Exhaust gas stack

a technology of exhaust gas stack and exhaust gas, which is applied in the direction of combustion process, combustion treatment, building components, etc., can solve the problems of reducing the noise level of the environment, affecting the efficiency of the exhaust system, and affecting the operation of the exhaust system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

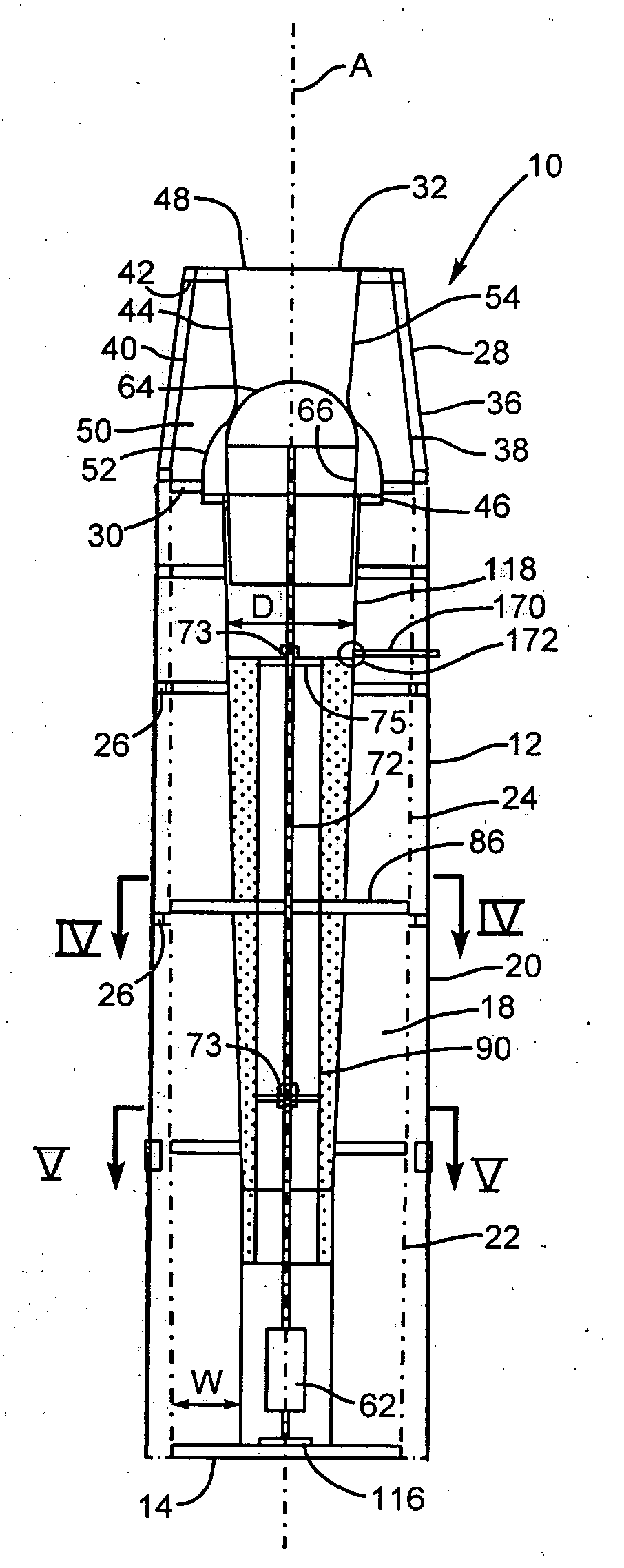

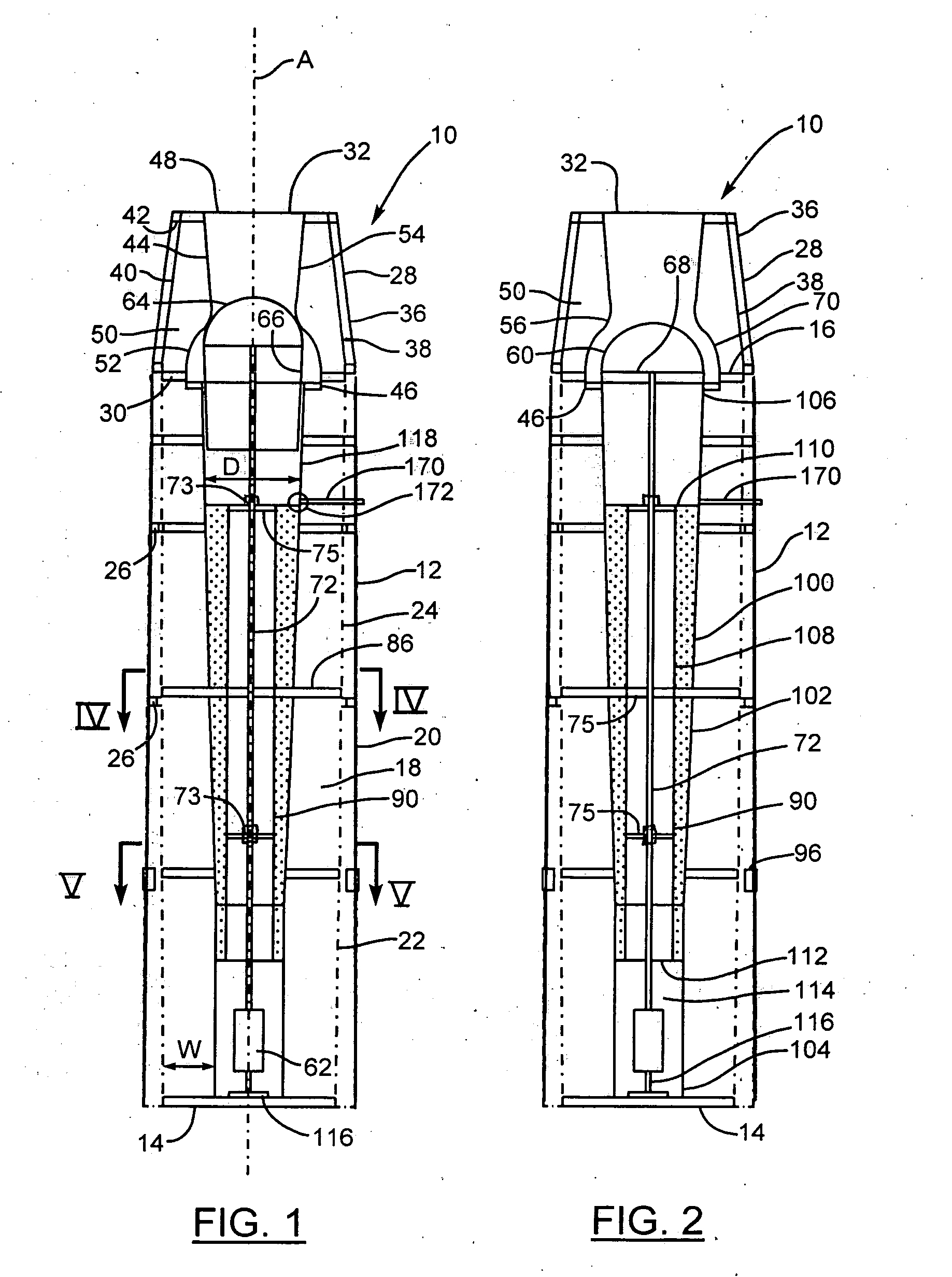

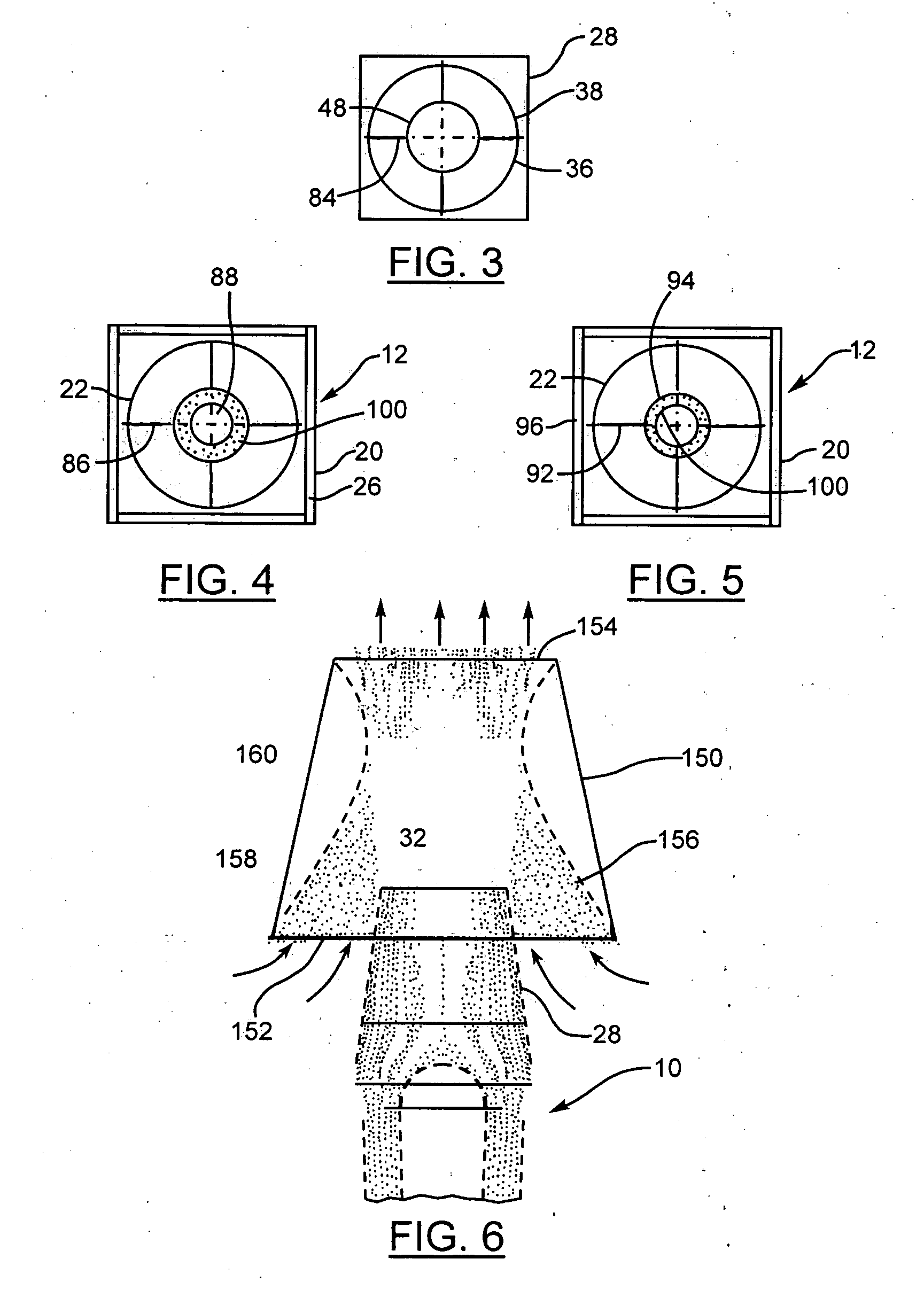

[0026]FIGS. 1 and 2 illustrate one exemplary embodiment of an exhaust gas stack constructed in accordance with the present disclosure. This exhaust gas stack includes an elongate, tubular stack member 12 having an inlet end 14, an outlet end 16, a central longitudinal first axis indicated at A and exhaust gas passage 18 extending between the inlet and outlet ends. The stack member is adapted to extend vertically with the inlet end being a bottom end when the stack is installed for use. The illustrated embodiment of the stack member has an exterior wall 20 which can be made of imperforate sheet metal such as sheet steel having sufficient thickness and strength to support the weight of the stack and external forces acting thereon such as wind. The illustrated stack member 12 has a square, horizontal cross-section defined by this exterior wall but it will be appreciated that the exterior horizontal cross-section can also be circular along the entire length of the stack member. Spaced i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com