Sectional three-dimensional model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

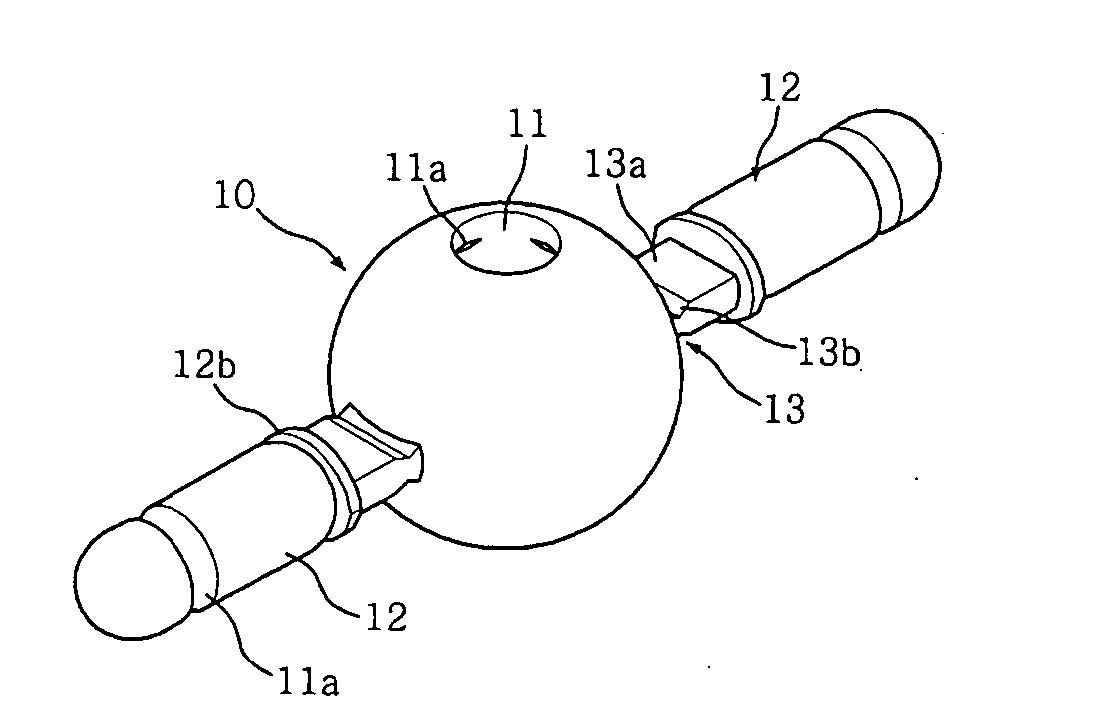

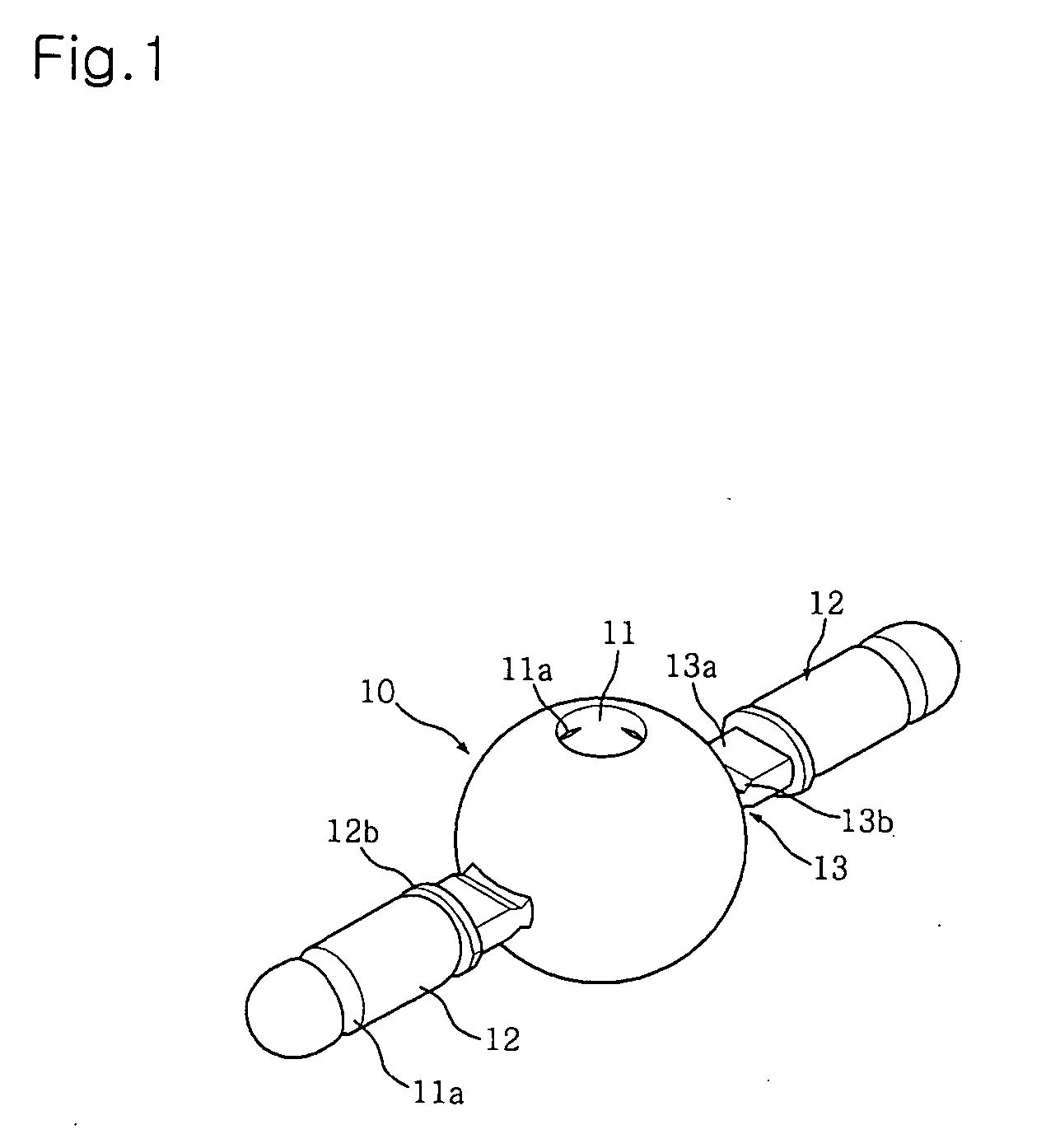

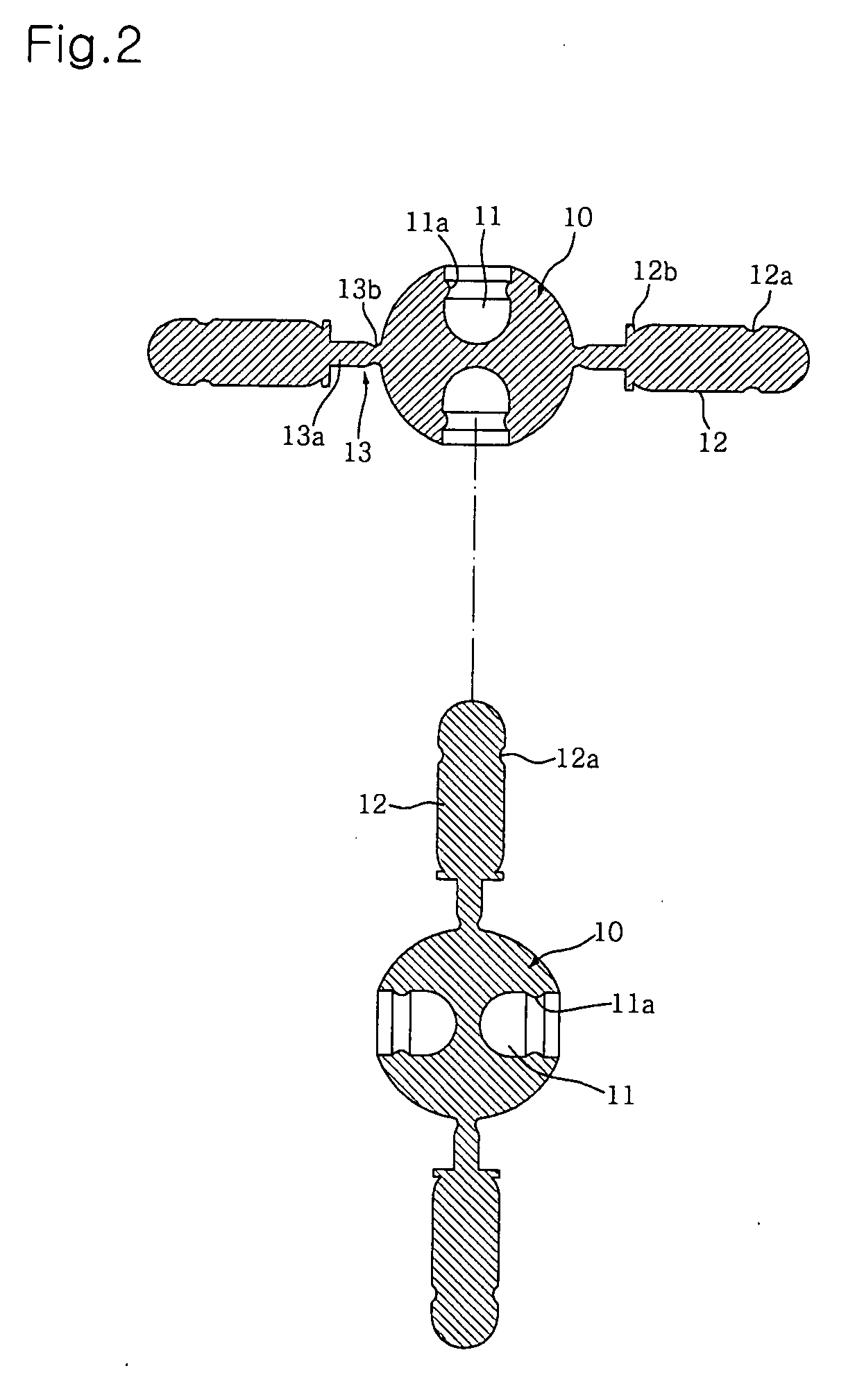

[0039]FIG. 1 is a perspective view illustrating one piece of a sectional three-dimensional model according to the present invention.

[0040] As shown in FIG. 1, the sectional three-dimensional model according to the first embodiment of the present invention includes a plurality of spherical pieces 10, and each spherical piece 10 has a pair of coupling recesses 11 and a plurality of coupling protrusions 12. The pair of coupling recesses 11 are symmetrically formed in the spherical piece 10 along the center axis of the spherical piece 10, and the plurality of coupling protrusions 12 are arranged in directions perpendicular to the coupling recesses 11. With this configuration, as the coupling protrusions 12 of one spherical piece 10 are selectively inserted into the coupling recesses 11 of another spherical piece 10, two or more spherical pieces 10 can be connected to one another.

[0041] Each coupling recess 11 of the spherical piece 10 has a semi-spherically dented bottom, and correspon...

second embodiment

[0049]FIG. 9 is a perspective view illustrating a connection pipe according to the present invention, which is partially cut-away. The connection pipe 30 has an inner diameter suitable to be fitted around the coupling protrusion 12 of the spherical piece 10. The connection pipe 30 is internally formed at opposite ends thereof with a pair of annular raised locking portions 30a each corresponding to the locking groove 12a of the associated coupling protrusion 12.

[0050] The connection pipe 30 has a pleated flexible portion 30b formed at approximately the center portion thereof. Providing the connection pipe 30 with the flexible portion 30b allows free bending of the connection pipe 30, and thus, is advantageous to assemble a curved model. Furthermore, the connection pipe 30 having the flexible portion 30b is length adjustable. Accordingly, for example, the length adjustable connection pipe 30 can be used to constitute a longer length side of a right-angled triangle connecting the remai...

third embodiment

[0051]FIGS. 10A to 10C illustrate a connection rod according to the present invention, FIG. 10A being a front view, FIG. 10B being an enlarged view of the circle “A” of FIG. 10A, and FIG. 10C being a sectional view taken along the line B-B of FIG. 10B.

[0052] As shown in FIGS. 10A to 10C, the connection rod 20 is shaped as an elongated bar having a circular cross section. The connection rod 20 has protuberances 21 formed at opposite ends thereof. Each protuberance 21 has the same semi-spherical shape as the end of the coupling protrusion 12 of the spherical pieces 10, so as to be inserted into the coupling recess 11 of the spherical piece 10. To allow the protuberance 21 of the connection rod 20 to be inserted into the coupling recess 11 of the spherical piece 10 without the risk of unintentional separation thereof, the protuberance 21 is formed with an annular locking groove 21a for the engagement of the raised locking portion 11a formed at the inner circumference of the associated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com