Rubber composition and pneumatic tire using the same

a technology of composition and rubber, which is applied in the direction of special tyres, rolling resistance optimization, transportation and packaging, etc., can solve the problems of reducing performance, increasing fuel cost, and rubber scorching called gelation, so as to improve the processability, abrasion resistance, rolling resistance property and wet skid performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0051]The present invention is specifically explained based on Examples, but the present invention is not limited only thereto.

[0052]Then, various chemicals used in Examples and Comparative Examples are collectively explained in the following.

Natural rubber (NR): RSS#3

[0053]Styrene-butadiene rubber (SBR): SBR 1502 (styrene unit amount: 23.5% by weight) available from JSR Corporation

Silica: NIPSIL ER (N2SA: 110 m2 / g) available from Tosoh Silica Corporation

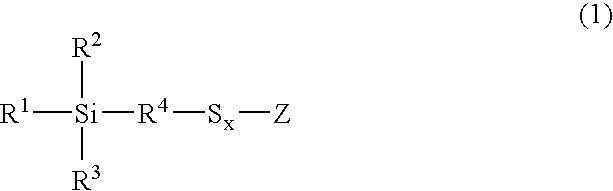

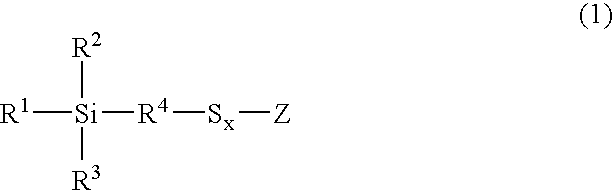

Silane coupling agent A: Si69 (bis(3-triethoxysilylpropyl)tetrasulfide) available from Degussa Corporation

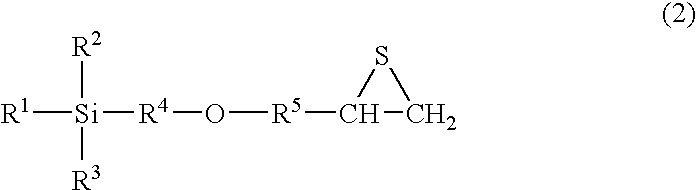

Silane coupling agent B: prepared by the following preparation process

[0054]Surface-treated silica 1: prepared by the following preparation process (untreated amount: 41.8% by weight)

Surface-treated silica 2: prepared by the following preparation process (untreated amount: 14.9% by weight)

Surface-treated silica 3: prepared by the following preparation method (untreated amount: 7.1% by weight)

Surface-treated silica 4: prepared by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| nitrogen adsorbing-specific surface area | aaaaa | aaaaa |

| nitrogen adsorbing-specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com