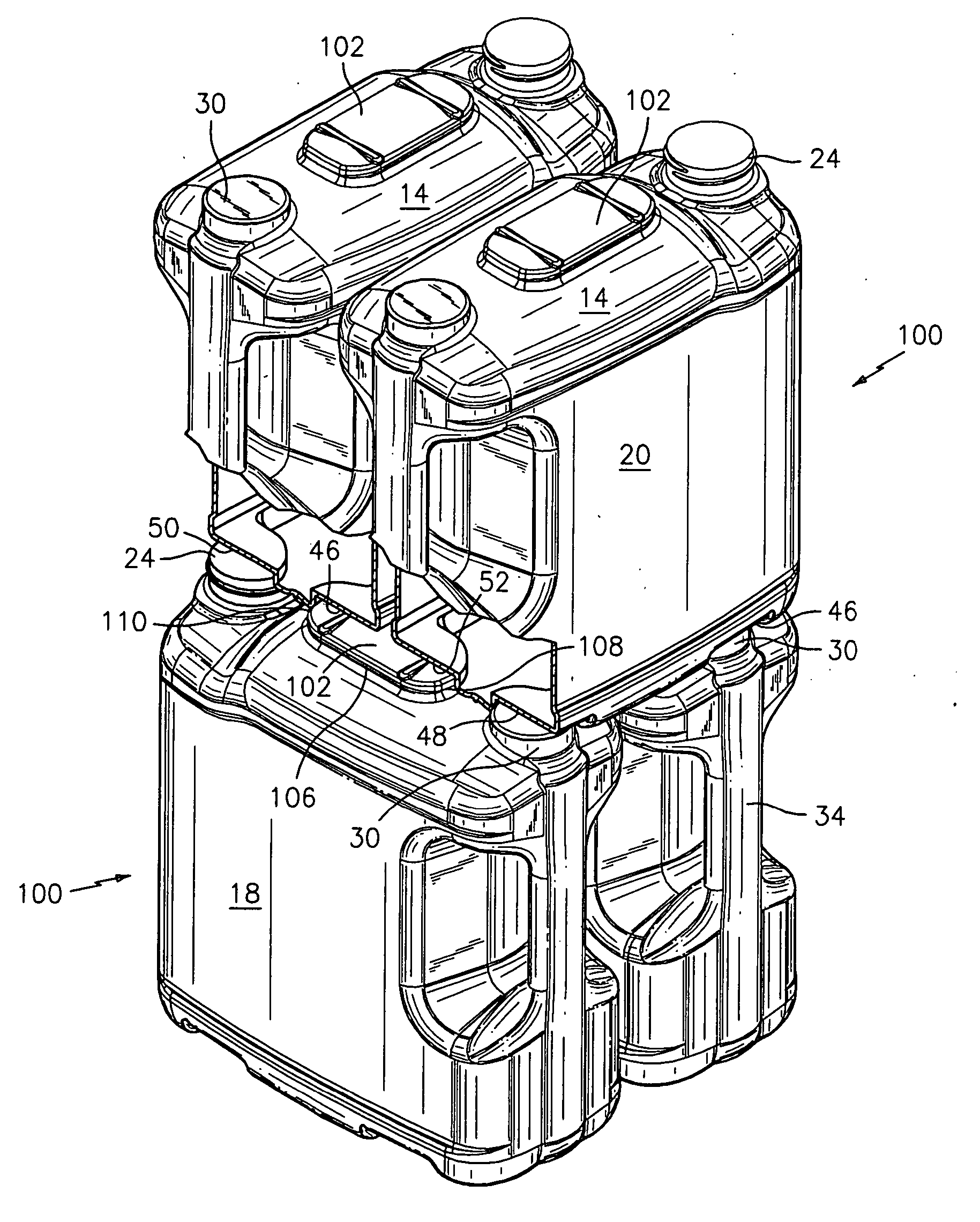

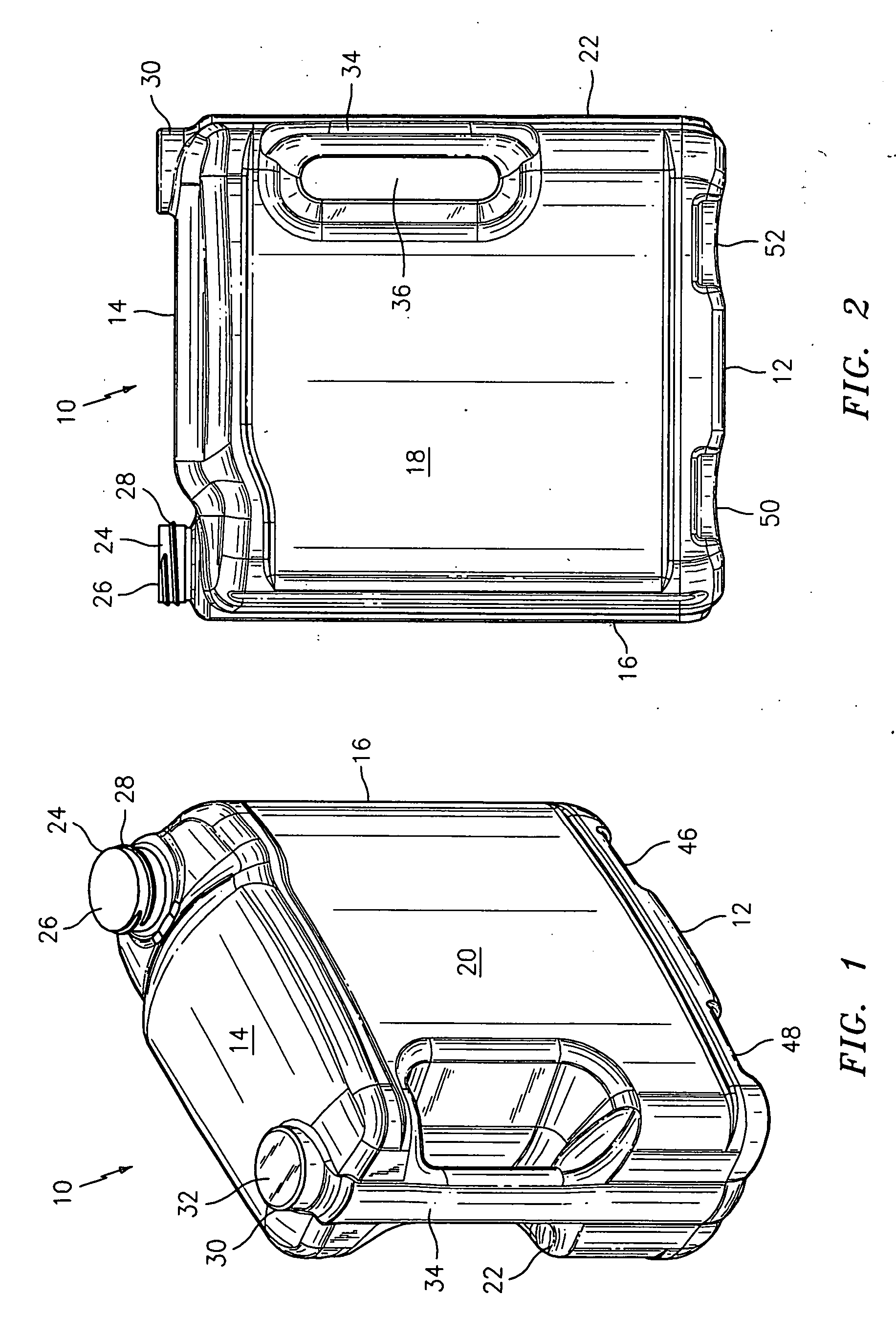

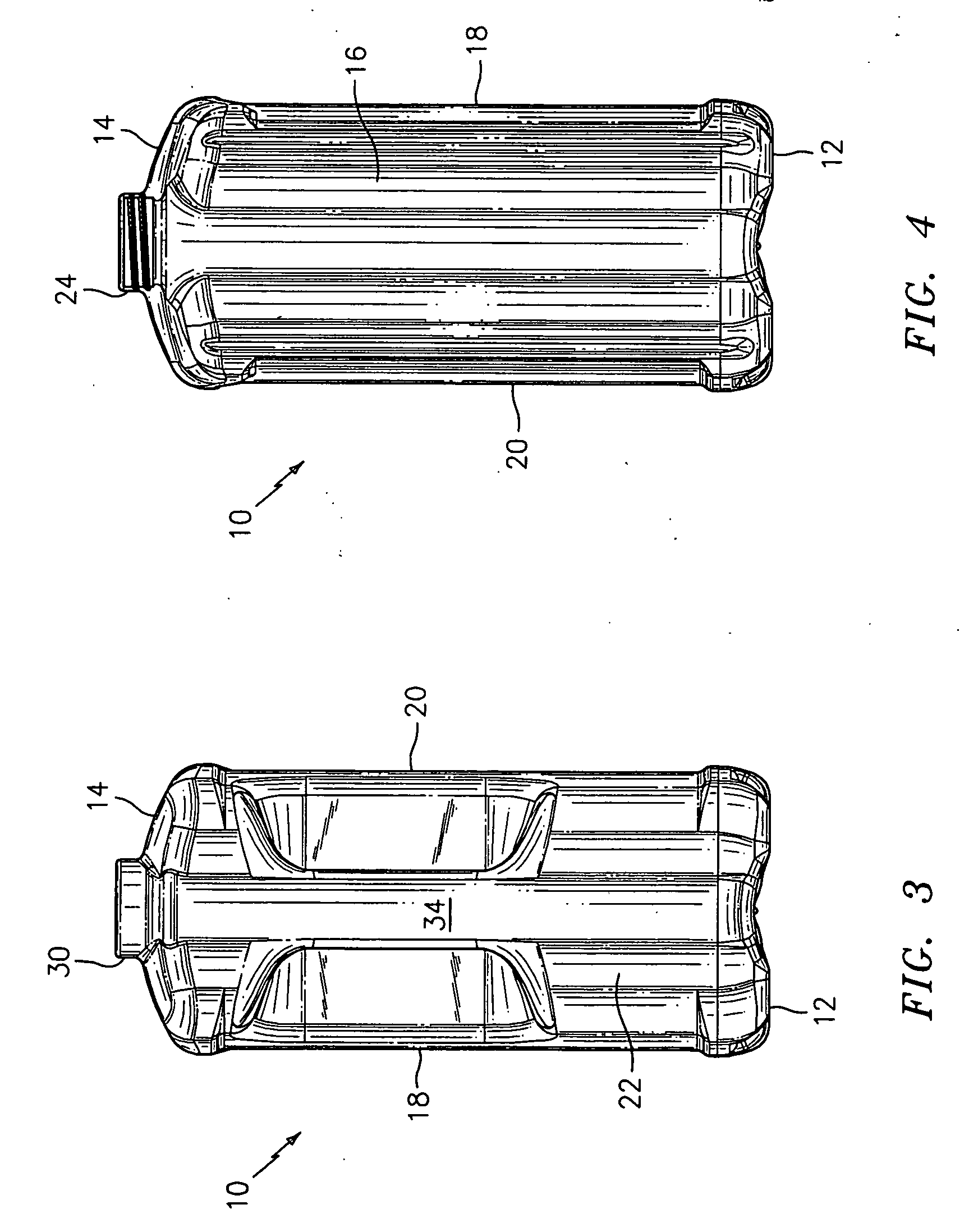

[0033] Referring to the drawings, FIGS. 1-6 show one embodiment of the container of the present invention. FIG. 1 shows a perspective view of the container of FIGS. 1-6. As shown in these figures, container 10 is a blow molded plastic container having a bottom or base portion 12, a top or finish portion 14 opposite the bottom portion, and four side wall portions extending therebetween, namely front side portion 16 (see FIG. 4), right side portion 18 (see FIG. 2), left side portion 20 (see FIG. 1), and rear side portion 22 (see FIG. 3). The side portions extend downwardly from the top or finish portion 14 and interconnect the top portion to the base or bottom portion 12 to provide a container 10 with an essentially rectangular configuration which is preferred. That is, the container 10 has two longer sidewall portions, right side portion 18 and left side portion 20, which alternate with two shorter sidewall portions, front side portion 16 and rear side portion 22. However, while this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com