Sectional golf tee

a golf tee and sectional technology, applied in the field of golf tees, can solve the problems of inconvenient manual realignment of tee pieces in the field, lack of convenience of handling a single piece of tee in its ground penetration, and inability to provide a solution for aligning component tees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

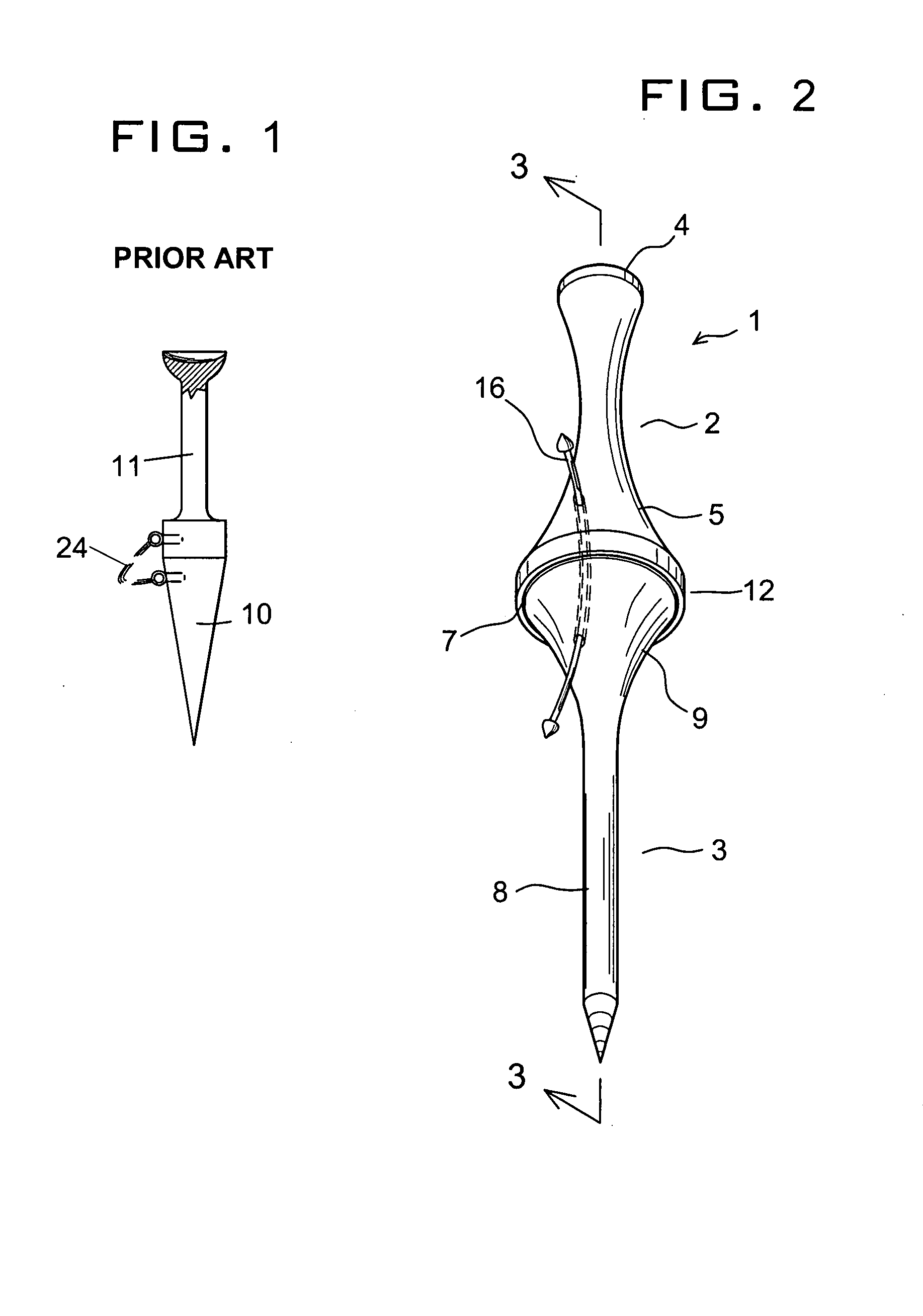

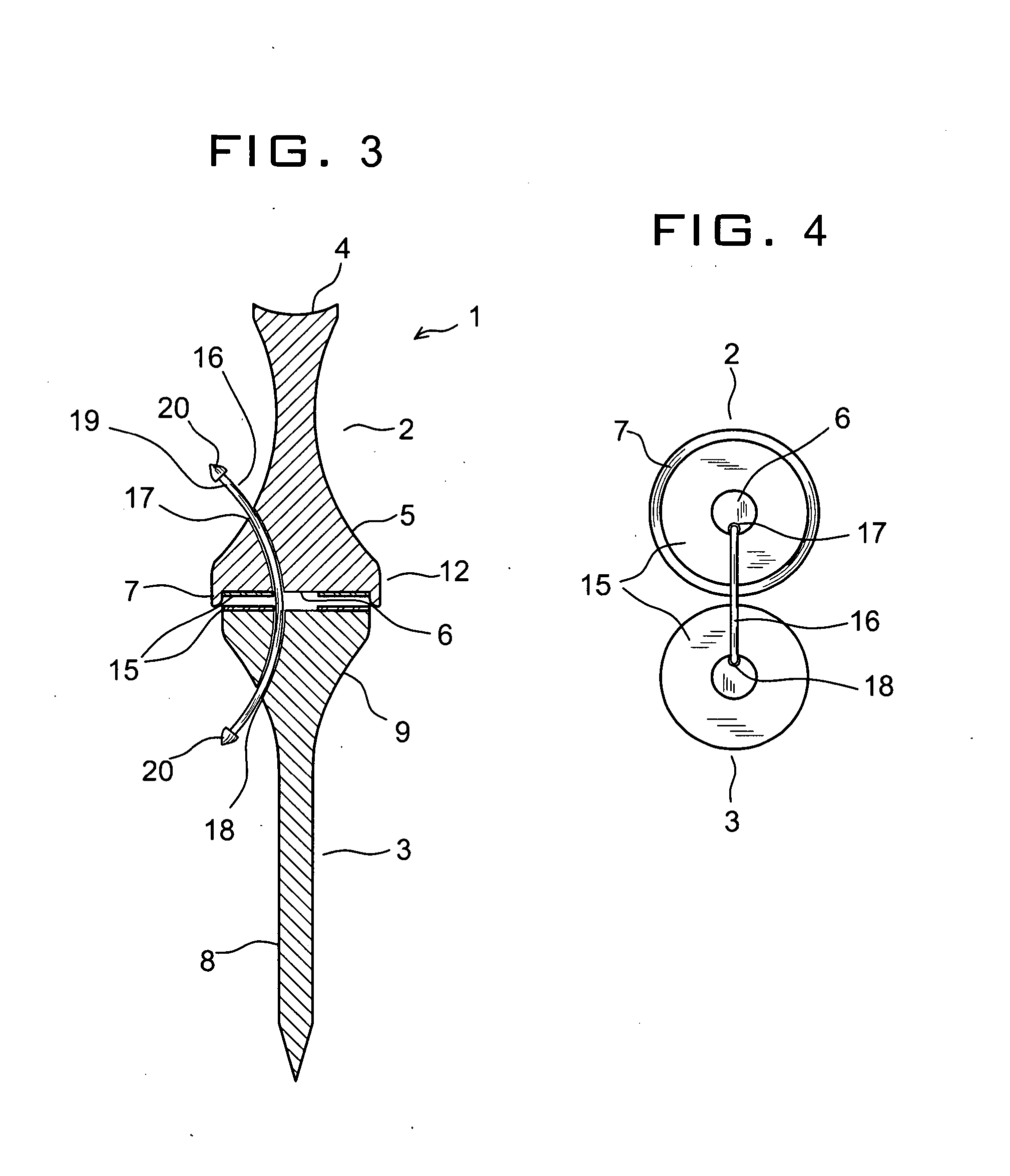

[0025] With reference to FIGS. 2 and 3, a golf tee 1 according to the present invention generally comprises a longitudinal tee top 2 and a tee base 3, which is mated to the tee top 2 and extends along a common longitudinal axis. Both tee members 2 and 3 are formed of a rigid material including wood and plastic to have round sidewalls. They may be made of the same material or a hybrid of two different materials as needed.

[0026] The tee top 2 is constricted in the middle to provide an easy grip for facilitating its handling at the teeing ground. Top end 4 of the tee top 2 is concave to conform to a bottom section of a golf ball, not shown. The tee top 2 has a cone section 5 at it lower end, which has a flat bottom 6. The bottom 6 has a protrusion extending downwardly and circumferentially to form a short annular wall 7 adapted to mate two tee members 2 and 3 in a concentric relation. The height of the wall 7 is set so that it is just enough to assist in aligning the tee members 2 and ...

second embodiment

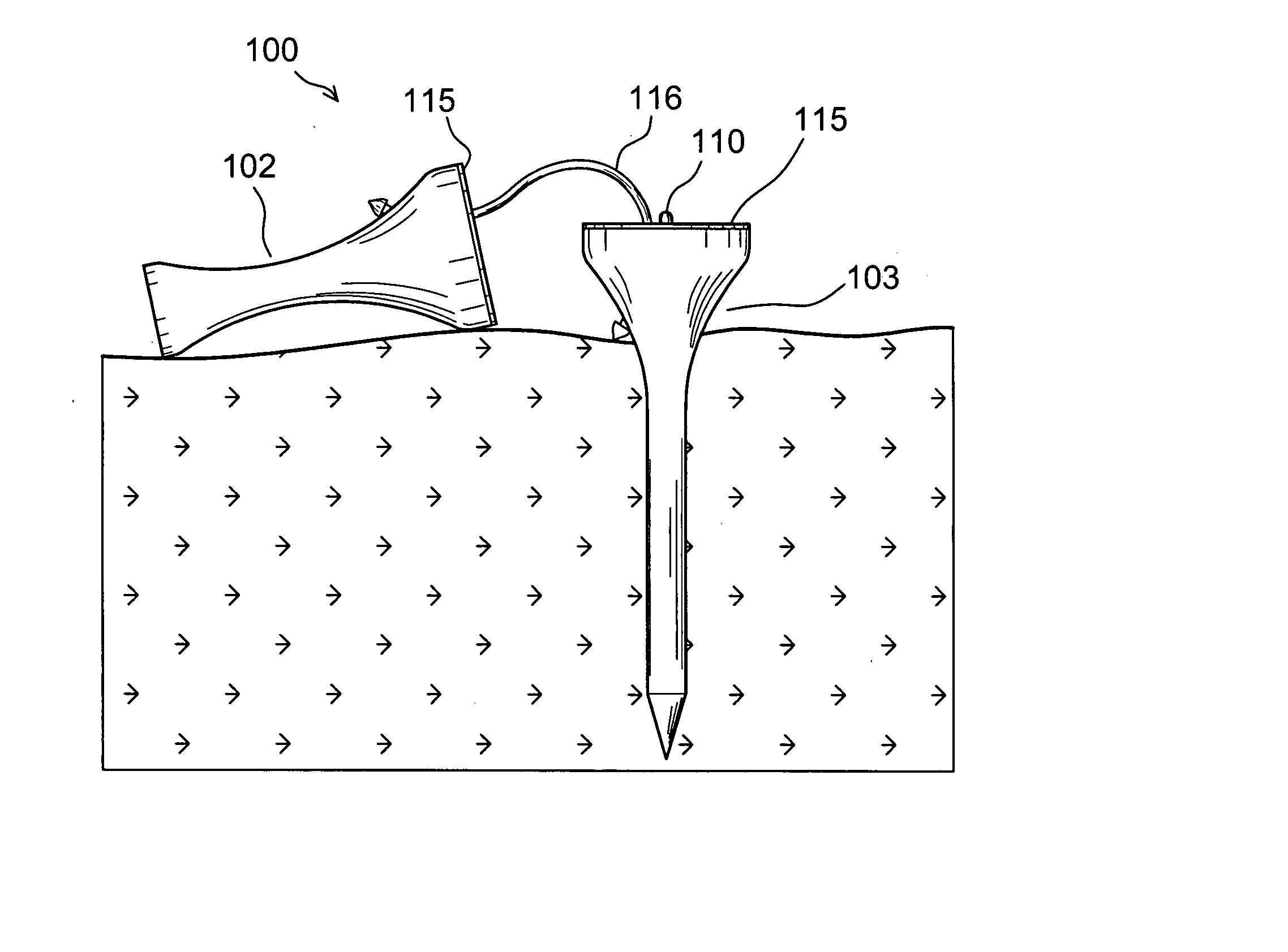

[0034]FIG. 5 shows a sectional golf tee 100 of the present invention wherein an alternative centering means is used between a tee top 102 and a tee base 103, which can be mated to the tee top 102 extending along a common longitudinal axis.

[0035] The tee top 102 is constricted in the middle to provide an easy grip for facilitating its handling at the teeing ground. Top end 104 of the tee top 102 is concave. The tee top 102 has a cone section 105 at it lower end, which has a generally flat bottom 106. The bottom 106 is recessed upwardly in the center to form a shallow cave 107 adapted to mate two tee members 102 and 103 in a concentric relation. The depth of the cave 107 is set so that it is just enough to assist in aligning the tee members 102 and 103 but does not hinder a lateral flipping action of the tee top 102 away from the tee base 103.

[0036] The tee base 103 takes the form of a pointed peg 108 for an easy penetration into the ground and has an inverted cone section 109 at its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com