Leveling of reflector

a reflector and leveling technology, applied in the field of luminaires, can solve the problems of affecting the performance of the reflector, and the inability to achieve higher reflectances, so as to achieve the effect of increasing the proportion of specularly reflected light from the luminaire and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

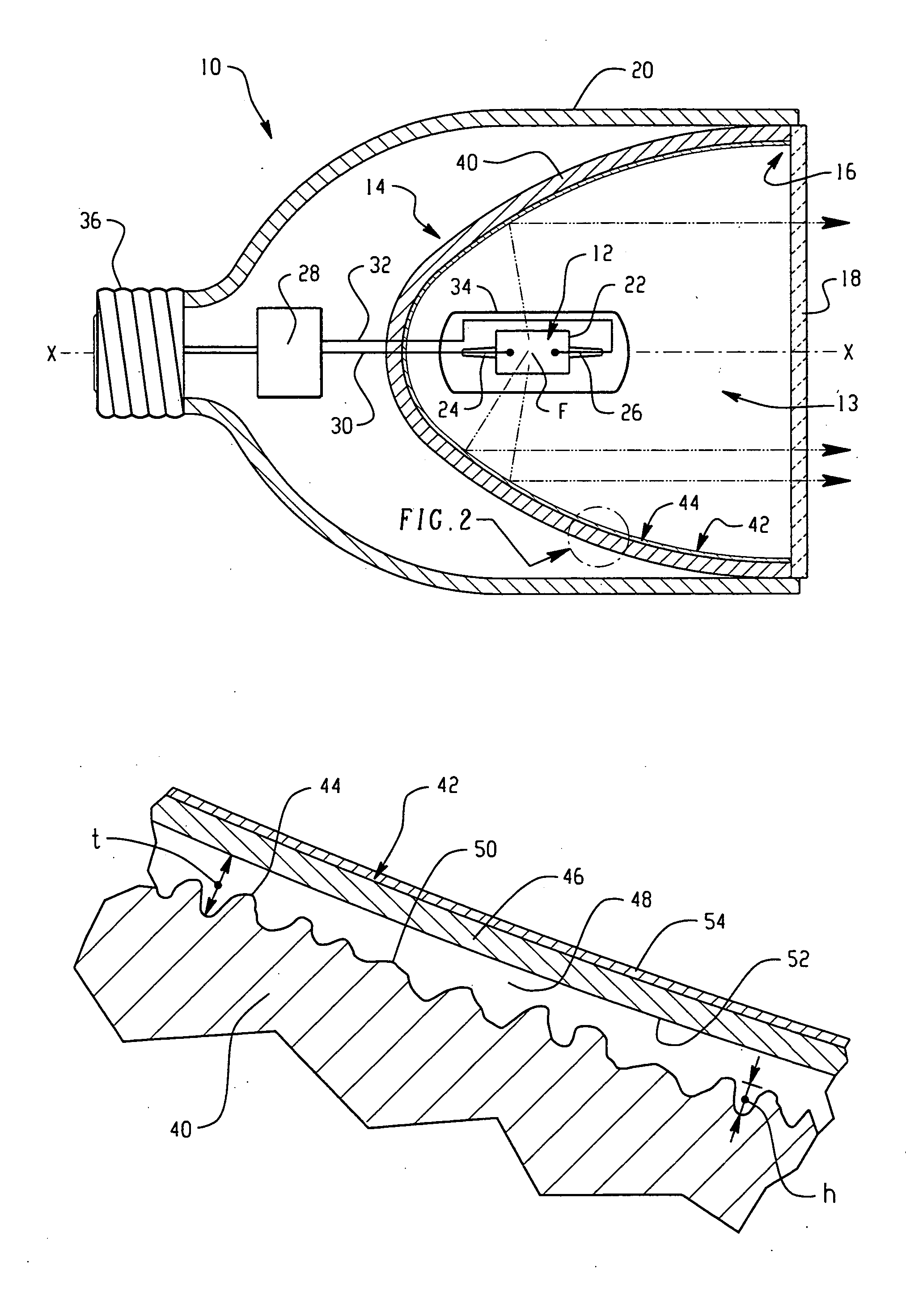

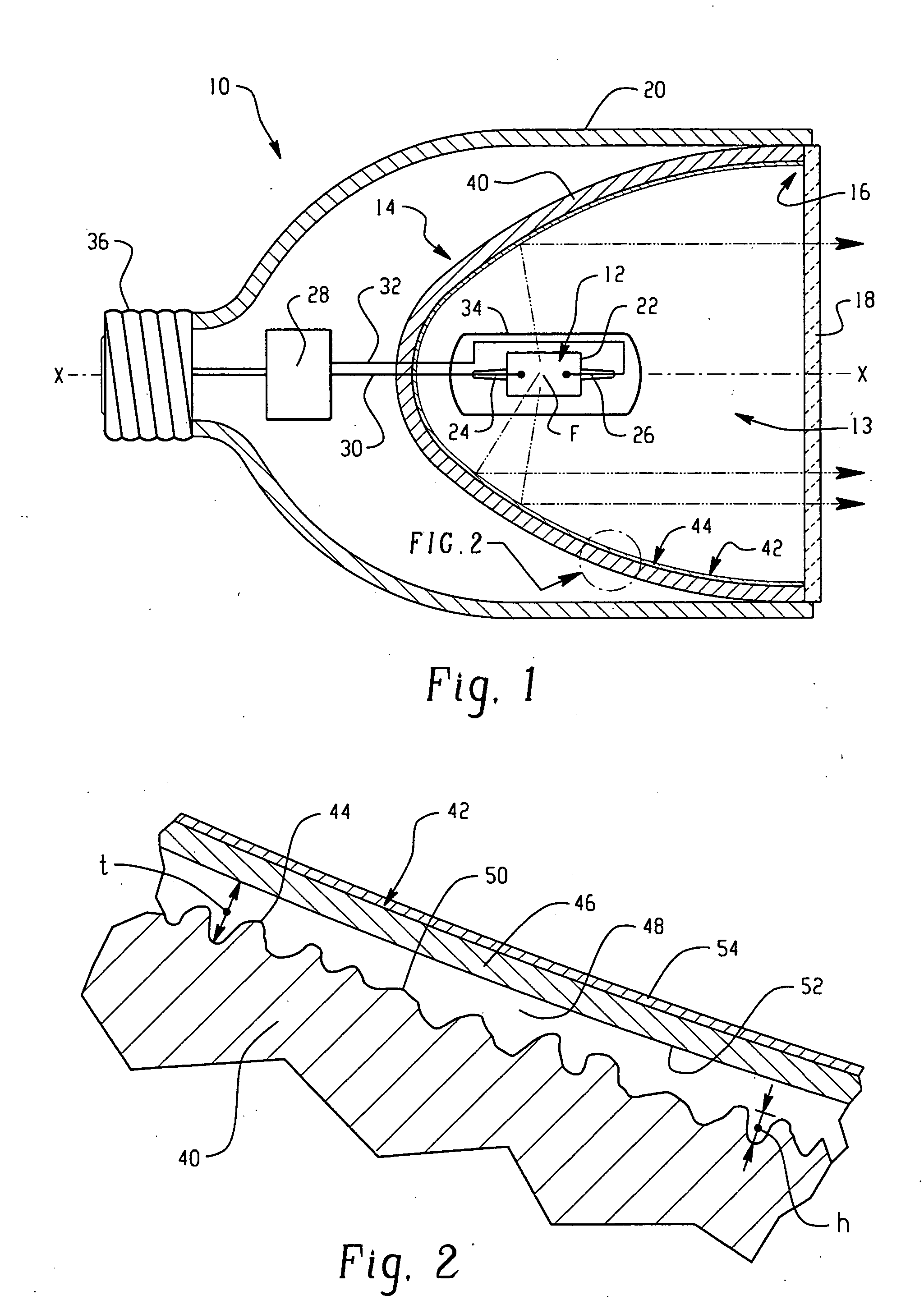

[0015] Aspects of the exemplary embodiment relate to a reflector for a luminaire which is suited to use in exterior environments, such as to illuminate sports arenas and roadways. The reflector includes a layer of a leveling material which reduces surface irregularities in the reflector. The resulting luminaire has a high beam efficiency and is capable of operating at temperatures in excess of 100° C., in particular, temperatures in excess of 150° C., and which can exceed 200° C., without significant impairment to the beam efficiency. Accordingly, more of the light from the present lamp reaches the distant object that the luminaire is intended to illuminate than is the case for an otherwise identically formed conventional luminaire.

[0016]“Beam efficiency” can be defined as the ratio of the flux emitted by the luminaire inside the solid angle defined by the beam spread to the flux of the bare light source. The beam spread is generally considered to be the angle between points of 50%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com