Glitter glue tube dispensing apparatus

a technology of glitter glue and dispensing apparatus, which is applied in the direction of instruments, pliable tubular containers, volume meters, etc., can solve the problems of difficult to reliably control the amount of glitter glue being dispensed from the tube, user is often unable to dispense most of the glitter glue tube from the tube, and not all of the glitter glue tube, etc., to achieve convenient control and improve the dispensing of glitter glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

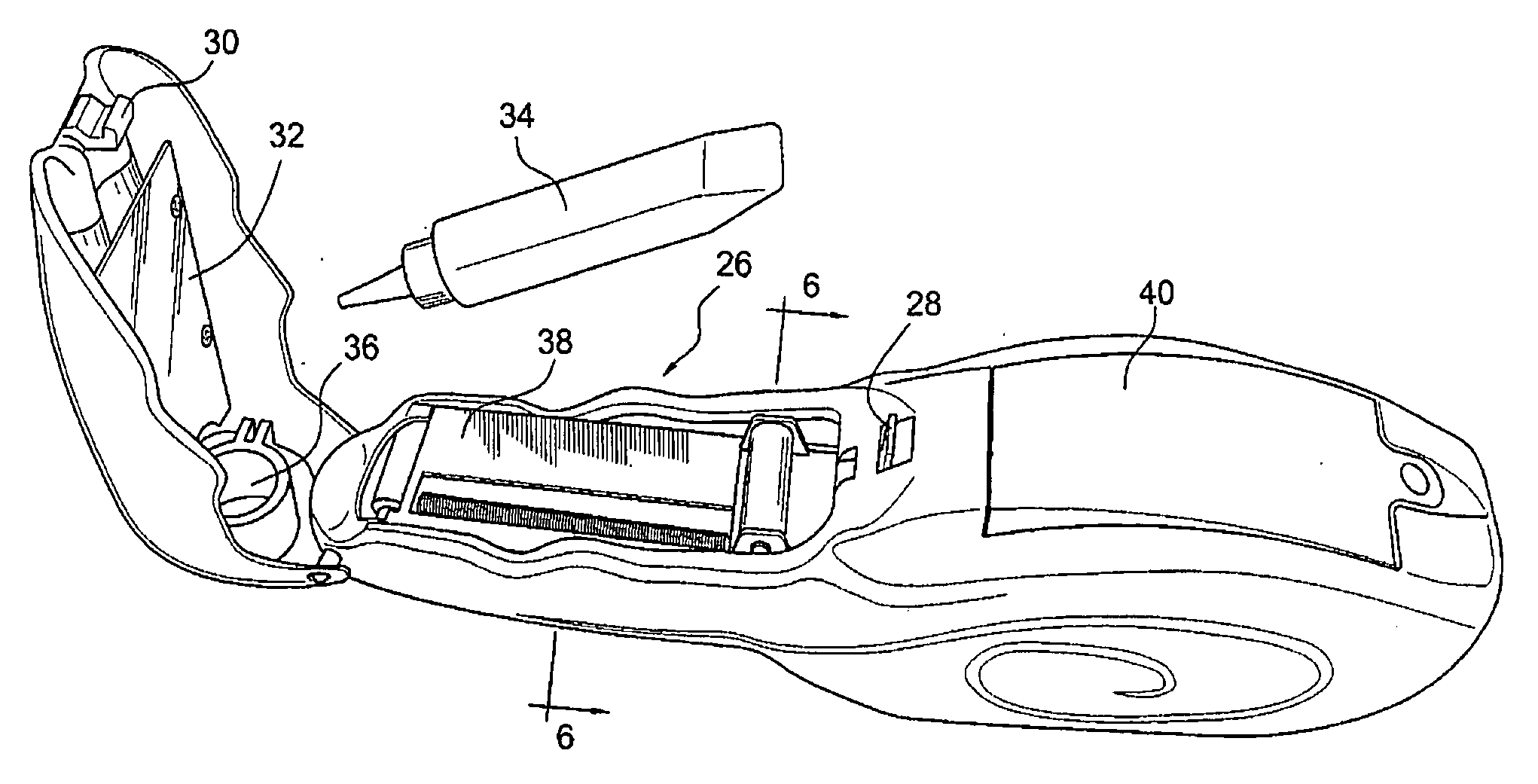

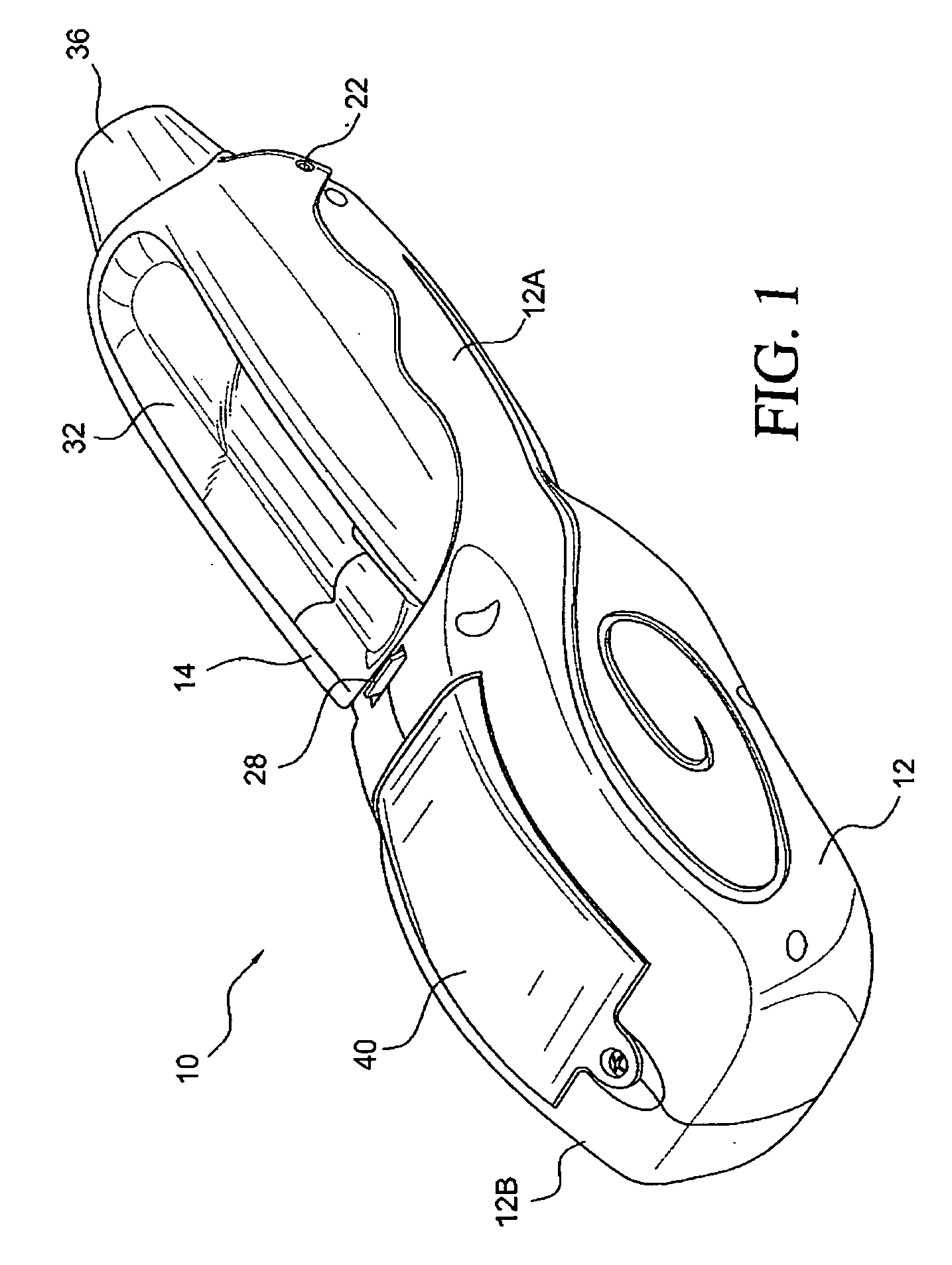

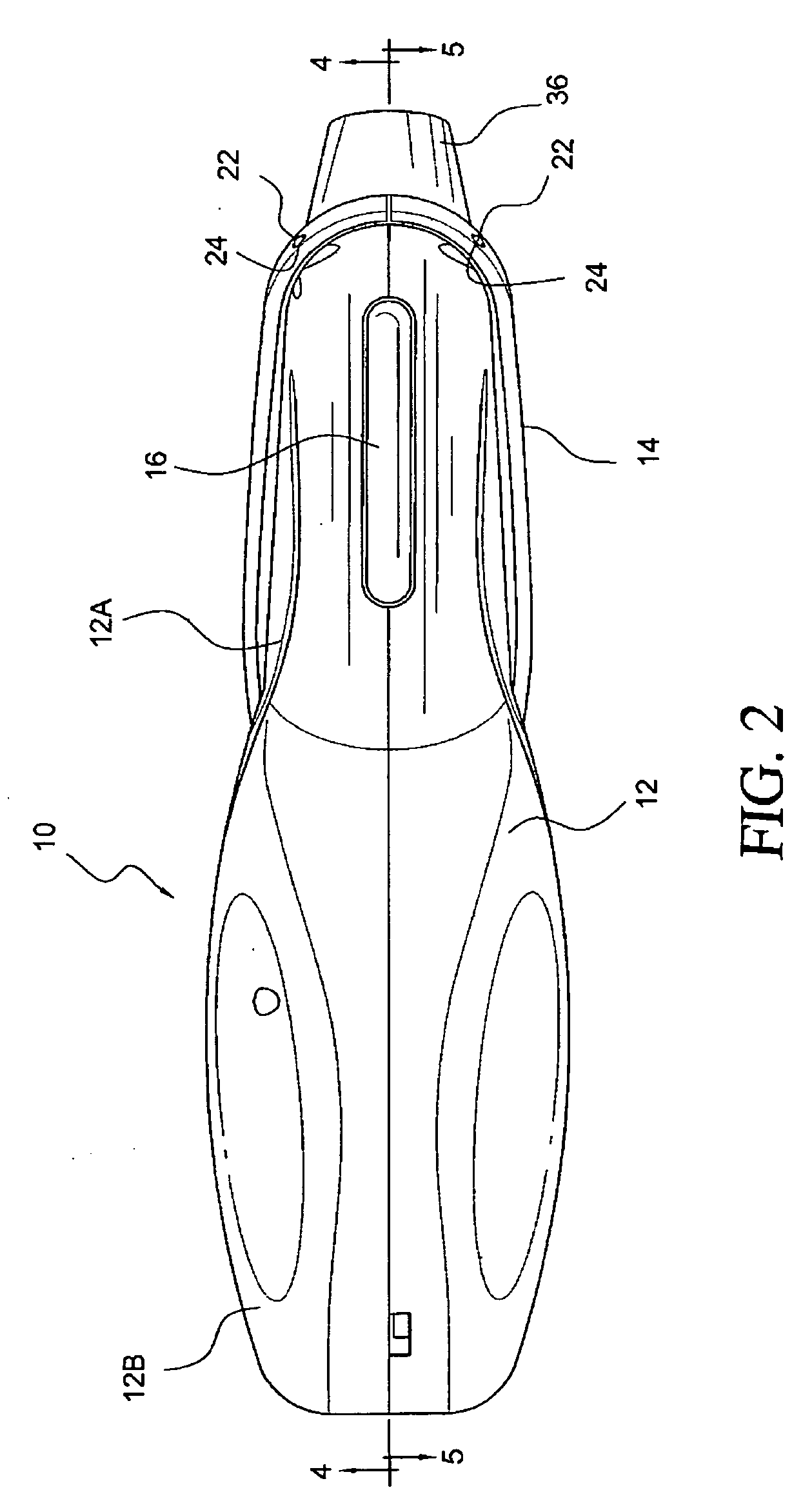

[0019]Referring to the accompanying drawings wherein like reference numbers refer to the same or similar objects, FIG. 1 shows a dispensing apparatus in accordance with the invention for dispensing glitter glue from glitter glue tubes and is designated generally as 10. Dispensing apparatus 10 includes an elongate housing 12, a cover member 14 movably connected to a front portion 12A of the housing 12 and a trigger 16 projecting from a bottom of the front portion 12A of the housing 12 below the cover member 14. Rear portion 12B of the housing 12 has a form which provides for easy manual handling. Housing 12 can be made from two complementary plastic parts 18, 20 and connected together via screws (see FIGS. 4 and 5).

[0020]Cover member 14 is pivotally connected to the housing 12 via pivot pins 22 formed on the front portion 12A of the housing 12 and corresponding apertures 24 formed on the cover member 14 (see FIG. 2). Cover member 14 defines a glitter tube-retaining compartment 26 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com