Garbage disposer replacement unit

a garbage disposal and garbage technology, applied in the field of garbage disposal, can solve the problems of overburdening community wastewater systems, excessive food service waste, and environmental problems of restaurant food waste from rinsing dirty dishes, and achieve the effect of reducing the amount of garbag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

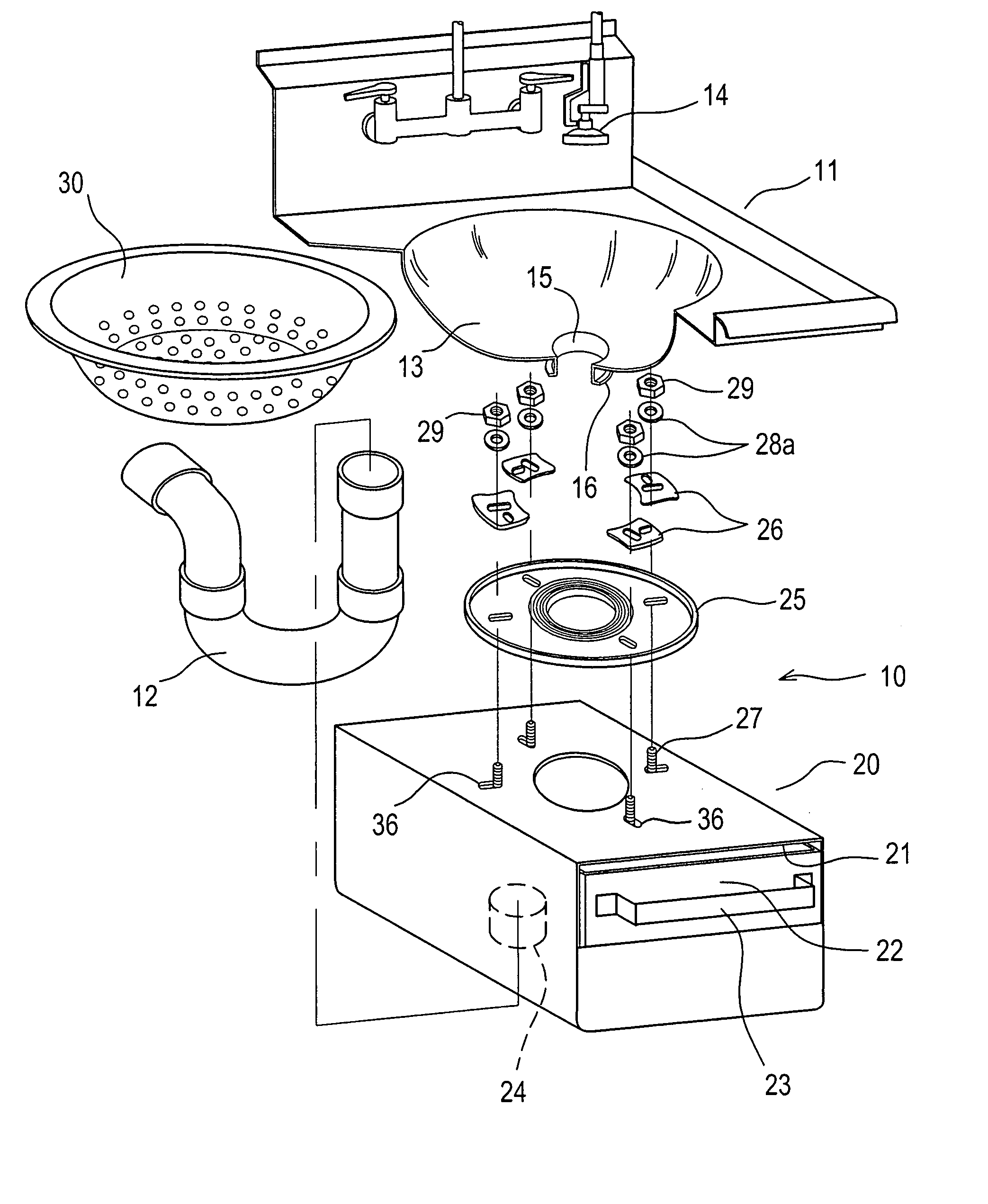

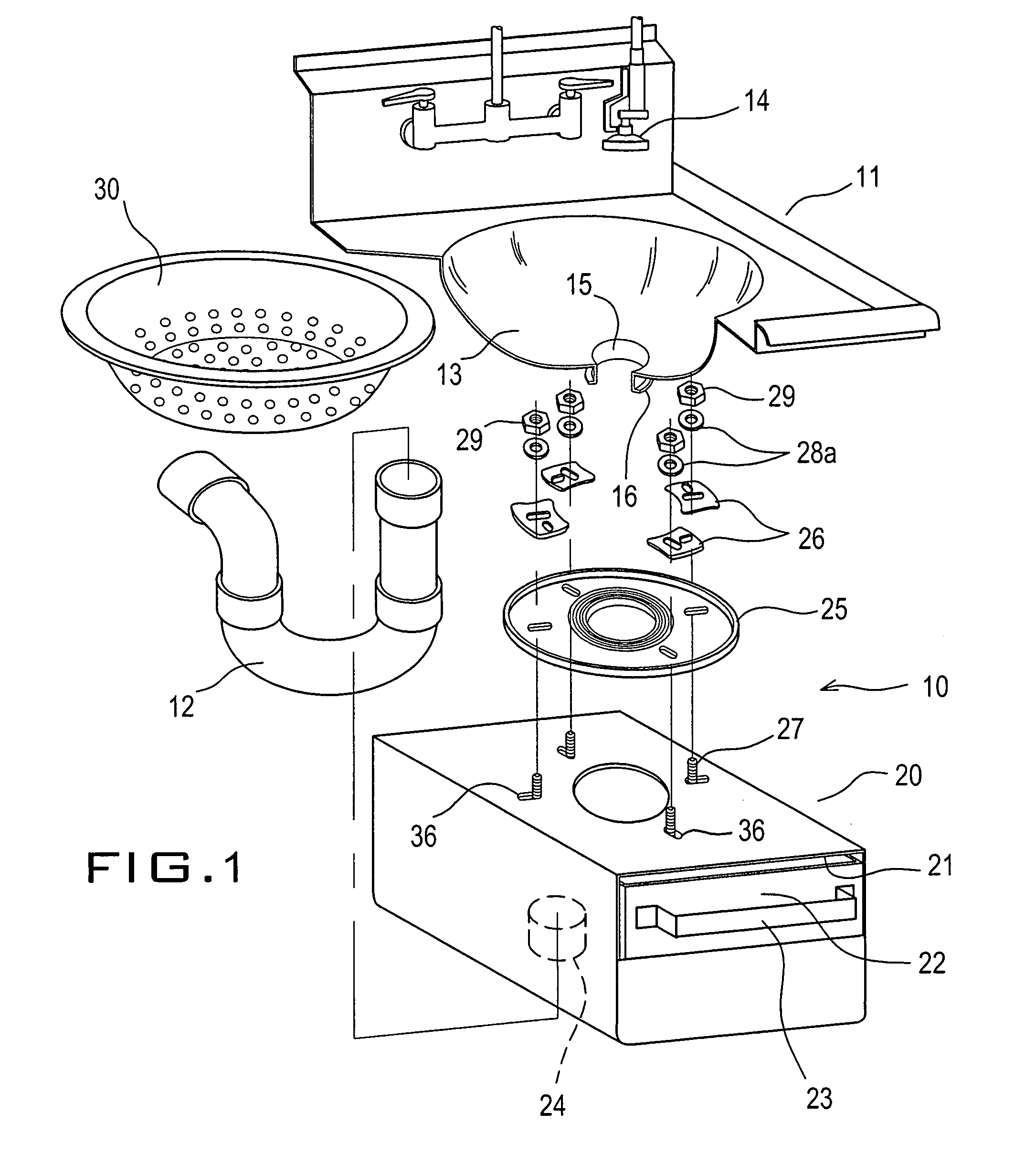

[0023] Referring to FIG. 1, a garbage disposer replacement unit according to the present invention is generally referenced by number 10 and is shown in an exploded view to show its installation to a kitchen sink 11 as well as a wall plumbing 12 typical in any kitchen setting. The kitchen sink 11 has a bus bowl 13 wherein dishes are washed as it drains wastes with running water from a faucet 14. At the bottom enter of the bus bowl 13 is formed a typical drain 15 with certain diameter terminated by outward flanges 16 for installing a waste treatment means such as a motorized garbage disposer, which the inventive sink unit 10 is replacing.

[0024] Different bus bowls with various drain diameters have produced and are available in the market. For, example, small drains are sized 3½″, 4″, 4½″, 5″, 5½″, 6″, and 6½″. Bigger drains include diameters of 7½″, 8″, 8½″ and 9″.

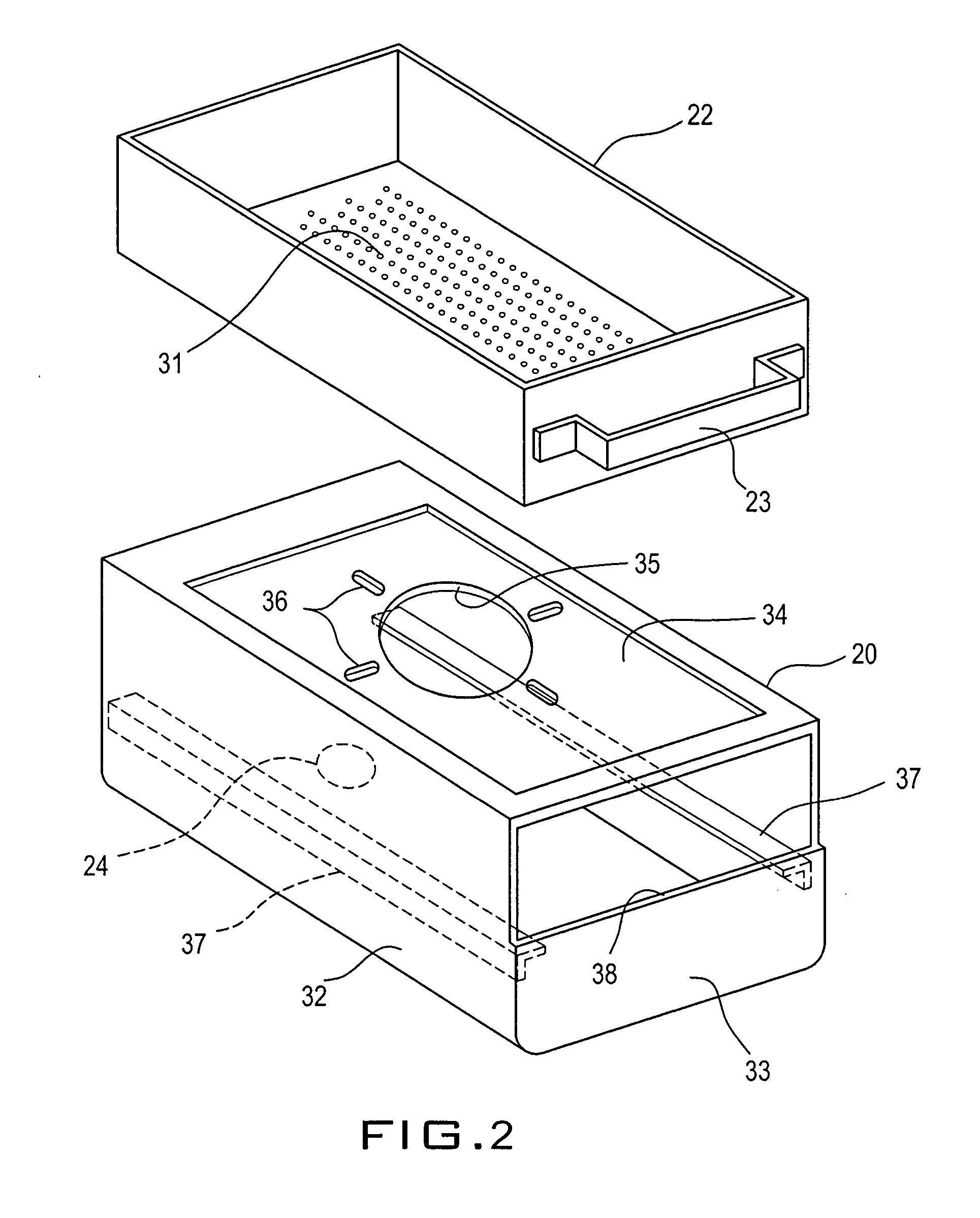

[0025] The garbage disposer replacement unit is also called a sink unit 10. The sink unit 10 comprises a main body 20 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com