Jersey and associated method of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

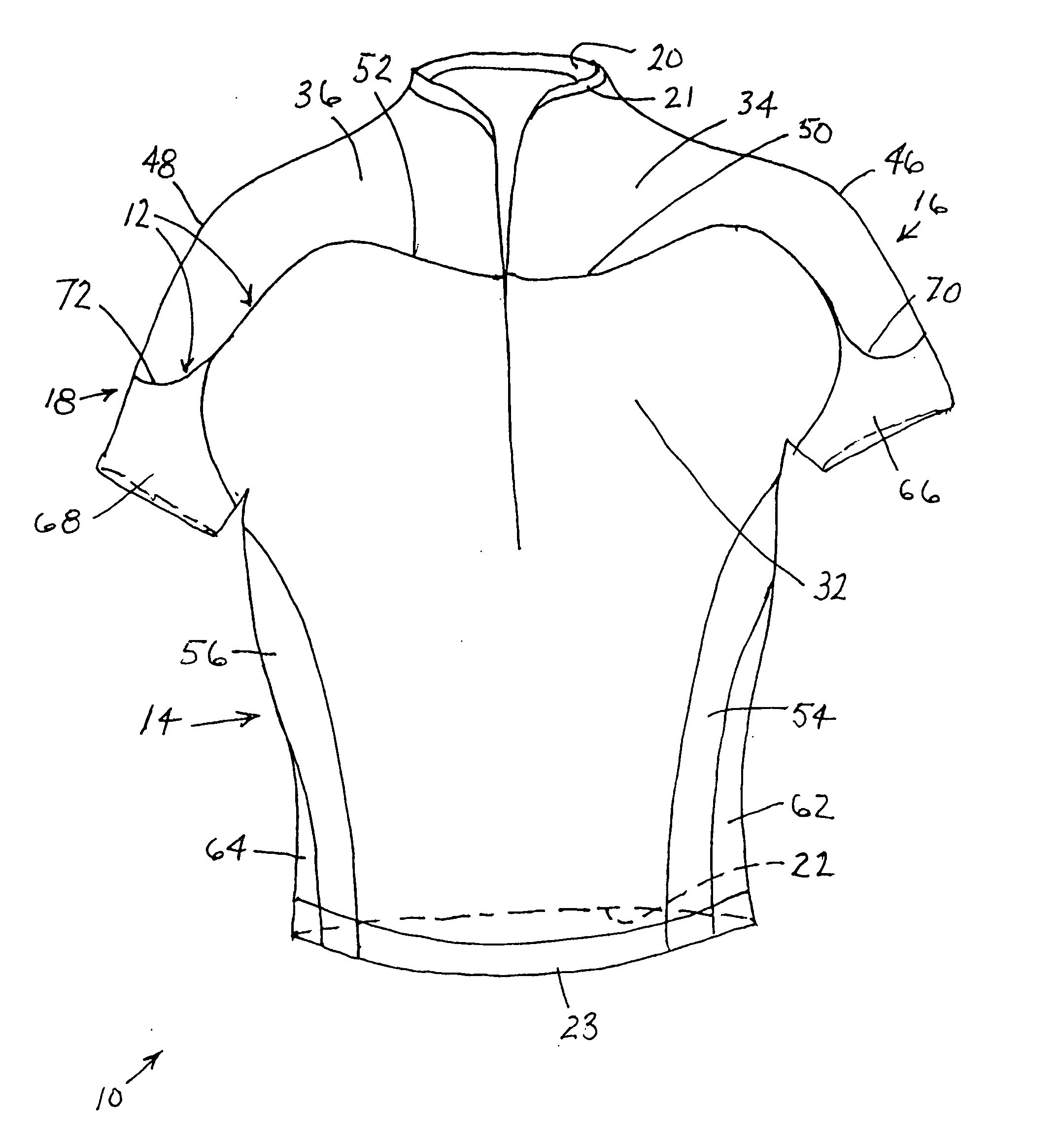

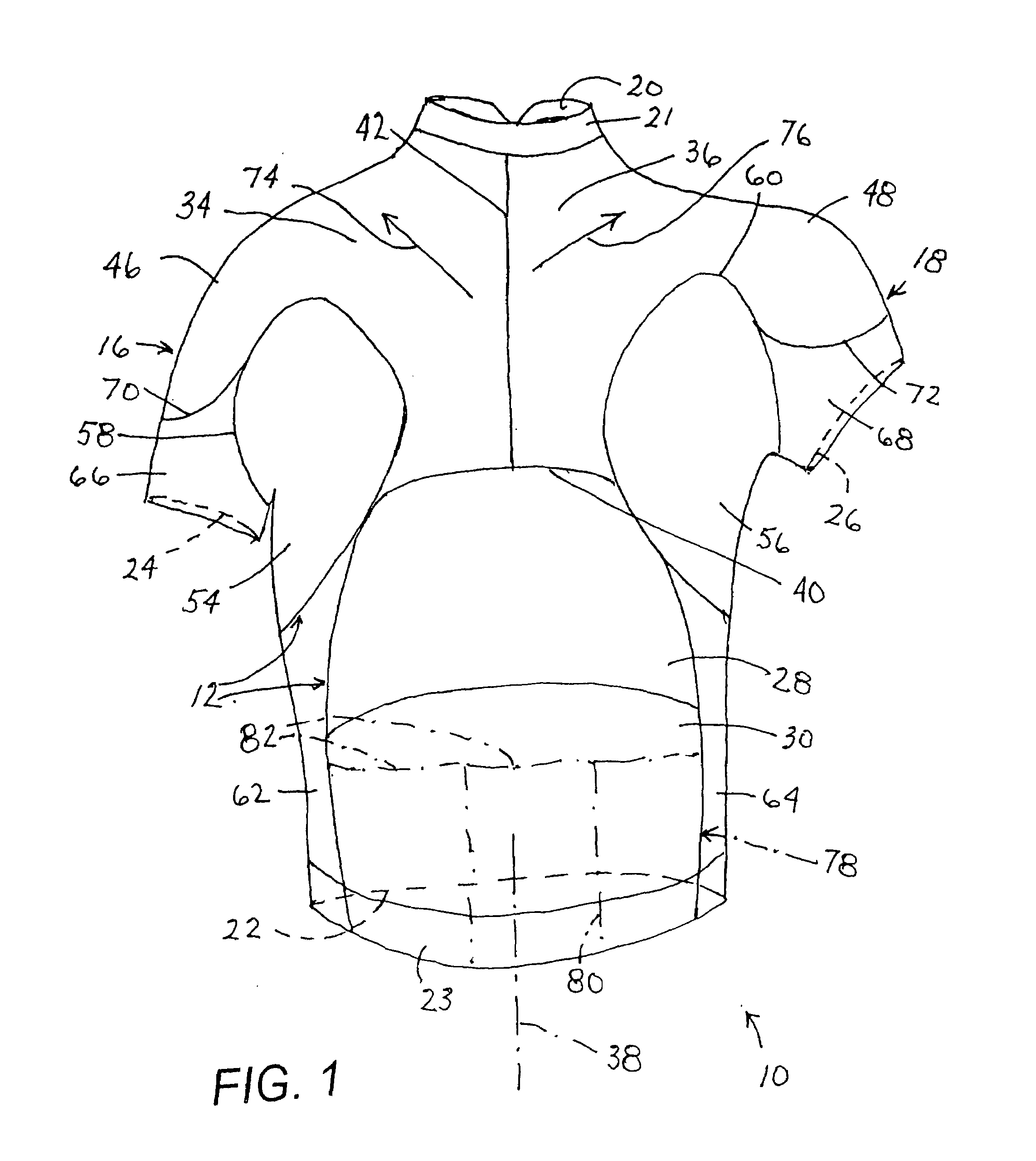

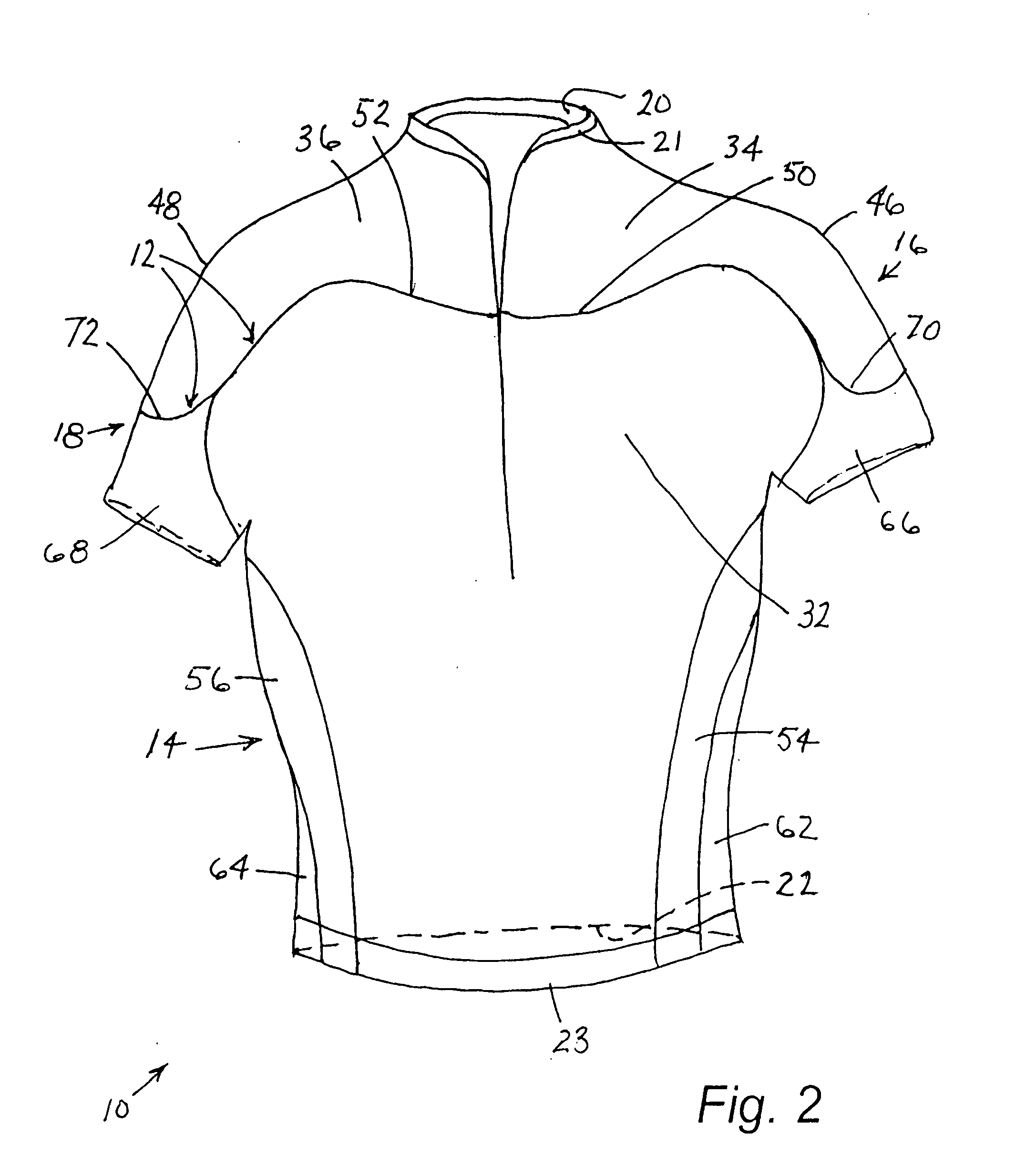

[0021]A jersey or shirt 10 is assembled from a plurality of fabric panels or sections 12 attached to one another to form a tubular torso 14 and a pair of tubular sleeves 16 and 18. Torso 14 has a neck opening 20 at one end defined by a collar 21 and a waist opening 22 at an opposite end defined by a waist band 23, while sleeves 16 and 18 have free ends provided with respective arm openings 24 and 26. Fabric panels or sections 12 include a first lower back panel 28, a second lower back panel 30, at least one chest panel 32 (FIG. 2) and two shoulder panels 34 and 36. Back panel 30 is located below back panel 28

[0022]Torso 14 has a longitudinal axis 38 extending from neck opening 20 or collar 21 to waist opening 22 along a back side of torso 14. Shoulder panels 34 and 36 are connected on the back side of torso 14 to lower back panel 28 along a substantially horizontal seam 40 oriented substantially transversely to longitudinal axis 38. Shoulder panels 34 and 36 are joined to one anothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com