Fastener engaging caulking tube nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

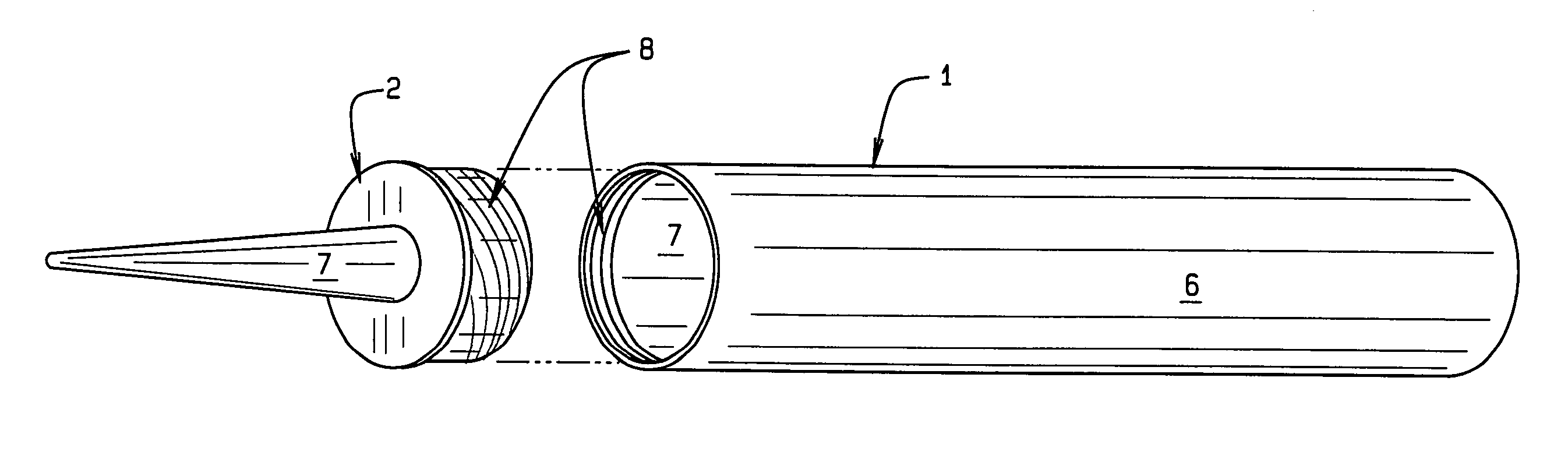

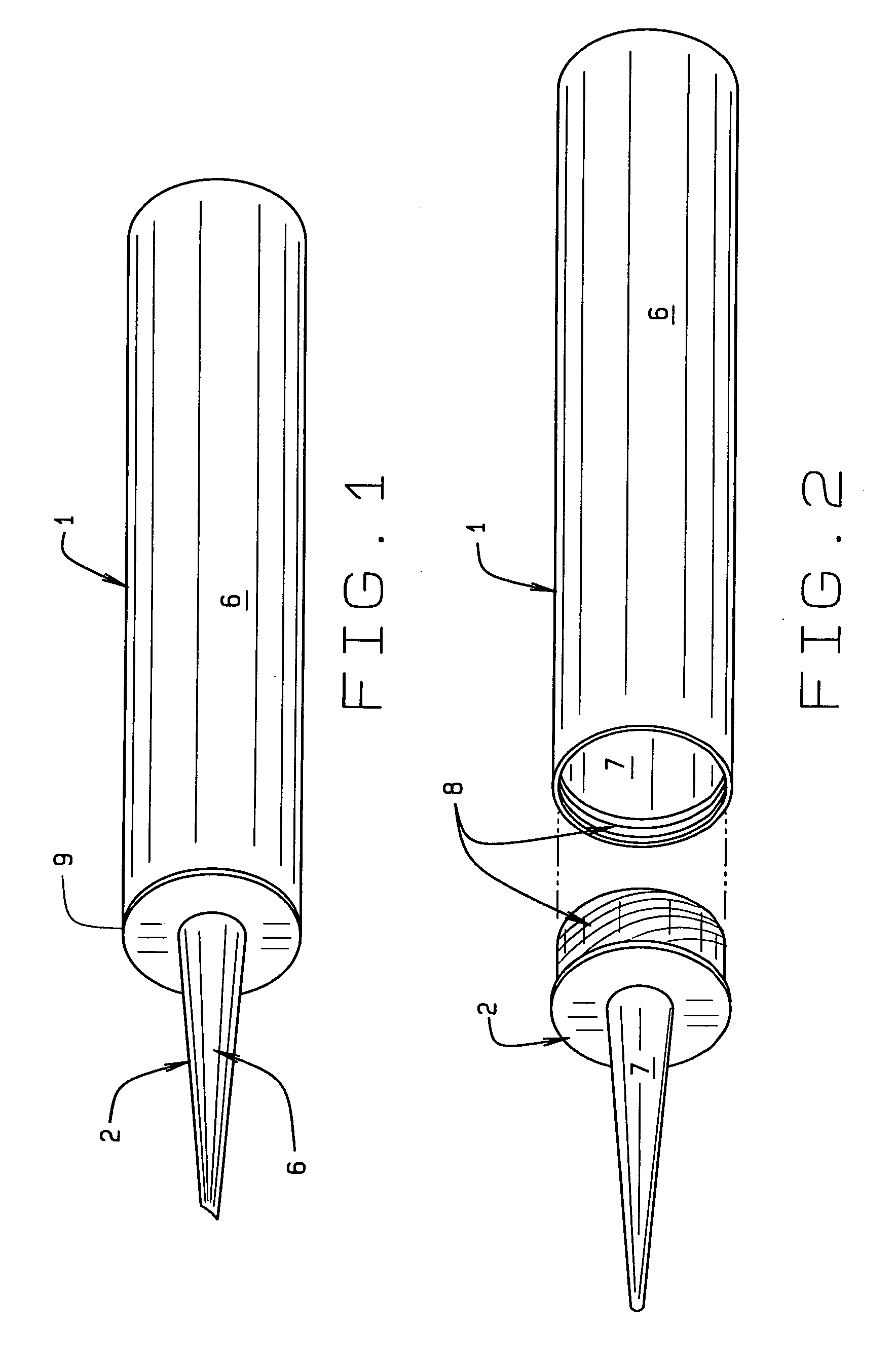

[0017] In referring to the drawings, and in particular FIG. 1, therein is shown a typical cartridge containing caulk or other material 6. Normally, this is a cylinder or tube 1, which holds the supply of caulk, in preparation for usage. The cylinder 1 includes an integrated nozzle 2, onto the top of the standard type of tube, for application to a caulking gun. After the nozzle 2 has been initially cut, and material 6 has been forced from the tube, during usage, as through the nozzle 2, there is normally some remaining amount of material that is left within the upper portion of the tube, and its nozzle, after usage. After prolonged storage, such caulking material can become reasonably hardened, over time, making it impossible to force the remaining material 6 through the nozzle 2, during subsequent usage.

[0018] As can also be seen, the integrated nozzle 2 has a flange 9 that extends out to embrace the upper edge of the tube 1, so as to provide for further sealing at that location, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com