Bow riser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

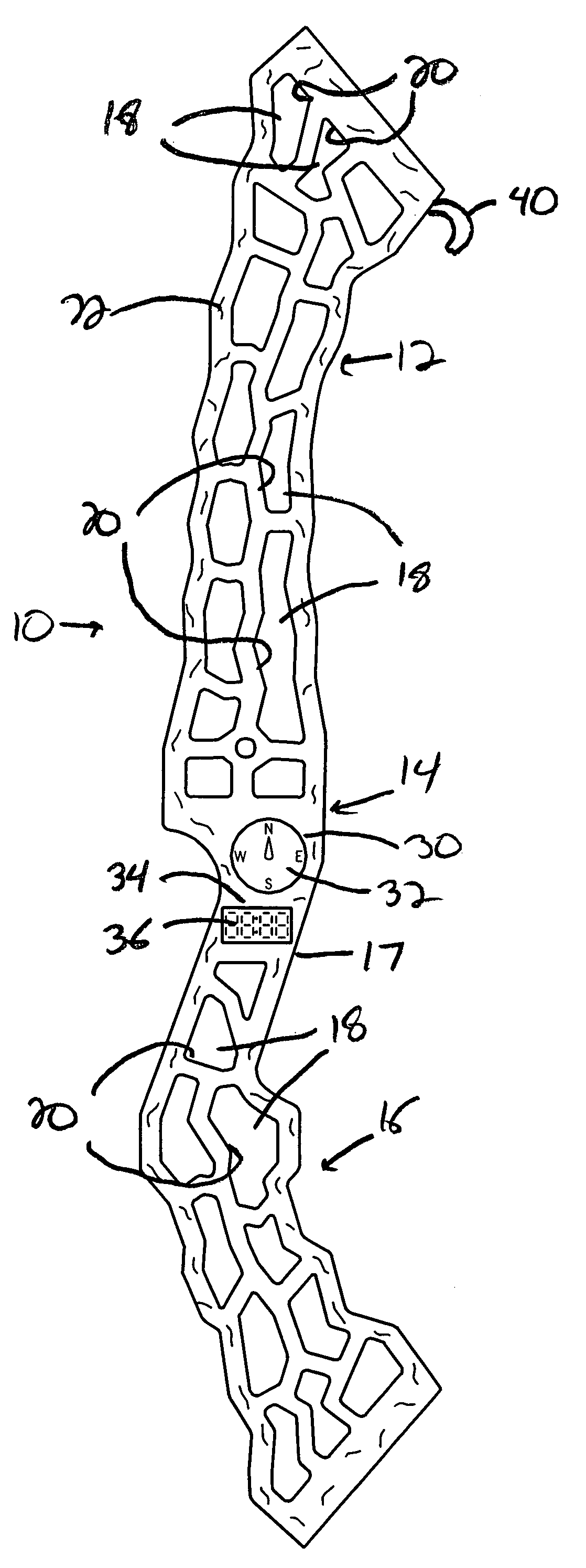

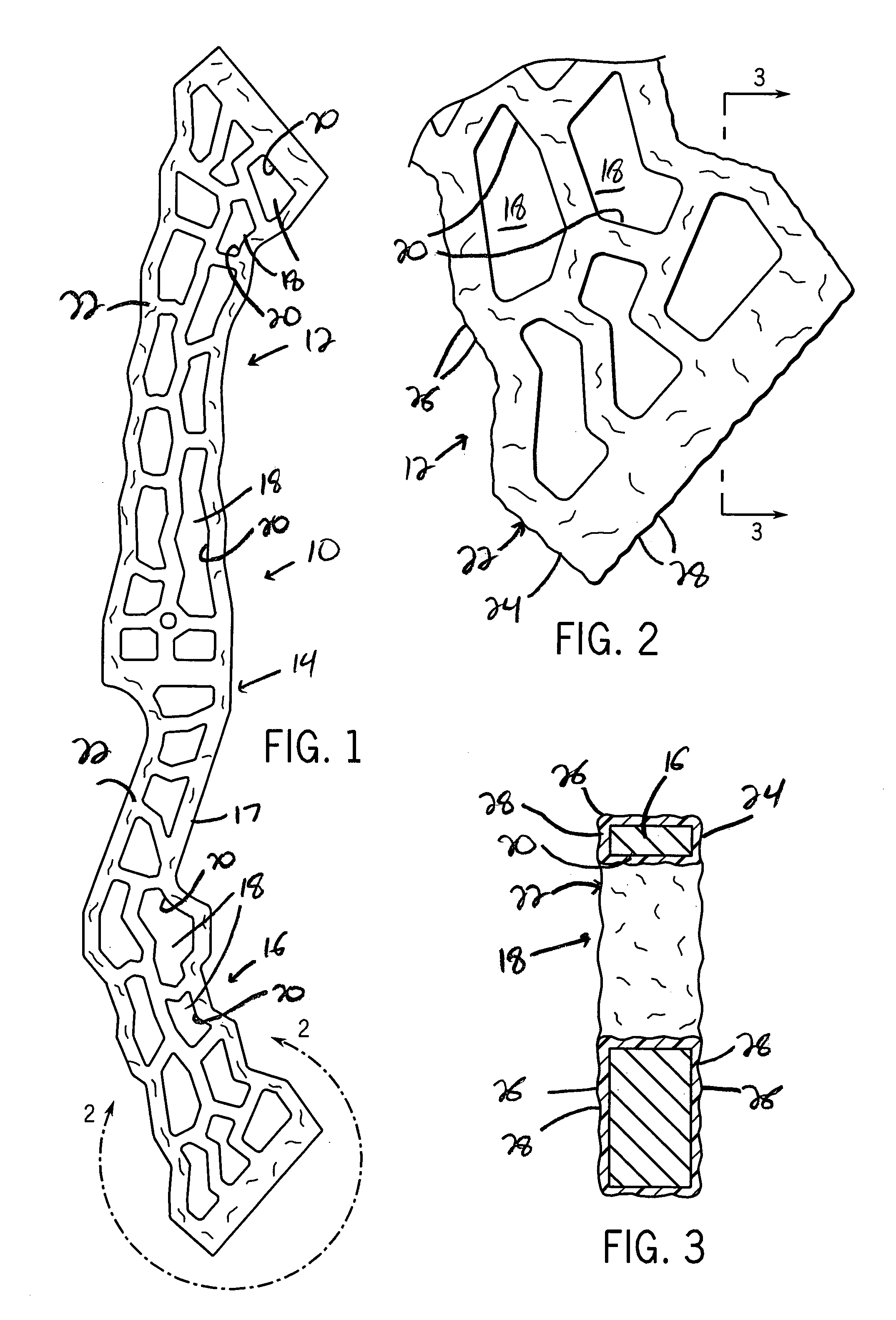

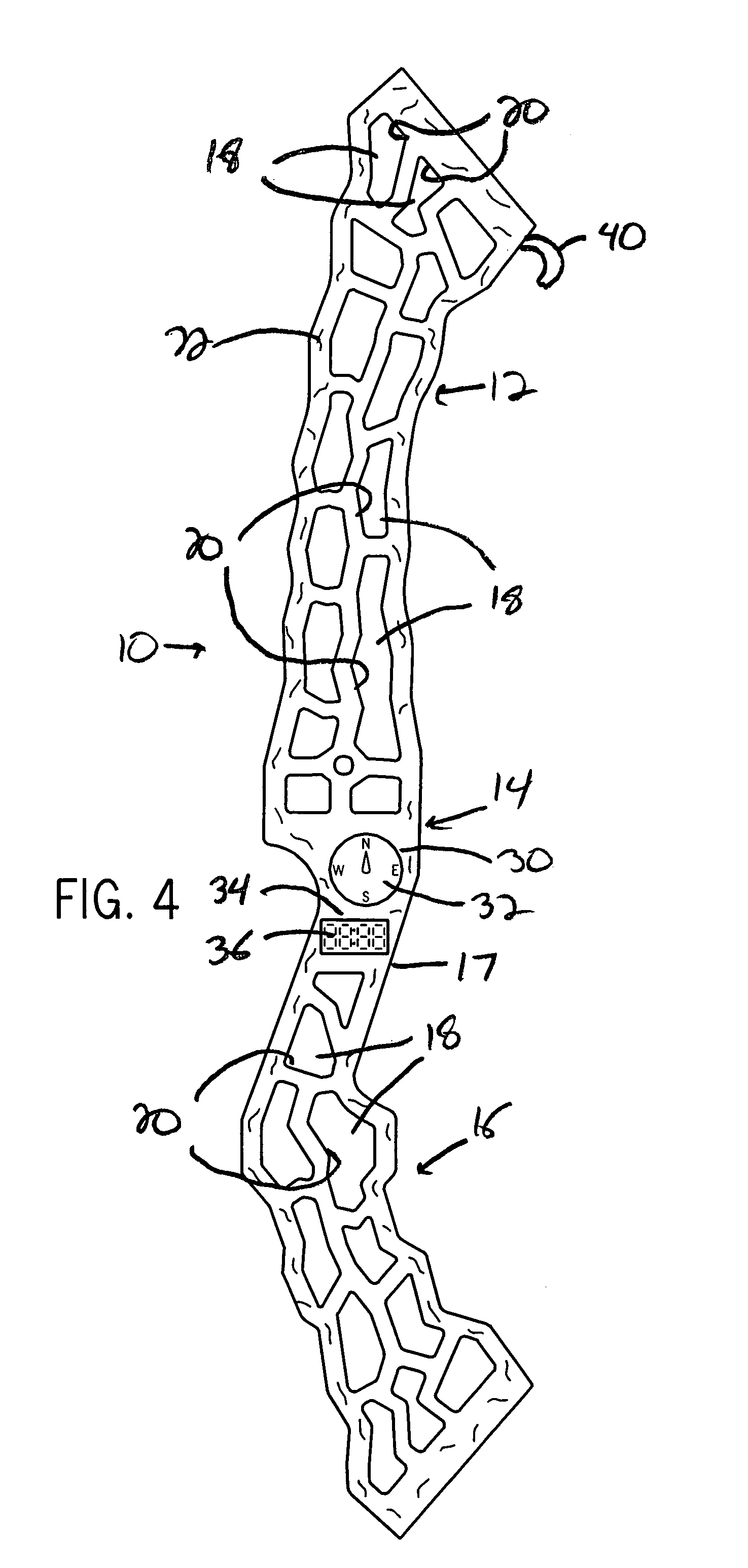

[0018]With regard to the drawing figures in which like reference numerals designate like parts throughout the disclosure, a bow riser constructed according to the present invention is indicated generally at 10 in FIG. 1. The bow riser 10 is adapted to be secured to a pair of curved bow ends (not shown) between which can be strung a bowstring (not shown) in order to form a complete bow (not shown) in any known manner. The bow riser 10 defines an upper portion 12, a central portion 14, and a lower portion 16, which can be formed from any suitably rigid and lightweight material such as a metal, carbon fiber, or hard plastic. The upper portion 12 and lower portion 16 extend from opposite sides of the central portion 14, which is formed to be narrower than the upper portion 12 and lower portion 16 to define a handgrip 17 for an individual to hold the riser 10, and bow, when in use. Various other well known functional members can also be secured to the various portions 12-16 of the riser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com