Mounting apparatus using ball and socket joints with gripping features

a technology of ball and socket joint and mounting apparatus, which is applied in the direction of mechanical apparatus, machine supports, instruments, etc., can solve the problems of limited support of the tripod device in the manner, and achieve the effect of facilitating the use of the tripod for gripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

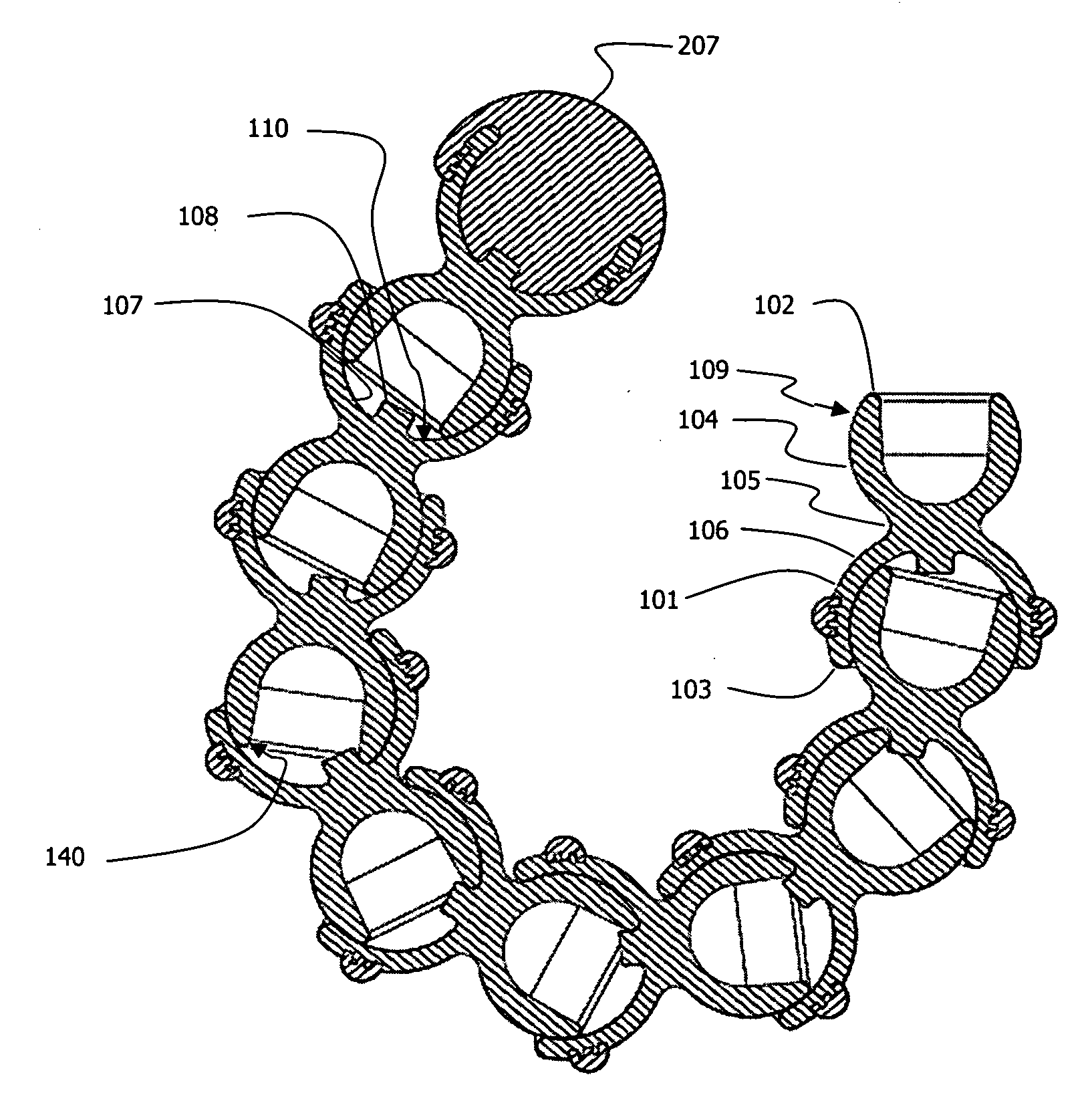

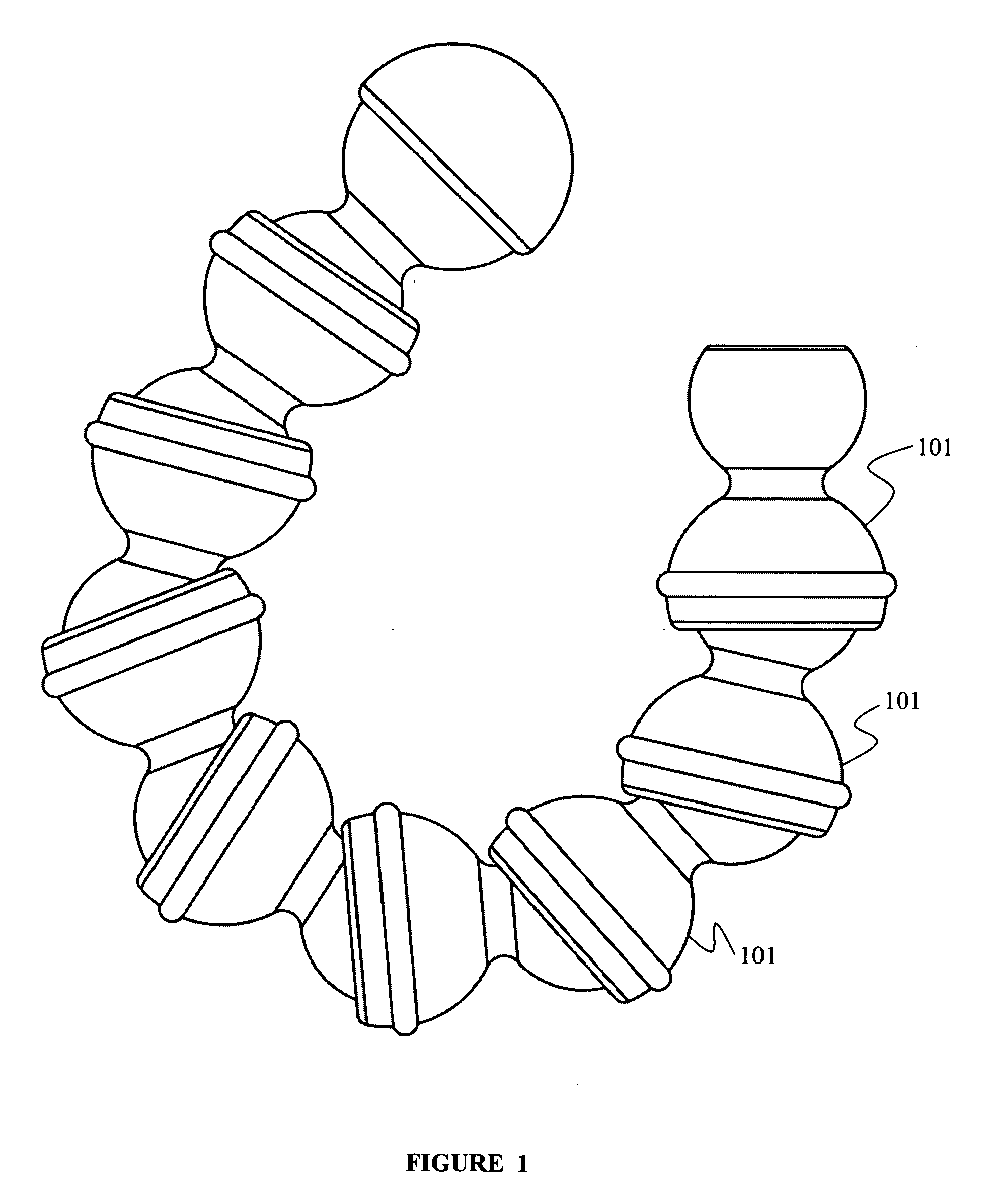

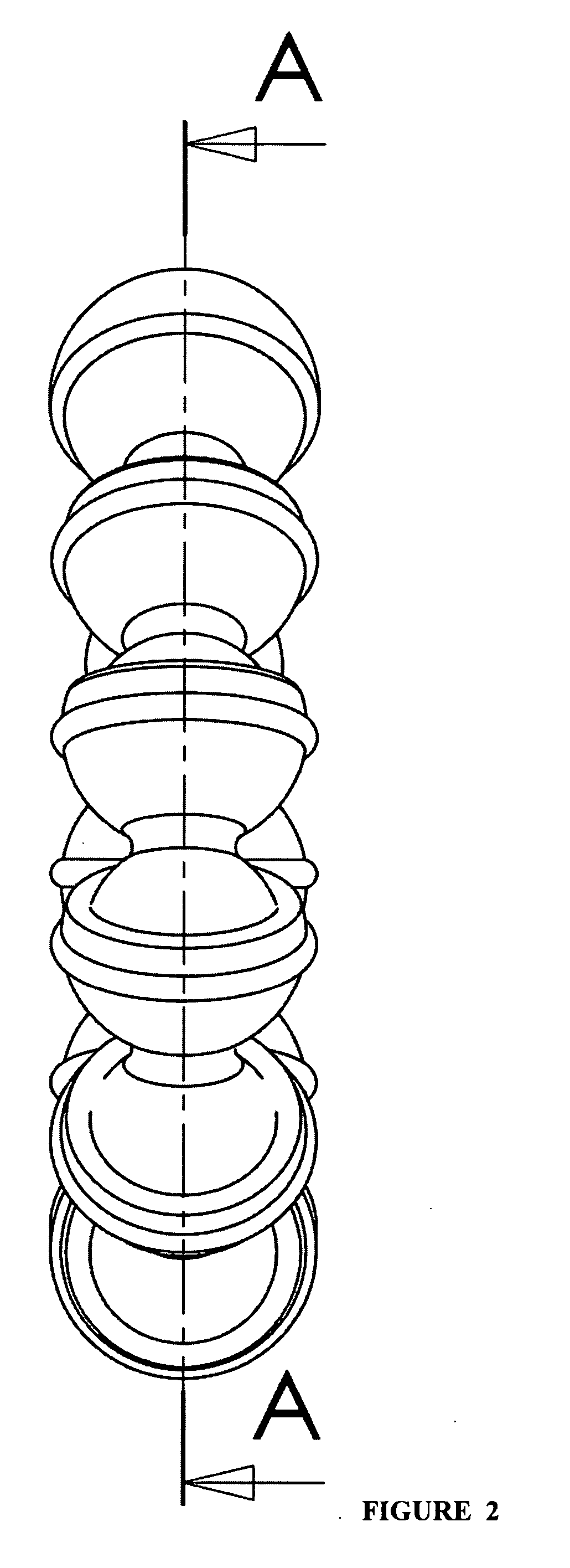

[0022]FIGS. 1, 2, and 3 illustrate a plurality of ball and socket joint connectors 101 according to some embodiments of the present invention. A connector 101 has a first end portion 102 and a second end portion 103. A socket engaging end surface 104 is present at the first end 102. The first end portion 102 is substantially hollowed out.

[0023] The second end portion 103 has a body 106 with an internal socket receiving cavity 107. The inner surface 110 of the an internal socket receiving cavity 107 is adapted to fit over the socket engaging end surface 104 of another connector 101, or of another piece with a similar socket engaging end surface. A neckdown 105 separates the first end portion 102 from the second end portion 103. A stop nub 108 acts as a mechanical stop to prevent over angulation and possible unintentional separation of a ball and socket joint connector pair.

[0024] As seen in FIG. 4, the connector 101 has a primary axis 111 in some embodiments. The connector 101 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com