Anti-allergen fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

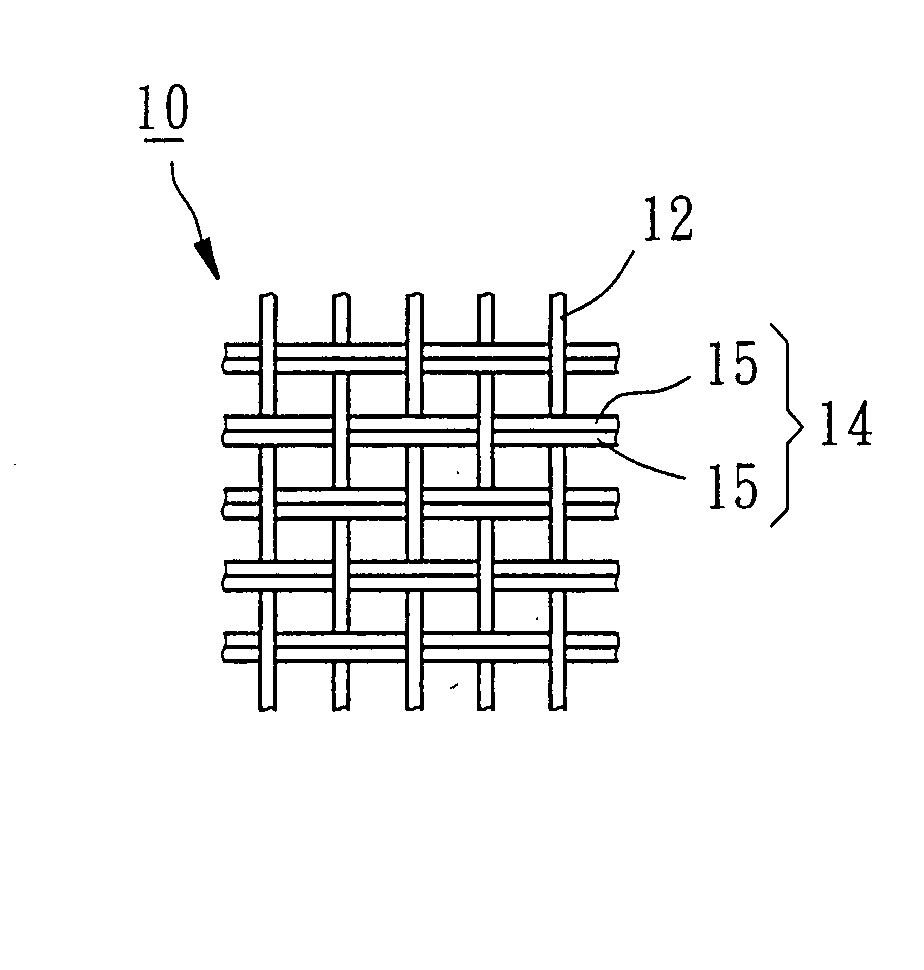

[0020] Referring to FIG. 1, an anti-allergen fabric 10 in accordance with the present invention is a woven fabric of warp yarns 12 and weft twines 14. Each warp yarn 12 is formed of twisted cotton fibers. Each weft twine 14 is formed of two yarns 15 arranged in parallel. The mean pore size of the anti-allergen fabric 10 is about 9 μm so that the anti-allergen fabric 10 can effectively block allergens such as pollens, dust mites, etc. Because each weft twine 14 is formed of two yarns 15, the strength of the weft twine 14 is substantially increased. During weaving, the weft twines 14 can bear a high stretching force so that more weft twines 14 can be woven in each unit area. Therefore, natural fibers of usual class can be used to make the weft twines 14 and the warp yarns 12, and sufficient weft twines 14 and warp yarns 12 can be woven into each unit area to form the desired anti-allergen fabric 10 having a mean pore size equal to or less than about 9 μm, which can effectively block a...

third embodiment

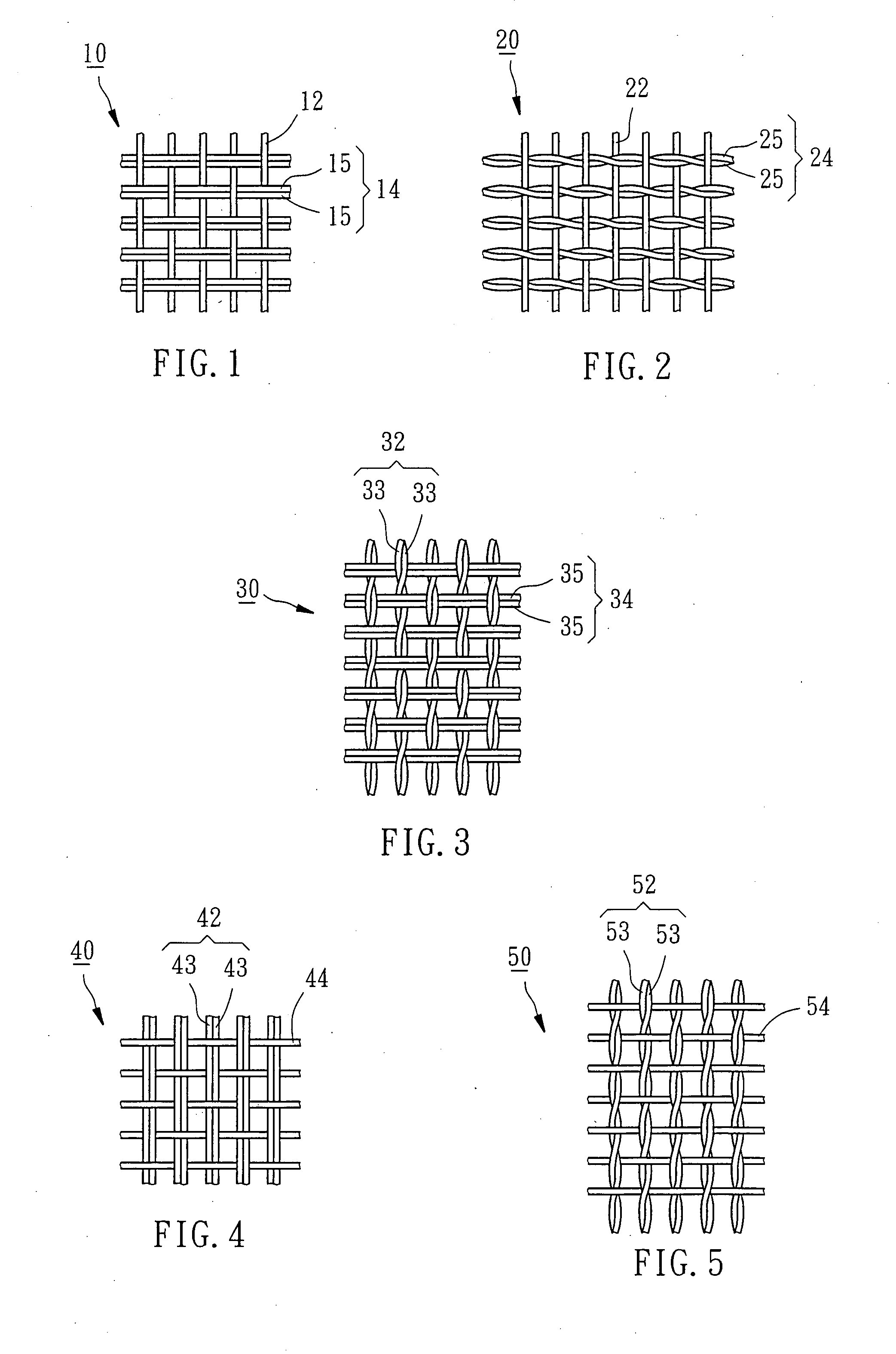

[0023] It is to be easily understood that there are a variety of alternative embodiments that can achieve the same effects as the aforesaid embodiments without departing from the spirit and scope of the invention. For example, FIG. 3 shows an anti-allergen fabric 30 in accordance with the present invention. The anti-allergen fabric 30 is a woven fabric of warp twines 32 and weft twines 34. According to this embodiment, each warp twine 32 is formed of two yarns 33 that are arranged in parallel, and each weft twine 34 is formed of two yarns 35 that are twisted together. This embodiment allows more yarns to be woven in each unit area so that the woven fabric can have a relatively smaller mean pore size. Further, this embodiment allows the use of relatively cheaper fibers to save the cost.

fourth embodiment

[0024]FIG. 4 shows an anti-allergen fabric 40 in accordance with the present invention. The anti-allergen fabric 40 is a woven fabric of warp twines 42 and weft yarns 44. According to this embodiment, each warp twine 42 is formed of two yarns 43 arranged in parallel.

[0025]FIG. 5 shows an anti-allergen fabric 50 in accordance with a fifth embodiment of the present invention. The anti-allergen fabric 50 is a woven fabric of warp twines 52 and weft yarns 54. The fifth embodiment is similar to the aforesaid fourth embodiment with the exception that according to this embodiment, each warp twine 52 is formed of two yarns 53 that are twisted together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com