Patents

Literature

66results about How to "Wet performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

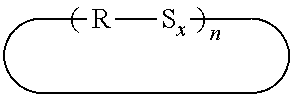

Rubber composition for tire

ActiveUS20110301280A1Wet of performanceWet sustainabilitySpecial tyresRolling resistance optimizationPolysulfideSulfide

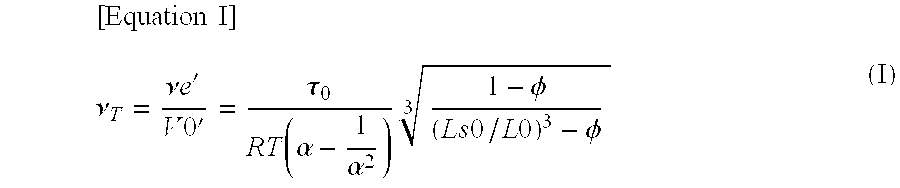

A rubber composition for a tire is blended with diene-based rubber containing 50 wt % or more of SBR, and 0.2 to 5 parts by weight of cyclic polysulfide represented by the below formula (I), 1 to 30 parts by weight of aromatic denatured terpene resin, 20 to 80 parts by weight of silica, and 40 to 100 parts by weight of carbon black relative to 100 parts by weight of the diene-based rubber. Further, a total blending amount of the silica and the carbon black is 70 to 130 parts by weight.In the formula, R represents a substituted or unsubstituted alkylene group having 2 to 18 carbon atoms, a substituted or unsubstituted oxyalkylene group having 2 to 18 carbon atoms, or an alkylene group including an aromatic ring, x represents an average number of 2 to 6, and n represents an integer of 1 to 15.

Owner:YOKOHAMA RUBBER CO LTD

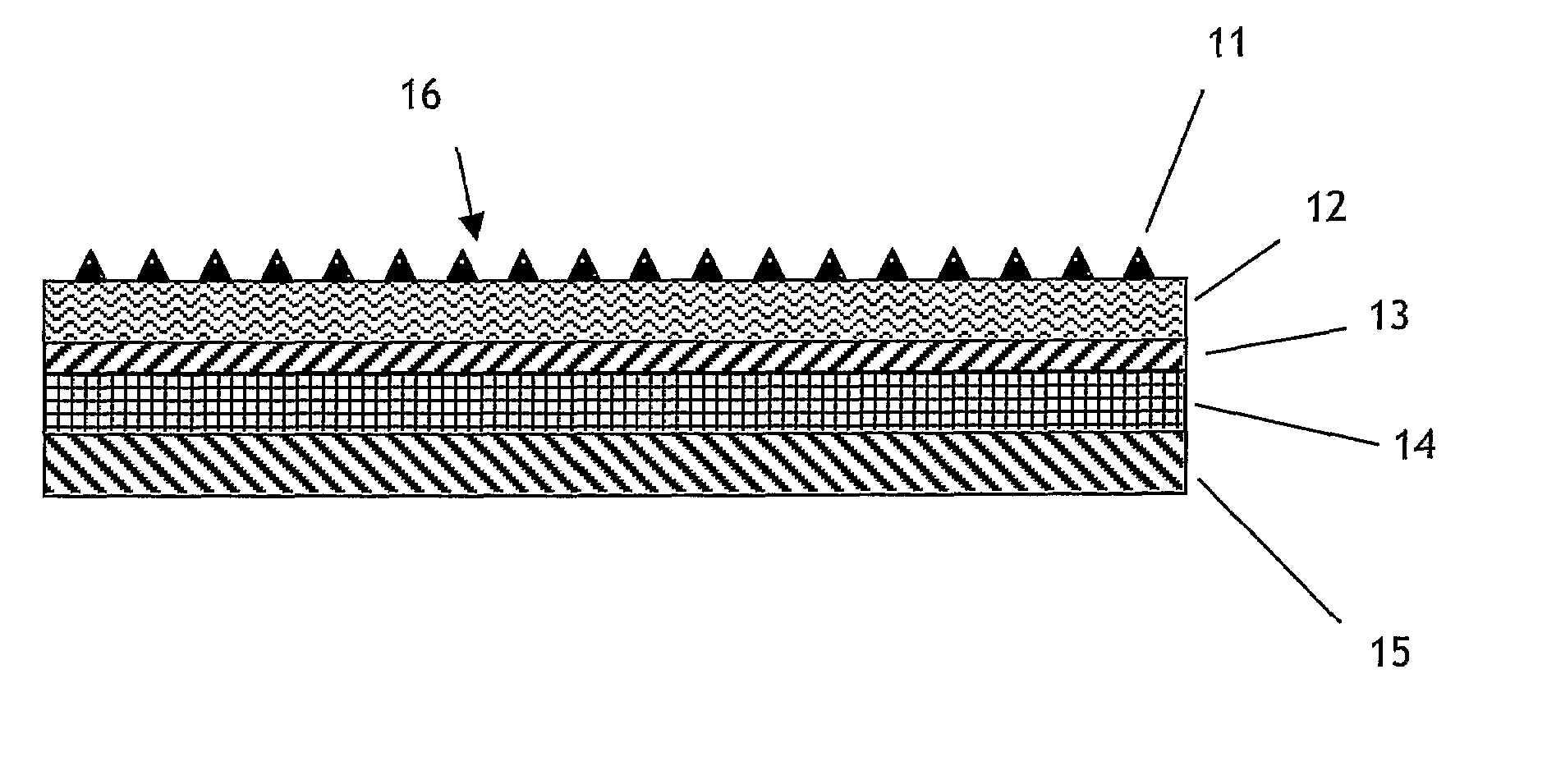

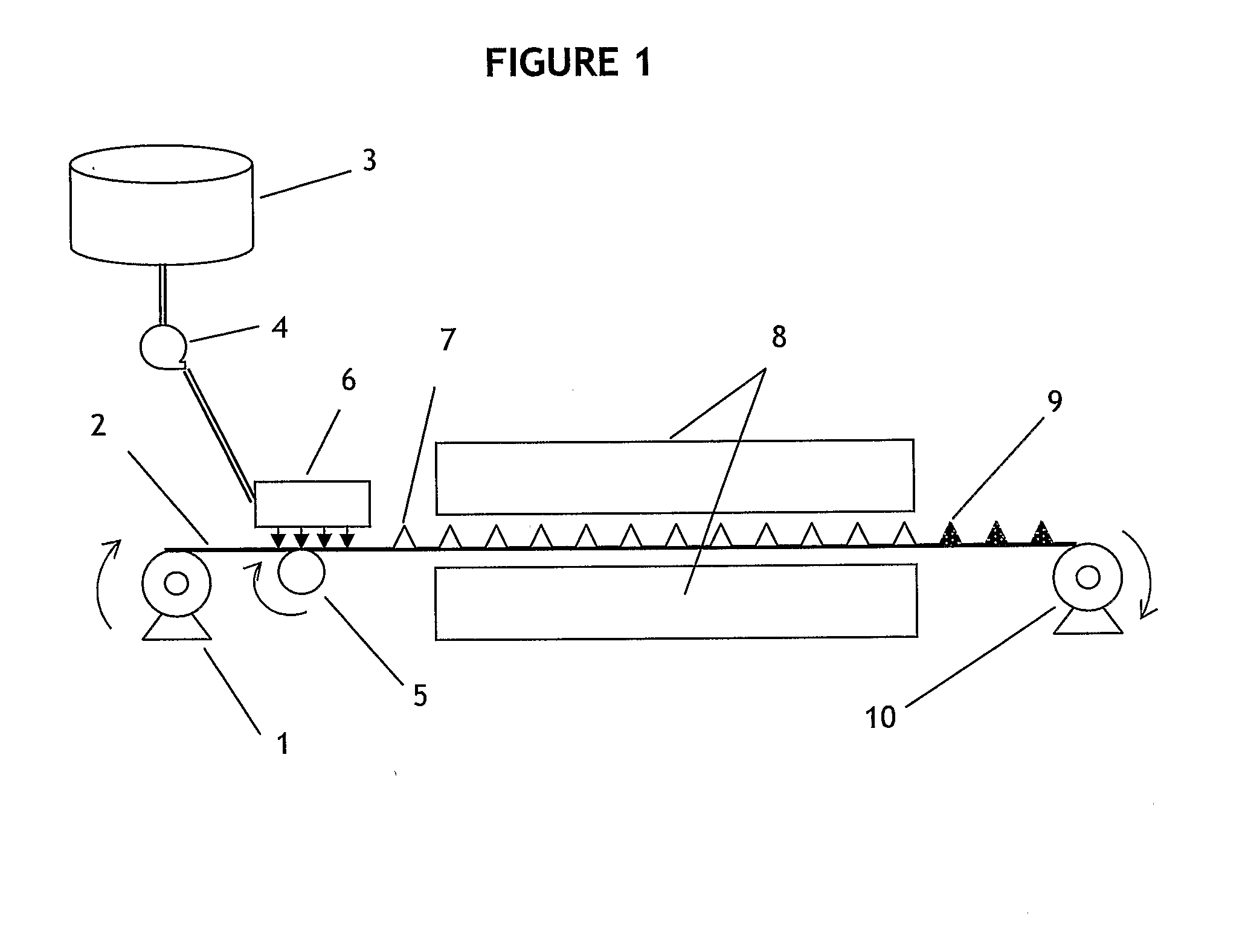

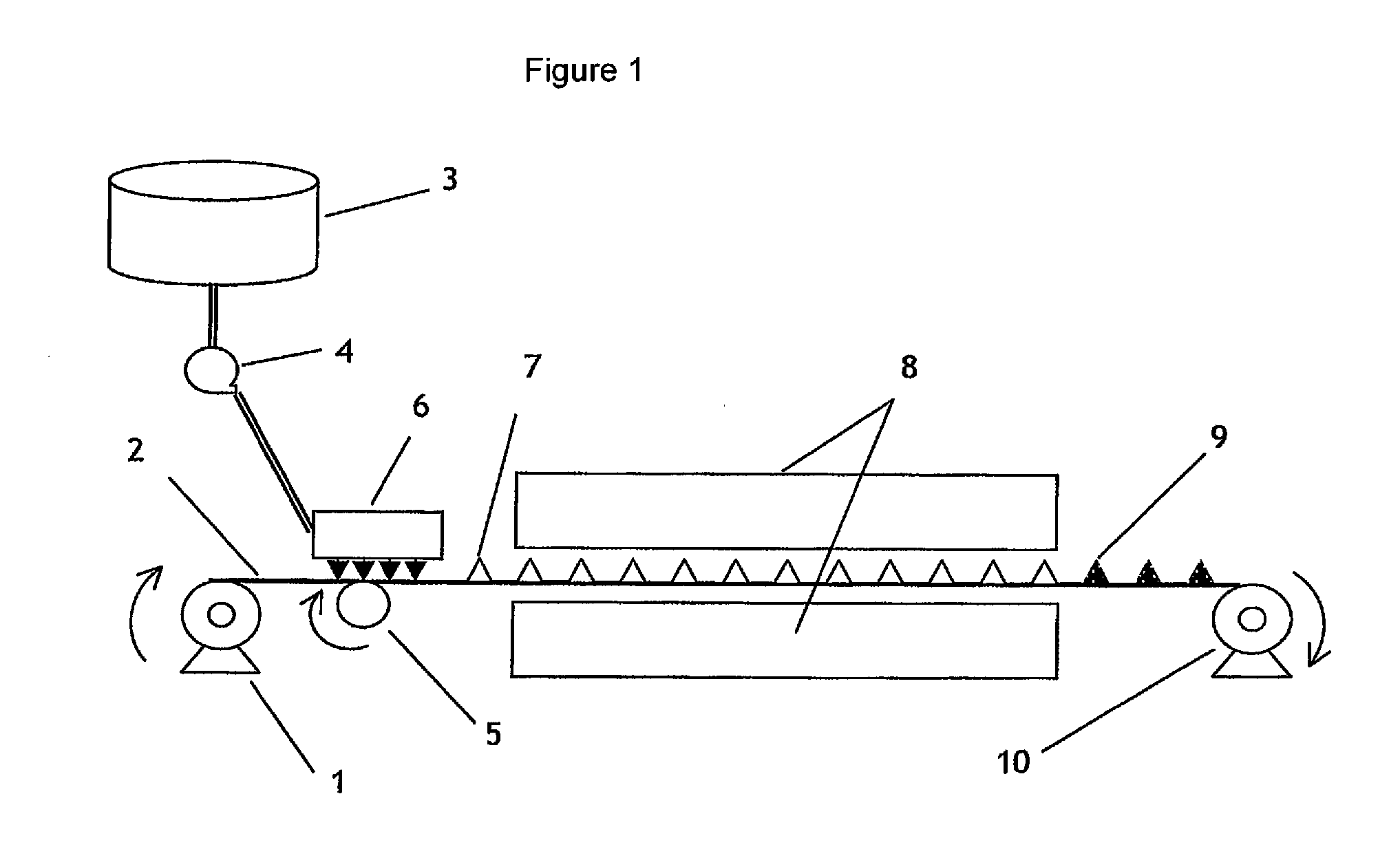

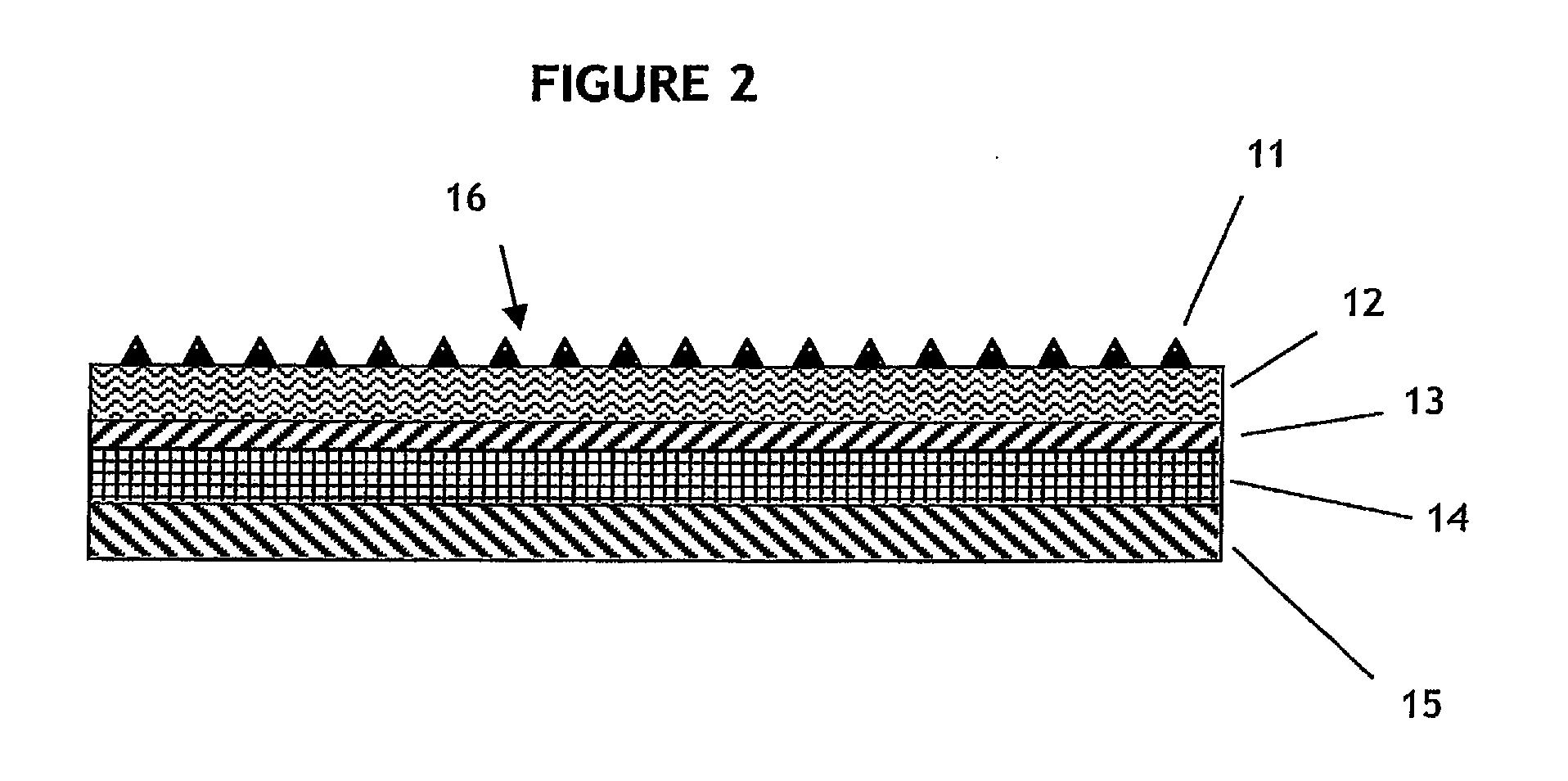

Waterproofing Membrane For Use on Inclined Surfaces

InactiveUS20080152867A1Wet performanceDecorative surface effectsFloorsPolymer sciencePolyvinyl chloride

The present invention provides a waterproofing membrane for use on inclined surfaces. The membrane is fabricated from one or more layers of flexible sheet material preferably consisting of woven or nonwoven synthetic polymers of polypropylene. A skid resistant pattern of polymer elements is applied to the top surface of the membrane. The polymer has a Tensile Modulus<15 MPa (ASTM D638, 23C, 50 mm / min), a Tensile Yield Elongation>50% (ASTM D538, 23C, 50 mm / min, and a Shore A Hardness (ASTM D2240, 23C, 0 sec)<90. In a preferred embodiment the polymer elements are made from polyvinyl chloride polymer with a Tensile Modulus<7 MPa (ASTM D638, 23C, 50 mm / min), a Tensile Yield Elongation>50% (ASTM D638, 23C, 50 mm / min, and a Shore A Hardness (ASTM D2240, 23C, 0 sec)<75. The pattern of polymer elements may be applied directly on the top surface of the membrane or produced on one side of a carrier sheet which is attached to the top surface of the membrane.

Owner:DI PEDE SANDRO

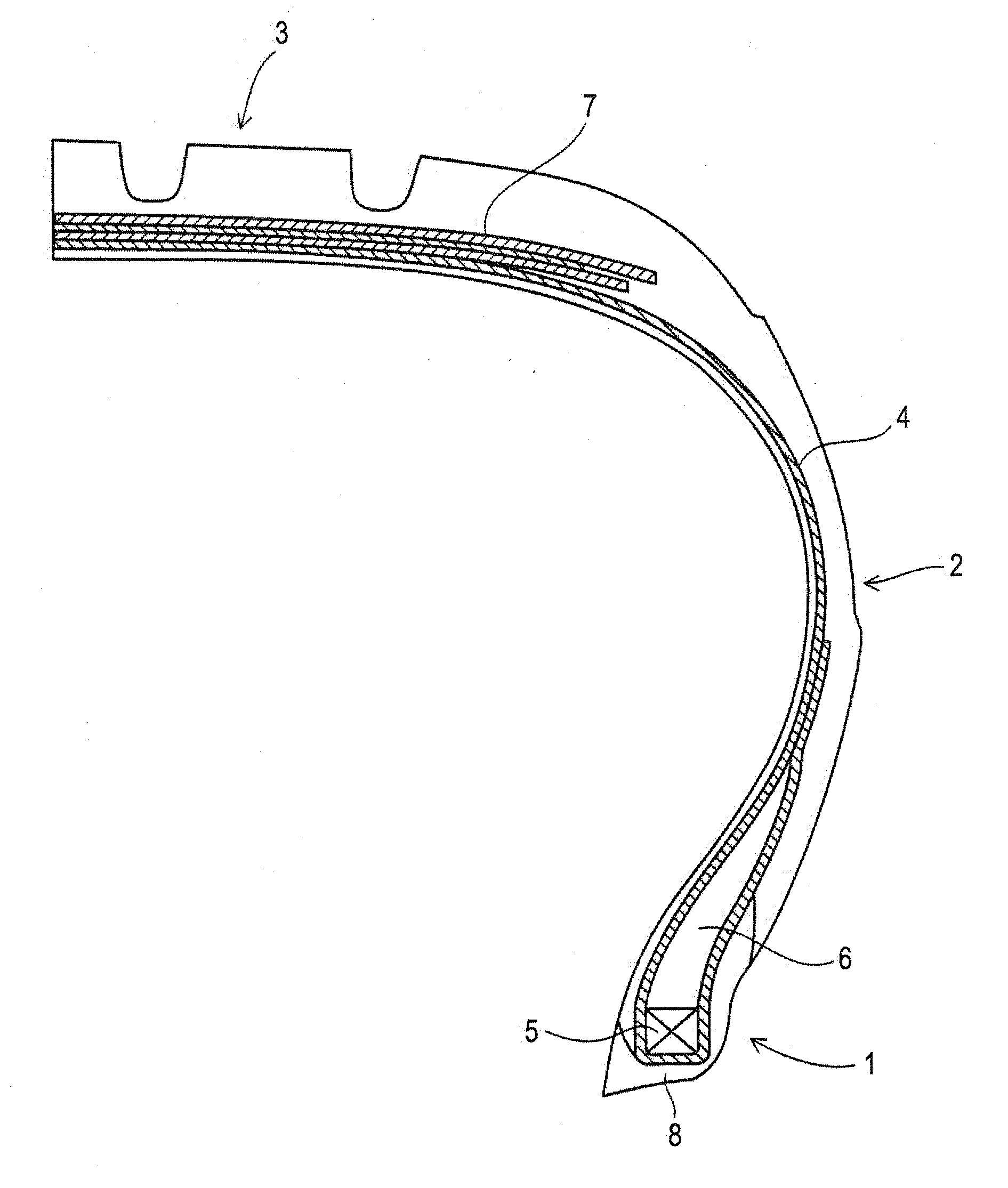

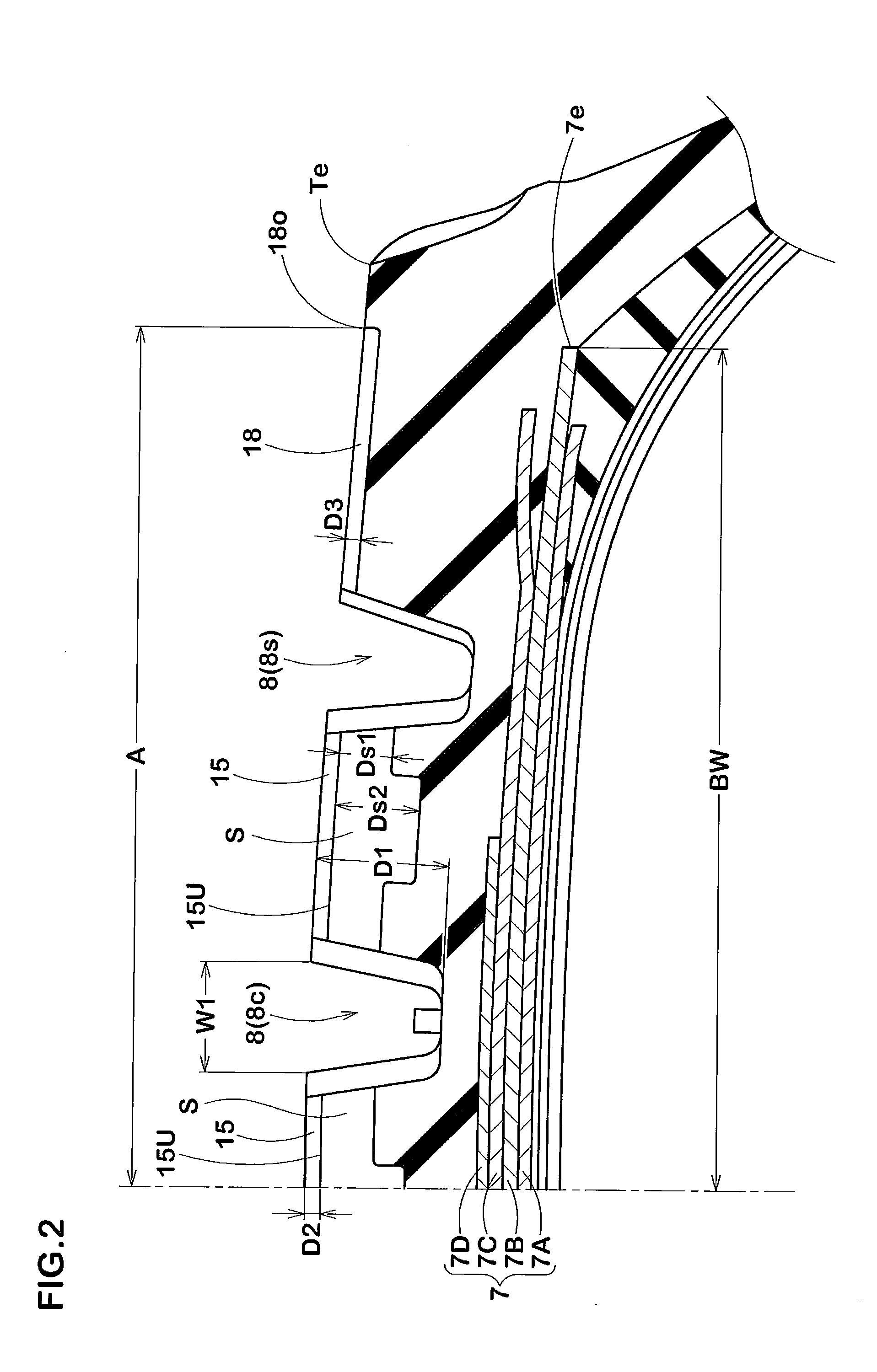

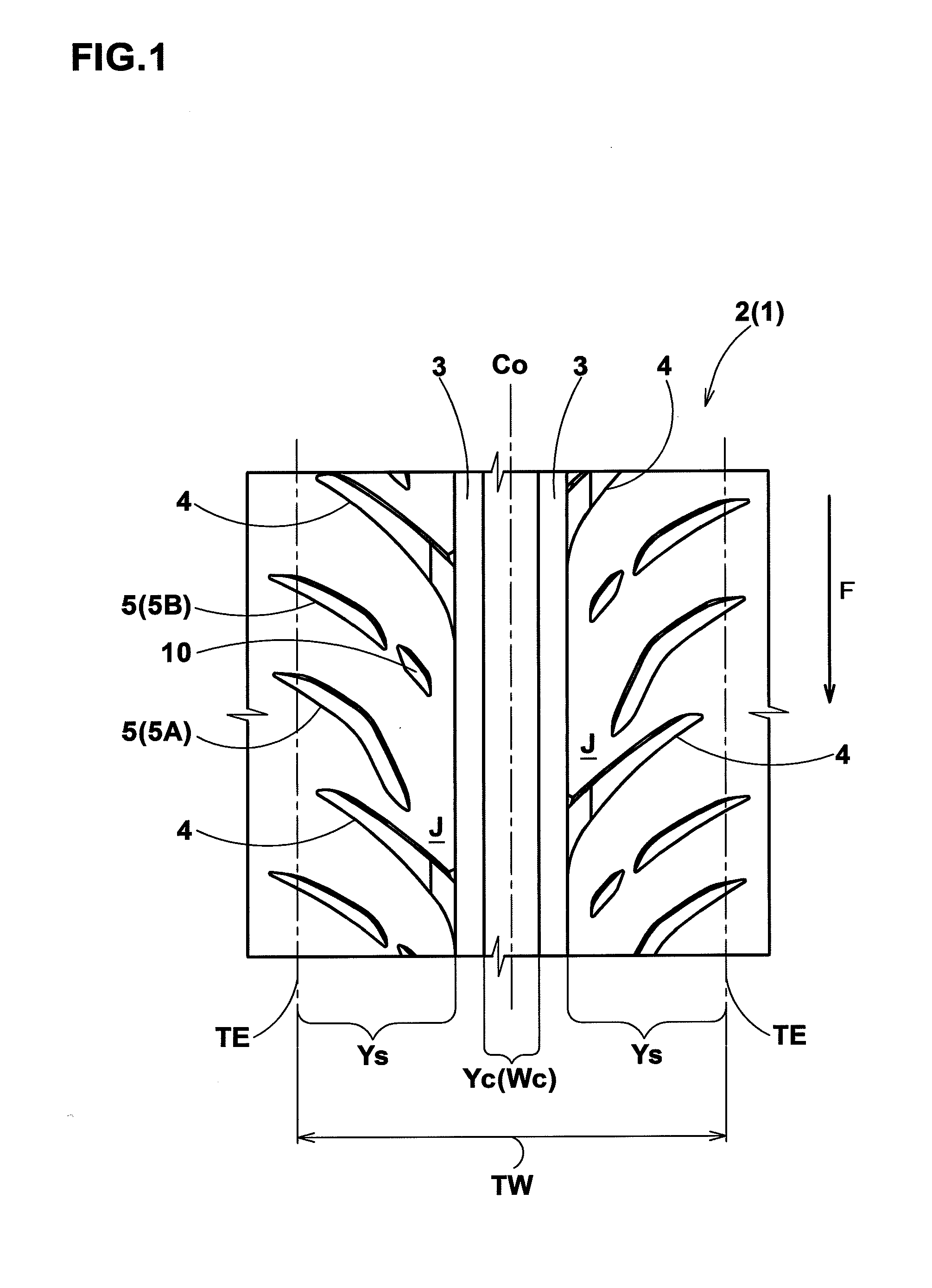

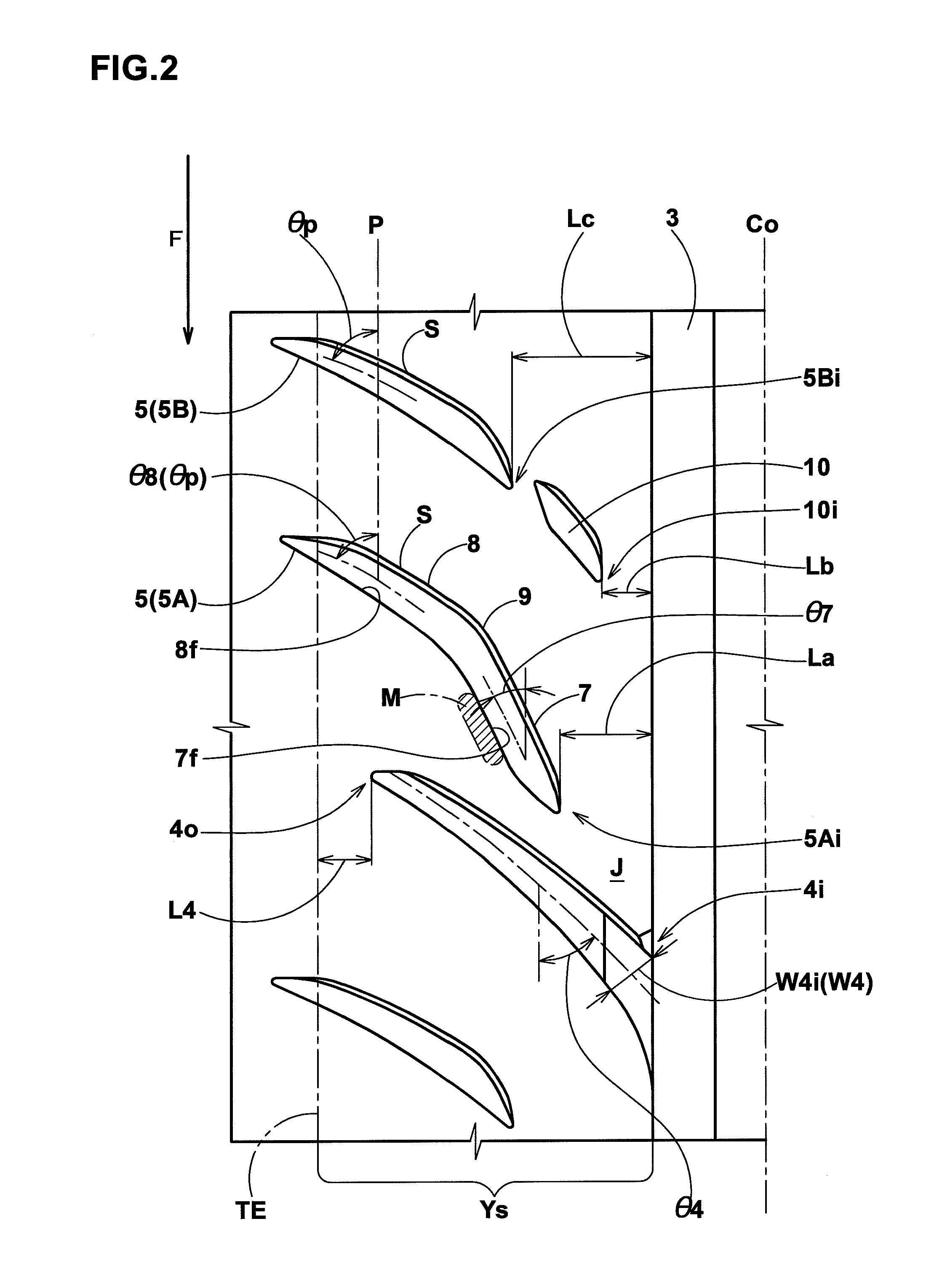

Heavy duty tire

InactiveUS20110192513A1Improve resistanceWet performanceHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

Owner:SUMITOMO RUBBER IND LTD

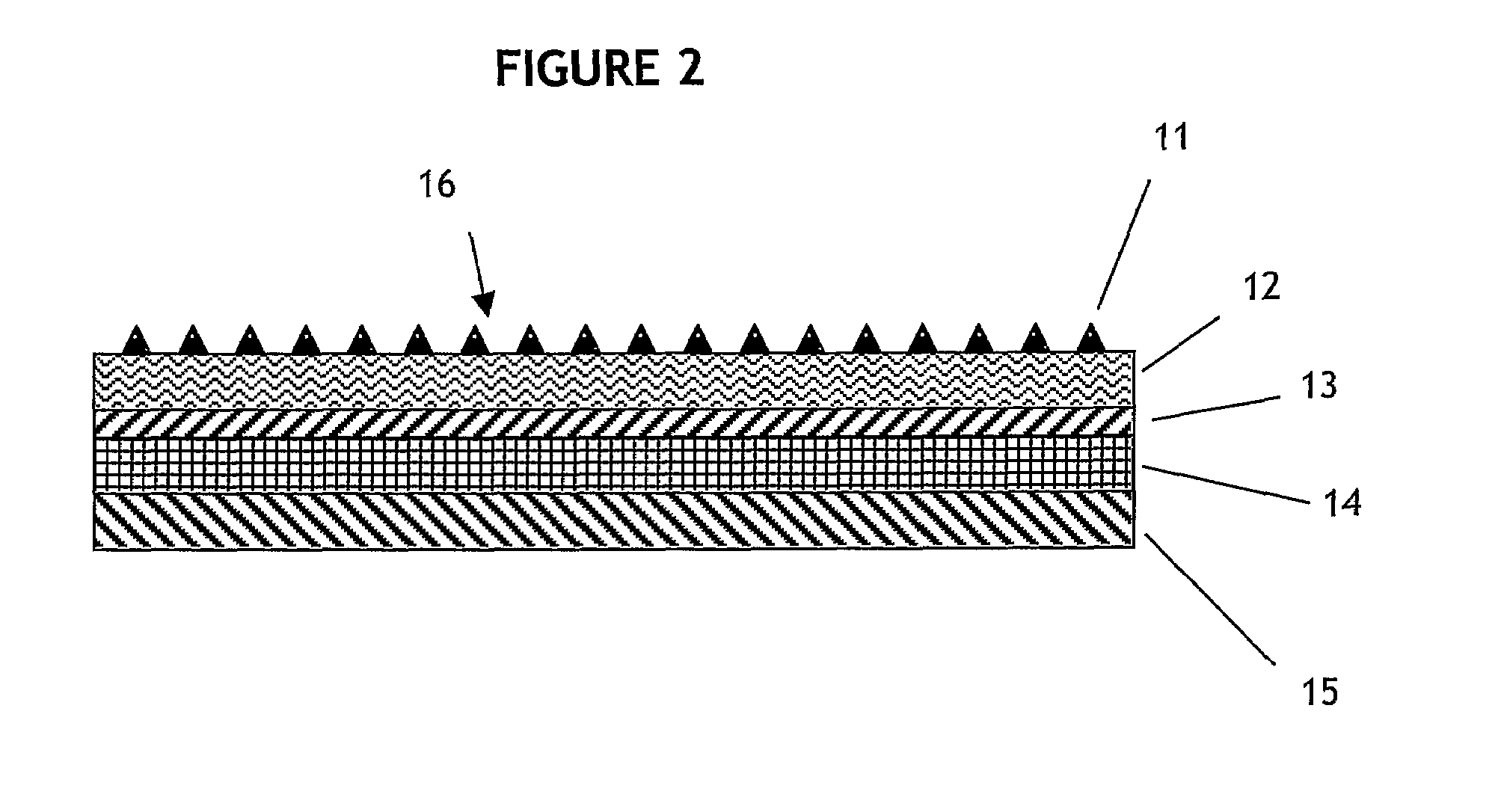

Waterproofing Membrane for Use on Inclined Surfaces

ActiveUS20100215924A1Wet performanceRoof covering using tiles/slatesLamination ancillary operationsPolyvinyl chlorideHardness

The present invention provides a waterproofing membrane for use on inclined surfaces. The membrane is fabricated from one or more layers of flexible sheet material preferably consisting of woven or nonwoven synthetic polymers of polypropylene. The membrane has a top surface and a bottom surface, where the bottom surface is intended to face the inclined surface. A skid resistant pattern of polymer elements is applied to the top surface of the membrane. The polymer has a Tensile Modulus <15 MPa (ASTM D638, 23C, 50 mm / min), a Tensile Yield Elongation >50% (ASTM D638, 23C, 50 mm / min, and a Shore A Hardness (ASTM D2240, 23C, 0 sec)<90. In a preferred embodiment the polymer elements are made from polyvinyl chloride polymer with a Tensile Modulus <7 MPa (ASTM D638, 23C, 50 mm / min), a Tensile Yield Elongation >50% (ASTM D638, 23C, 50 mm / min, and a Shore A Hardness (ASTM D2240, 23C, 0 sec)<75. The pattern of polymer elements may be applied directly on the top surface of the membrane or produced on one side of a carrier sheet which is attached to the top surface of the membrane. Where a carrier sheet is utilized, the carrier sheet is comprised of woven or nonwoven materials selected from the group consisting of synthetic polymers of polyethylene(PE), polypropylene (PP), polyethyleneterephthalate (PET), nylon, or copolymers and blends thereof, as well as glass or cotton, or blends thereof. In a preferred embodiment the carrier sheet is comprised of woven or nonwoven polypropylene (PP) or polyethyleneterephthalate (PET).

Owner:INTERTAPE POLYMER CORP

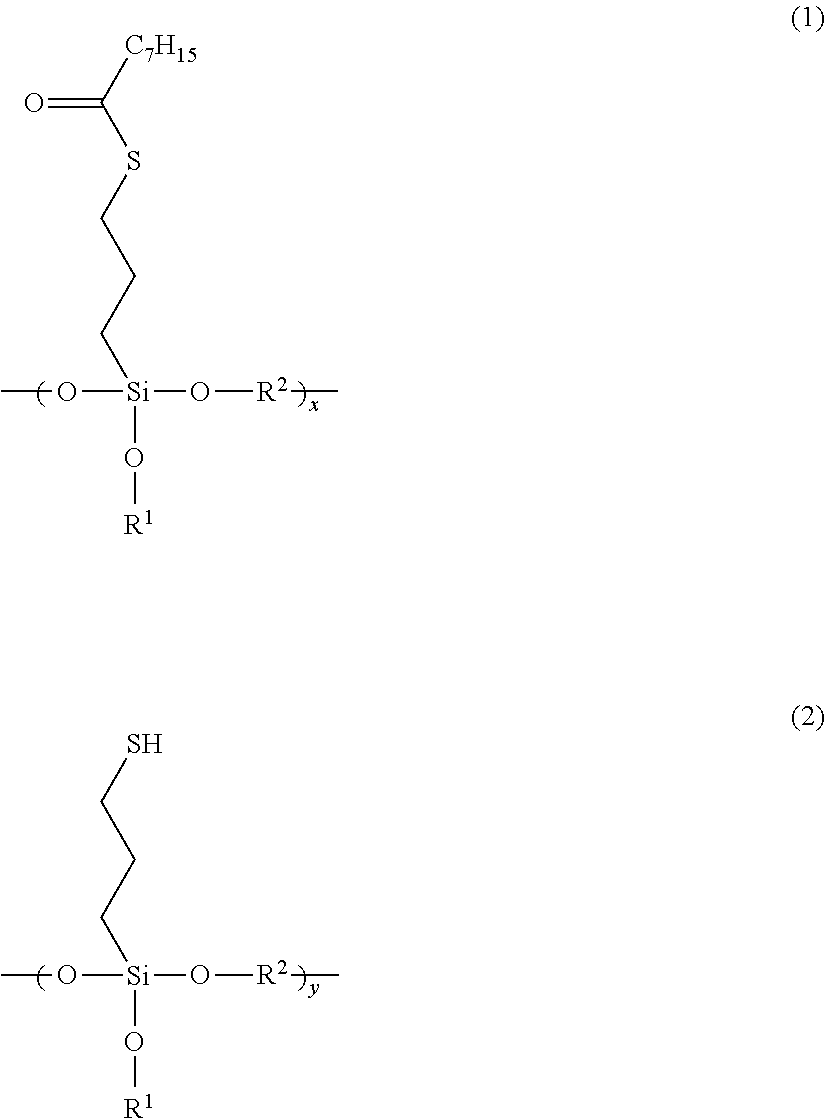

Silane coupling agent treated-silica and rubber composition containing the same

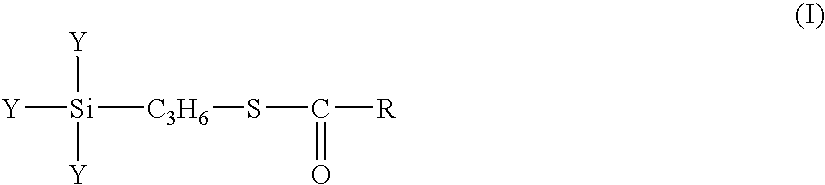

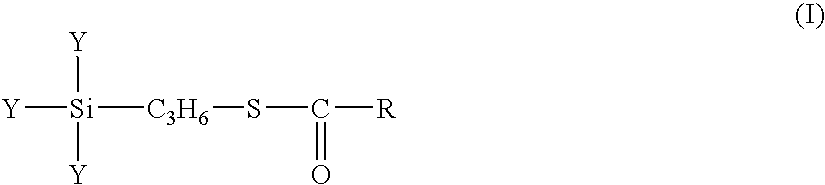

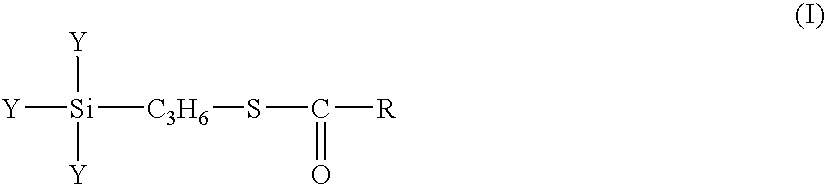

InactiveUS20070078202A1Dispersibility wetWet performanceSilicaSynthetic resin layered productsArylPolymer science

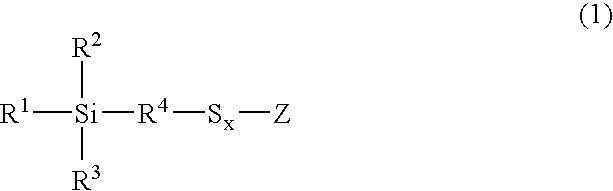

A rubber component containing at least one a diene-based rubber in an amount of 100 parts by weight and a surface-treated silica treated, on the surface thereof, with at least one silane coupling agent X represented by formula (I): wherein Y independently indicate a methoxy, ethoxy, propoxy, isopropoxy, butoxy, isobutoxy or acetoxy group, R indicates a C1 to C18 hydrocarbon group selected from a linear, cyclic or branched alkyl group, alkenyl group, aryl group, and aralkyl group and a rubber composition containing the same.

Owner:THE YOKOHAMA RUBBER CO LTD +1

Pneumatic tire

ActiveUS20130220499A1Improve wettabilitySteering stability during runningTyre tread bands/patternsNon-skid devicesEngineeringTread

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tread and pneumatic tire

InactiveUS20110160337A1Wet performanceProcessability wetSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

It is an object of the present invention to provide: a rubber composition for a tread, which improves processability, rolling resistance, wet skid performance, abrasion resistance, and handling stability in good balance; and a pneumatic tire having a tread produced from the rubber composition. The present invention relates to a rubber composition for a tread, including: a rubber component; an aromatic vinyl polymer; silica; and a mercapto group-containing silane coupling agent, wherein the aromatic vinyl polymer is a resin obtained by polymerization of α-methylstyrene and / or styrene, and the amount of the aromatic vinyl polymer is 3 to 25 parts by mass, and the amount of the silica is 15 to 150 parts by mass, based on 100 parts by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and pneumatic tire

ActiveUS20150126674A1Improve fuel economyImprove wet grip performanceSpecial tyresPolymer scienceWear resistance

The present invention provides a rubber composition capable of improving fuel economy and wet grip performance while maintaining good processability, abrasion resistance and handling stability or improving them, as well as a pneumatic tire including the rubber composition. The rubber composition contains carbon black, silica, and a polymer mixture obtained by modifying a polymer derived from a conjugated diene compound and / or an aromatic vinyl compound with a compound containing an ester group and / or a carboxyl group, the polymer mixture having a weight average molecular weight of from 1.0×103 to 1.0×105, the rubber composition having a tan δ peak temperature of −20° C. or higher, a rubber hardness of from 63 to 75, and a tan δ at 70° C. of from 0.15 to 0.45.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tread and pneumatic tire

InactiveUS20110082234A1Improve rolling resistanceWell-balanced mannerSpecial tyresRolling resistance optimizationCrack resistanceRolling resistance

The present invention has its object to provide a rubber composition for a tread which can prevent reversion and can also achieve environmental performance (excellent rolling resistance, response to depletion of oil resources, attention to CO2 emission), wet grip performance, dry grip performance, handling stability, and durability (abrasion resistance, crack resistance) in a well-balanced manner. The present invention also aims to provide a pneumatic tire using the rubber composition for the tread thereof. The rubber composition for a tread includes a rubber component containing 35% by mass or more of an epoxidized natural rubber; and a white filler, wherein a total sulfur content is less than 1.75% by mass, and a crosslink density is 7.0×10−5 mol / cm3 or more.

Owner:SUMITOMO RUBBER IND LTD

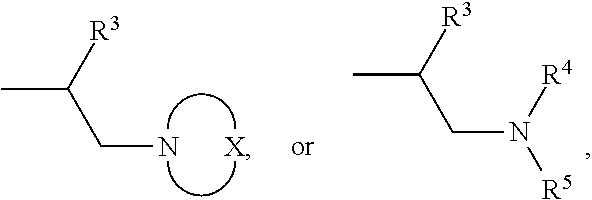

Rubber composition and pneumatic tire

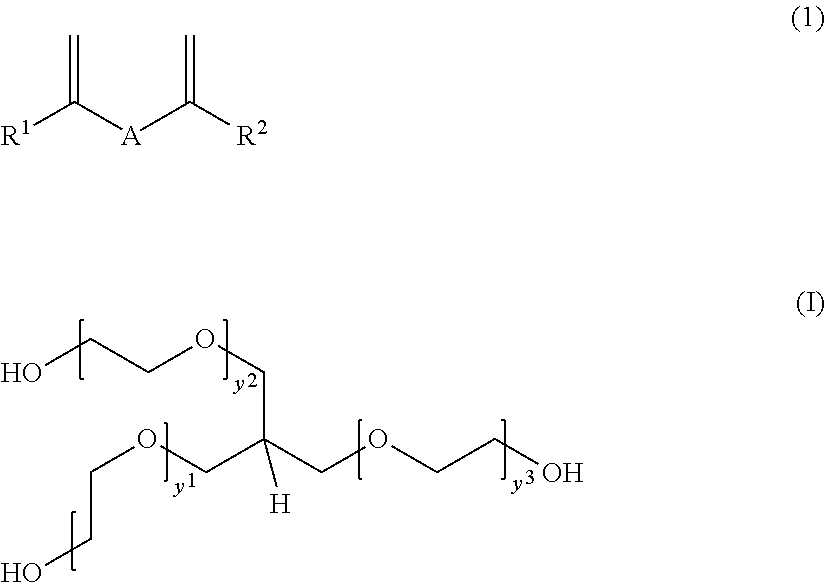

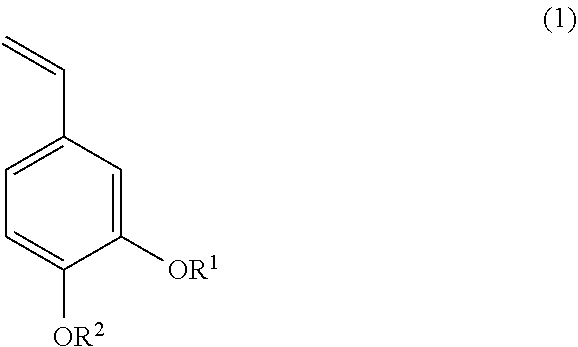

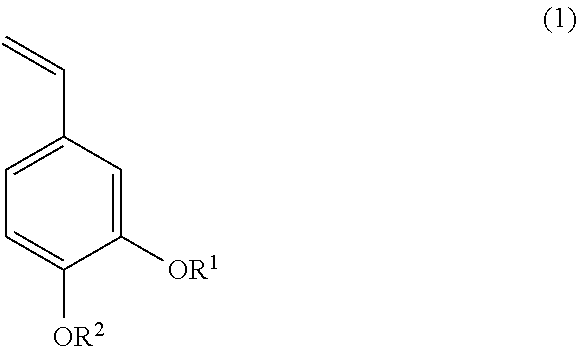

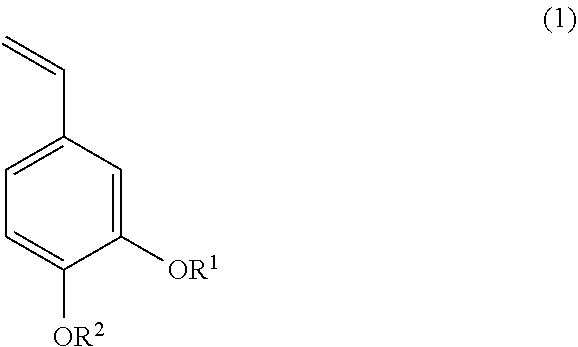

InactiveUS20140187707A1Improve fuel economyImprove wet grip performanceSpecial tyresPolymer scienceNitrogen

Provided are: a rubber composition that improves fuel economy and wet grip performance together while maintaining the balance between them; and a pneumatic tire whose component (in particular tread) includes the rubber composition. The invention relates to a rubber composition containing: a rubber component containing a copolymer; silica; and a diene rubber gel bearing a hydroxyl group, wherein the copolymer is obtained by copolymerization of 1,3-butadiene, styrene, and a compound represented by formula (I) below, has an amino group at a first chain end and a functional group containing at least one atom selected from the group consisting of nitrogen, oxygen, and silicon at a second chain end, and has a weight average molecular weight of 1.0×105-2.5×106, and the diene rubber gel has a Tg of −40 to −10° C., and is present in an amount of 10-30 parts by mass per 100 parts by mass of the rubber component;

Owner:SUMITOMO RUBBER IND LTD

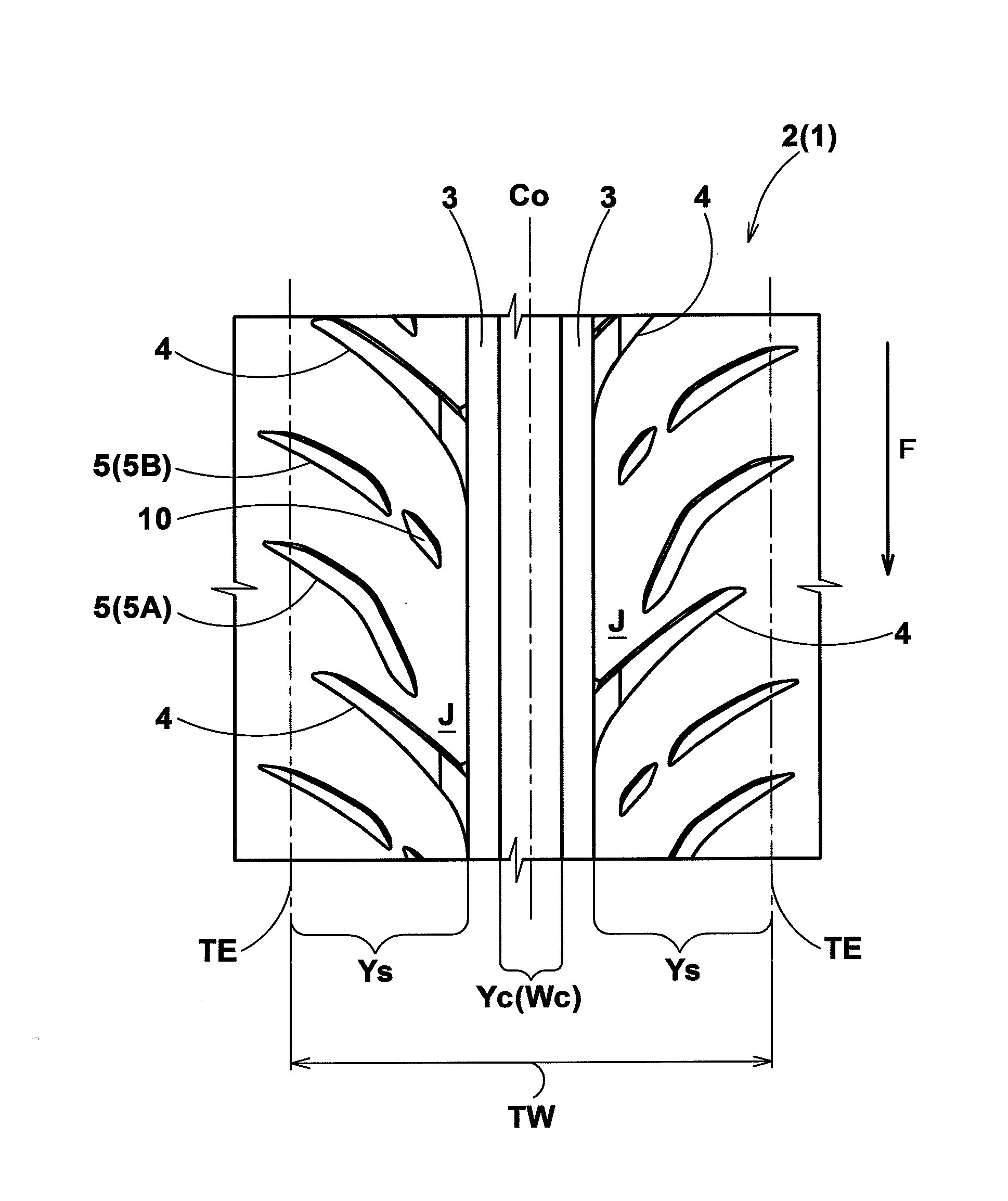

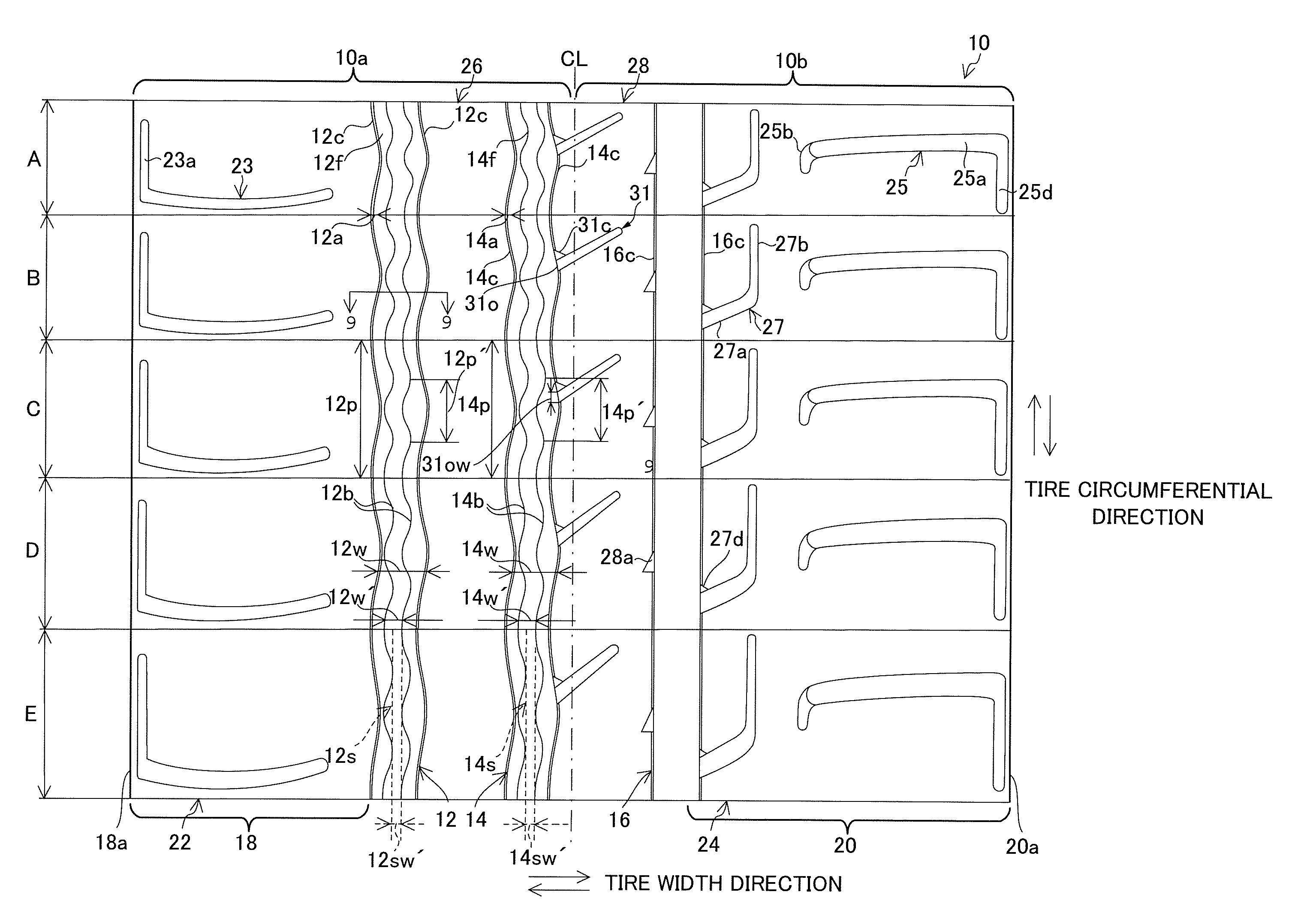

Pneumatic tire

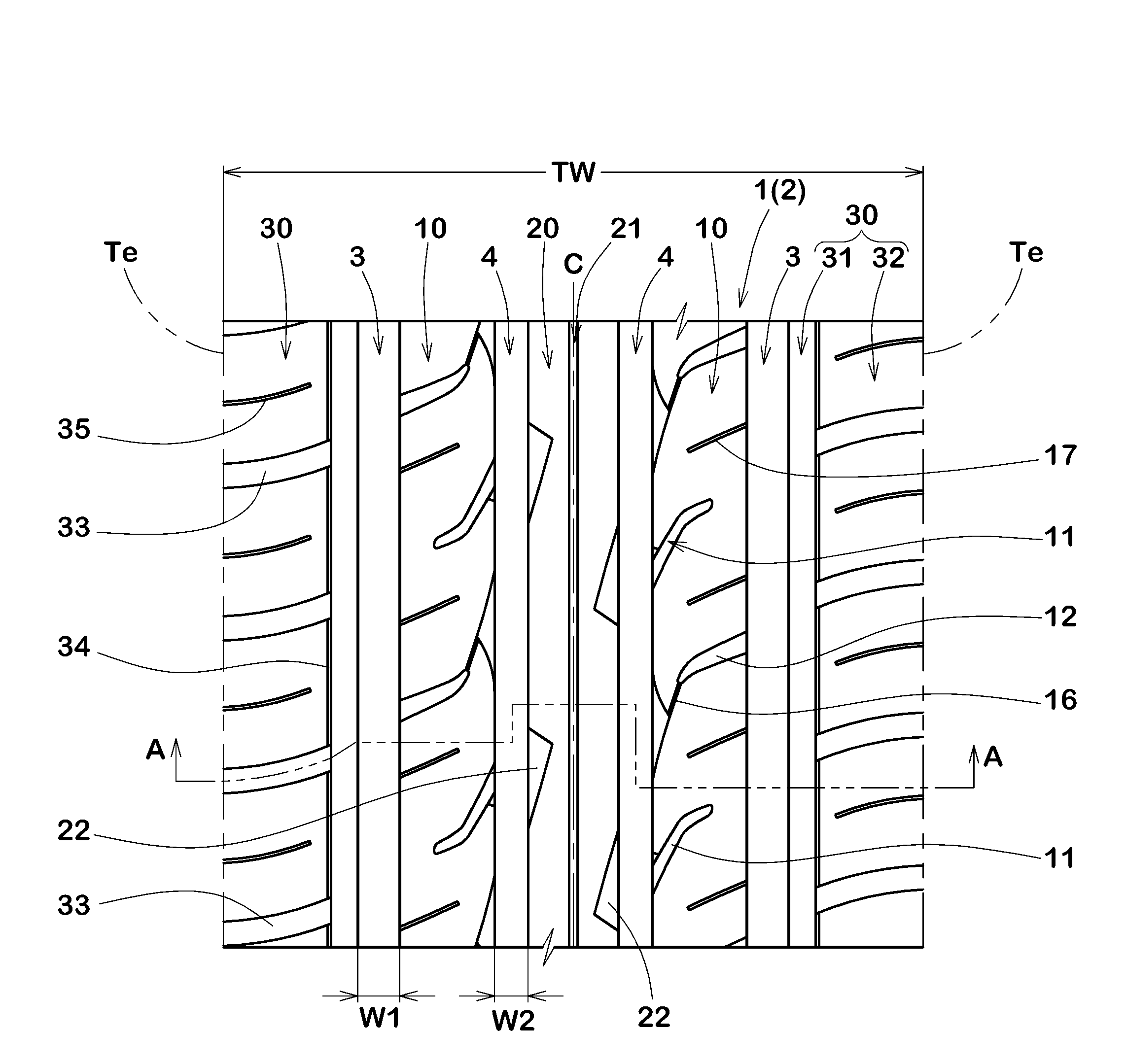

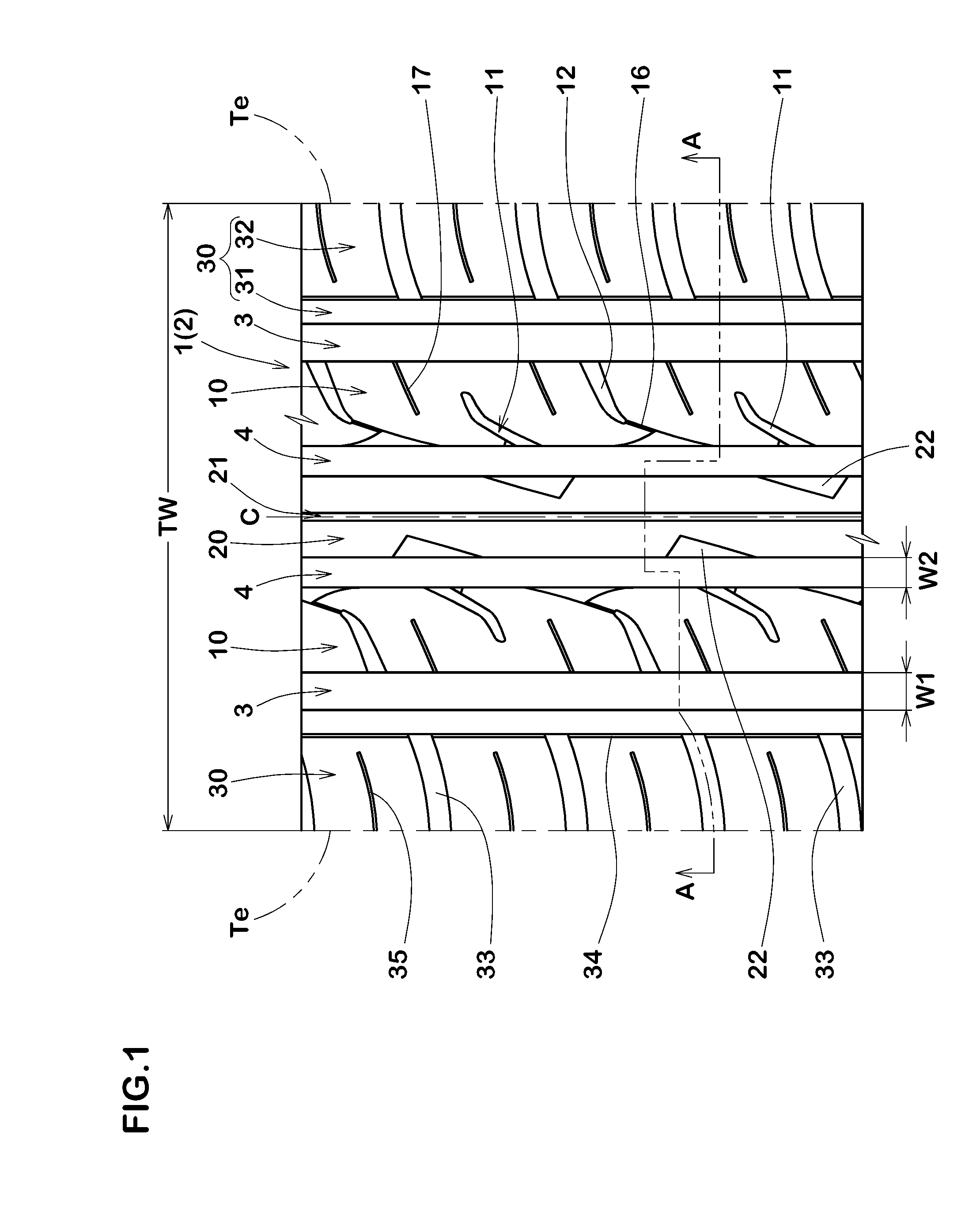

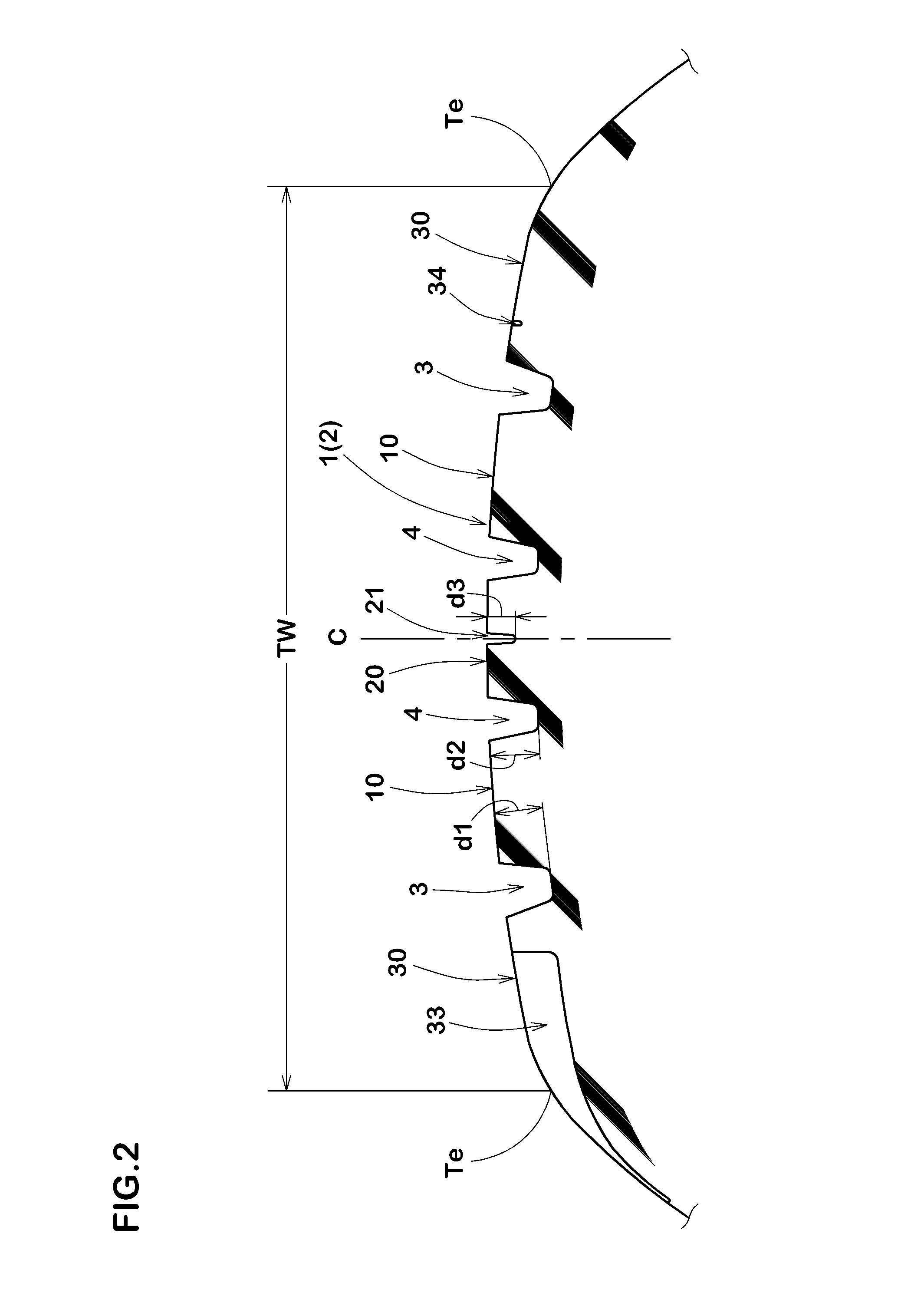

ActiveUS20150231928A1Improve performance stabilityImprove steering stabilityTyre tread bands/patternsNon-skid devicesEngineeringEquator

Owner:SUMITOMO RUBBER IND LTD

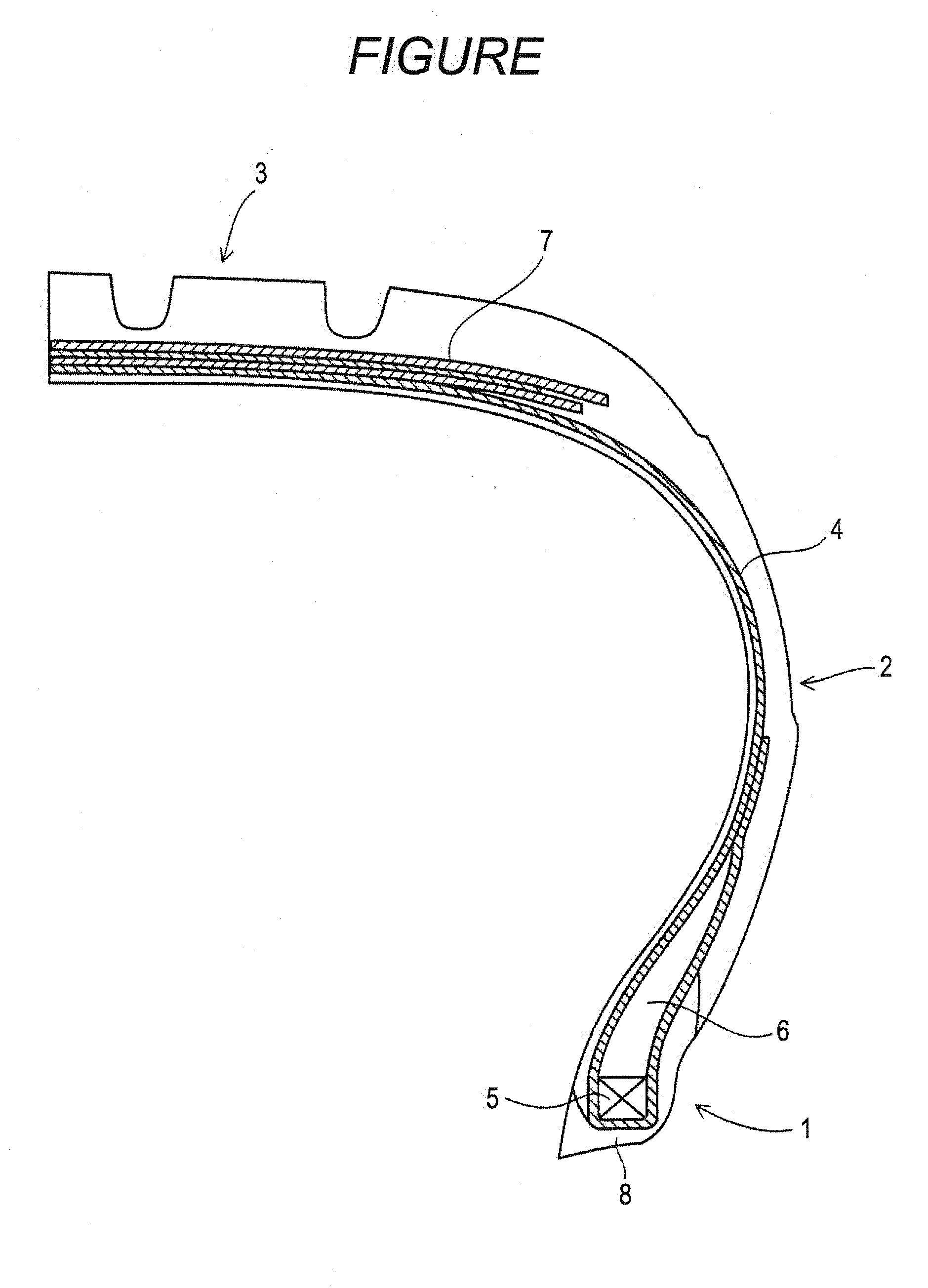

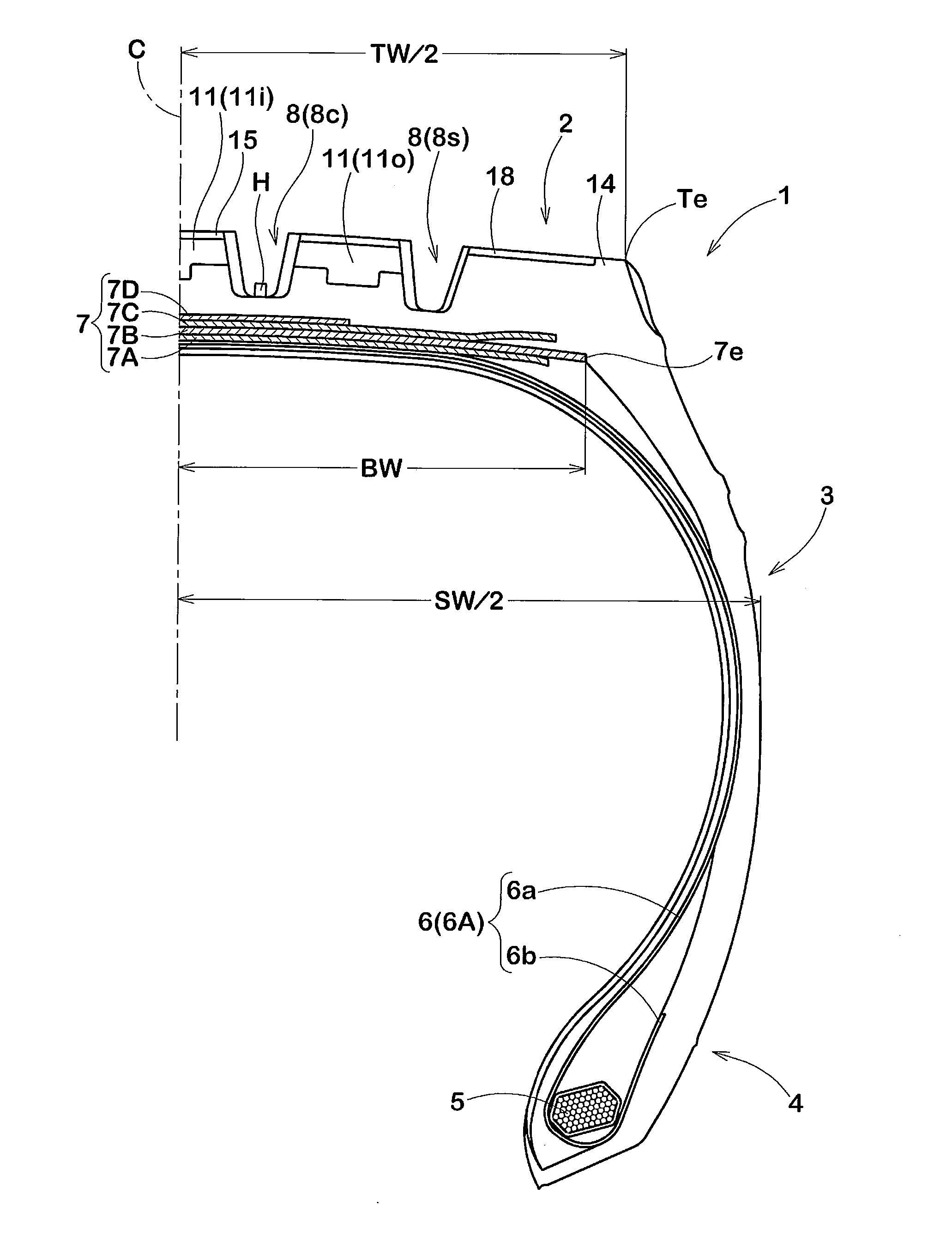

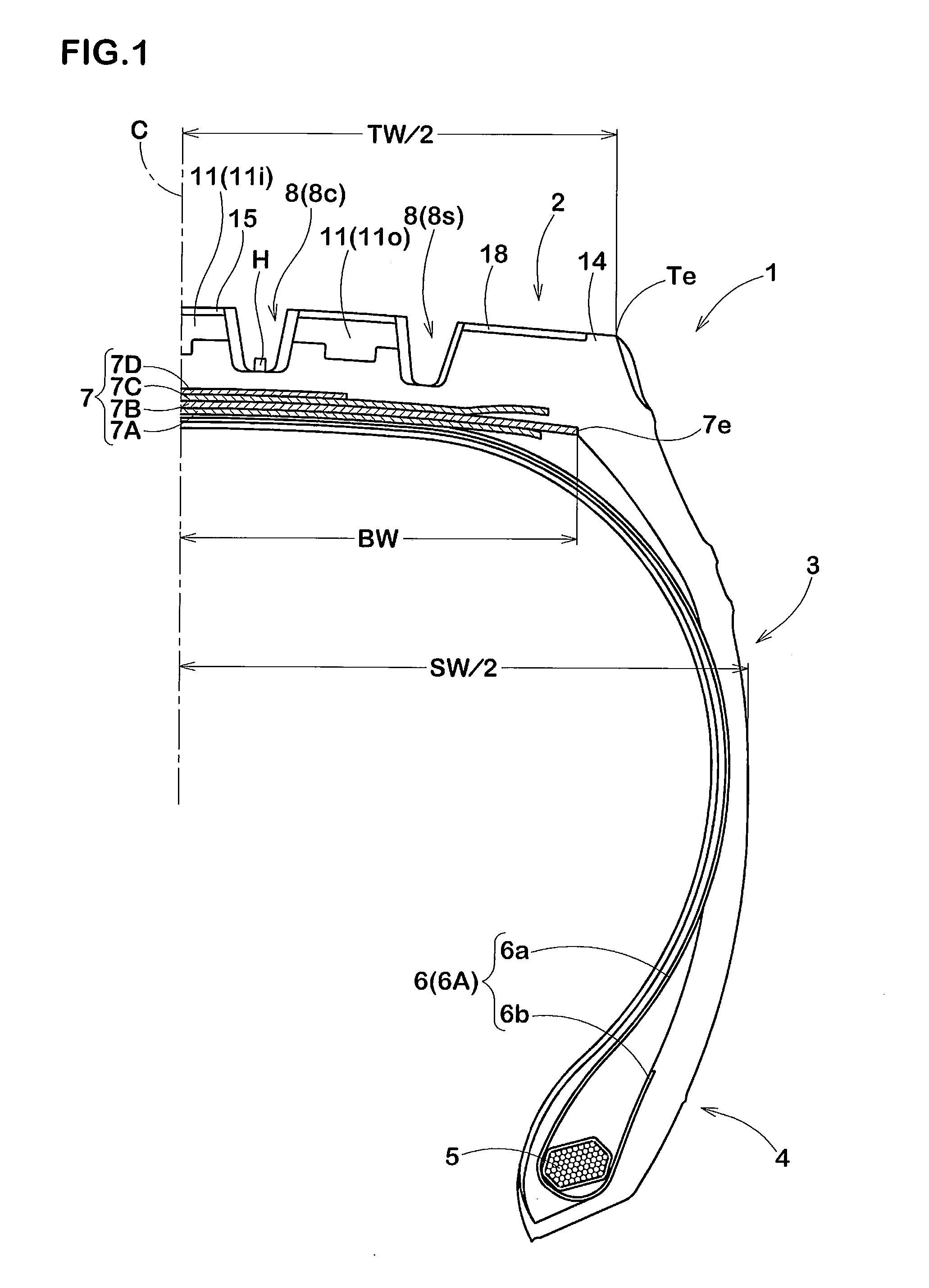

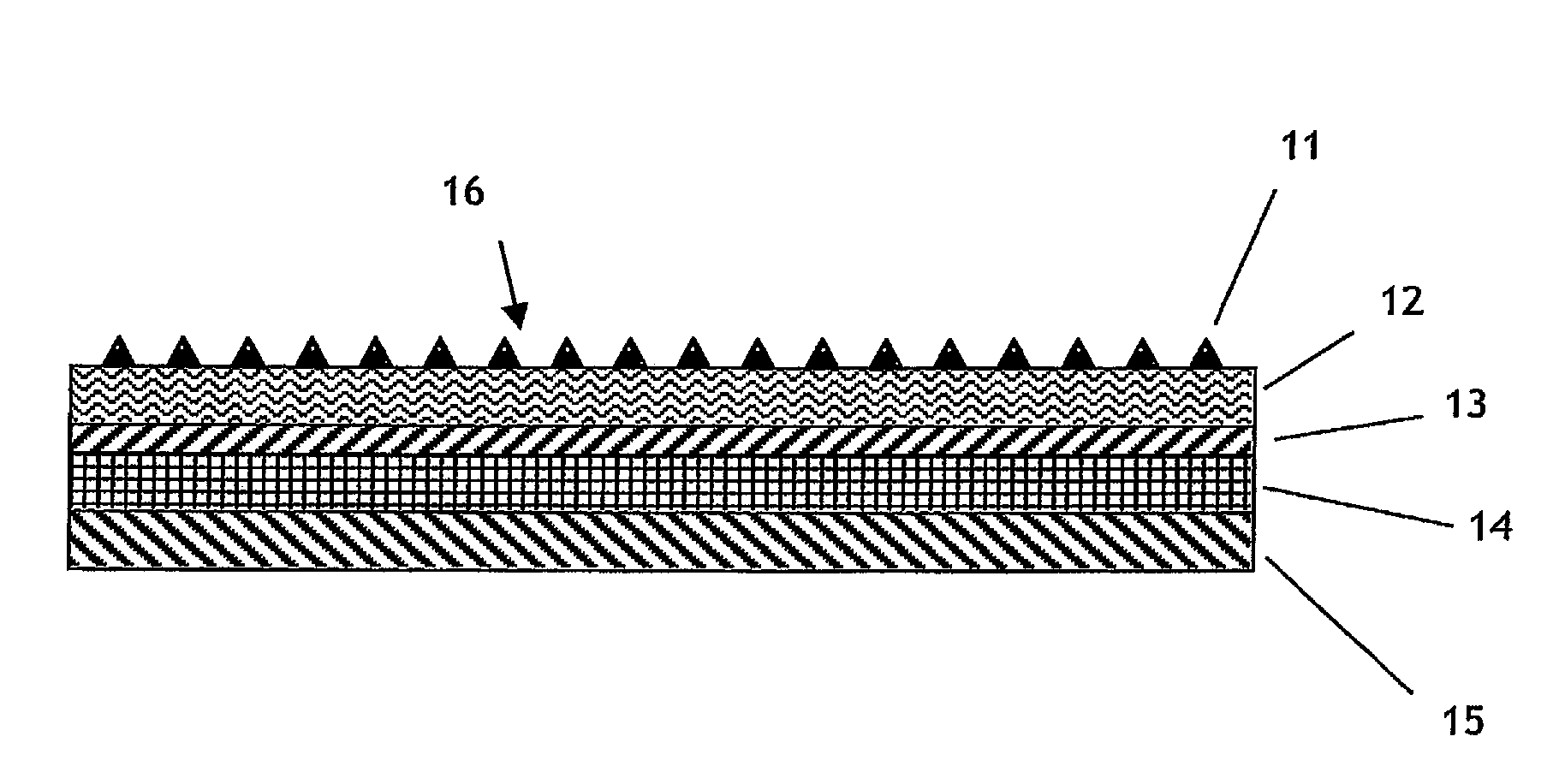

Pneumatic tire

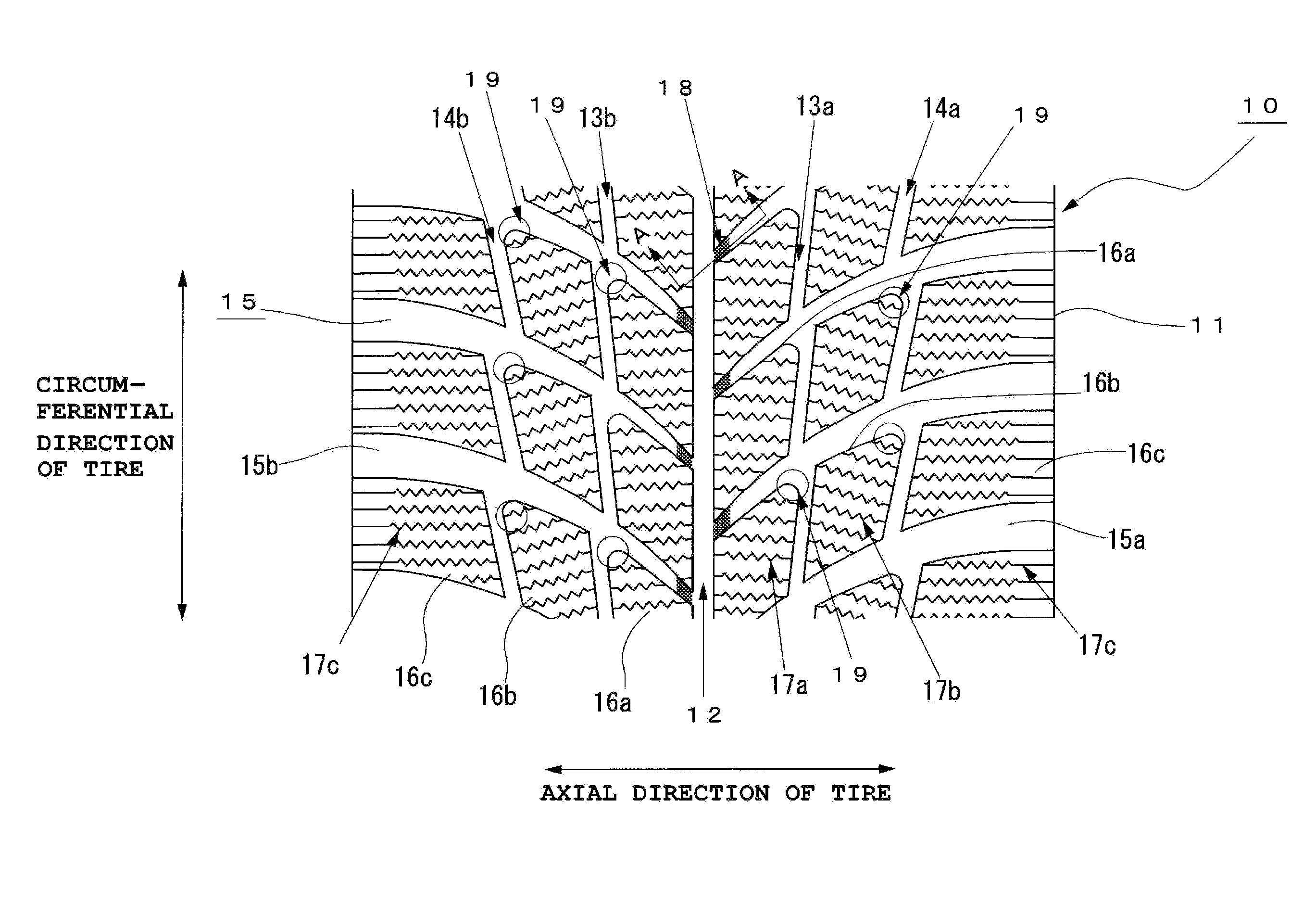

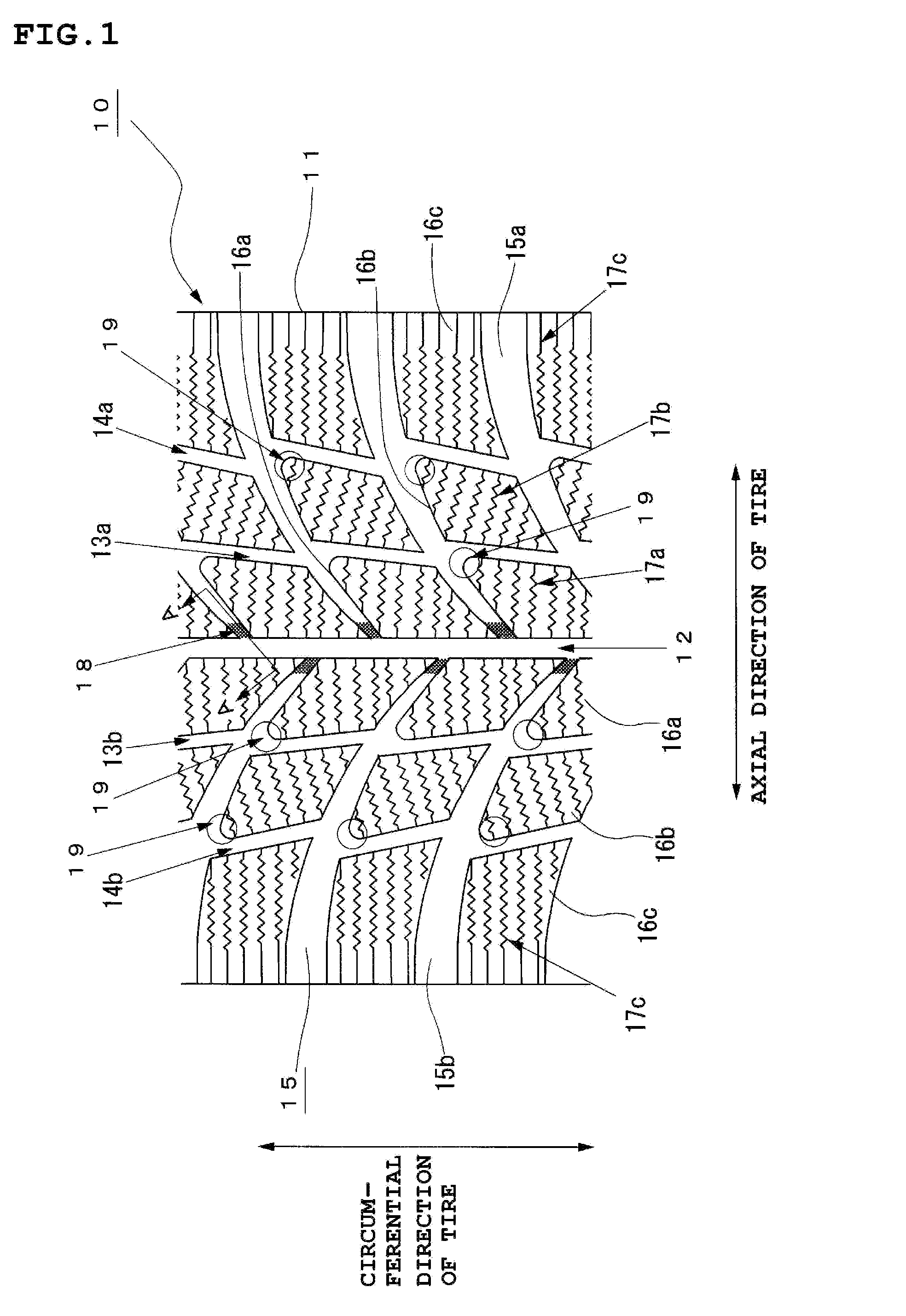

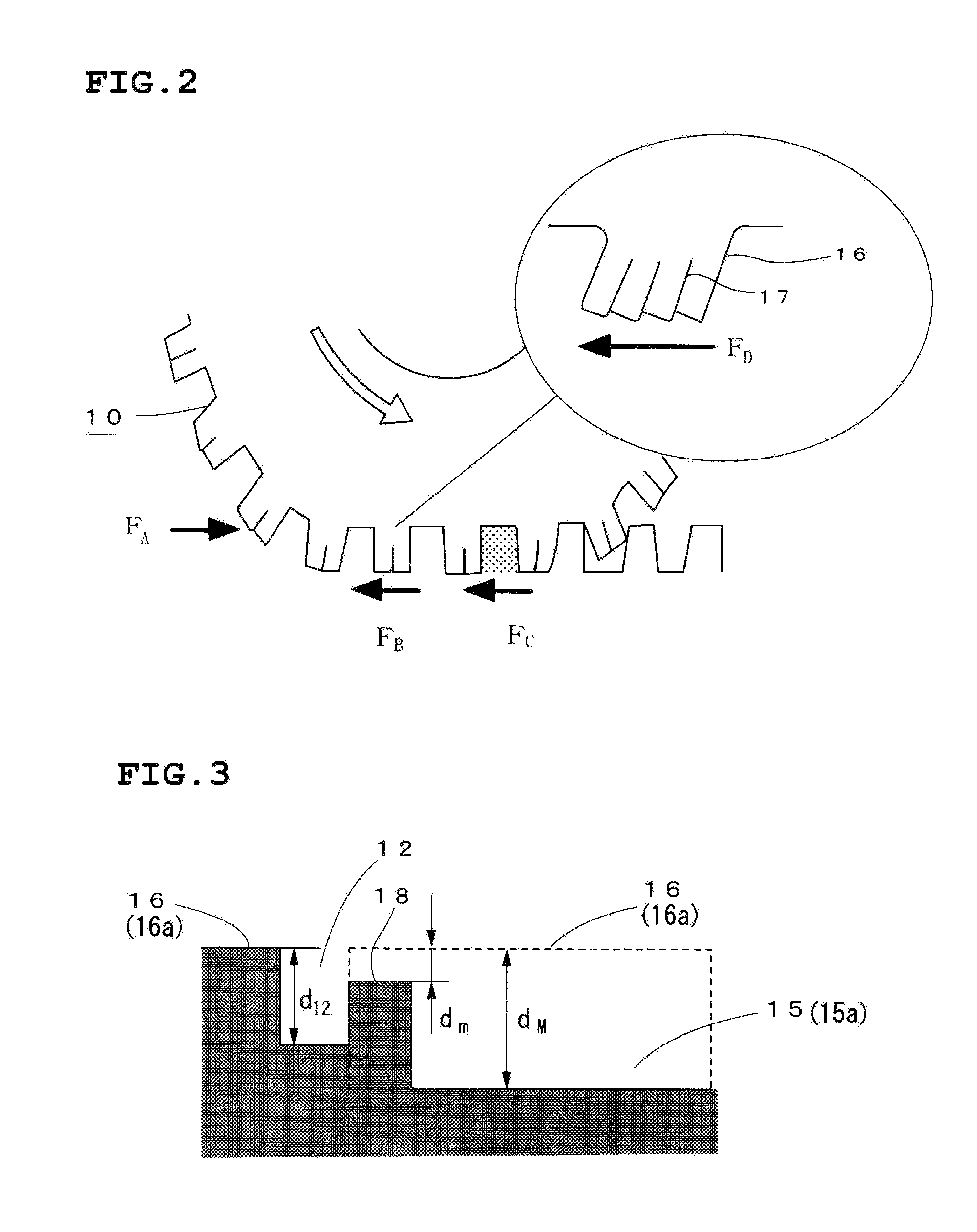

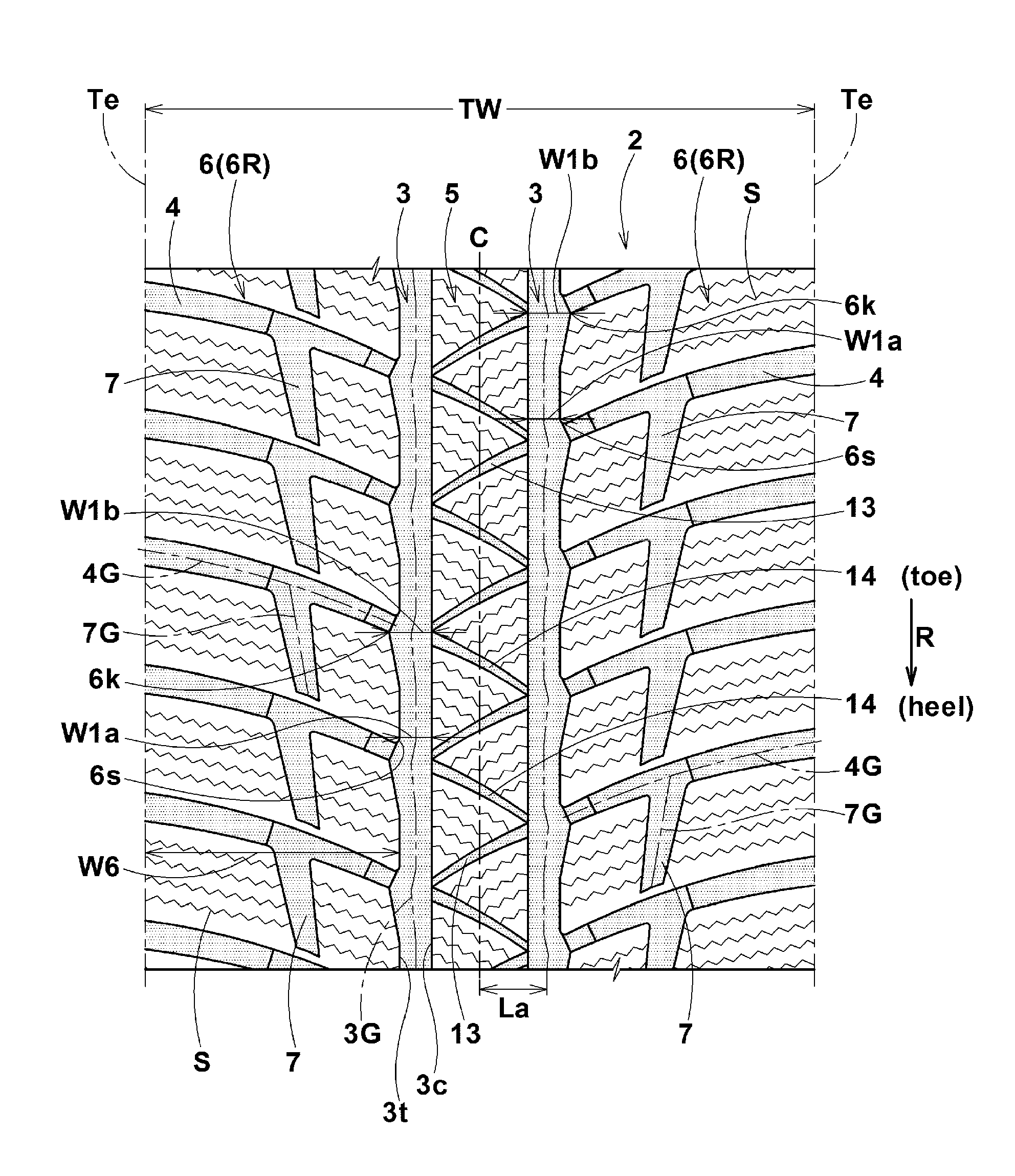

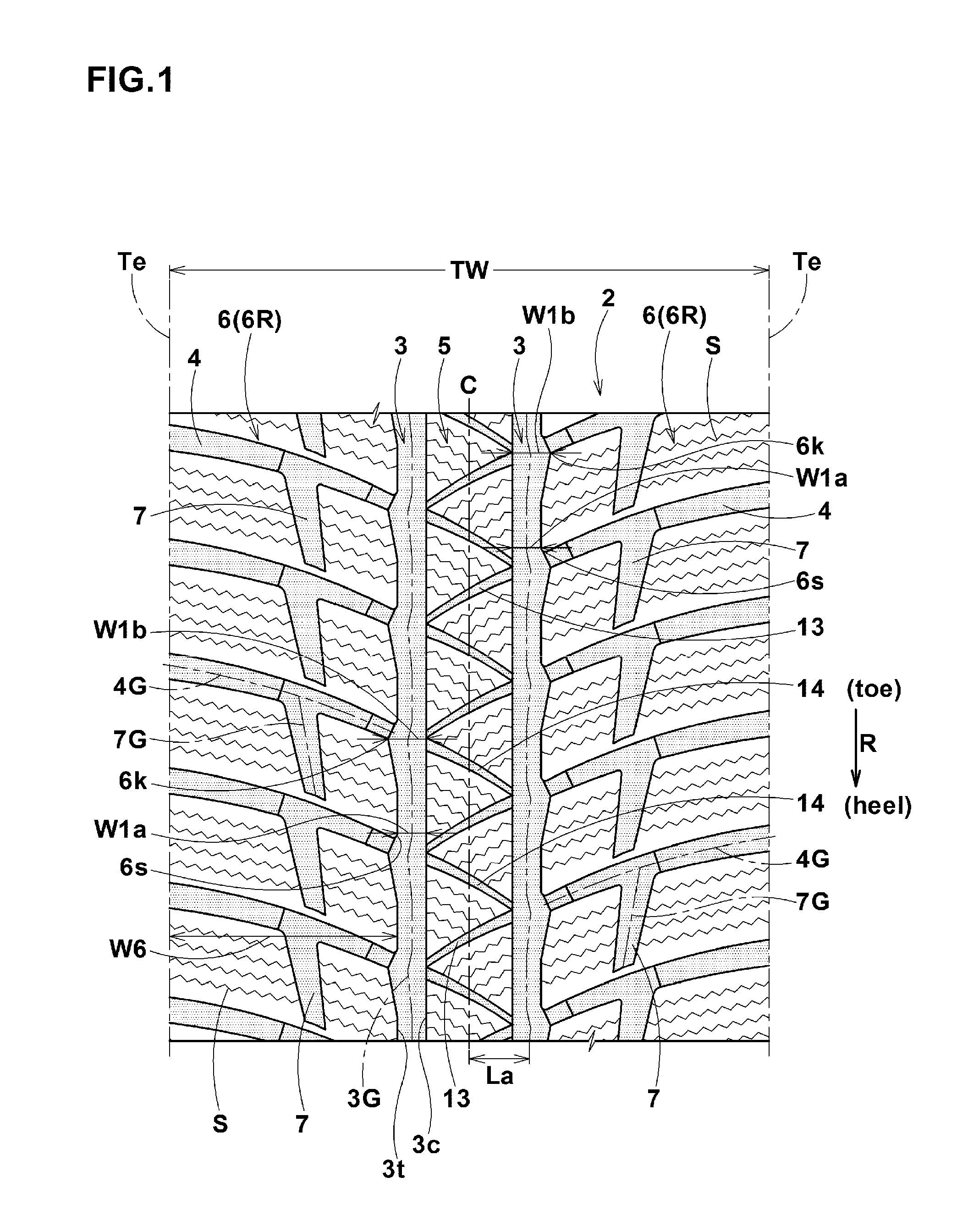

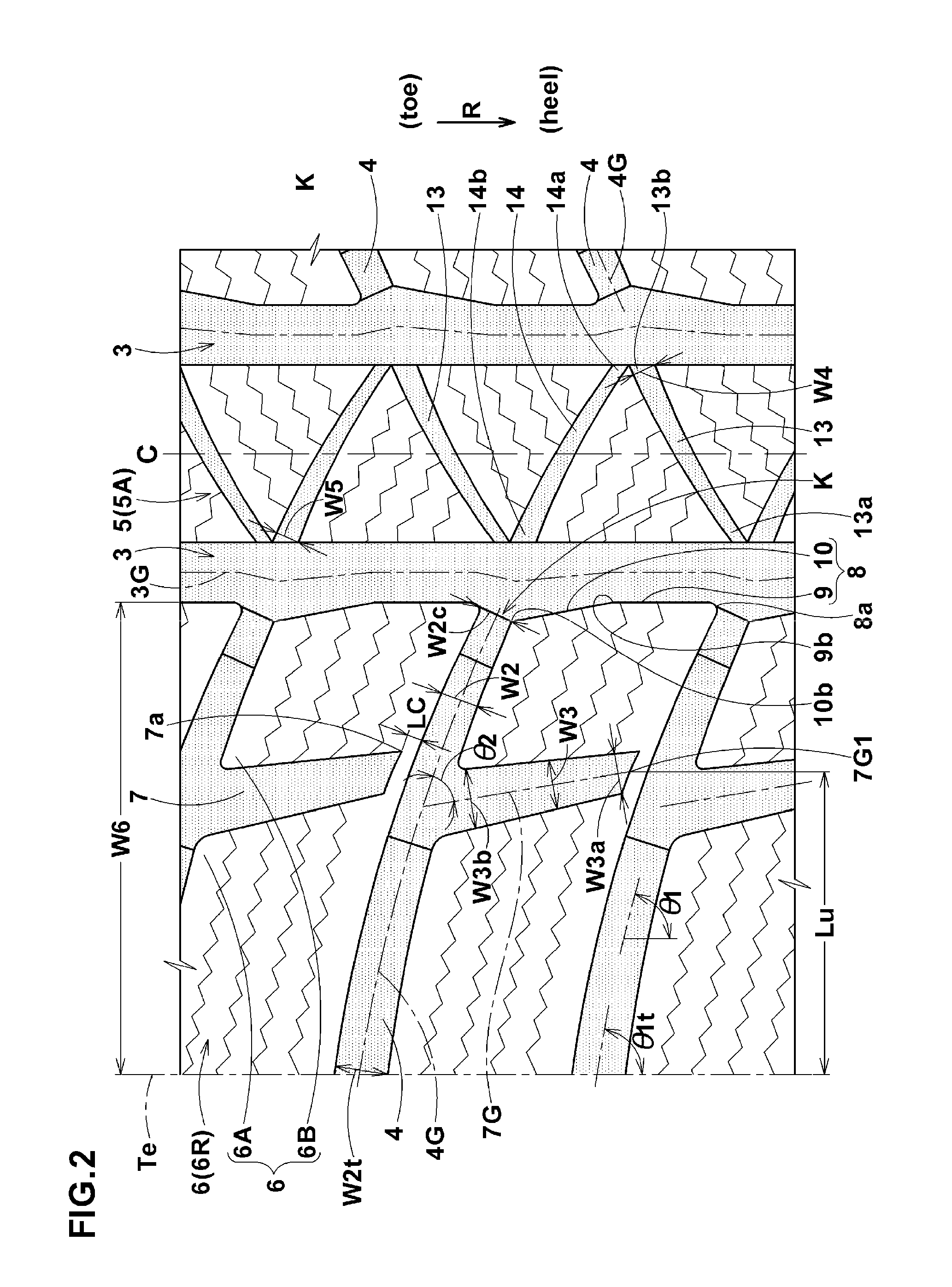

ActiveUS20150321518A1Drop in block rigidityReduced wet braking performanceTyre tread bands/patternsNon-skid devicesShoulder regionWear resistance

A pneumatic tire (10) has, in the surface of the tread (11), a central circumferential groove (12) located at the center of the contact patch width and extending circumferentially around the tire, a plurality of longitudinal grooves (13 (13a, 13b)) formed on the axially outside of the central circumferential groove (12), lug grooves (15), and blocks (16 (16a to 16c)) defined by the central circumferential groove (12), the longitudinal grooves (13), and the lug grooves (15). Each of the lug grooves (15) is formed such that its width in the shoulder region is greater than its width in the central region, and the sum of the groove area of the central circumferential groove (12) and the groove area of the longitudinal grooves (13) is smaller than the area of the lug grooves (15). As a result, the pneumatic tire (10) not only secures the wet braking performance and wear resistance performance on paved roads, but also improves the acceleration performance and braking performance and the steering stability performance on snowy roads.

Owner:BRIDGESTONE CORP

Rubber composition and tire

InactiveUS20150329704A1Prevent mold contaminationMaintaining abrasion resistanceSpecial tyresPolymer scienceVulcanization

An object of the present invention is to provide a rubber composition which can prevent mold contamination while maintaining abrasion resistance and wet grip performance, and a tire which has a tread composed of the rubber composition. The rubber composition of the present invention comprises a predetermined amount of at least one selected from the group consisting of stearic acid, a metal salt of saturated fatty acid and a specific mold release agent, a specific resin, silica and a silane coupling agent, based on a diene rubber component, where an amount of an unreacted silane coupling agent in the rubber composition before vulcanization is within a predetermined range.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and pneumatic tire using the same for tread

InactiveUS20070112121A1Maintain roll resistanceWet performanceSpecial tyresRolling resistance optimizationAspect ratioEngineering

Owner:SUMITOMO RUBBER IND LTD

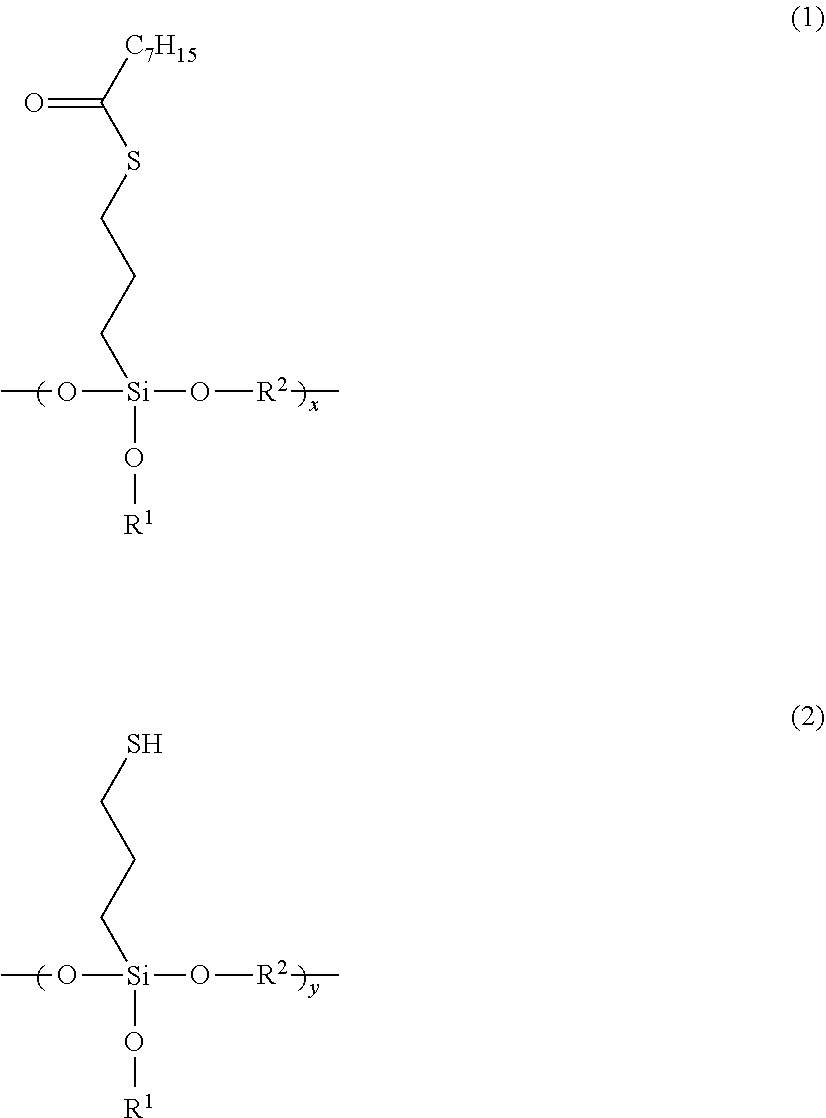

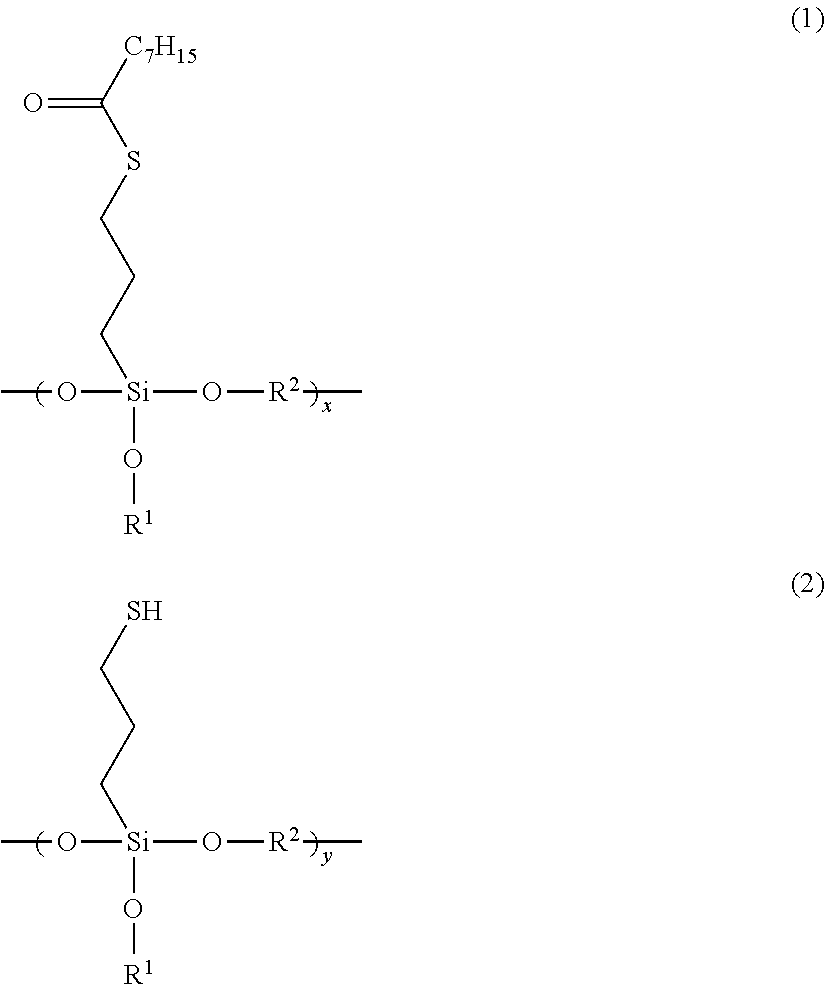

Rubber composition and pneumatic tire using the same

InactiveUS20070149648A1Abrasion resistance wetProcessability wetSpecial tyresRolling resistance optimizationRolling resistancePolymer science

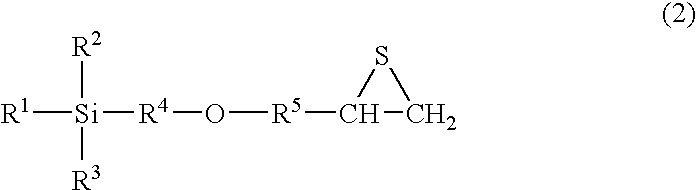

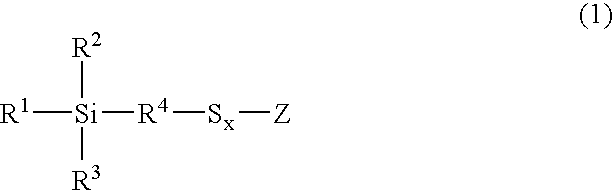

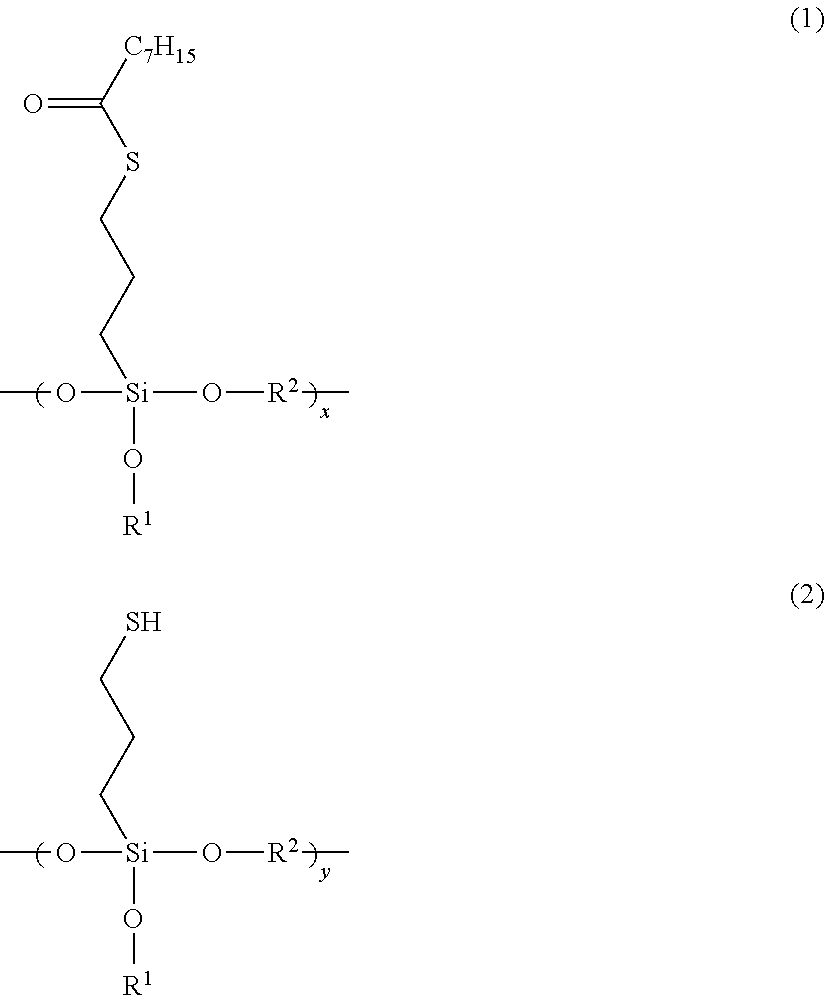

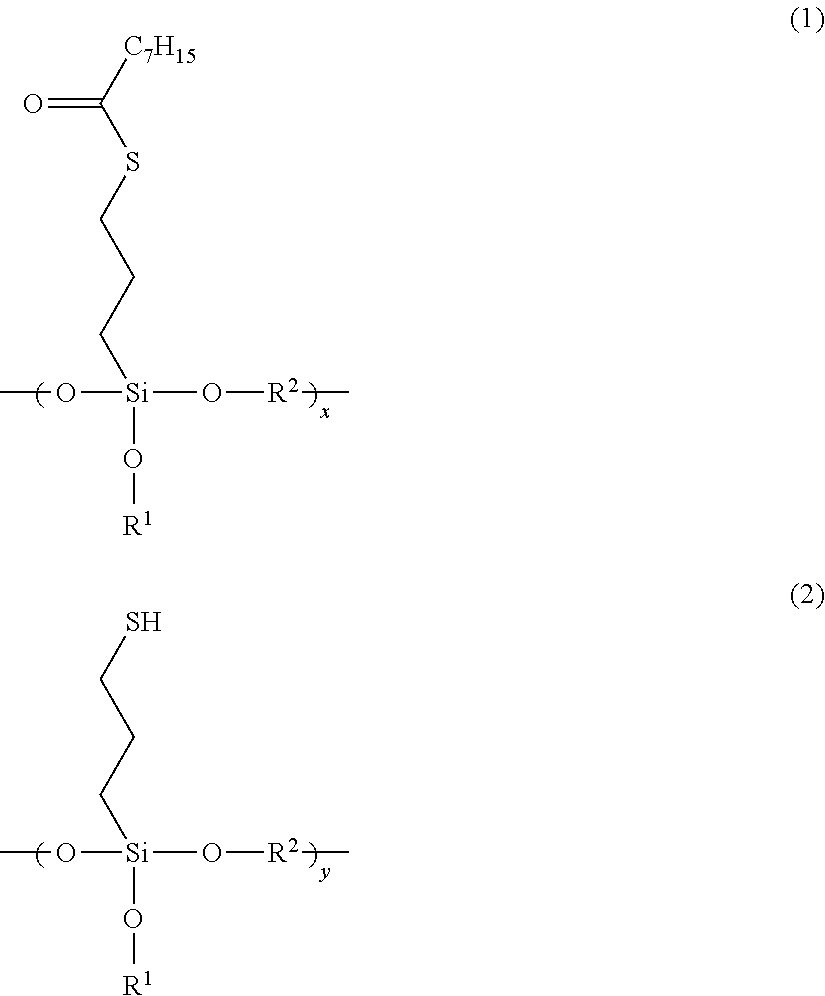

A rubber composition capable of improving all of processability, abrasion resistance, rolling resistance property and wet skid performance and a pneumatic tire using the same are provided.A rubber composition comprising 25 to 100 parts by weight of a surface-treated silica based on 100 parts by weight of a rubber component comprising a natural rubber and / or a diene synthetic rubber, the surface-treated silica being obtainable by mixing a silica and a sulfur-containing organic silicon compound represented by the general formula (1):or the general formula (2):in an amount of 1 to 20 parts by weight of the sulfur-containing organic silicon compound on the basis of 100 parts by weight of the silica under a temperature of 130° to 180° C.

Owner:SUMITOMO RUBBER IND LTD

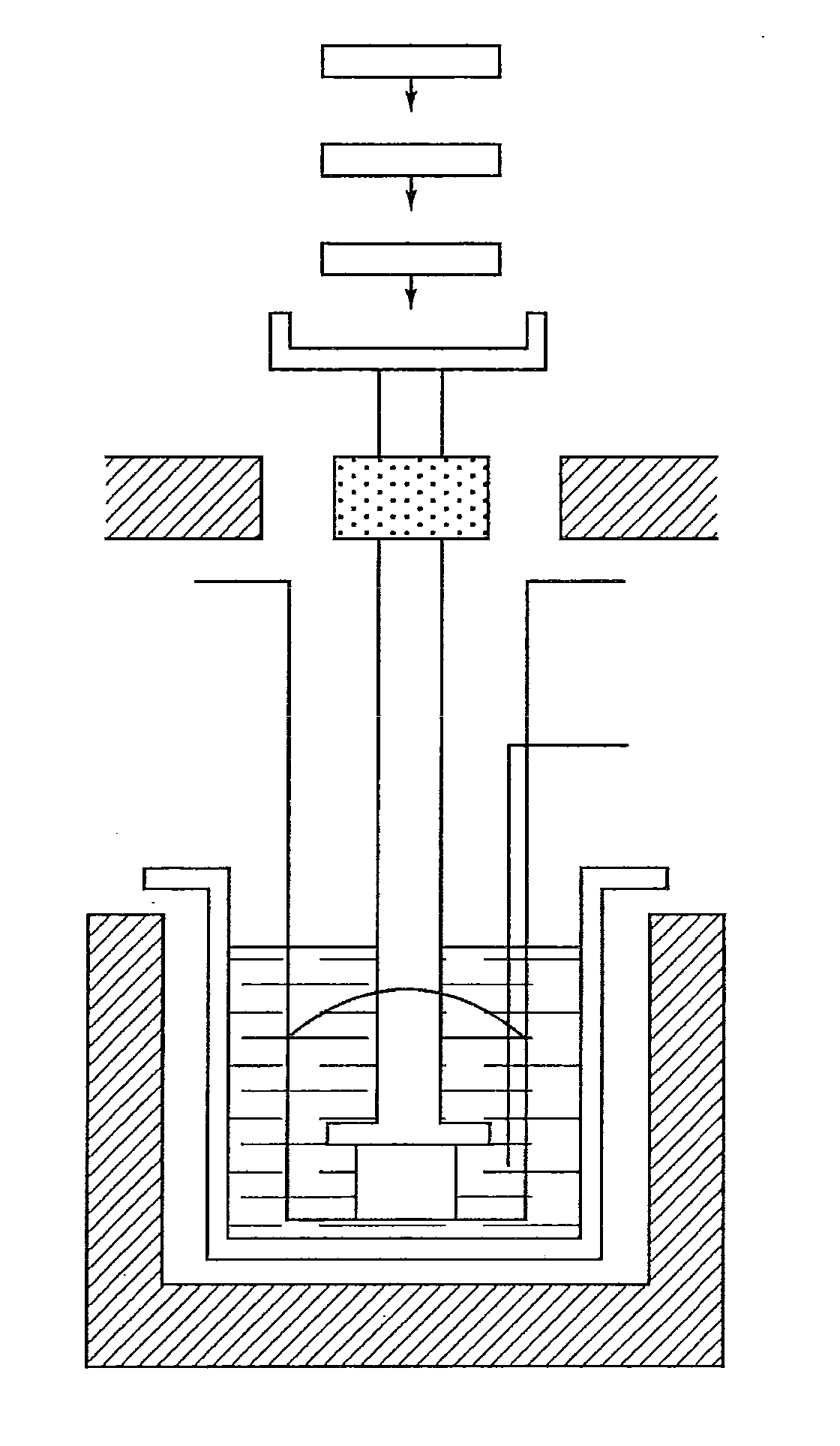

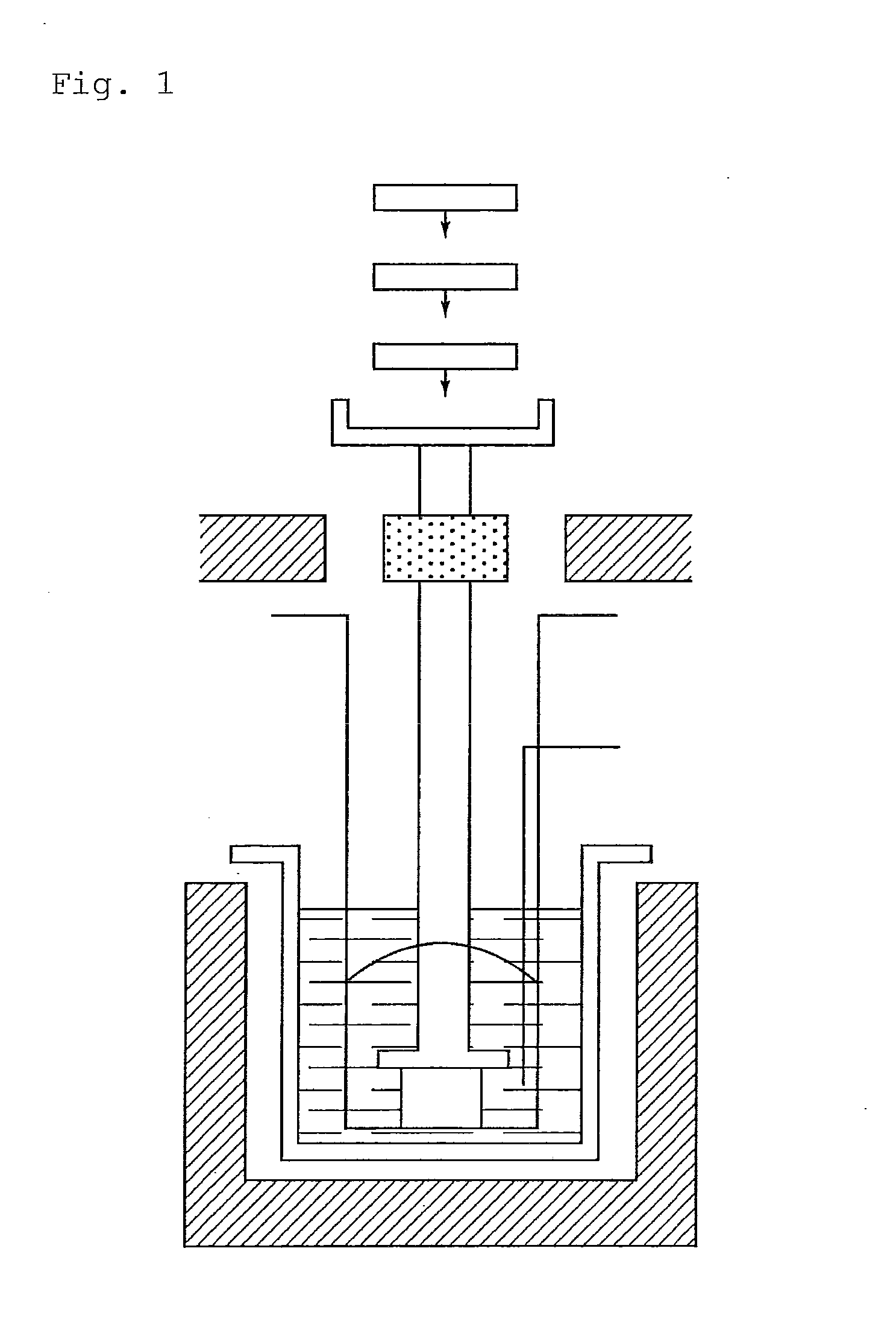

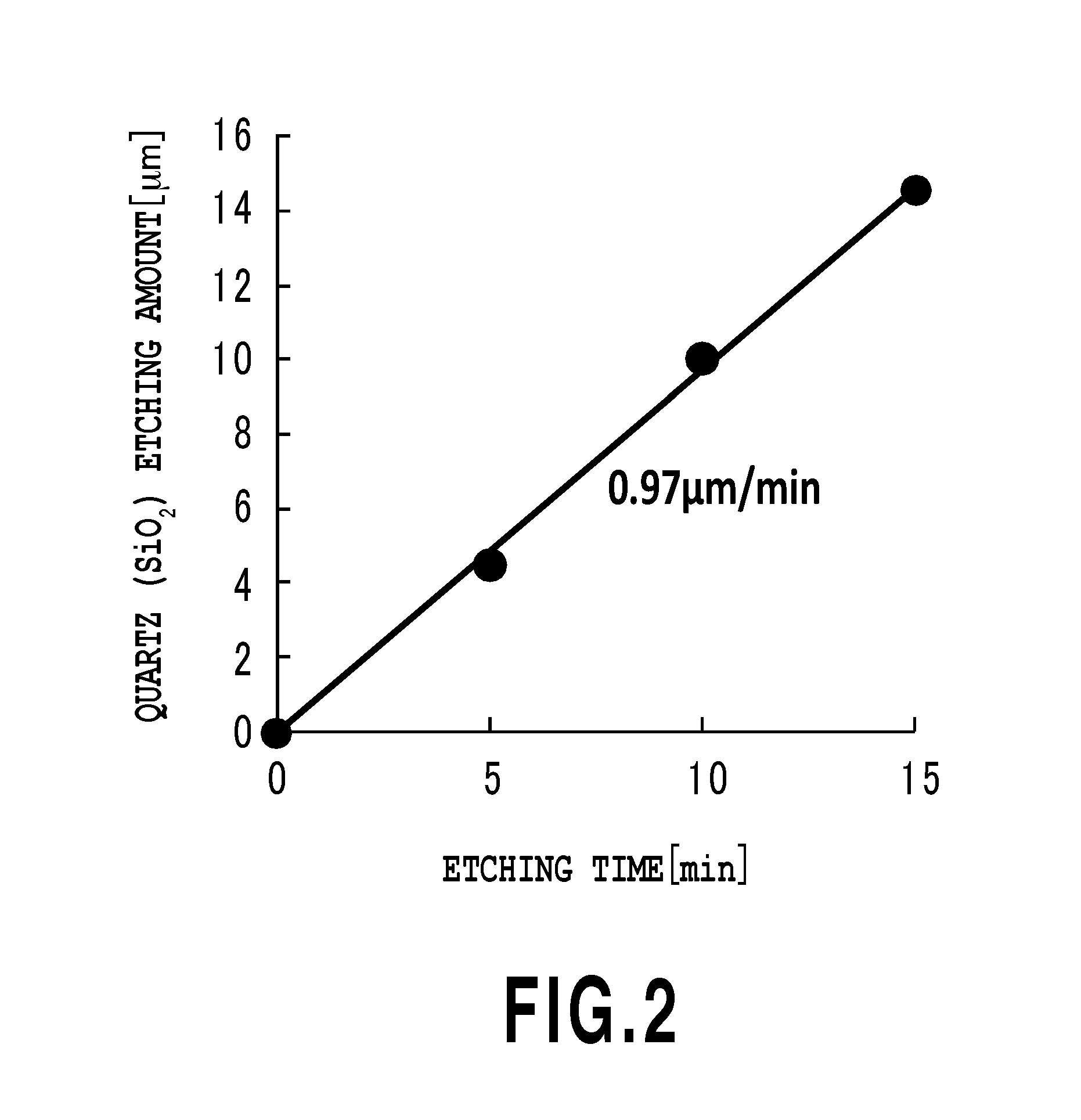

Method of etching of soi substrate, and back-illuminated photoelectric conversion module on soi substrate and process of manufacture thereof

ActiveUS20130320477A1Wet performanceImprove flatnessSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryEngineering

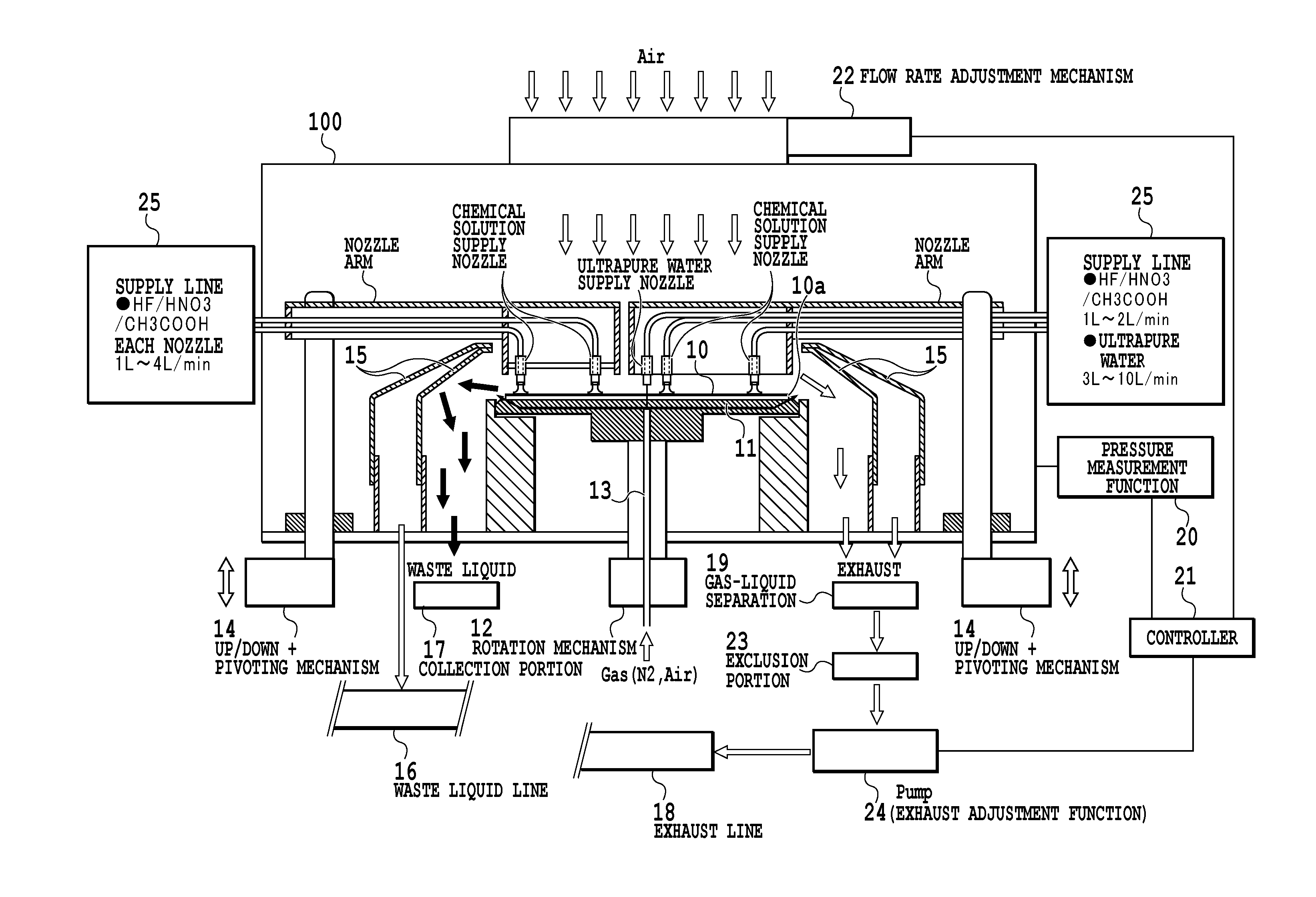

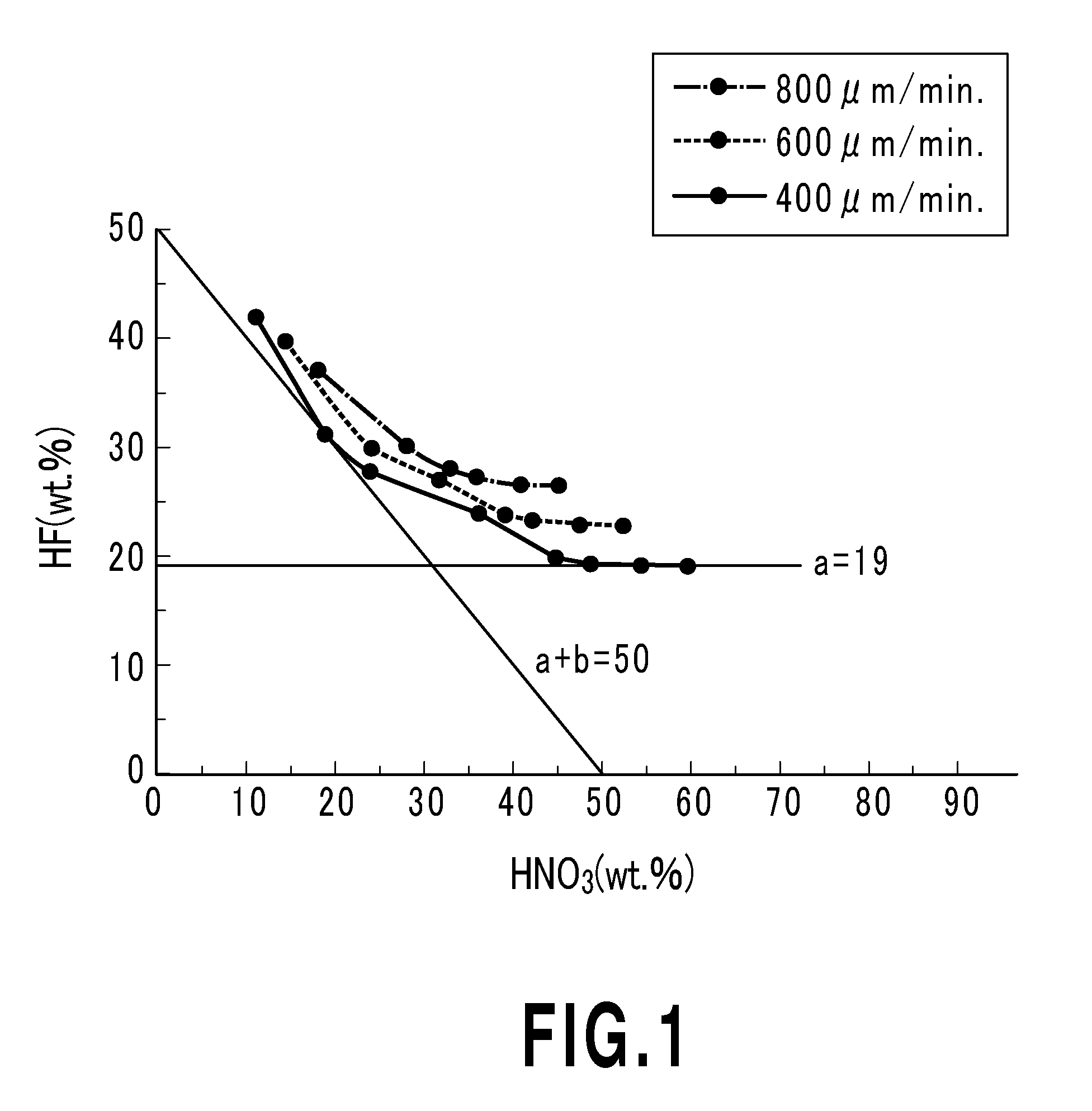

A method of etching capable of rapidly and flatly performing wet etching on a Si substrate using fluonitric acid represented by HF(a)HNO3(b)H2O(c) (where the unit of a, b and c is wt % and a+b+c=100). The etching rate of an SiO2 layer with the highly concentrated fluonitric acid is significantly lowered by the appropriate selection of its composition as compared with the etching rate of the Si substrate, and etch the Si substrate until the SiO2 layer is exposed. In this way, it is possible to rapidly etch the Si substrate and significantly enhance the flatness of the etched surface.

Owner:TOHOKU UNIV

Rubber composition for use in tires, and pneumatic tire

InactiveUS20130303683A1Improve fuel economyImprove wet grip performanceSpecial tyresRolling resistance optimizationPolymer scienceBackbone chain

The present invention provides a rubber composition for a tire, which improves in fuel economy, wet grip performance, and abrasion resistance; and a pneumatic tire using the same. The present invention relates to a rubber composition for a tire, including: a rubber component including a modified styrene butadiene rubber that contains a constitutional unit derived from a specific nitrogen-containing compound in a main chain; silica; and a specific silane coupling agent.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and pneumatic tire comprising tread formed from said rubber composition

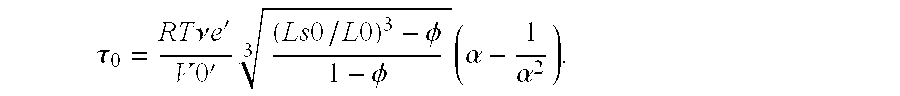

Provided is a rubber composition that achieves a balanced improvement in fuel economy, abrasion resistance, and wet grip performance while having good processability. Also provided is a pneumatic tire including a tread formed from the rubber composition. The present invention relates to a rubber composition containing: a rubber component including a copolymer; and carbon black and / or silica, the copolymer containing a structural unit derived from a conjugated diene monomer and a structural unit derived from a compound represented by the following formula (1):wherein R11 represents a C1-C30 hydrocarbon group.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

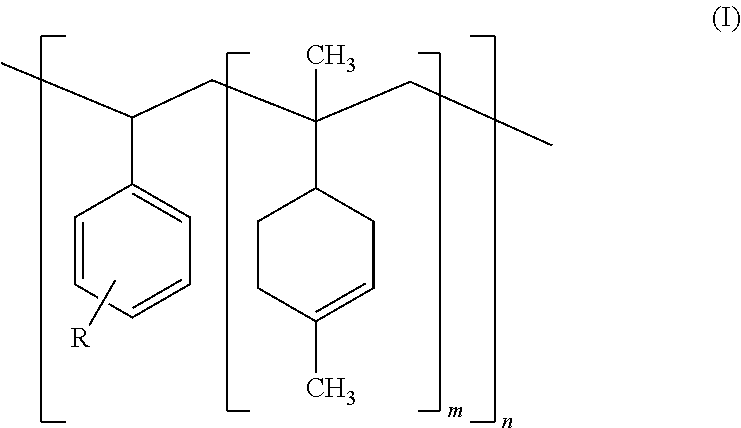

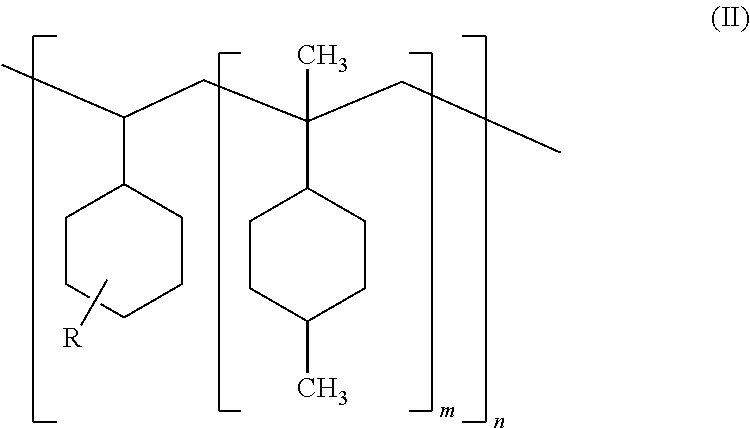

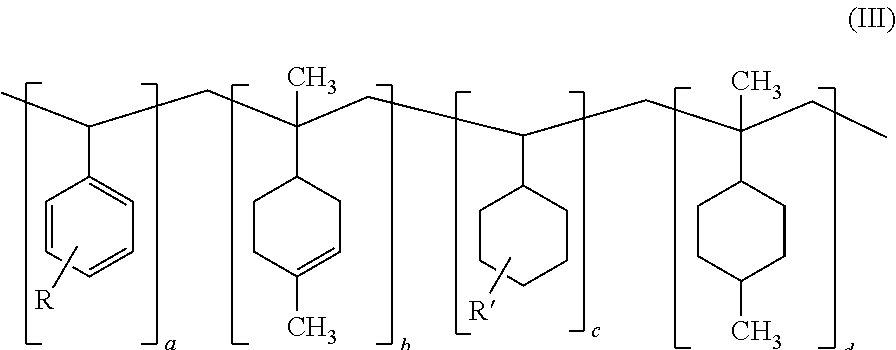

The present invention provides a pneumatic tire including a tread formed from a rubber composition that can simultaneously highly improve initial grip performance and stable grip performance during the middle and late periods of running, and further can reduce the occurrence of blowing even during high-temperature running. The present invention relates to a pneumatic tire including a tread, the tread being formed from a rubber composition containing a diene rubber, the rubber composition further containing a hydrogenated terpene aromatic resin obtained by hydrogenation of the double bonds of a terpene aromatic resin, the hydrogenated terpene aromatic resin having a degree of hydrogenation of double bonds of 5-100%, a hydroxyl value of 20 mg KOH / g or less, and a softening point of 116-180° C., the hydrogenated terpene aromatic resin being present in an amount of 1-50 parts by mass per 100 parts by mass of the diene rubber.

Owner:SUMITOMO RUBBER IND LTD

Tire rubber composition and pneumatic tire

InactiveUS20110136968A1Abrasion resistance wetMechanical strength wetSpecial tyresRolling resistance optimizationRolling resistanceEngineering

It is an object of the present invention to provide a tire rubber composition and a pneumatic tire produced using the rubber composition, which improve mechanical strength, abrasion resistance, rolling resistance, wet grip performance, and dry grip performance in good balance. The present invention relates to a tire rubber composition comprising: a rubber component that contains a modified diene rubber; and a silica component that contains a silica surface-treated with a silane coupling agent, wherein the amount of the modified diene rubber in 100% by mass of the rubber component is 15% by mass or more, and the dispersion ratio of the silica component is 70% or higher.

Owner:SUMITOMO RUBBER IND LTD

Tire rubber composition and pneumatic tire

InactiveUS8669321B2Improve performanceIncrease resistanceSpecial tyresInksRolling resistanceEngineering

It is an object of the present invention to provide a tire rubber composition and a pneumatic tire produced using the rubber composition, which improve mechanical strength, abrasion resistance, rolling resistance, wet grip performance, and dry grip performance in good balance. The present invention relates to a tire rubber composition comprising: a rubber component that contains a modified diene rubber; and a silica component that contains a silica surface-treated with a silane coupling agent, wherein the amount of the modified diene rubber in 100% by mass of the rubber component is 15% by mass or more, and the dispersion ratio of the silica component is 70% or higher.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS20120285594A1Sacrificing steering stabilityReduce stiffnessTyre tread bands/patternsNon-skid devicesEngineeringTread

Owner:SUMITOMO RUBBER IND LTD

Starch compositions and methods for use in papermaking

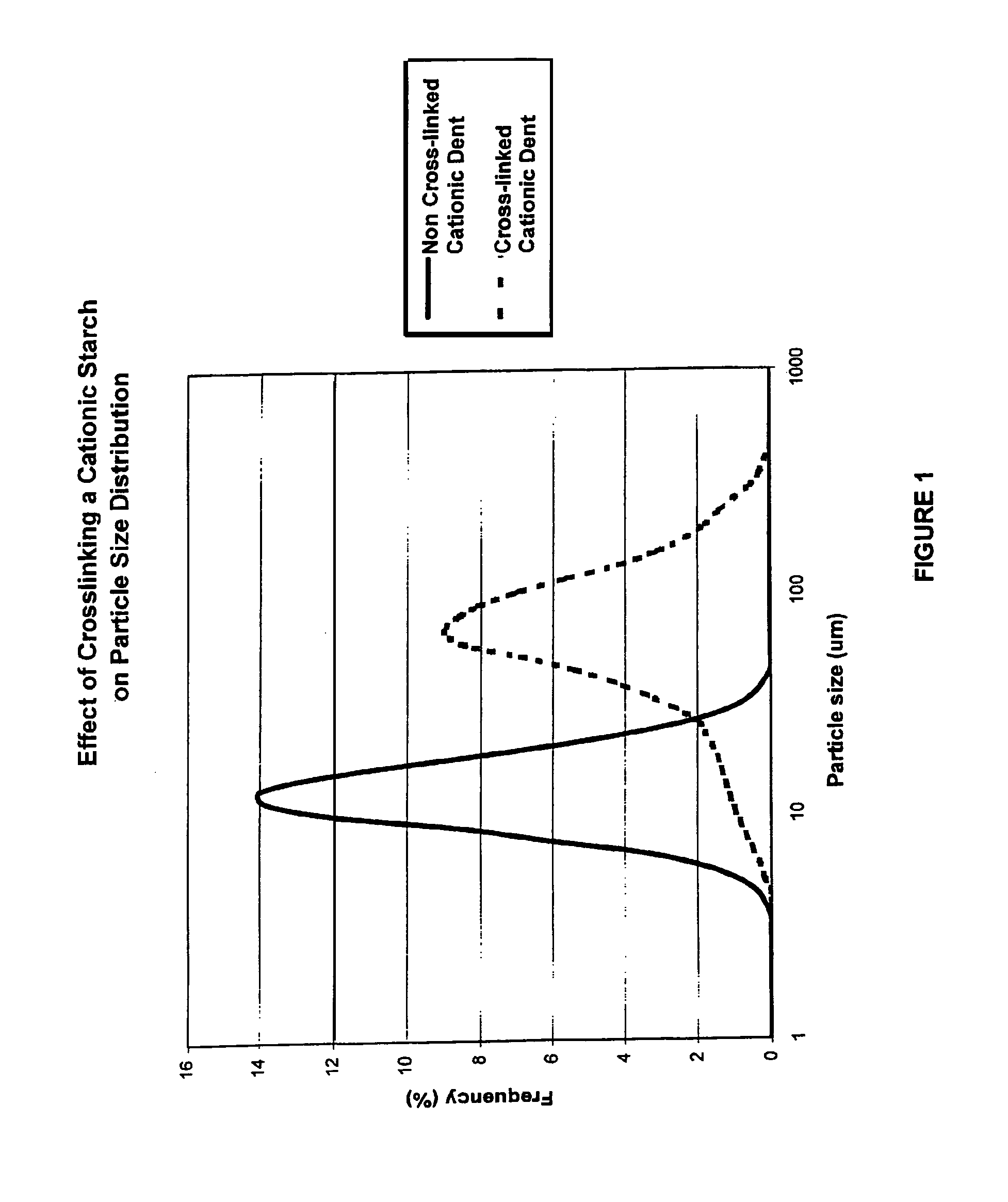

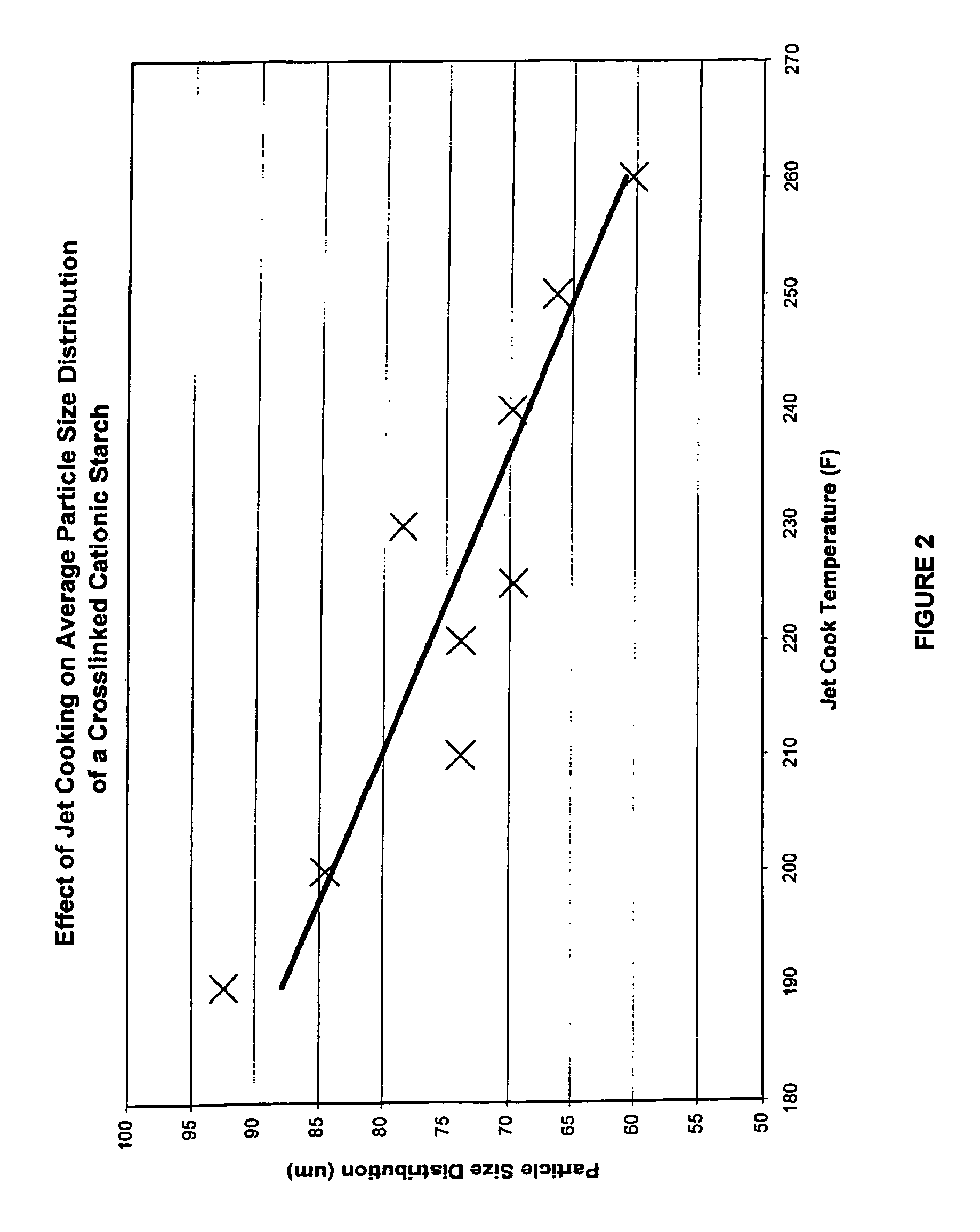

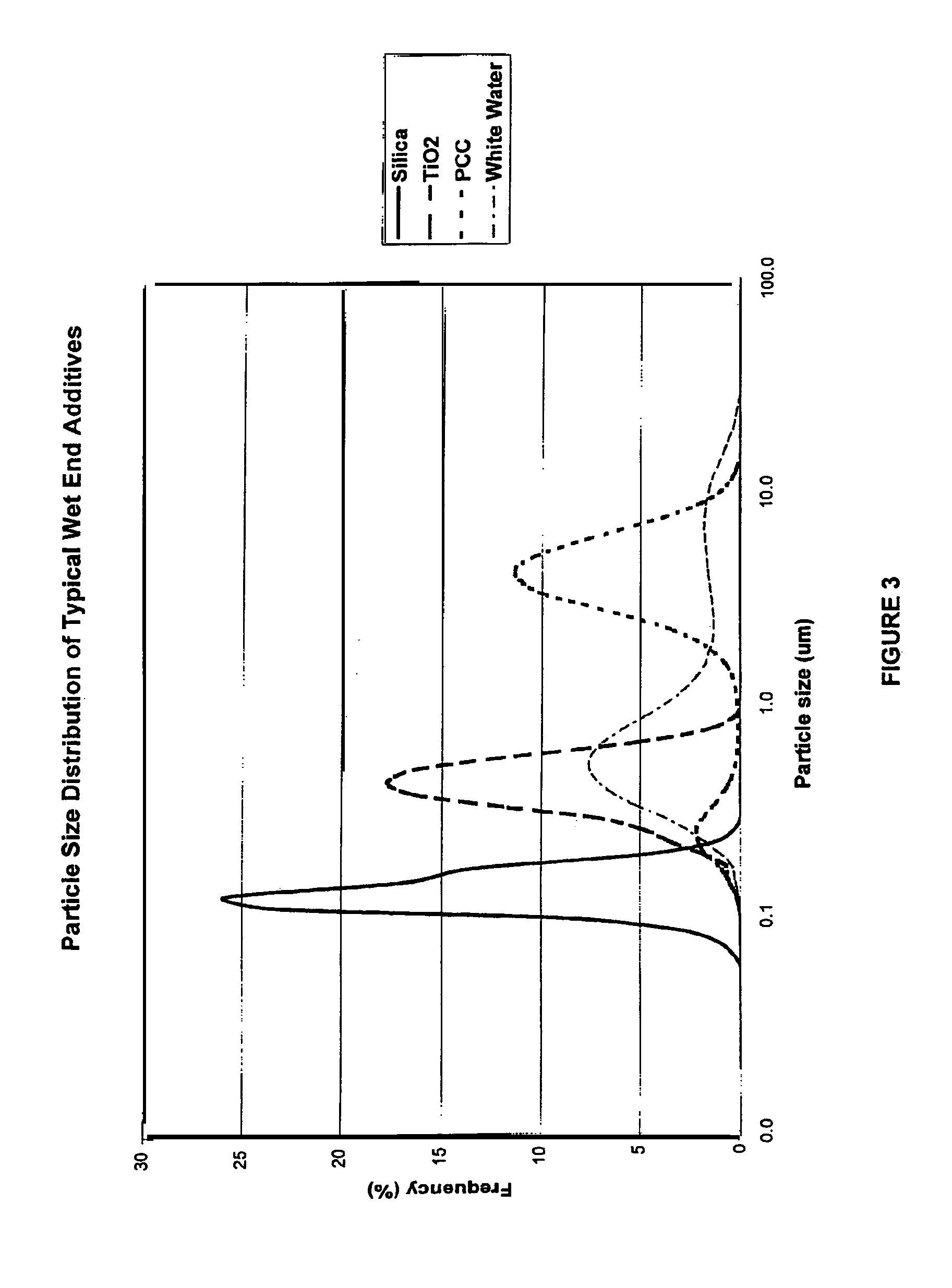

InactiveUSRE44519E1Improve performanceDrainage property alteredNatural cellulose pulp/paperSpecial paperPapermakingChemistry

Starch compositions, including cationic crosslinked starches, and methods of using those starches in papermaking are disclosed. In particular, a cationized crosslinked starch and use of the starch in the wet end system of a paper machine is disclosed. The starch compositions of the disclosure are particularly adapted for customization for specific wet end systems, and allow for modification to correspond to variations in the wet end of the papermaking machine.

Owner:CARGILL INC

Rubber composition for tread and pneumatic tire

InactiveUS8759432B2Improve rolling resistanceWell-balanced mannerSynthetic resin layered productsSpecial tyresCrack resistanceRolling resistance

Owner:SUMITOMO RUBBER IND LTD

Rubber composition and tire

InactiveUS20190389995A1Improve balanceWet abrasionSpecial tyresRolling resistance optimizationPolymer scienceFuel efficiency

An object of the present invention is to provide a rubber composition having improved fuel efficiency, wet grip performance and abrasion resistance in good balance, and a tire having a tire member composed of the rubber composition. The rubber composition is a rubber composition comprising: 5 to 20 parts by mass of a terpene resin having a weight-average molecular weight of 500 to 4,000, 5 to 30 parts by mass of a liquid rubber and / or a liquid resin having a weight-average molecular weight of 100 to 4,000, and 95 to 160 parts by mass of silica, based on 100 parts by mass of a diene rubber, wherein a volume change rate of the rubber composition measured in accordance with JIS K 6258 after having been dipped in toluene of 40° C. for 24 hours is of 220 to 270%.

Owner:SUMITOMO RUBBER IND LTD

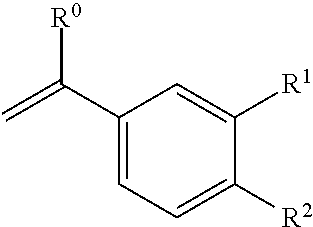

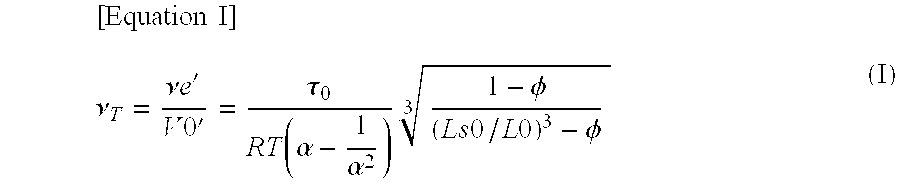

Rubber composition for tire, and pneumatic tire

Provided are a rubber composition for a tire capable of improving fuel economy, wet grip performance, abrasion resistance, and processability, and a pneumatic tire including the composition. Included is a rubber composition for a tire including: a diene polymer; silica; and a compound of formula (I) below, the diene polymer being a modified diene polymer obtained by reacting components (A) and (B), the amount of the compound of formula (I) being 0.1-10 parts by mass per 100 parts by mass of the rubber component, the component (A) being an active alkali metal-terminated conjugated diene polymer obtained by polymerizing a conjugated diene monomer alone or with an aromatic vinyl monomer, in the presence of a component (C), the component (B) being a modifying agent containing a functional group, and the component (C) being a chemical species obtained by reacting an organic alkali metal compound with a compound of formula (1) below.

Owner:SUMITOMO RUBBER IND LTD

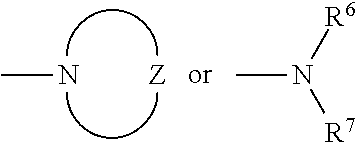

Copolymer, rubber composition, and tire

ActiveUS20210230416A1Improve fuel economyWet performanceSpecial tyresRolling resistance optimizationPolymer scienceOrganic chemistry

Provided are copolymers which provide improved overall performance in terms of fuel economy and wet grip performance, as well as rubber compositions and tires containing the copolymers. Included is a copolymer obtained by copolymerizing an aromatic vinyl compound, a conjugated diene compound, and a compound represented by the formula (1) below or by copolymerizing a conjugated diene compound and a compound represented by the formula (1) below, the copolymer having a weight average molecular weight of 1.0×103 to 2.5×106,wherein R1 and R2 may be the same or different and each represents a functional group containing at least two selected from the group consisting of carbon, hydrogen, and silicon, and R1 and R2 may be joined together to form a ring structure.

Owner:SUMITOMO RUBBER IND LTD

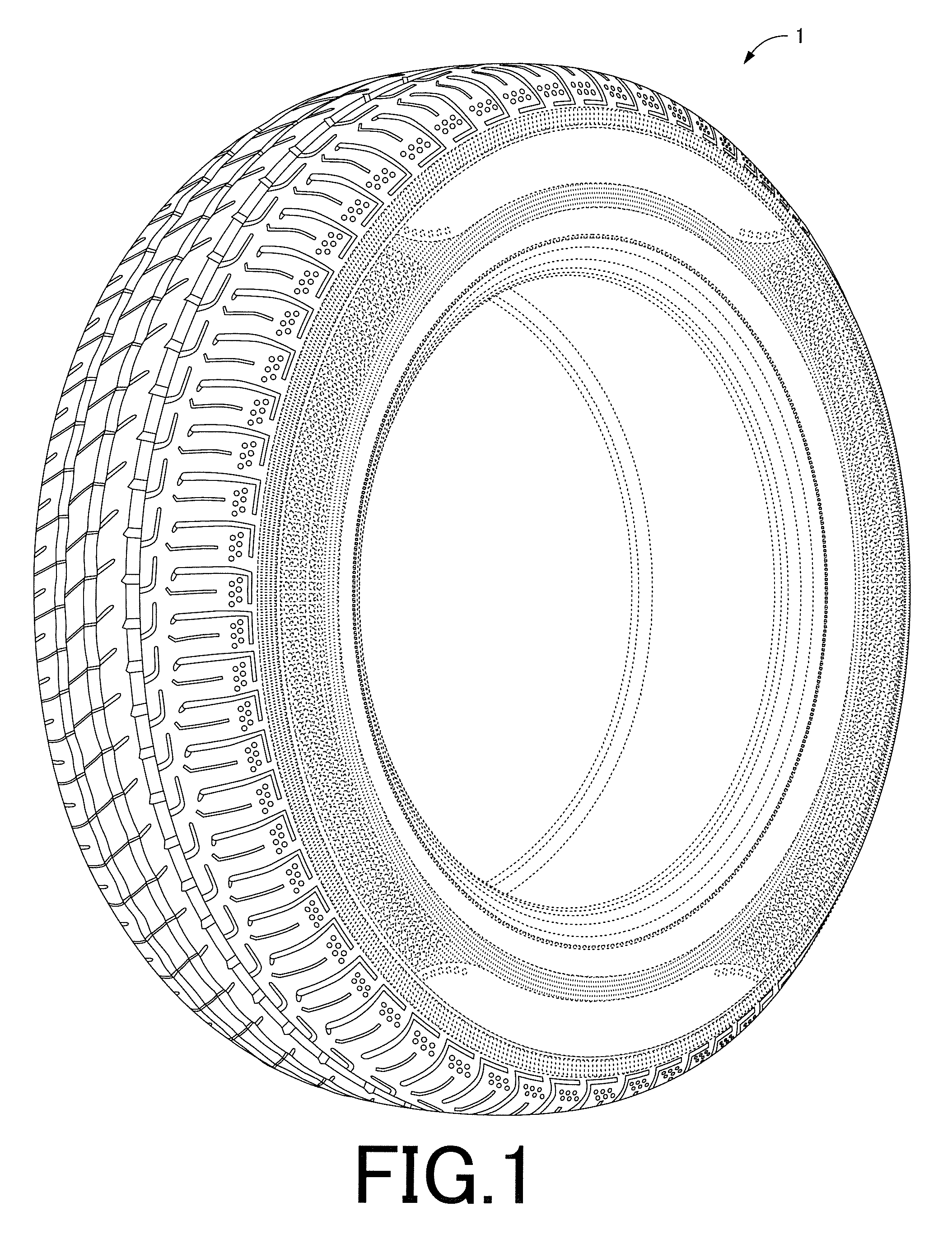

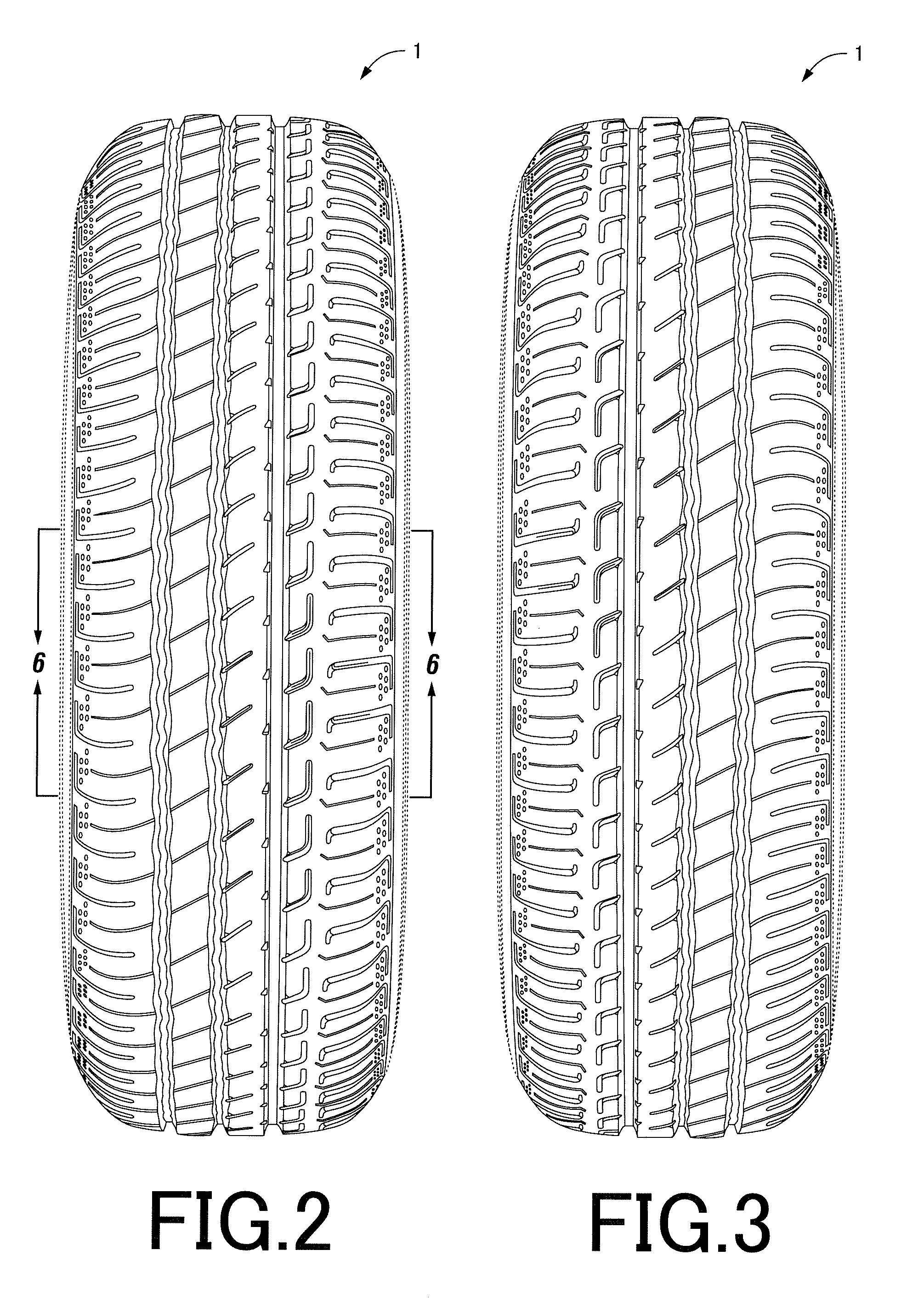

Pneumatic tire with tread having wave shaped circumferential groove

InactiveUS8770241B2Reduce widthWet performance and tire noise performance are not reducedTyre tread bands/patternsTyre sidewallsGroove widthWave shape

A pneumatic tire includes a plurality of circumferential grooves and a first land portion. The circumferential grooves extend continuously in a tire circumferential direction. The first land portion extends in the tire circumferential direction between a pattern end and one of the circumferential grooves in a shoulder region located outside the circumferential grooves in a tire width direction. The first land portion has first lug grooves extending from the pattern end in the tire width direction and closed without communicating with the circumferential grooves are arranged in the tire circumferential direction. At least one circumferential groove is wave-shaped with a constant groove width in the tire width direction at a tread surface and formed in a wave shape in the circumferential direction at the tread surface and groove bottom. The wave-shaped circumferential groove has a shorter cycle length of waves at the groove bottom than at the tread surface.

Owner:THE YOKOHAMA RUBBER CO LTD

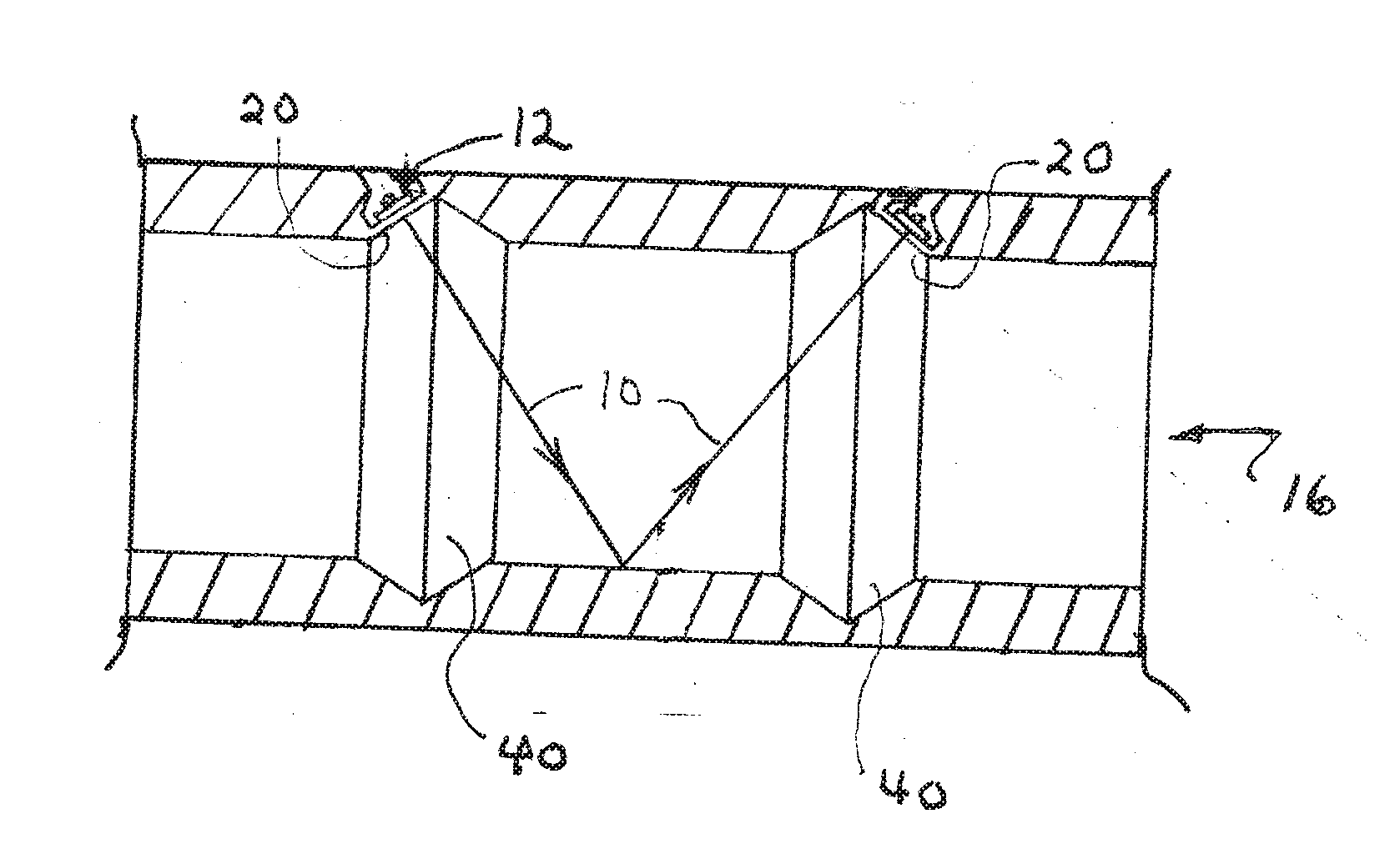

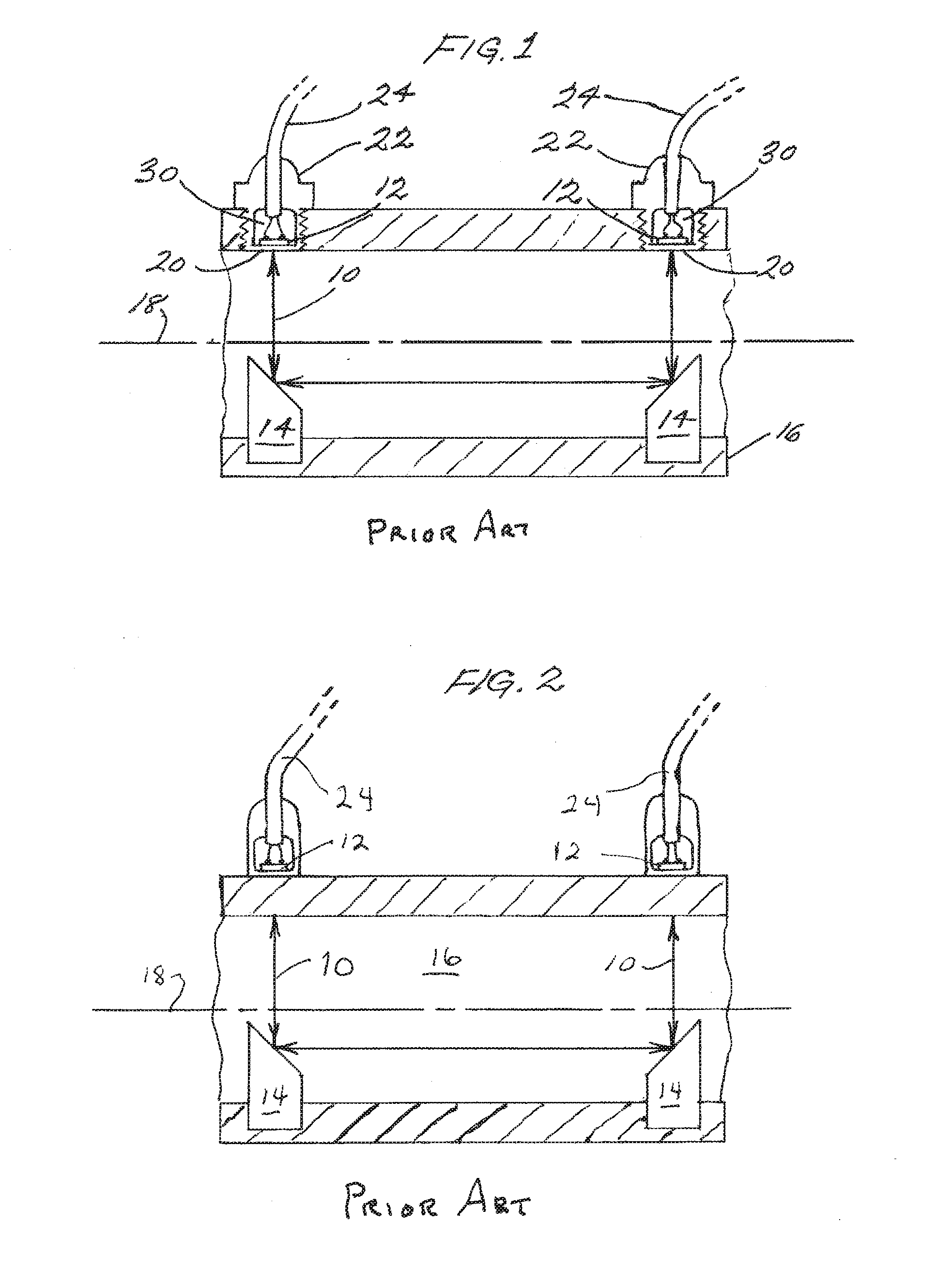

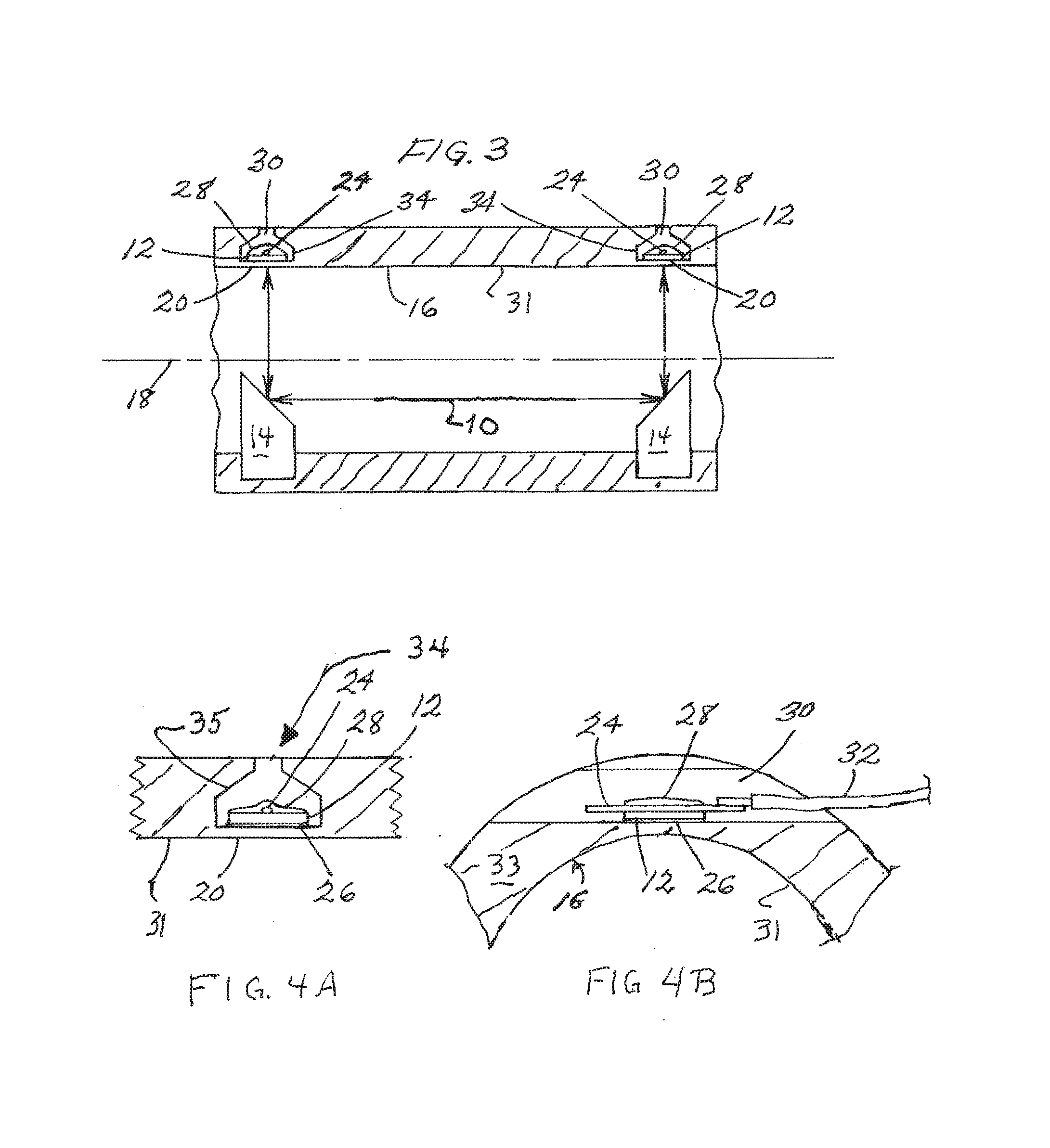

Transducer Mounted Between Two Spaced-Apart Interior Surfaces Of A Cavity In The Wall Of A Flow Tube

An ultrasonic flow meter comprises a cavity disposed in the wall of a flow tube. This cavity is preferably elongated along a direction perpendicular to a flow axis and has a flat interior surface portion proximal an interior surface of a wall of the flow tube. A piezoelectric transducer has a surface bonded to the flat interior surface portion of the cavity so as to transmit and receive acoustic signals through a thin window in the wall of the flow tube. An encapsulant, which may be combined with other elements, such as a mechanical strengthening piece, bonds the second side of the piezoelectric wafer to a second surface of the cavity. In a particular preferred embodiment, the cavity may be a dovetailed groove cut into a wall of the flow tube.

Owner:ONICON INC

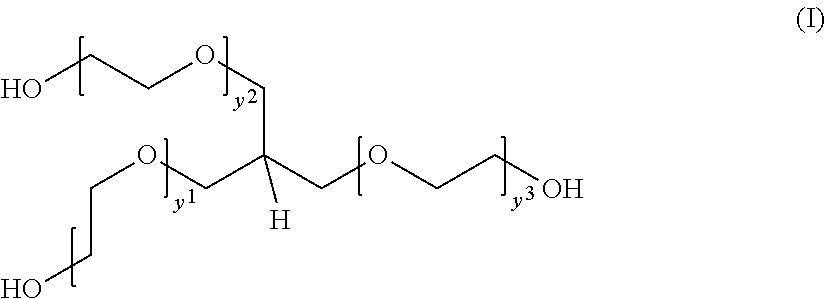

Alkoxylate compositions and their use as agricultural adjuvants

InactiveUS20150237852A1Wet performanceImprove performanceBiocideCarbohydrate active ingredientsAdjuvantSURFACTANT BLEND

Provided is a surfactant blend and its use as an adjuvant in agricultural compositions. The surfactant blend comprises: (a) an alkoxylate of formula I: R1O-(AO)x-(EO)y—H (I); and (b) an alkoxylate of formula II: R2O-(EO)r—(PO)p-(EO)q—H (II) wherein R1, R2, x, y, r, p, and q are as defined herein.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com