Hydraulic Fluid Compositions and Preparation Thereof

a technology of hydraulic fluid and composition, applied in the direction of additives, petroleum industry, lubricant compositions, etc., can solve the problems of less ventilation, reduced hydraulic fluid reservoir capacity, and accelerate oxidation and thermal degradation of hydraulic fluid, so as to reduce the oxidative degradation of hydraulic fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

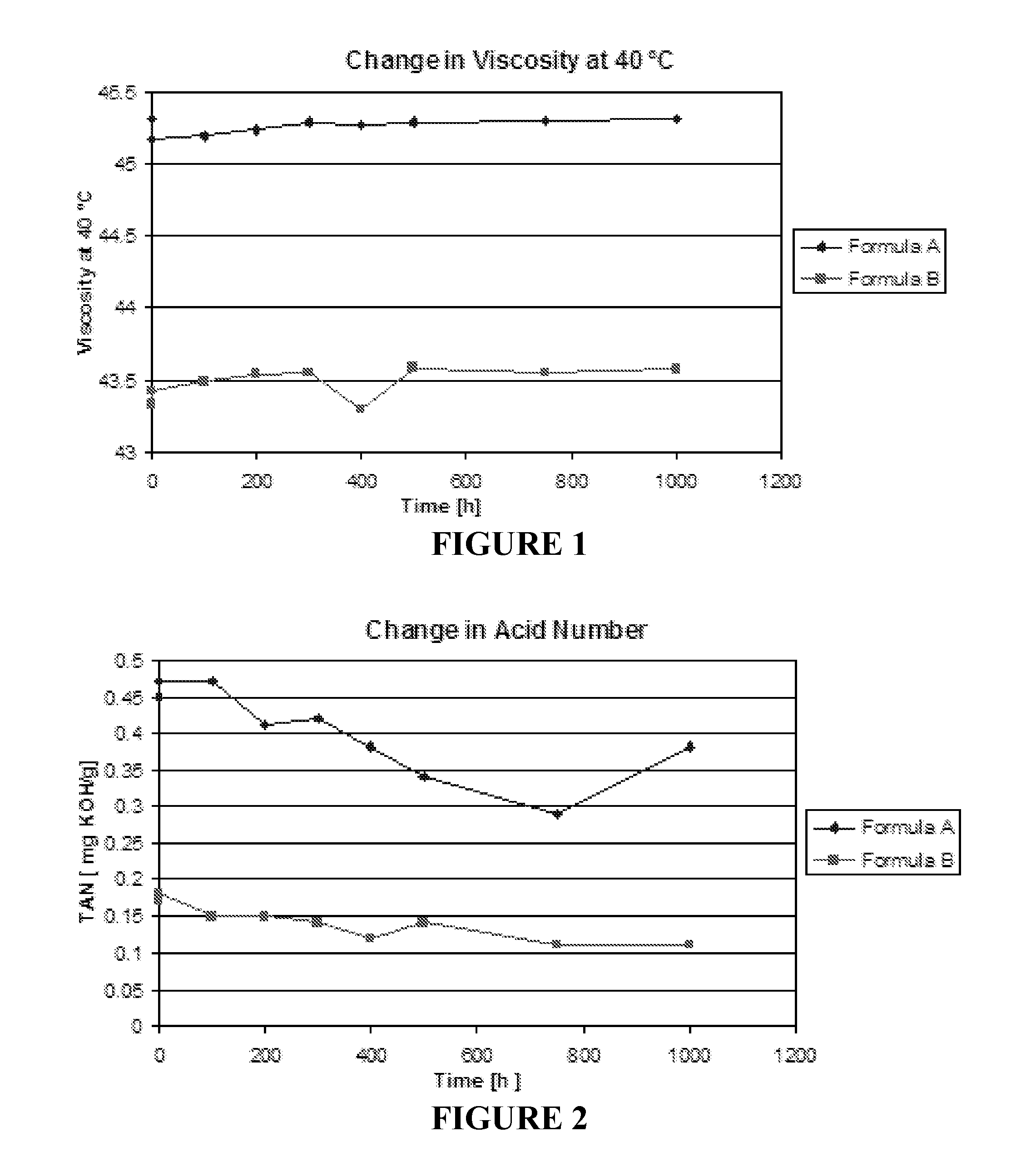

[0099] The Examples were prepared by mixing the components in the amounts indicated Table 1. The formulae were subject to the piston pump test according to JCMAS HK standard specifications developed by the Fuels and Lubricants Technical Committee of Japan Construction Mechanization Association (JCMA).

[0100] FTBO base oils are from Chevron Corporation of San Ramon, Calif. The properties of the FTBO base oils used in the examples are shown in Table 4.

[0101] Nexbase™ 3060 is a colorless, catalytically hydroisomerized and dewaxed Group III base oil from Neste Oil Corporation.

[0102] Pennzoil™ HC 575 is a Group II mineral oil from Pennzoil-Quaker State Company.

[0103] Additive 1 is a commercially available rust and oxidation package.

[0104] Additive 2 is a triaryl phosphate ashless antiwear and extreme pressure additive.

[0105] Additive 3 is an amine phosphate an ashless multifunctional additive with extreme pressure / antiwear and antirust activity, typically containing 4.9% phosphorus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com