Adjustable clamp assembly

a clamp assembly and adjustable technology, applied in the direction of washstands, scaffold accessories, lighting support devices, etc., can solve the problems of unwanted breakage of sheet glass, clamp assemblies in use today, and are limited to securing sheet materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

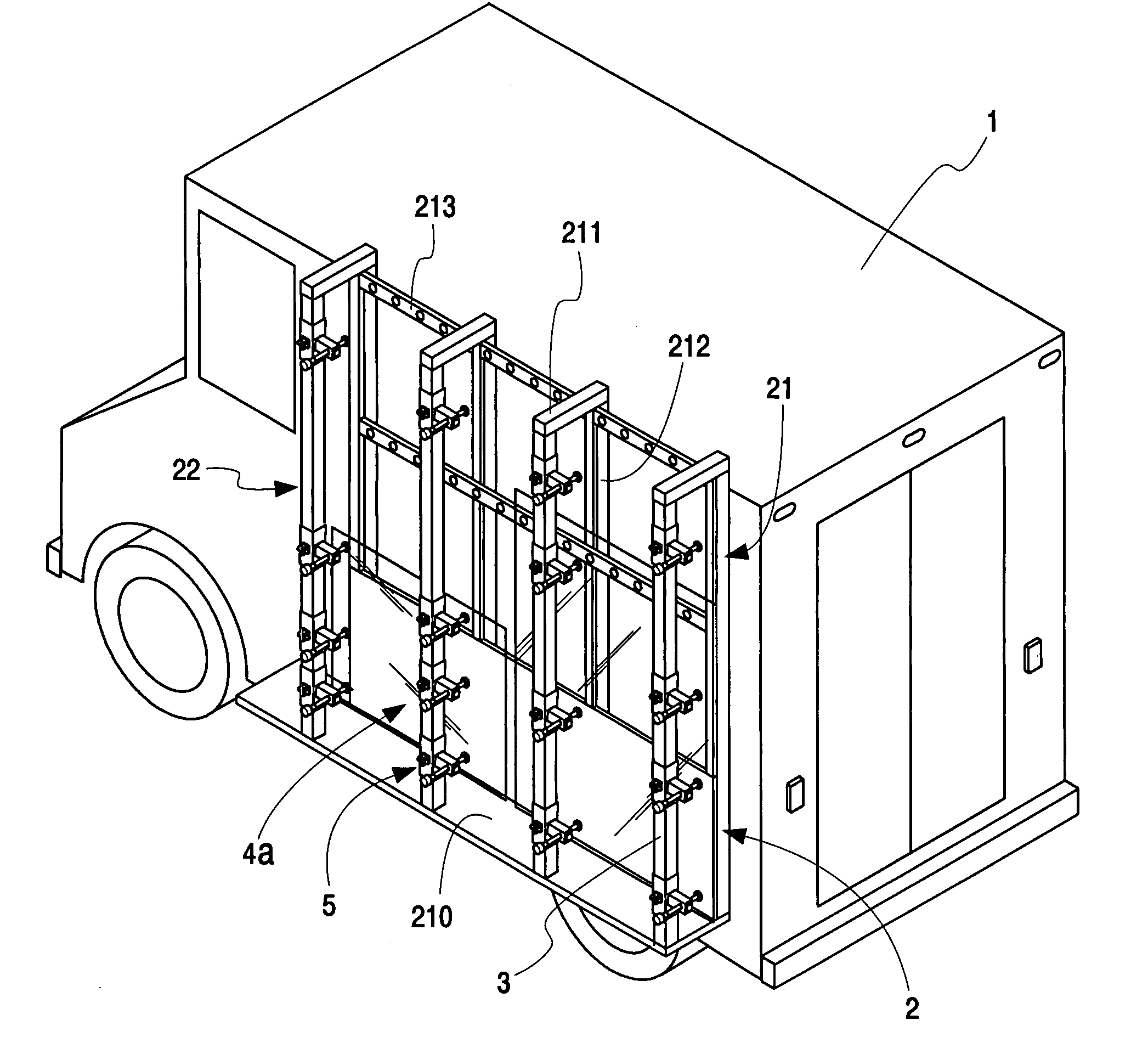

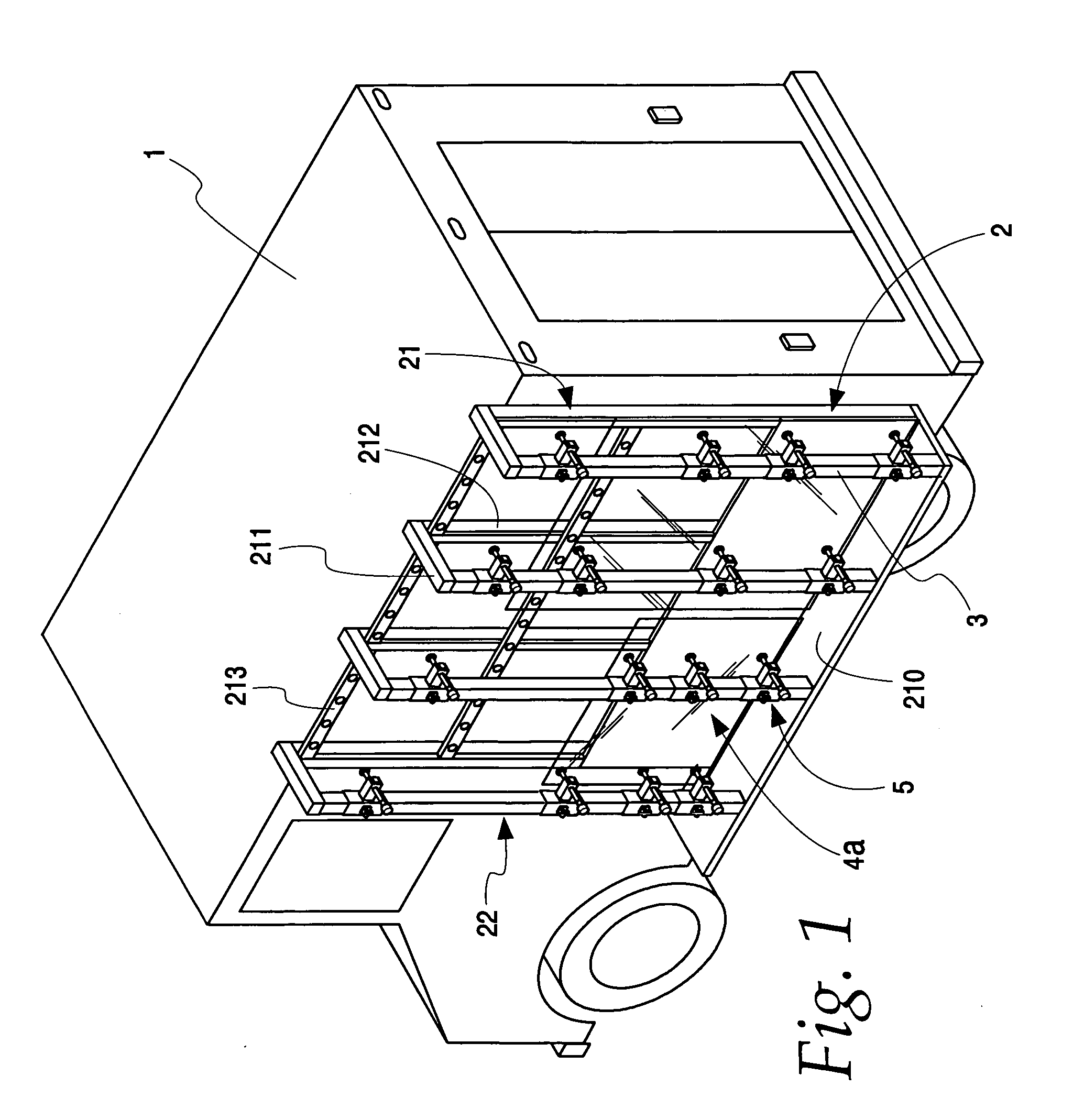

[0023]Referring first to FIG. 1, there is shown a rack 2 mounted on a vehicle 1. The rack 2 has two opposed sides, one affixed to a side of the vehicle (21) and one adjacent thereto (22). The first side 21 consists of a horizontal bottom shelf 210, a horizontal top member 211 and horizontally spaced-apart vertical posts 212 joining the bottom shelf 210 and top member 211 together. A plurality of vertically spaced-apart horizontal support bars 213 are fastened to the vertical posts 212 over the shelf 210.

[0024]The second side 22 of the supporting rack 2 comprises a plurality of vertical stakes 3. The stakes 3 are adapted to be mounted to the first side 21 of the rack 2 between the bottom shelf 210 and top member 211 and to extend generally parallel to the vertical posts 212 but spaced a short distance therefrom, and from the support bars 213 carried by the posts 212. The vertical stakes 3 are removably mounted on the first side 21 of the rack 2. In FIG. 1 each stake 3 has a square pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com