Production process and production equipment of woollen knitted velvet fabric

A technology of production equipment and production process, applied in the field of wool spinning knitted fleece fabric production technology and production equipment, can solve the problems of difficulty in obtaining high-density fleece, high fluff density, rough hand feeling, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

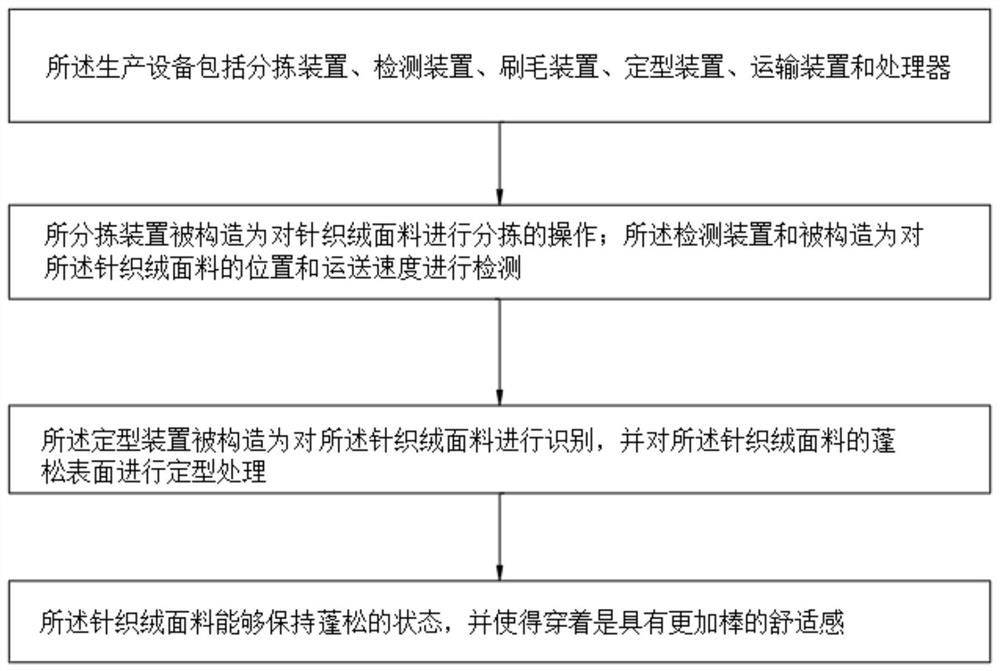

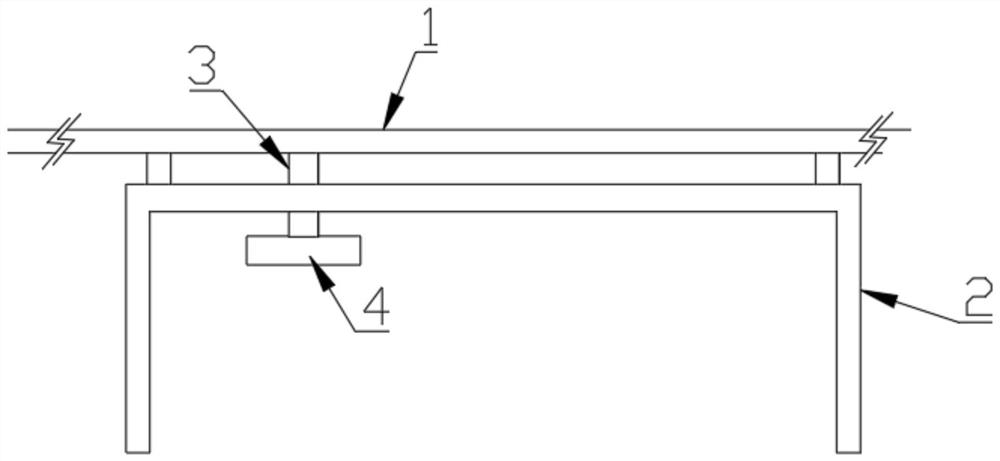

[0033] Embodiment 1: a kind of production equipment of wool spinning knitted velvet fabric 11, said production equipment comprises a sorting device, a detection device, a bristle device, a shaping device, a transport device and a processor, and the sorting device is configured to process the knitted velvet fabric 11 sorting operation; the detection device is configured to detect the position and conveying speed of the knitted fleece fabric 11; the brushing device is configured to comb the surface of the knitted fleece fabric 11, so The sizing device is configured to label the knitted velvet fabric 11, and carry out a sizing treatment to the fluffy surface of the knitted velvet fabric 11; the transport device is configured to transport the knitted velvet fabric 11; The detection device includes a detection element 4, a moving mechanism and a reversing mechanism. The reversing mechanism is configured to reverse the knitted velvet fabric 11, and cooperate with the detection device...

Embodiment 2

[0036] Embodiment 2: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis thereof. Specifically, a production equipment for woolen knitted fleece fabric 11 is provided, and the production equipment Including a sorting device, a detection device, a brushing device, a sizing device, a transport device and a processor, the sorting device is configured to sort the knitted fleece fabric 11; The position and the conveying speed of fleece fabric 11 are detected; the bristle device is configured to card the surface of the knitted fleece fabric 11, and the shaping device is configured to mark the knitted fleece fabric 11 and to mark the knitted fleece fabric 11. The fluffy surface of the knitted fleece fabric 11 is shaped; the transportation device is configured to transport the knitted fleece fabric 11; specifically, the sorting device is used in conjunction with the detection...

Embodiment 3

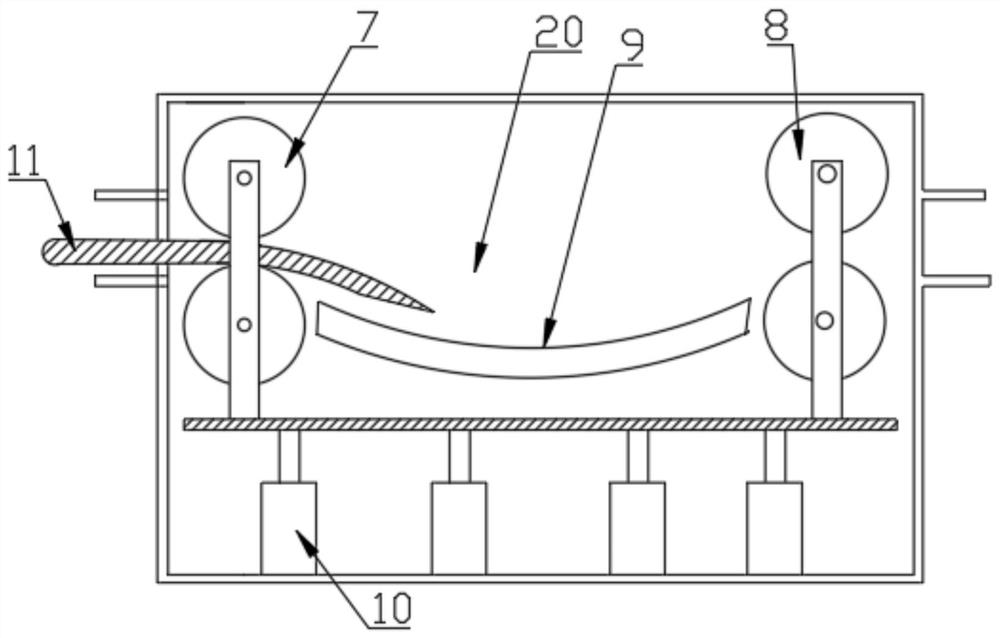

[0039] Embodiment 3: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and is further improved on the basis of it. Specifically, a brushing device is provided, which includes a rolling mechanism, an adsorption mechanism, a sliding mechanism, and a third drive mechanism, the sliding mechanism is configured to support the rolling mechanism and the adsorption mechanism; the rolling mechanism is configured to comb the knitted fleece fabric 11 and coordinate The adsorption mechanism absorbs the impurities or the shedding wool in the knitted fleece fabric 11; the sliding mechanism includes a set of sliding grooves, a set of sliding seats 3 and an identification unit, and a set of sliding grooves is arranged on the The two sides of the transportation device, and the direction of a group of sliding grooves is the same as the conveying direction of the knitted fleece fabric 11, and a group of sliding seats 3 is configure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com