Leak detector for process valve

a technology of leak detector and process valve, which is applied in the field of leak detector, can solve the problems of ruining the batch, hazard for plant personnel, and high cost of both results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention describes techniques for monitoring tight shut-off valves for leakage when the valves are in a fully closed position. Such tight shut-off valves are typically used in steam or other high-energy gas or liquid delivery systems within industrial processes.

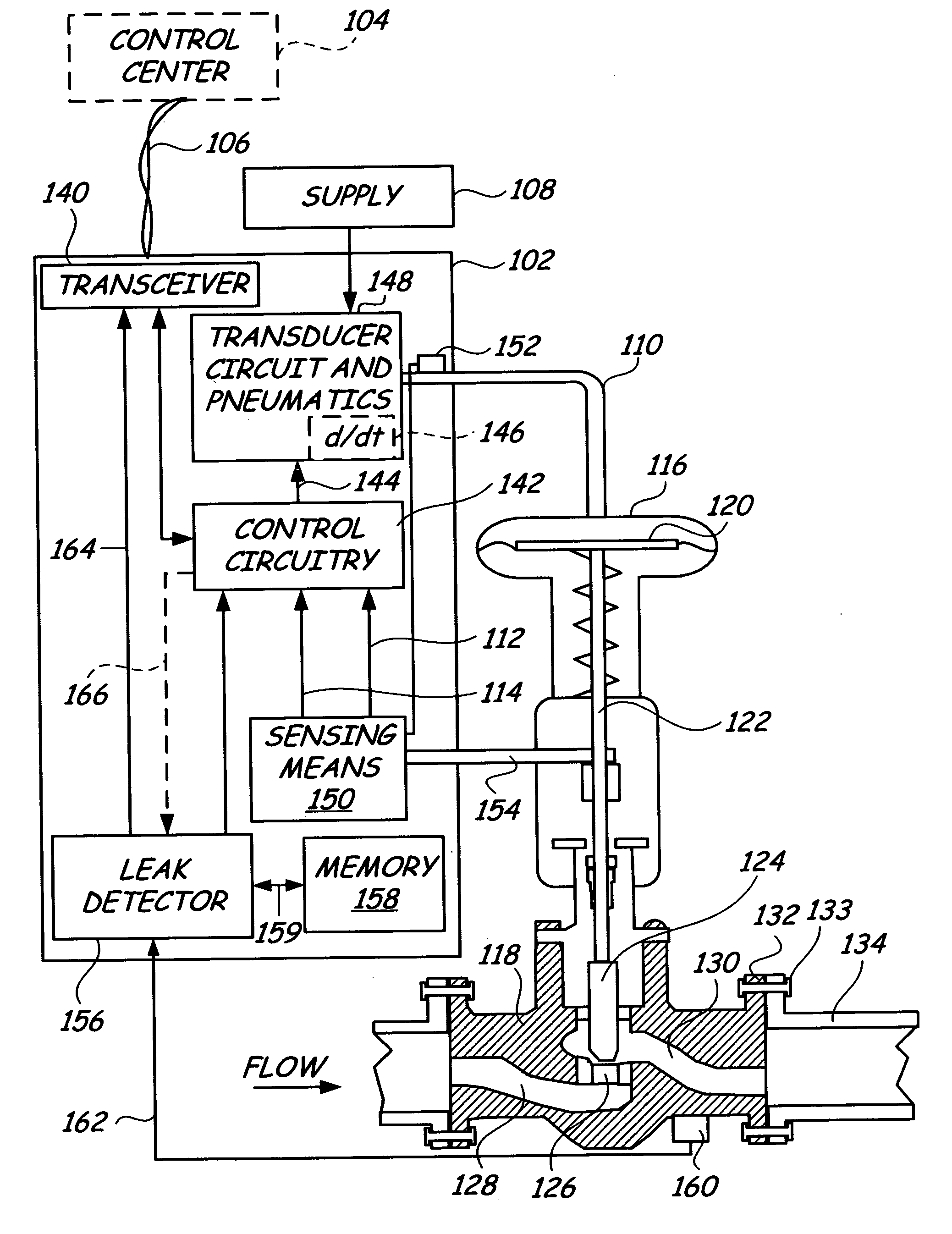

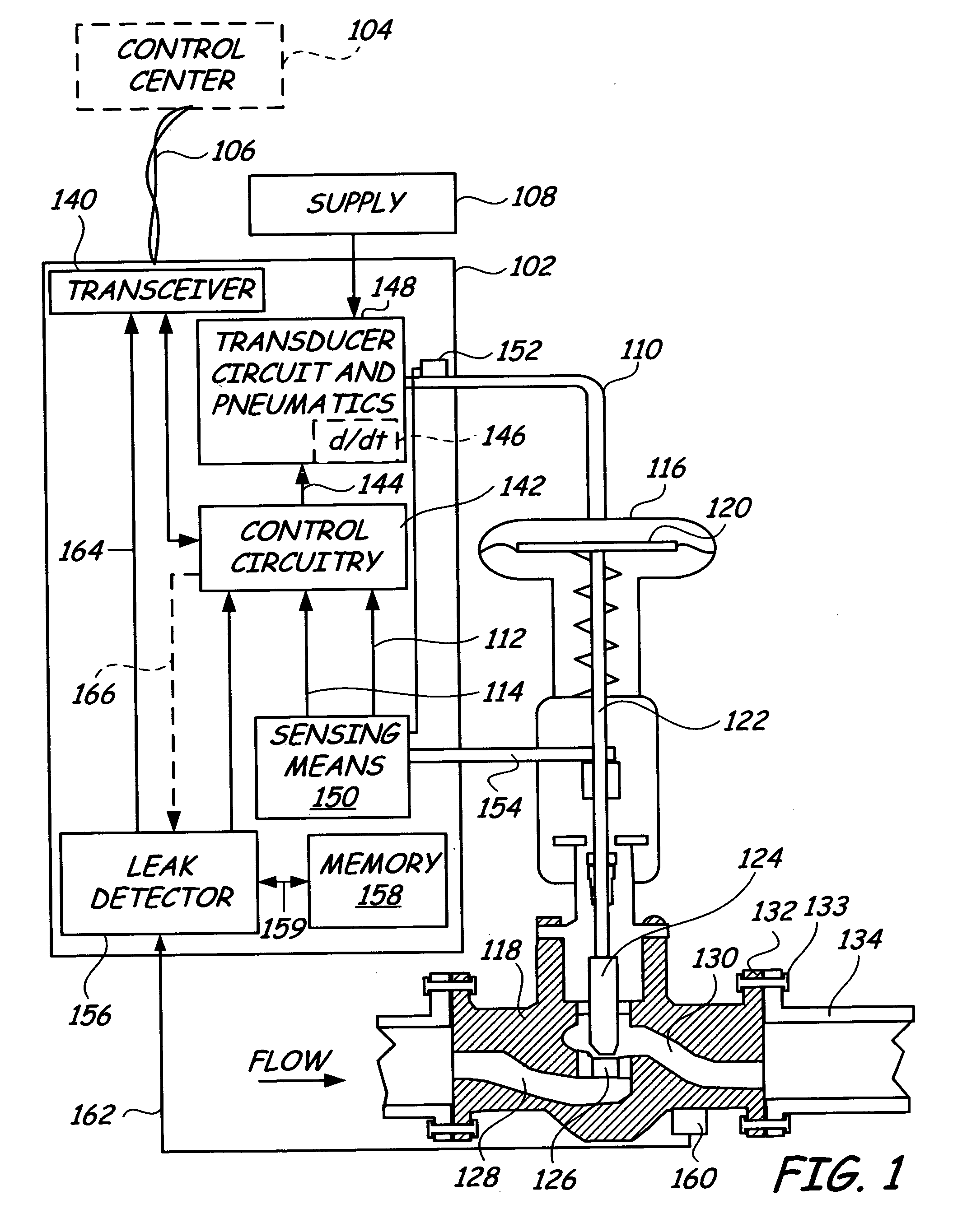

[0019]FIG. 1 is a simplified block diagram of tight shut-off valve assembly 100 with a positioner / transmitter 102 adapted to open and close the valve. Generally the control room 104 transmits a desired valve position signal to valve positioner / transmitter 102 over a two-wire current loop 106. Other communications loops may also be used, including three-wire and four-wire current loops, as well as wireless communication links.

[0020] Positioner 102 receives a supply of pneumatic air 108 and provides a control pressure 110 as a function of the desired valve position set point from the control center 104 and two variables: the derivative of the control pressure signal 112 and a sensed position signal 114. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com